7

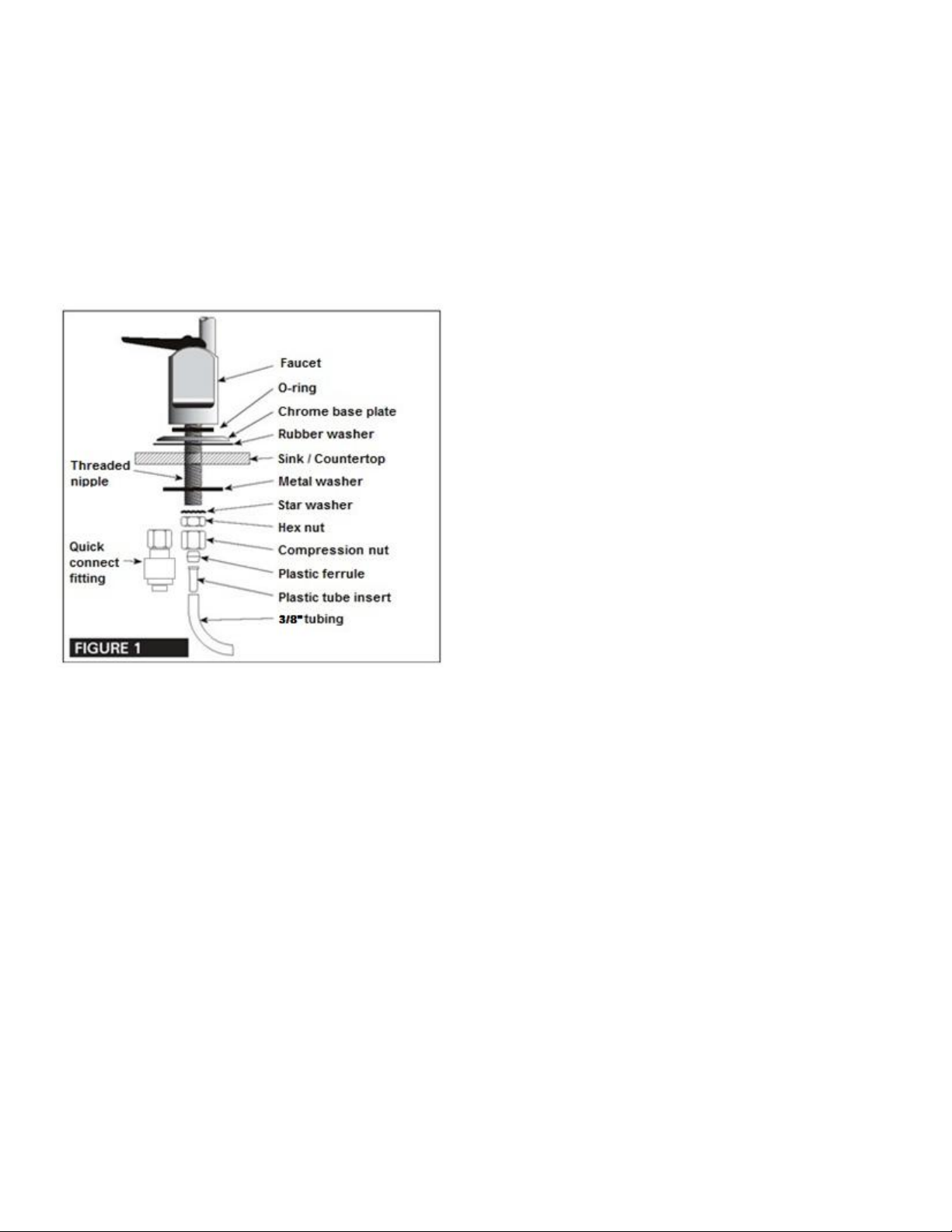

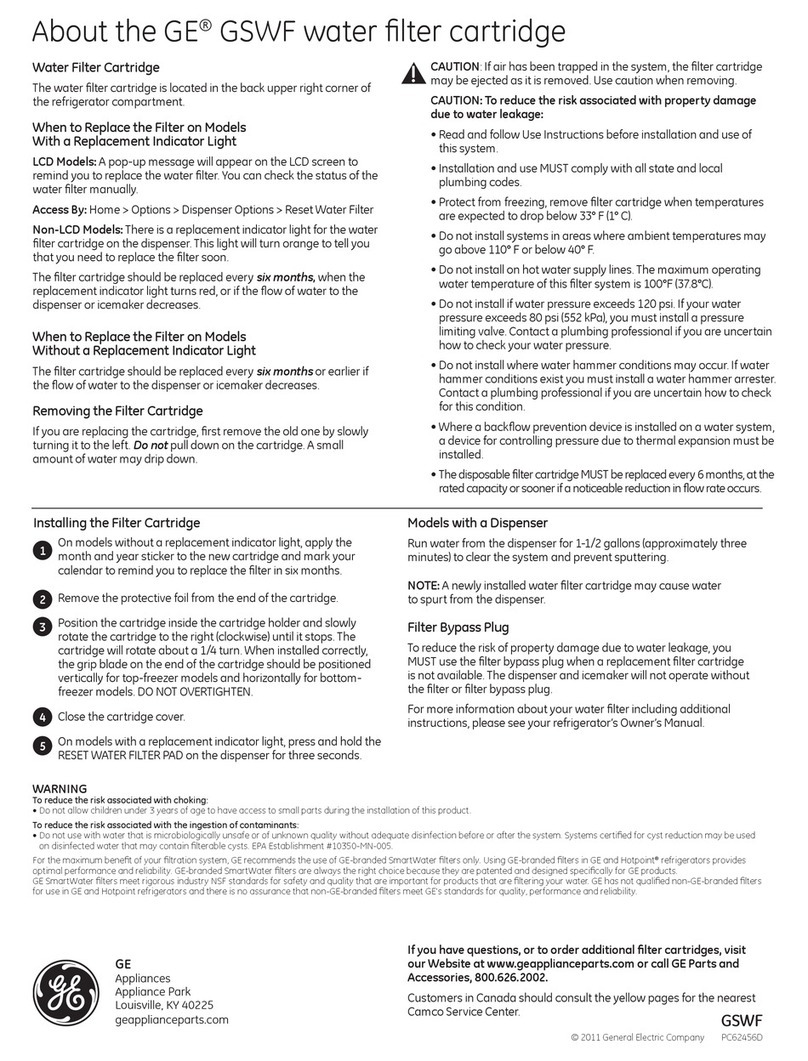

2. Mount the Faucet:

a) Familiarize yourself with all components

shown in faucet diagram.

b) Disassemble hardware from the threaded

nipple, except for chrome base plate and

rubber washer.

NOTE: Rubber washer may be replaced with bead

of plumber’s putty for neater appearance.

c) Connect length of standard 1/4" tubing to

faucet. Ensure plastic insert is in tubing.

Push on firmly until it seats.

d) Feed the threaded nipple through

sink/counter mounting hole and orient the

faucet as discussed with the customer.

e) From below sink/counter assemble the

black plastic washer, star washer and hex

nut on threaded nipple and tighten by hand.

f) After rechecking faucet orientation, tighten

hex nut (9/16" wrench or deep socket) until

faucet feels secure.

g) From above the sink make any minor

orientation corrections by turning the faucet

with a padded adjustable wrench.

h) Install plastic ferrule and compression nut

on tubing.

Note: Flats on chrome faucet may be used for

tightening with an adjustable wrench. Use care not

to mar chrome finish.

B. Install the Feed Water Valve and Tubing

The saddle tapping valve supplied is designed for

use with 3/8" to 1/2" OD soft copper supply tubing

(plain or chromed), rigid metal pipe, or CPVC

plastic pipe. Do not use with flexible ribbed supply

tubing which has too thin a wall thickness and

requires special hard ware.

Saddle Valve Installation

SOFT COPPER TUBING INSTALLATION:

1) Turn off cold water valve under the sink, or

main valve for the house.

2) Before installing saddle tapping valve, make

sure piercing lance does not protrude

beyond rubber gasket.

3) Assemble saddle tapping valve on copper

tubing. Tighten clamp.

4) To pierce soft copper tube, turn handle

clockwise until it is firmly seated. The valve

is closed in this position.

5) Turn on main supply valve to pressurize

coldwater line. Check for leaks. With a

wrench snug nut/seal around valve stem.

6) Connect one end of the tubing to the feed

water valve using brass compression nut

and plastic sleeve.

NOTE: For basement installations the existing feed

water tubing may have to be longer to reach feed

valve.

RIGID METAL PIPE AND CPVC PLASTIC PIPE

INSTALLATION:

1) Turn off cold water supply valve and drain the

line to prevent spillage.

2) Drill 3/16" hole at the desired location. To pre-

vent shock hazard, use a battery operated drill.

3) Before installing saddle tapping valve, make

sure piercing lance does not protrude beyond

rubber gasket.

4) Assemble saddle tapping valve on copper

tubing.

5) Turn saddle valve handle clockwise to close

valve. With a wrench tighten nut/seal around

valve stem.

6) When you wish to open valve and supply cold

water to the unit, turn valve handle counter

clock wise.

7) Connect one end of the tubing to the feed

water valve using brass compression nut and

plastic sleeve.

NOTE: For basement installations the existing feed

water tubing may have to be longer to reach feed

valve.

C. Make Initial Tubing Connections

It is advantageous to make some of the tubing

connections at this time, since the under-sink work

area is not so cramped and access to the

components is easier.