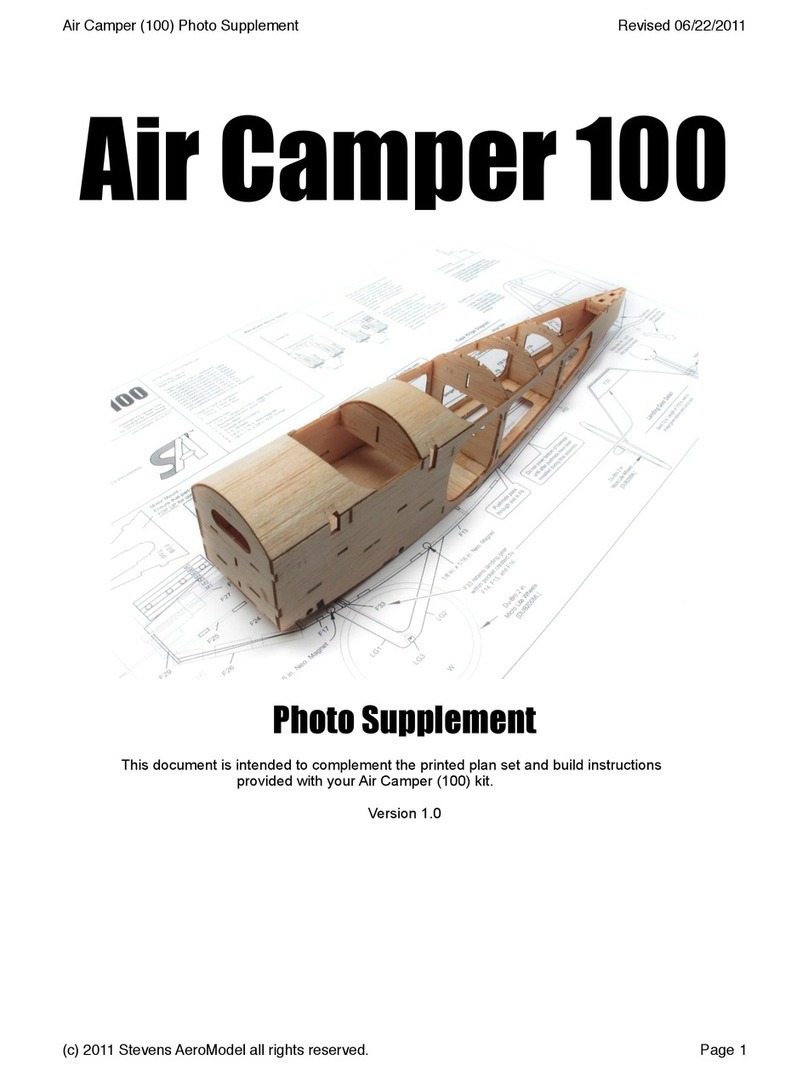

29. Revisit all tack glued joints between and

along parts with thin or medium CA glue to

more thoroughly bond the assembly. Go easy

on the glue as this can add significant weight

to the completed model.

Now, lightly sand fuselage smooth. Remove

excess from any tabs that protrude through

the fuselage sides, especially around the wing

mount. Trim and sand the rear dowel

supports F18 to flow smoothly from former F4

into the contours of the aft fuselage. Tip:

When shaping parts, protect the areas that

you do not wish to sand, or reduce through

sanding, with masking tape.

30. Lightly sand the edges of the nose to a

pleasing, rounded shape. Leaving the

fuselage square where the wind screen will

be installed. Set fuselage aside until final

assembly.

Tail Group

The horizontal and vertical stabilizers, rudder, and

elevator are cut from the 3/32 in. balsa sheet and

designated with a “H”, “V”, “R”, or “E” as

appropriate, followed by a numeric. Parts have

been numbered so that the assembly and

required parts follows in numeric order. Assemble

components over the plan sheets, protecting the

plan from glue spills with the poly bag that this kit

shipped in.

31. Assemble the Horizontal Stabilizer over the

plan, from parts H1 through H6. Bond with

CA. Lightly sand stabilizer following the

sanding instructions given on the plan set.

32. Assemble Elevator over the plan, from parts

E1 through E5. Bond with CA. Lightly sand

Elevator following the “Stabilizer and Elevator

Tape Hinge Diagram” and sanding

instructions given on the plan set.

33. Assemble the Vertical Stabilizer over the plan

from parts V1 through V5. Bond with CA.

Lightly sand stabilizer following the sanding

instructions given on the plan set.

34. Assemble the Rudder over the plan from

parts R1, R2, and R3. Bond with CA. Lightly

sand Rudder following the “Stabilizer and

Rudder Tape Hinge Diagram” and sanding

instructions given on the plan set.

Wing

The wing is composed of one spar, leading edge,

trailing edge, ribs and tip sheeting. Wing parts

are designated with a “W” followed by a numeric.

Parts have been numbered so that the wing

assembly and required parts follows in numeric

order from W1 to W28.

The wing is assembled one section at a time - left,

then right inner sections, center section, and the

wing tips separately. When a part is required in

the build sequence (for instance “W3”) refer to the

plan set for part placement.

You will dry fit the majority of this wing assembly

together only gluing at the final instructional steps.

When parts cannot easily be retained with friction,

use a single tiny drop of medium CA glue applied

sparingly through a CA glue applicator tip to “tack

glue” the part in place. Should you commit an

error in assembly it will be easier to recover from

the mistake and remove or correct the part fit in

error if you do not slather the assembly in glue

after each step! Further, this method of assembly

will allow our interlocking design to do it’s job as

each successive part installed within the wing will

help pull the entire structure square and true.

Wing Center

35. Begin by building left half of wing. Locate

parts W1 (main spar), and one each of ribs

W2, W3, and W4. Using the plan set as a

guide, dry fit ribs W2, W3, and W4 to deeper

slots within spar W1.

Note: The bottoms of all ribs should seat flush

with bottom of spars, if they do not, double

check your rib installation over the plan set.

36. Fit trailing edge W5 to ribs W2, W3, and W4

with the arrow marked on W5 pointing to wing

rib W2. Tack glue part to retain.

37. Fit and bond gusset W6 to trailing edge and

rib W2.

38. Fit leading edge web W7 to ribs W2, W3, and

W4 with the arrow marked on W7 pointing to

wing rib W2. Tack glue part to retain.

39. Fit leading edge W8 to leading edge web W6

with arrow marked on W8 pointing to wing rib

W2. Tack glue part to retain.

40. Fit and tack glue sub-ribs W9 and W10 to W1

spar and W7/W8 leading edge.

Build Instructions

© 2012 Stevens AeroModel all rights reserved.!Page 7 of 12