Stevens SOLO Programming manual

1

Ver. 12-Oct-16

Quick Start Instructions For

Power Management System

DESCRIPTION

Stevens is much more than just a solar charge controller and regulator. It is an intelligent power

management system. performs the features of a charge controller, a power monitor, SDI-12

bus activity monitor, and a remote power controller all in a single compact package.

The goal of is to keep your remote data collection platform operating

smoothly year after year while avoiding data outages and costly site visits.

2

Ver. 12-Oct-16

CHARGE CONTROLLER

Stevens features a float charger that can be used with PV arrays or power supplies having power

ratings as high as 40 watts (or larger under controlled conditions).

Battery temperature is sensed by a sensor installed at the terminal labeled “Temp Sensor” on the

controller. The float level of the changes by approximately –23 millivolt per degree C, colder

temperatures causing a higher float level. If the battery is located far from or in an area with

differing temperature, it is recommended to place the temperature sensor on the battery and extend

using standard low voltage wire.

The float threshold of is adjustable via an adjustment screw located on the top of labeled

“Float Adjust”. The 20 degree C float threshold may be set to any level between 11 and 16 volts. The

charge controller will charge a fully discharged battery at the full current output of the solar panel and

will automatically taper the charging current to zero as the terminal voltage of the battery approaches

the float level of the charger. The charger then supplies whatever trickle current is required by the

battery to maintain the battery at the float level, assuming sufficient sunlight. Any additional current,

due to the load on the battery, is automatically supplied as needed, so long as there is sufficient

sunlight to produce the current.

An LED indicator located on the top of the unit and labeled “Charge” indicates when the charger is

charging or holding the battery at the float level. The main purpose of this LED is to give an indication

that the charger and solar panel are functional. The LED is powered from the solar panel, and will not

be illuminated if there is no sunlight. A dimly lit LED will occur with low sunlight levels insufficient for

battery charging.

POWER MONITOR

Using SDI-12 commands, can be treated like a sensor, making measurements of Solar panel

voltage, Battery voltage, and Load current. Both instantaneous and averaged measurements can be

made. Measurement averaging sample rate and time period are adjustable with extended SDI-12

commands (see Appendix, SOLO SDI-12 Extended Commands for details).

To request measurement data using the SDI-12 protocol send aM! (where a is the address,

default 0). responds with a0006 to indicate 6parameters of data are available. These 6

parameters are Instantaneous Load Current, Instantaneous Input Voltage, Instantaneous

Battery Voltage, Average Load Current, Average Input Voltage and Average Battery Voltage.

Current is measured in amperes, voltage is measured in volts. All measurement are fixed point

with two digits to the left of the decimal and 4to the right. Instantaneous Measurements are

returned in response to the command aD0!. Average measurements are returned in response to

the commands aD1!. A typical response to aDn! is in the format:

3

Ver. 12-Oct-16

a+CC.cccc+VV.vvvv+VV.vvvv (e.g. 0+01.2714+12.9881+11.2222) where the first parameter

is Load Current, the second is Input Voltage and the third is Battery Voltage.

POWER MANAGER

Power cycling is often the main solution to a troubled data collection station. allows for this to

happen remotely and/or automatically, eliminating costly and unnecessary trips to the remote site.

Load power can be turned off and on using a set of SDI-12 extended commands. A power cycle (with

programmable delays) can also be initiated with a manual button on the side of or with a pulse

input at the “Pulse In” terminal block. Both these inputs have the delay and off-time controlled by the

relevant SDI-12 commands.

Additionally, can be used as an SDI-12 bus activity monitor. An extended command sets the

‘watchdog’ timeout period. If does not detect SDI-12 bus activity before the timer expires, then

load power will be cycled. In this way, can automatically monitor whether your logger is issuing

commands to your SDI-12 sensors. If the logger ceases to issue commands, for instance due to a

software crash, then will automatically restart the system.

See Appendix: SDI-12 Extended Commands for all commands relating to power

management.

4

Ver. 12-Oct-16

WIRING

Refer to the nameplate label on the top of the unit for proper

wiring. Terminal connections may be made to the solar panel,

battery and load in any sequence. Be careful to connect the

polarity correctly. Reverse connection of the solar panel and

battery will not cause damage. Reverse connection to the

load, however could damage the load equipment depending

on what it is.

SPECIFICATIONS

Maximum input voltage: Not to exceed 28 volts including transients and spikes.

Maximum charging current and/or power dissipation: Typically 4amps. The controller will

conservatively handle currents to 10 amps so long as the power dissipated by the controller doesn’t

exceed approximately 15 watts for longer than 5seconds ( would in this case need to be properly

heatsinked). For example, assume is driven by a solar panel or power supply that is supplying 4

amps at a terminal voltage of 16 volts. Assume also that the battery terminal voltage is 13 volts. The

power dissipated by the controller may be calculated as follows:

P = (16 –13)(4) = 12watts

Higher charging currents can be handled if the input voltage is closer to the charging voltage. The

maximum allowable solar panel or power supply terminal voltage for a given charging current can be

calculated as follows:

V = (15/ I) = Vbat

where: V= Maximum allowable terminal voltage of solar panel or power supply. (In no case should

V be allowed to exceed 28 volts).

I = Charging current

Vbat = terminal voltage of battery

As an example, 7.5amps of charging current can be handled by if the solar panel or power supply

terminal voltage doesn’t exceed:

V = (15/7.5) + Vbat = 2+ Vbat

Solar Panel Wattage: typically 40 Watts

5

Ver. 12-Oct-16

Current consumption: 4-7mA, unloaded. The LED requires approximately 3ma, however this current

is supplied from the solar panel.

Temperature compensation: Approximately –23 millivolt/degree C.

Operating Temperature: -50 degree C to +55 degree C.

Storage Temperature: -55 degree C to +85 degree C.

ADJUSTING FLOAT THRESHOLD

This procedure assumes that the magnitude of the desired float level has been determined for the

corresponding temperature of the temperature sensor. The float voltage can be determined as follows:

Vfloat = V20 + (20 –Ts)(.0234)

where: V20 = The specified float voltage for the battery at 20 degrees C.

Ts= actual ambient temperature of the temperature sensor in degrees C.

Step 1Disconnect the battery from the battery leads of .

Step 2Connect a voltmeter across the battery leads of .

Step 3If the adjustment is being made in the field, be sure that the solar panel is producing adequate

voltage, (several volts higher than the float level desired for the battery). If the adjustment is

being made in the shop, connect a power supply to the solar input terminals, (DO NOT SET

THE POWER SUPPLY OUTPUT HIGHER THAN 28 VOLTS OR YOU MAY DAMAGE ).

Step 4 Adjust the screwdriver adjustment control on the top of until the voltmeter reads the

desired float voltage.

Step 5Remove the voltmeter and re-connect the battery to the battery terminals.

NOTES

If is used as a float regulator in conjunction with a power supply, be sure that the maximum

output voltage from the supply never exceeds 28 volts. If the power supply is unfiltered, then the peaks

of the rectified cycles must not exceed 28 volts. Keep in mind that a dc meter generally gives a reading

that represents the average of the waveform, not the peak value. An oscilloscope should be used to

accurately determine the peak value of the output waveform of a non-filtered power supply. Allow a

20% or more margin for high power line voltage.

6

Ver. 12-Oct-16

There is no current limiting in , so be careful not to short the BATTERY leads when is being

powered by a power supply. Shorting the battery leads from will reflect the short back onto the

power supply, and may damage the power supply and/or . WILL NOT be damaged by

shorts on the battery leads when supplied by a solar panel.

DO NOT CHANGE THE BATTERY CHEMISTRY FLOAT LEVEL (USING THE SDI-12 EXTENDED

COMMAND SHOWN BELOW) WHEN UNIT IS CONNECTED TO A BATTERY. Also, changing battery

chemistry will require a readjustment of the float voltage level. settings default for use with

standard lead-acid type batteries. An SDI-12 extended command can be issued to to change

internal settings when using Gel-Cell type batteries.

Setting the proper float level for the particular type of battery will optimize the charging voltage over

temperature and extend the life of the battery

7

Ver. 12-Oct-16

Appendix: SDI-12 Extended Commands for :

a = SDI-12 device address

### = a 3-digit number value

aXJ0! - Switch OFF load

aXJ1! - Switch ON load

aXJR!- Initiate power cycle NOTE: aM9! will also initiate a power cycle. This is provided as a convenience for

data loggers that do not support extended commands.

aXJD###!- Set off-time in seconds [001 to 255]. Must enter all 3digits.

Note: Entering aXJD! restores default value (10 seconds of off-time)

aXJZ###!- Set restart delay time in minutes [000 to 255]. Must enter all 3digits

Note: Entering aXJZ! restores default value (0, turn-off delay disabled).

aXJW###!- Set SDI-12 bus monitor watchdog timeout in minutes [000 to 255]. Must enter all 3digits

Note: Entering aXJW! restores default value of (0, disable SDI-12 bus monitor).

aXJT###!- Set the Time between measurements in seconds used for historical averaging [001 to 120].

Must enter all 3digits.

Note: Entering aXJT! restores default value of 1second.

aXJM###!- Set the number of sample measurements used in historical averaging [002 to 030].

Note: Entering aXJM! restores default value of 002.

aXJB[L or G]! - Set the battery type ["L"= lead acid "G" = Gel Cell]. Default is "L".

aXFR!- Display all programmable values

Response is of the form:

aXFR:S=s,A=a,D=ddd,Z=zzz,W=www,T=ttt,M=mmm,B=b

where:

s - 0 flash has been erased, 1 flash has been programmed

a - SDI address

ddd –power cycle off-time (in seconds)

zzz –power cycle delay time (in minutes)

www –SDI-12 bus monitor watchdog timeout period (in minutes)

ttt - time between sensor measurements (in seconds)

mmm - measurement samples to be averaged

b - battery chemistry, G for gel cell, L for lead acid

Table of contents

Popular Controllers manuals by other brands

Rockwell Automation

Rockwell Automation SLC 500 Thermocouple Selection guide

Allen-Bradley

Allen-Bradley PLC-5 series installation instructions

Heatit

Heatit Z-WATER installation guide

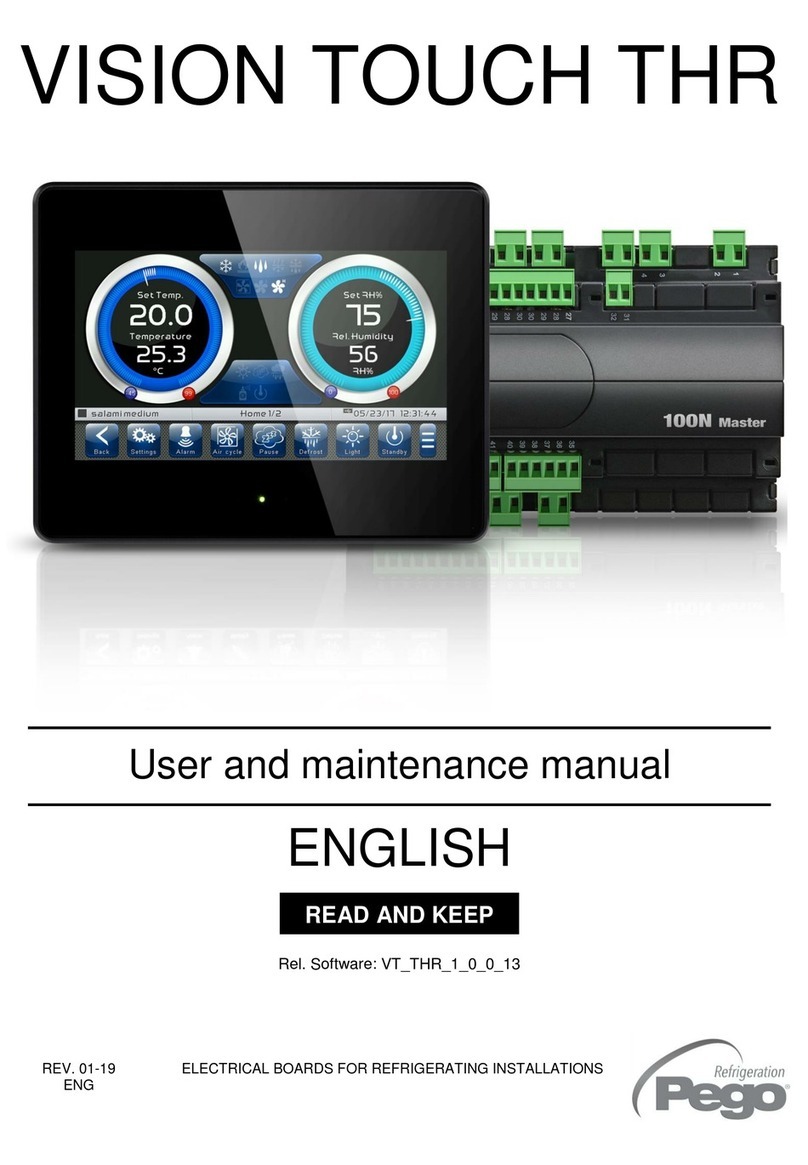

Pego

Pego VISION TOUCH THR User and maintenance manual

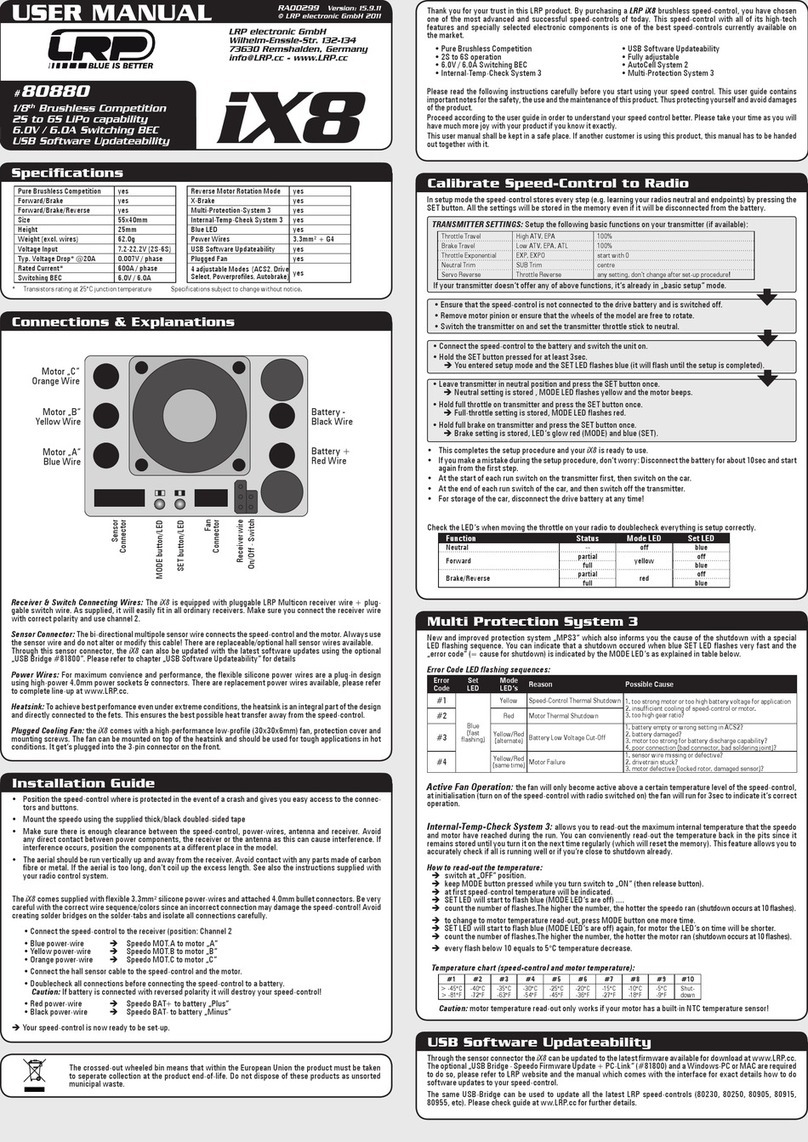

LRP electronic

LRP electronic iX8 user manual

Branson

Branson Emerson Ultraseal 20 operating manual