10

Filling of the system

6. Now you have to drain the following quantity of li-

quid:

Quantity A: 0,17 l for each liter of liquid content in the

DrainMaster (for 10 l liquid content in the DrainMaster

= 1,7 l)

Quantity B: 0,04 times installation content (for 30 l

installtion content = 1,2 l)

Total draining quantity = quantity A + quantity B (exa-

mple 1,7 l + 1,2 l = 2,9 l)

7. Close the shut-off valve at the pressure-side of

the pump again and ll in quantity A. By doing so

the necessary prepressure of the installation can be

reached.

8. Now the report of the controller should disappear

or the collector temperature should appear. If an error

report or the report „lling level reached“ is shown,

the installation is overlled and has to be drained until

the report diappears.

9. Open the shut-off valve, close the lling and drai-

ning valve and switch on the pump. Check the func-

tionality of the installation and switch over to an auto-

matic operation.

Installation without level indicator

1. Close the shut-off valve in the collector back ow

(pressure-side of the pump).

2. Loosen the upper connection at the DrainMaster.

3. Open the lling and draining valve, connect the

lling pump and slowly ll the installation until the

DrainMaster is completely lled with liquid.

4. Close lling and draining valve and open the shut-

off valve (pressure-side of the pump).

5. Slowly rell the liquid until the DrainMaster is com-

pletely completely lled.

6. Now you have to drain the following quantity of li-

quid:

Quantity A: 0,17 l for each liter of liquid content in the

DrainMaster (for 10 l liquid content in the DrainMaster

= 1,7 l)

Quantity B: 0,04 times installation content (for 30 l

installtion content = 1,2 l)

Total draining quantity = quantity A + quantity B (exa-

mple 1,7 l + 1,2 l = 2,9 l)

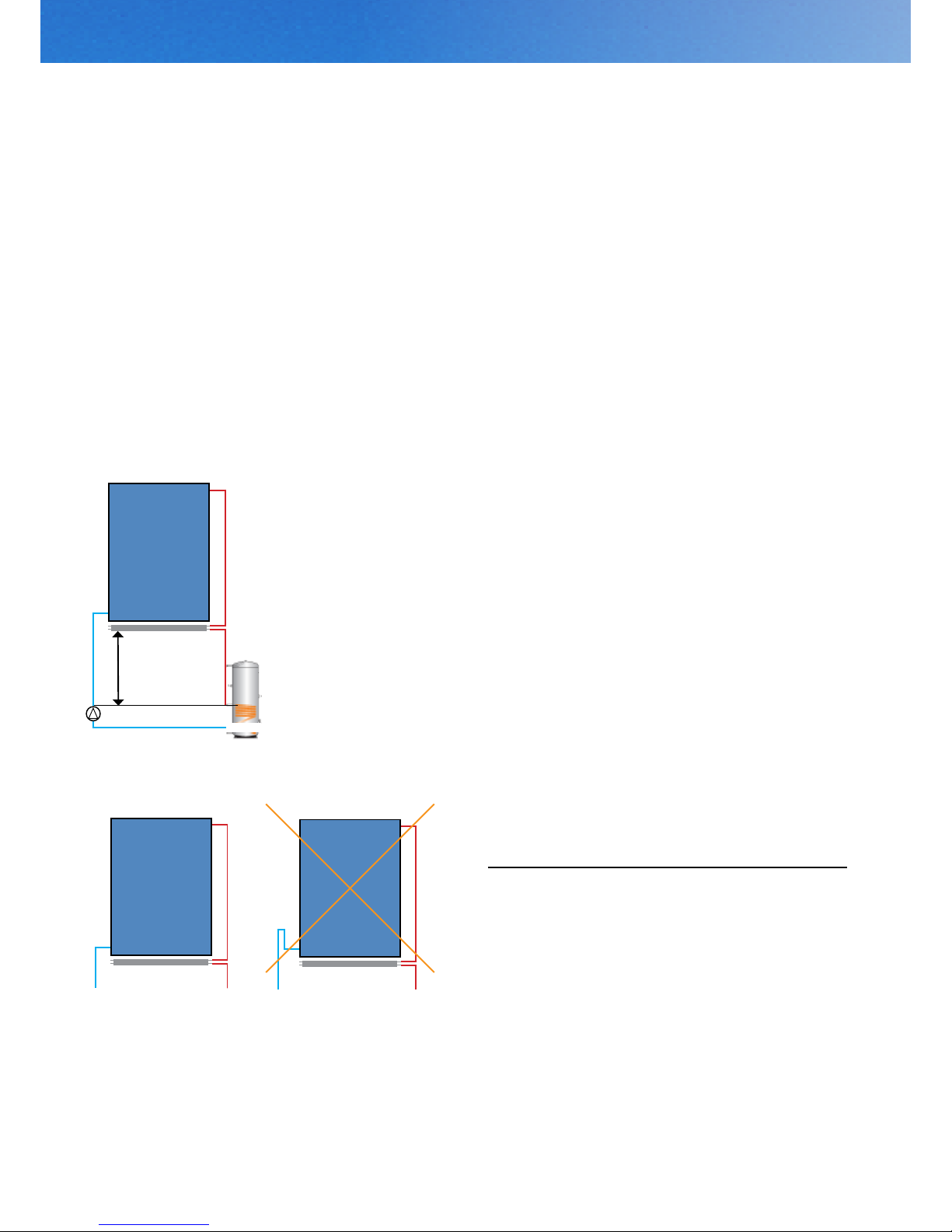

Attention!

When lling the installation, the solar uid must not

be warmer than 25 °C!

The circulating pump must not be working while lling.

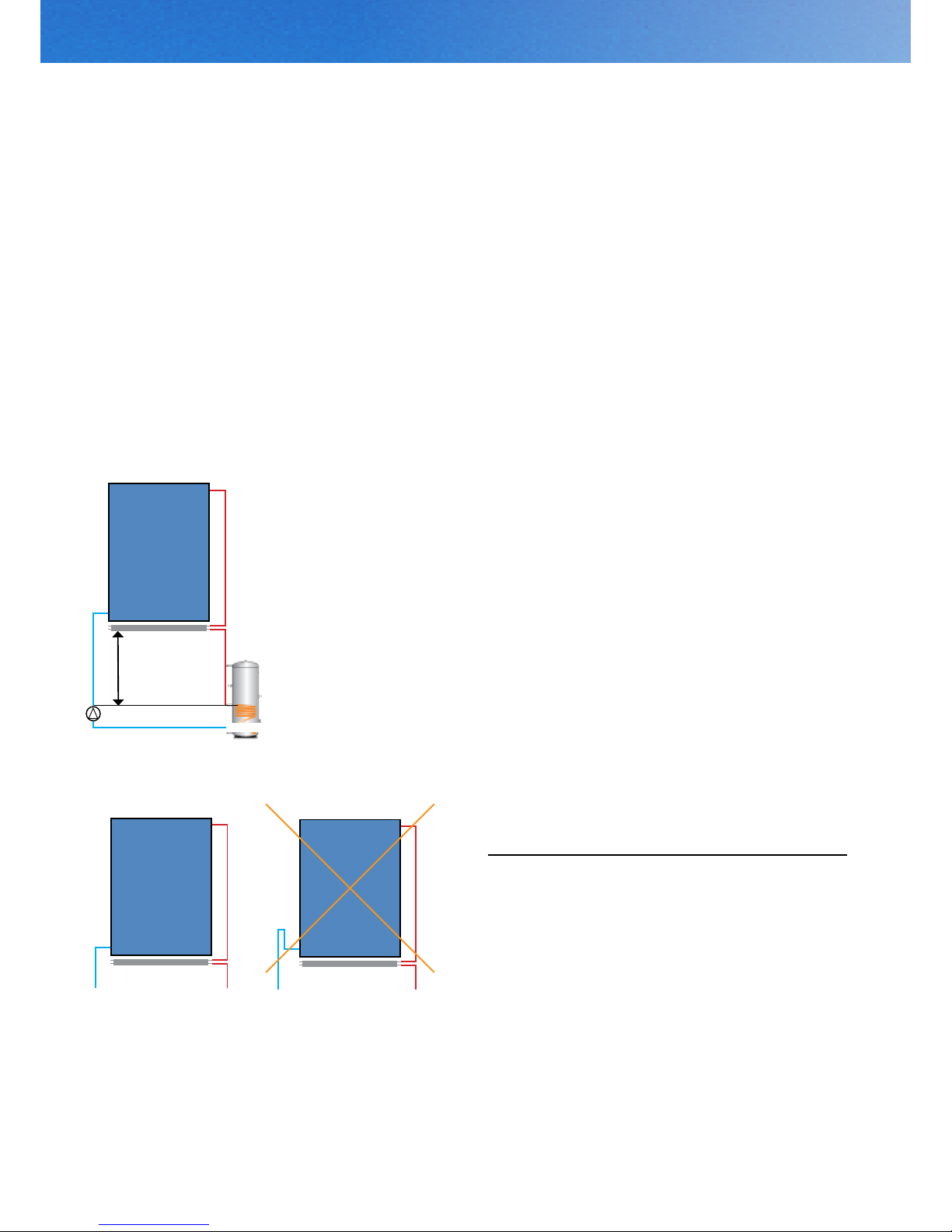

Filling under cloudy skies

The prepressure of the installation is calculated as

follows:

Prepressure in bar = static height in meter / 10 + 0,2

Filling in sunshine

The prepressure of the installation depends on the

temperature of the collector during the lling.

Rule of thumb for the prepressure:

Prepressure in bar = static height in meter / 10 + 0,2

+ gure stated below:

For collector temperature of approx. 50 °C + 0,1 bar

For collector temperature of approx. 100 °C + 0,2 bar

For collector temperature of approx. 150 °C + 0,3 bar

For collector temperature of approx. 200 °C + 0,4 bar

Installation with level indicator

1. Close the shut-off valve in the collector back ow

(pressure-side of the pump).

2. Open the lling and draining valve of the safety

device.

3. Connect the lling pump at the lling and

draining valve at the suction side of the pump. Fill

the installation slowly until the probe presents the

maximum lling level (when using special controllers,

the report „maximum lling level reached“ is going

to be shown).

4. Close lling and draining valve and open the

shut-off valve (pressure-side of the pump).

5. Slowly ll in the liquid until the probe presents

the maximum lling level once again (when using

special controllers, the report „maximum lling level

reached“ is going to be shown).