BR 200

English

6

Working Technique

To minimize blowing time, use a rake

and broom to loosen dirt particles before

you start blowing.

Recommended working technique to

minimize air pollution:

–If necessary, dampen the surface to

be cleaned in order to avoid creating

too much dust.

–Do not blow particles in the direction

of bystanders, in particular in the

direction of children, pets, open

windows or freshly washed

vehicles. Take special care in such

situations.

–Remove the blow-swept debris in

rubbish bins – do not blow it onto the

neighbor's land.

Recommended working technique to

minimize noise:

–Operate your power tool at

reasonable times only – not early in

the morning, late at night or during

midday rest periods when people

could be disturbed. Observe local

rest periods.

–Operate blowers at the lowest

engine speed necessary to

accomplish the task.

–Check your blower before starting

work. Pay special attention to the

muffler, air intakes and air filter.

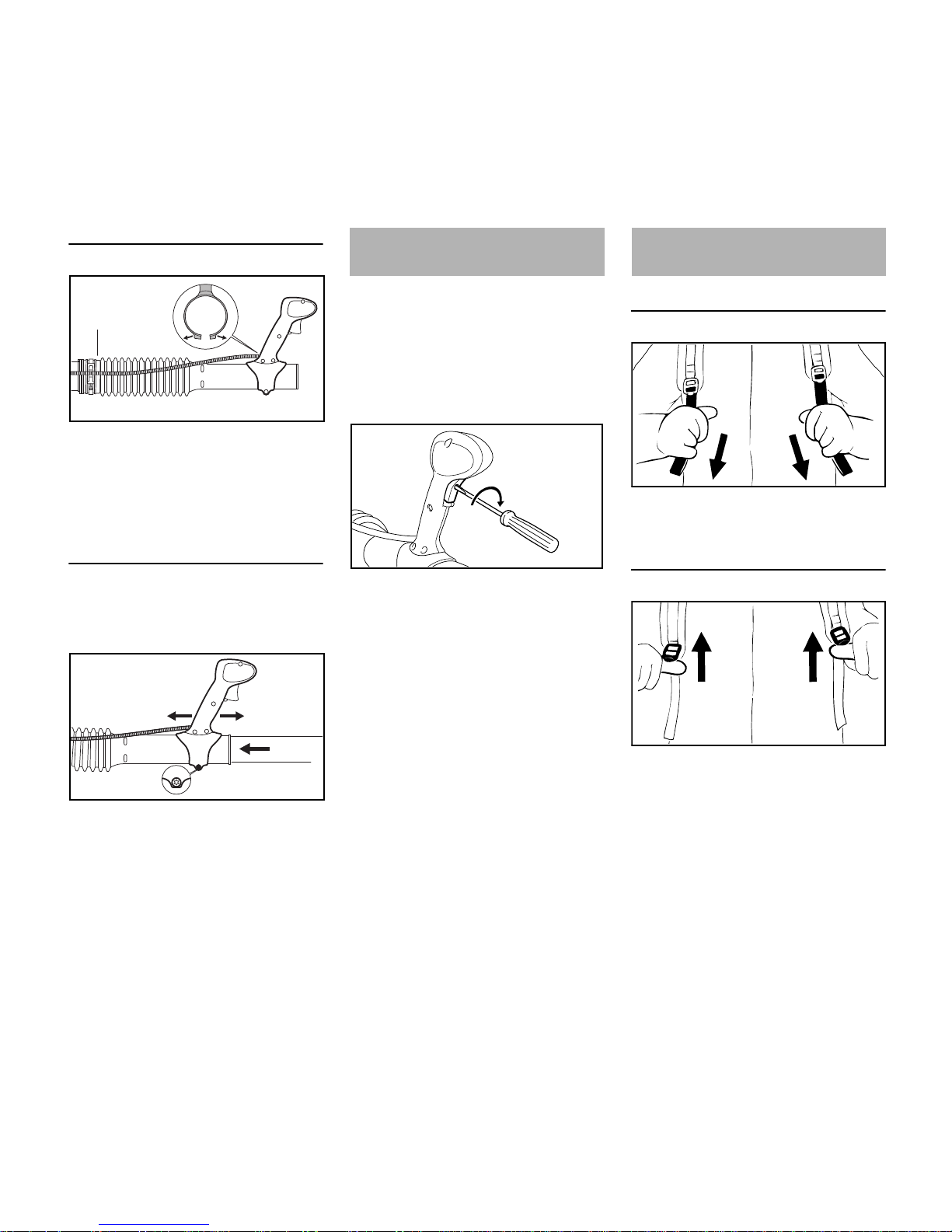

Vibrations

Prolonged use of the power tool may

result in vibration-induced circulation

problems in the hands (whitefinger

disease).

No general recommendation can be

given for the length of usage because it

depends on several factors.

The period of usage is prolonged by:

–Keeping your hands warm

–Work breaks

The period of usage is shortened by:

–Any personal tendency to suffer

from poor circulation (symptoms:

frequently cold fingers, itching).

–Low outside temperatures.

–Gripping force (a tight grip hinders

circulation).

Continual and regular users should

monitor closely the condition of their

hands and fingers. If any of the above

symptoms appear (e.g. tingling

sensation in fingers), seek medical

advice.

Maintenance and Repairs

Service the machine regularly. Do not

attempt any maintenance or repair work

not described in the instruction manual.

Have all other work performed by a

servicing dealer.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer. STIHL dealers are

regularly given the opportunity to attend

training courses and are supplied with

the necessary technical information.

Only use high-quality replacement parts

in order to avoid the risk of accidents

and damage to the machine. If you have

any questions in this respect, consult a

servicing dealer.

STIHL recommends the use of genuine

STIHL replacement parts. They are

specifically designed to match your

model and meet your performance

requirements.

To reduce the risk of injury, always shut

off the engine before carrying out any

maintenance or repairs or cleaning the

machine. – Exception: Carburetor and

idle speed adjustments.

Do not turn the engine over on the

starter with the spark plug boot or spark

plug removed since there is otherwise a

risk of fire from uncontained sparking.

Do not service or store your machine

near open flames.

Check the fuel filler cap for leaks at

regular intervals.

Use only a spark plug of the type

approved by STIHL and make sure it is

in good condition – see "Specifications".

Inspect the ignition lead (insulation in

good condition, secure connection).

Check the condition of the muffler.

To reduce the risk of fire and damage to

hearing, do not operate your machine if

the muffler is damaged or missing.

Do not touch a hot muffler since burn

injury will result.