worn AV buffers will tend to have

higher vibration levels.

- Maintain a firm grip at all times, but

do not squeeze the handles with

constant, excessive pressures, take

frequent breaks.

All the above mentioned precautions do

not guarantee that you will not sustain

whitefinger disease or carpal tunnel

syndrome. Therefore continual and

regular users should monitor closely the

condition of their hands and fingers.

If any of the above symptoms appear,

seek medical advice immediately.

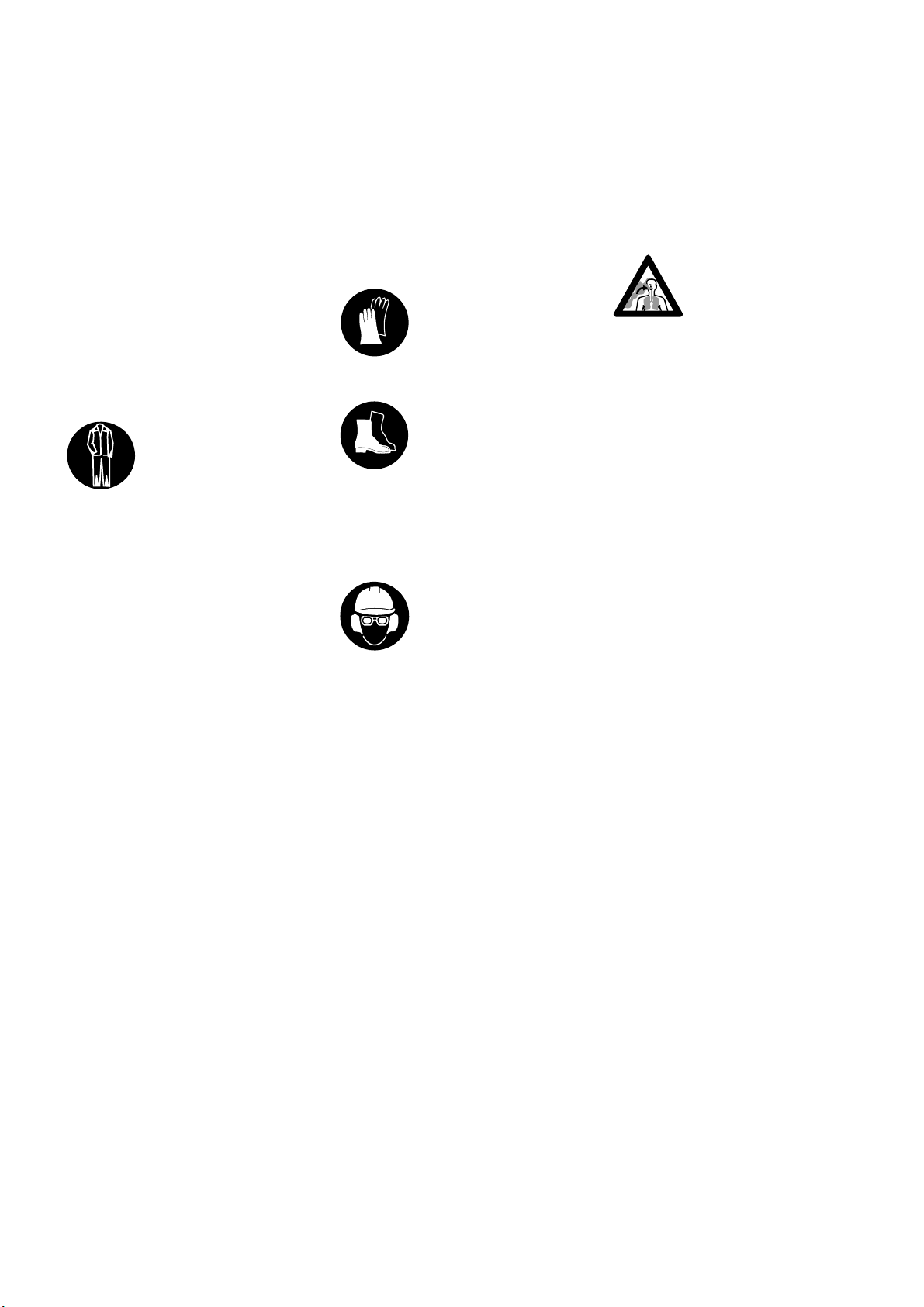

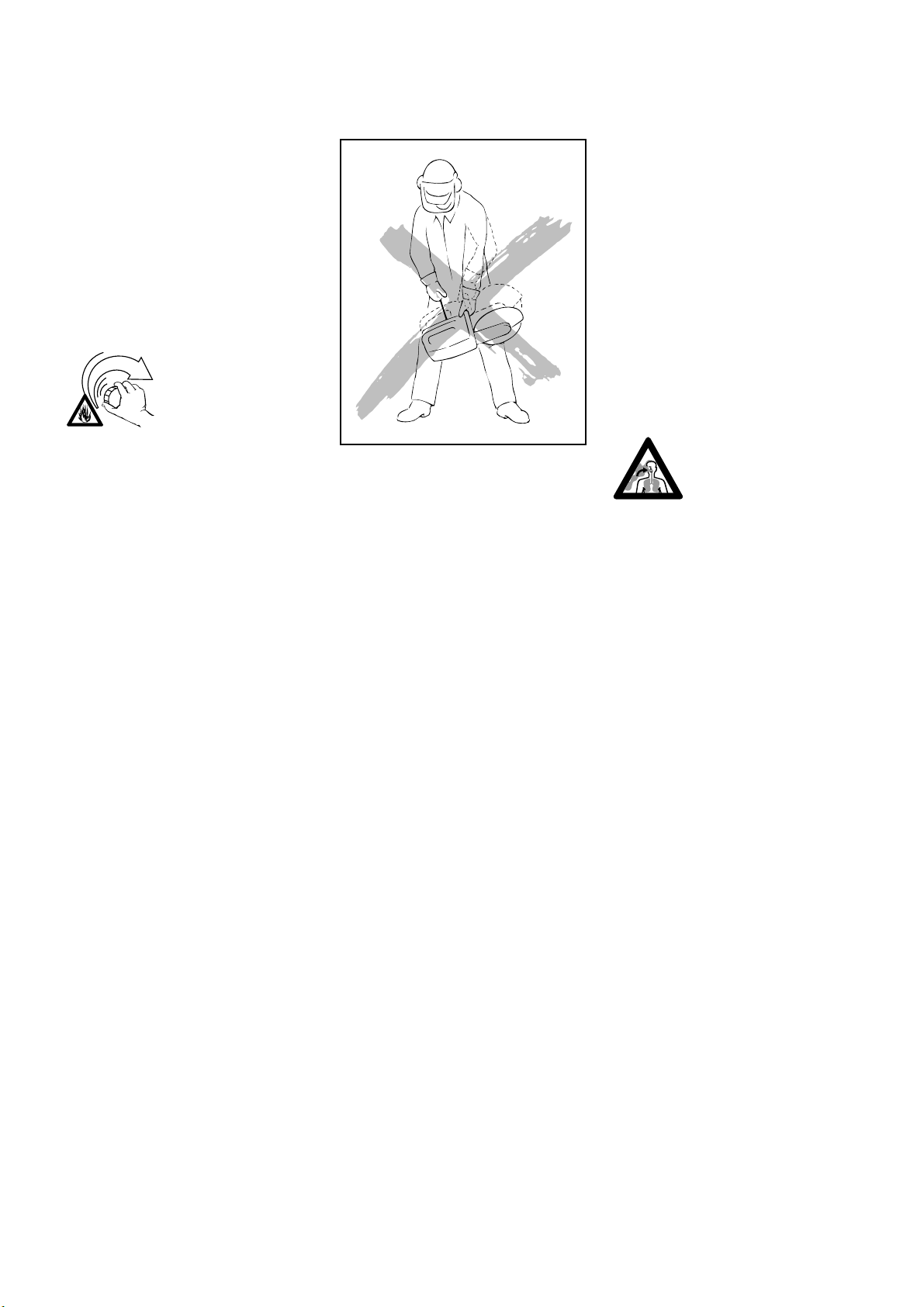

3URSHU&ORWKLQJ

Clothing must be sturdy

and snug-fitting, but allow

complete freedom of

movement. Avoid loose-

fitting jackets, scarfs,

neckties, jewelry, flared or cuffed pants,

unconfined long hair or anything that

could become caught on any obstacles

or moving parts of the unit. Wear over-

alls or long pants to protect your legs.

Do not wear shorts.

:DUQLQJ

When cutting metal, a cut-off machine

generates sparks which can ignite

clothing. Most fabrics used in clothing

are flammable - even flame retardant

fabrics will ignite at higher temperatures.

To reduce the risk of burn injury STIHL

recommends wearing clothing made of

leather, wool, flame-retardant treated

cotton or a tightly woven, heavier cotton

such as denim. Some flame-retardant

synthetic fabrics are also suitable but

others such as polyester, nylon, rayon

and acetate can melt during fire into a

tar-like matter that burns into the skin.

Keep clothing free of oil, fuel, grease

and other flammable substances.

Protect your hands with

gloves when handling the

cut-off machine.

Heavy-duty, nonslip

gloves improve your grip

and protect your hands.

Good footing is most im-

portant in cut-off machine

work.

Wear sturdy boots with

nonslip soles. Steel-toed

safety boots are recommended.

:DUQLQJ

Loose objects may be thrown toward the

operator by the cutting tool.

To reduce the risk of

injury to your eyes never

operate a cut-off machine

unless wearing goggles

or properly fitted safety

glasses with adequate top and side

protection complying with ANSI Z 87.1.

Proper eye protection is a must.

Wear an approved safety hard hat to

protect your head. cut-off machine noise

may damage your hearing.

Always wear sound barriers (ear plugs

or ear mufflers) to protect your hearing.

Regular users should have their hearing

checked regularly.

:DUQLQJ

Use of this product to cut

masonry, concrete, metal

and other materials can

generate dust, mists and

fumes containing

chemicals known to cause serious or

fatal injury or illness, such as respiratory

disease, cancer, birth defects or other

reproductive harm. If you are unfamiliar

with the risks associated with the particu-

lar material being cut, review the material

safety data sheet and/or consult your

employer, the material manufacturer/-

supplier, governmental agencies such

as OSHA and NIOSH and other sources

on hazardous materials. California and

some other authorities, for instance,

have published lists of substances

known to cause cancer, reproductive

toxicity, etc.

Control dust, mist and fumes at the

source where possible. In this regard

use good work practices and follow the

recommendations of the manufacturer/-

supplier, OSHA/NIOSH, and occupatio-

nal and trade associations. A water

attachment kit is available for your cut-off

machine and should be used for dust

suppression when wet cutting is feasible.

When the inhalation of dust, mists and

fumes cannot be eliminated, the operator

76