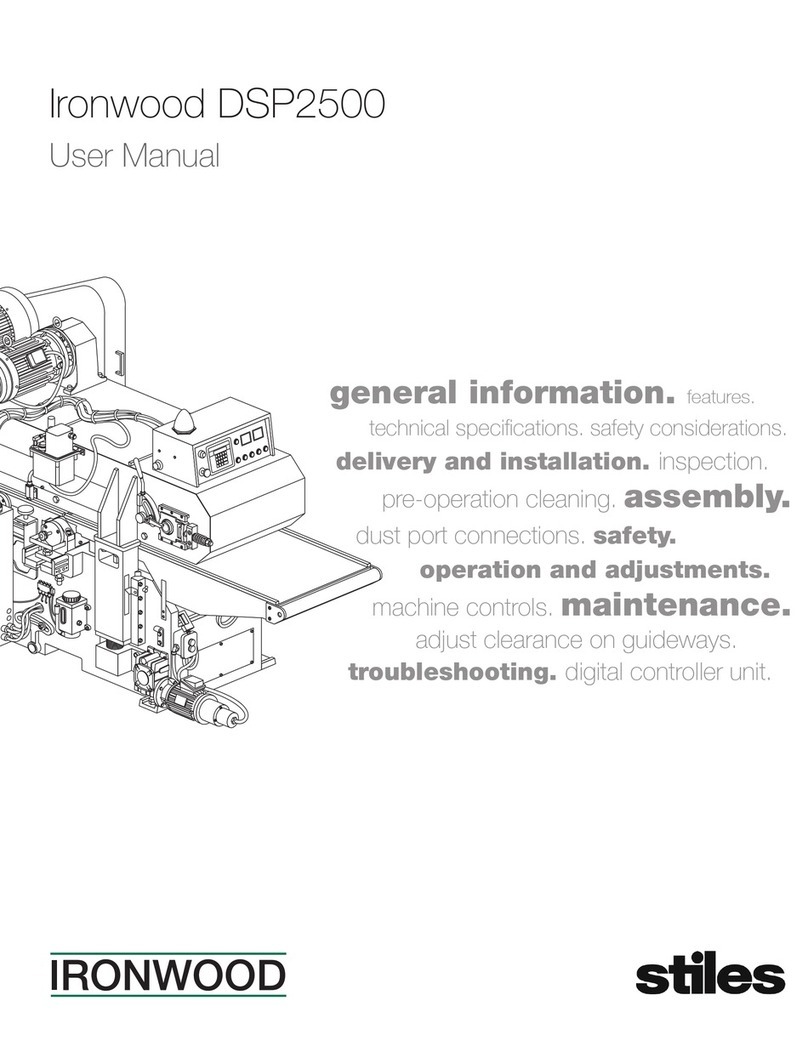

Stiles Ironwood DSP2500-HS User manual

Ironwood DSP2500-HS

User Manual

general information. features.

operation and adjustments.

machine controls. maintenance.

adjust clearance on guideways.

troubleshooting. digital controller unit.

delivery and installation. inspection.

pre-operation cleaning. assembly.

dust port connections. safety.

technical specifications. safety considerations.

Ironwood DSP2500-HS | User Manual2

1.0 General Information…............................................................... 3

1.1 Thank You

1.2 Before Contacting Stiles

1.3 Features

1.4 Intended Use

1.5 Technical Specications

1.6 Safety Considerations

2.0 Facility Preparation… ............................................................... 6

2.1 Floor

2.2 Work Space

2.3 Power

3.0 Delivery and Installation … ........................................................... 7

3.1 Receiving Your Machine

3.2 Unpack the Machine

3.3 Inspection

3.4 Move Machine to Final Position

3.5 Remove Machine from Pallet

3.6 Level

3.7 Pre-Operation Cleaning

4.0 Assembly ....................................................................... 11

4.1 Front Roller

4.2 Control Power Switch

4.3 Dust Port Connections

5.0 Connect to Power…............................................................... 12

6.0 Safety.......................................................................... 13

7.0 Operation and Adjustments ......................................................... 14

7.1 Machine Controls

7.2 Machine Operation

7.3 Tool Adjustments

8.0 Maintenance… ................................................................... 22

8.1 Lubrication

8.2 Inspection

8.3 Periodic Maintenance

8.4 Adjust V-Belt Tension of Cutterhead Motors

8.5 Adjust Clearance on Guideways

8.6 Adjust Clearance for Infeed Table Taper Gib

9.0 Troubleshooting .................................................................. 25

9.1 Machine Operation

9.2 Digital Controller Unit

9.3 Electrical Diagrams

Table of Contents

PLEASE REVIEW AND OBSERVE ALL SAFETY

INFORMATION / DIRECTIVES BEFORE INSTALLING,

OPERATING, OR PERFORMING MAINTENANCE ON

THIS MACHINERY.

Ironwood DSP2500-HS | User Manual 3

1.0 General Information

1.1 Thank You!

Thank you for your purchase of the Ironwood DSP2500-HS double

surface planer. At Stiles Machinery, our goal is to ensure that you are

fully satised with your purchase. This manual is provided so that

you may properly assemble, operate, and maintain your DSP2500-

HS. Should you need help, our team of dedicated service personnel

are available to answer your questions and provide any resource

recommendations you may need.

Warranty and Support

All Ironwood machines are designed to meet the exacting standards

demanded by craftsmen like you. Ironwood machines include a

one (1) year parts warranty and two (2) years of free 24/7 technical

support beginning at date of shipment. Standard technical support

remains in effect for free for the lifetime of the machine thereafter.

Warranty service work is not covered by manufacturer’s warranty.

Stiles’ service team is available for an additional charge.

1.2 Before Contacting Stiles

Please have your machine model and serial number available when

contacting Stiles Machinery with questions. The machine’s model

and serial number are listed on the metallic plate located on the

machine’s frame.

Information regarding the electrical system is also listed on the

metallic plate.

Machine information plate

Stiles Technical Support

616.698.6615

Stiles Parts

800.PARTS.80 (800.727.8780)

Website

www.stilesmachinery.com/ironwood/dsp-2500

Machine Model ____________________________________________

Machine Serial Number _____________________________________

1.3 Features

Insert latest drawing with call-outs for features:

• Overlapped pressure-nger conveyor secures workpieces rmly

and uniformly to maintain straightness and prevent movement

• 2 heavy-duty spiral cutterheads have six rows of 16 carbide

inserts, providing high chip-rate removal rate, superior surface

nishing, and reduced noise levels

• Innovative micro-switch enables quick thickness settings

• ½-hp motor raises and lowers table

• 5 hp feed motor has variable speed control (23-65 fpm)

• Heavy-duty 25 hp upper cutterhead motor and 20 hp lower

cutterhead motor

• Digital controller has keypad entry for table positioning

• Powered elevation of feed mechanism allows quick, easy

set-ups.

• Control panel is equipped with digital thickness readout, LED

display (inch/mm), current meters, and lighted power switches

for controls.

1.4 Intended Use

The Ironwood DSP2500-HS double-surface planer is designed

and manufactured for planing two sides of a workpiece in a single

operation. The lower cutterhead attens the workpiece and the

upper cutterhead planes the workpiece to the desired thickness for

fast and effective planing results.

The workpiece is fed into the machine by a pressure-nger conveyor

that holds the workpiece rmly for heavy-duty cutting applications.

The feed speed is variable to meet a wide range of workpiece

material requirements.

With hardened chrome-plated and precision ground tables, the

DSP2500-HS ensures smooth feeding motion, quiet operation, and

maximum wear resistance.

Ironwood DSP2500-HS | User Manual4

2 heavy duty

spiral cutterheads

Solid cast iron base

Overlapping pressur

e

nger conveyor

Conveniently located

control panel with digital

controller, current meters,

and lighted power switches.

1.5 Technical Specifications

Description Ironwood DSP2500-HS

Max Working Width 25" (635mm)

Max Working Thickness 8" (203mm)

Min Working Thickness 6

/

16" (9.5mm)

Min Length of Cut 12½" (317mm)

Upper Cutterhead Motor 40 hp

Lower Cutterhead Motor 25 hp

Feeding Cutterhead Motor 5 hp

Table Rise/Fall Motor 1/2 hp

Variable Feed Speed 26-131 fpm (8-40 m/min)

Cutterhead Speed 5,000 rpm

Cutterhead Diameter 5" (126mm)

Cutter Knives per Head 96

Max Stock Removal ½" (14mm) total / ¼" (7mm) per head

Table adjustment – Lower cutterhead Manual via handwheel

Table adjustment – upper cutterhead Motorized via keypad controller

Table position display Digital

Electrical 230v / 460v (3 phase)

Amperage 177 amps @ 230V / 88 amps @ 460V

Dust Port Diameter 2 ports, 6" each (150mm)

Dust Extraction Requirements 1,600 cfm @ 4,500 feet/min

Machine Dimensions (W x L x H) 107" x 45" x 68" (2717mm x 1145mm x 1725mm)

Gross Weight 7220 lbs (3275 kg)

Ironwood DSP2500-HS | User Manual 5

1.6 Safety Considerations

For your safety, read these instructions thoroughly before you install

and operate this machine. Always have these instructions available

at the machine for reference.

Observe all codes and regulations that apply to the installation and

operation of this machine.

Keep visitors at a safe distance from the workspace.

Keep children away from this and all machines. Childproof your

work area!

Familiarize yourself with the safety notices used in this manual.

CAUTION

If cautions are ignored, personal injury and/or machine damage

may result.

WARNING

If warnings are ignored, serious injury or death may result.

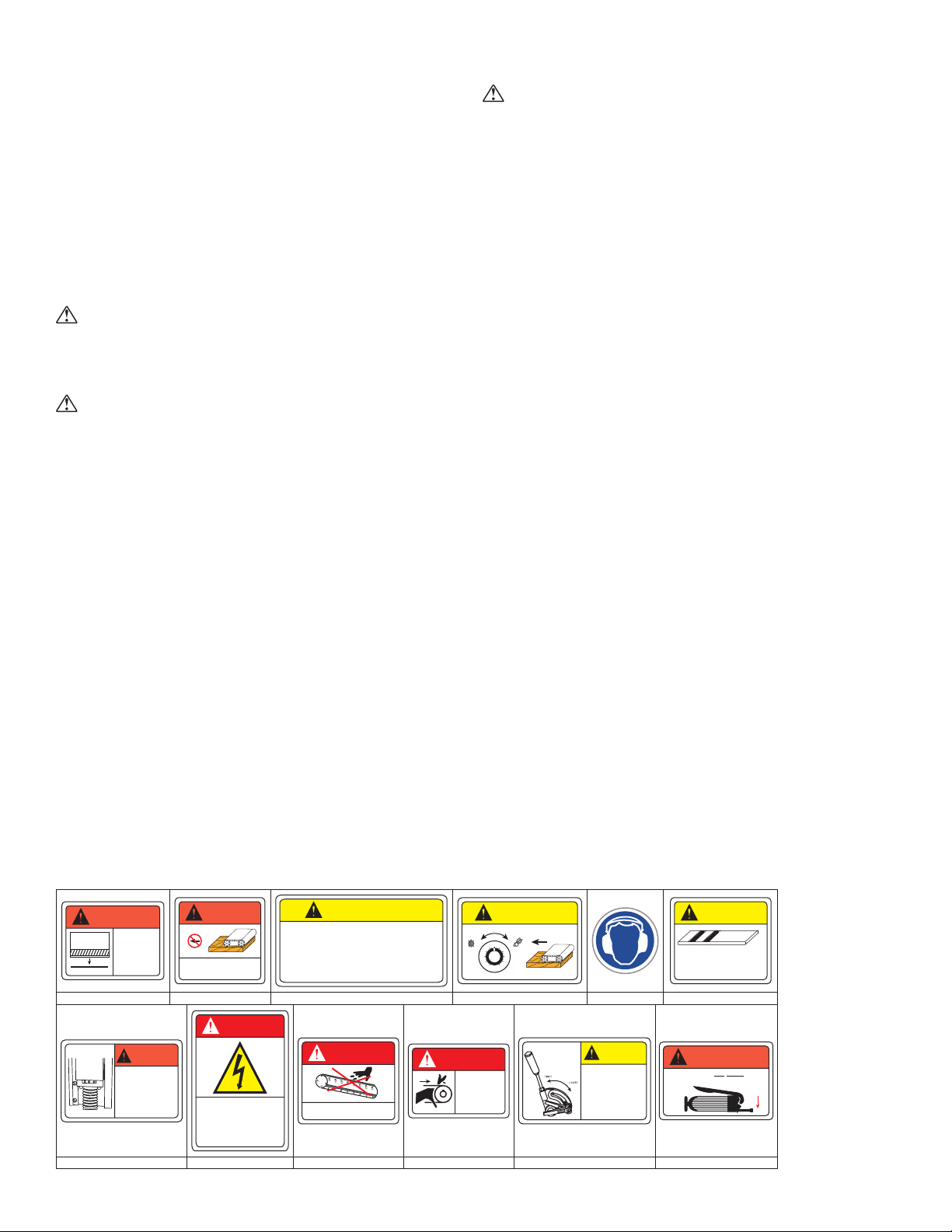

Warning Labels

This machine has warning labels attached to ensure safe operation.

These warning labels are very important and should be kept clean

and never removed. If warning labels become damaged or lost,

contact Stiles Machinery immediately for replacements.

Label 1: Keep work table clean

Label 2: Conveyor will stop if oil is too low

Label 3: Warning lamp: feeding system overload

Label 4: Feed speed adjustment

Label 5: Wear ear protection

Label 6: Keep rollers clean

Label 7: Do not adjust this device

Label 8: Hazardous voltage

Label 9: Keep hands away from cutterhead and knives

Label 10: Keep hands away from rollers

Label 11: Pressure adjustment for feed conveyor

Label 12: Greasing the shaft

WARNING

Never use the DSP2500-HS for purposes other than its intended

use. Do not modify or remove any guards or other safety features.

Improper use or modications may affect your warranty or result in

serious injury or death.

Training

This machine is intended for use by authorized, well-trained

operators only.

Do not operate until you have a complete working knowledge of

the machine and have been properly trained for its safe operation,

correct adjustment, and use. All operators should thoroughly read

and understand this manual and the workings of this machine prior

to operation.

It is essential that all operators be aware of the following:

• The dangers associated with the operation of this machine.

• The use of personal protective equipment for ear and eye

protection.

• The proper positioning of the operator and operator’s hands

relative to the cutterheads.

• The principles of machine operation.

• The safe handling of the workpiece when planing.

• The safe stacking of the workpiece before and after planing.

LABEL NO. 1 LABEL NO. 2 LABEL NO. 3LABEL NO. 4LABEL NO. 5LABEL NO. 6

LABEL NO. 7 LABEL NO. 8 LABEL NO. 9LABEL NO. 10 LABEL NO. 11 LABEL NO. 12

Clean up anything

on the working

table when it is

getting down.

WARNING

The conveyor will stop by itself

in case of running out of oil.

WARNING

In order to keep the roller smooth, be

sure to clean the wood chip and the

foreign substance in the chasm of the

roller on the worktable.

CAUTION

CAUTION

Feed speed adjustment

SLOW FAST

50

40 60

0 100

7030

9010

20 80

Except be authorized,

don’t adjust this device.

Otherwise, it will cause

the inaccuracy of the

machine and damage

the driving mechanism.

WARNING

TURN POWER OFF BEFORE

SERVICING.

HAZARDOUS VOLTAGE

DANGER

VOLTAGE ÉLEVÉ, ENLEVEZ

TOUT POUVOIR ÉLECTRIQUE

AVANT DE FAIRE L’ENTRETIENT

KEEP HANDS AWAY FROM

CUTTERHEAD AND KNIVES

DANGER

ROLLING

KEEP HANDS AND

ANY OBJECT AWAY

DANGER

BE SURE TO ADD SKF LGLT 2 GREASE

FOR HIGH SPEED SHAFT EVERY SIX

MONTHS.

WARNING

Do not adjust the

V belt too tight.

The proper belt

tension is approx.

1 cm by nger

pressure.

CAUTION

1. When the warning lamp lights up, it means an overload caused by the

mechanical feeding system.

3. The feeding system can not be started until the obstacle has been removed.

2. Fix the trouble by following the instructions below:

(A) Raise the upper mechanism about 100mm.

(B) Remove the bad workpiece or any obstacle.

(C) Return the upper mechanism to its original position.

(D) Start feeding system.

4. For other types of overload not caused by obstacles, follow the

troubleshooting instructions.

CAUTION

Table of contents

Other Stiles Industrial Equipment manuals