Stiles Ironwood CUT 18 User manual

Ironwood CUT 18

User Manual

general information. features.

adjust air pressure. cutting the workpiece.

maintenance. adjust v-belt tension.

troubleshooting. electrical diagram.

delivery and installation. inspection.

receiving the machine. assembly.

dust exhaust outlet. operation and adjustments.

technical specifications. safety considerations.

connect to power. safety.

Ironwood CUT 18 | User Manual2

1.0 General Information ................................................................ 3

1.1 Thank You!

1.2 Before Contacting Stiles

1.3 Features

1.4 Intended Use

1.5 Technical Specifications

1.6 Safety Considerations

2.0 Facility Preparation ................................................................. 6

2.1 Floor

2.2 Work Space

2.3 Power

3.0 Delivery and Installation ............................................................. 7

3.1 Receiving Your Machine

3.2 Unpack the Machine

3.3 Inspection

3.4 Move Machine to Final Position

3.5 Remove Machine from Pallet

3.6 Level

3.7 Pre-Operation Cleaning

4.0 Assembly ....................................................................... 10

4.1 Saw Blade

4.2 Dust Exhaust Outlet

4.3 Safety Guard Assembly

5.0 Connect to Power ................................................................ 12

6.0 Safety.......................................................................... 13

7.0 Operation and Adjustments ......................................................... 14

7.1 Control Panel

7.2 Emergency Stop

7.3 Pneumatic Control

7.4 Adjust Hold-Down Clamp

7.5 Adjust Air Pressure

7.6 Adjust Fence Squareness to Saw Blade

7.7 Cutting the Workpiece

8.0 Maintenance..................................................................... 18

8.1 Cleaning

8.2 Lubrication

8.3 Change the Saw Blade

8.4 Adjust V-Belt Tension

8.5 Replace V-Belts

9.0 Troubleshooting .................................................................. 20

9.1 Air Circuit Diagram

9.2 Electrical Diagram

Table of Contents

PLEASE REVIEW AND OBSERVE ALL SAFETY

INFORMATION / DIRECTIVES BEFORE INSTALLING,

OPERATING, OR PERFORMING MAINTENANCE ON

THIS MACHINERY.

Ironwood CUT 18 | User Manual 3

1.0 General Information

1.1 Thank You!

Thank you for your purchase of the Ironwood CUT 18 cut-off saw.

At Stiles Machinery, our goal is to ensure that you are fully satisfied

with your purchase. This manual is provided so that you may

properly assemble, operate, and maintain your CUT 18. Should you

need help, our team of dedicated service personnel are available to

answer your questions and provide any resource recommendations

you may need.

Warranty and Support

All Ironwood machines are designed to meet the exacting standards

demanded by craftsmen like you. Ironwood machines include a

one (1) year parts warranty and two (2) years of free 24/7 technical

support beginning at date of shipment. Standard technical support

remains in effect for free for the lifetime of the machine thereafter.

Warranty service work is not covered by manufacturer’s warranty.

Stiles’ service team is available for an additional charge.

1.2 Before Contacting Stiles

Please have your machine model and serial number available when

contacting Stiles Machinery with questions. The machine’s model

and serial numbers are listed on the metallic plate located on the

machine’s frame.

Information regarding the electrical system and pneumatic supply

are also listed on the metallic plate.

Stiles Technical Support

616.698.6615

Stiles Parts

800.PARTS.80 (800.727.8780)

Website

www.stilesmachinery.com/ironwood/cut18

Machine Model ____________________________________________

Machine Serial Number _____________________________________

1.3 Features

• A convenient foot pedal, or dual push buttons (depending on

saw configuration) controls the pneumatic operation of the

cutting cycle; air pressure is used to raise the saw blade and

lower the hold-down clamp.

• Solid steel construction and a precision ground table surface

ensure cutting accuracy and stability during heavy cutting

operations.

• Accommodates an 18" saw blade.

• Cutting capacity: up to 4" thick and 12" wide. See section 7.4 for

cutting capacity chart.

• Door safety switches ensure safe tool changes; access doors

can be opened only after blade has stopped rotating.

• Powerful, high-torque, 10-hp motor provides stability at fast

cutting speeds.

• Safety guard improves operator safety.

• 4" diameter dust extraction port keeps work area clean.

• Hold-down clamp adjusts to workpiece thickness.

• Doors are locked and unlocked only with a special unlocking

handle.

1.4 Intended Use

Use your CUT 18 for accurate, safe, and reliable wood crosscutting

for workpieces up to 4" thick and up to 12" wide. Rugged cast iron

construction and powerful motor ensure stability for heavy cutting

operations.

Performance and dependability are optimized when the machine is

operated with care and maintained properly. When used according

to the instructions in this manual, you can expect years of trouble-

free operation.

Ironwood CUT 18 | User Manual4

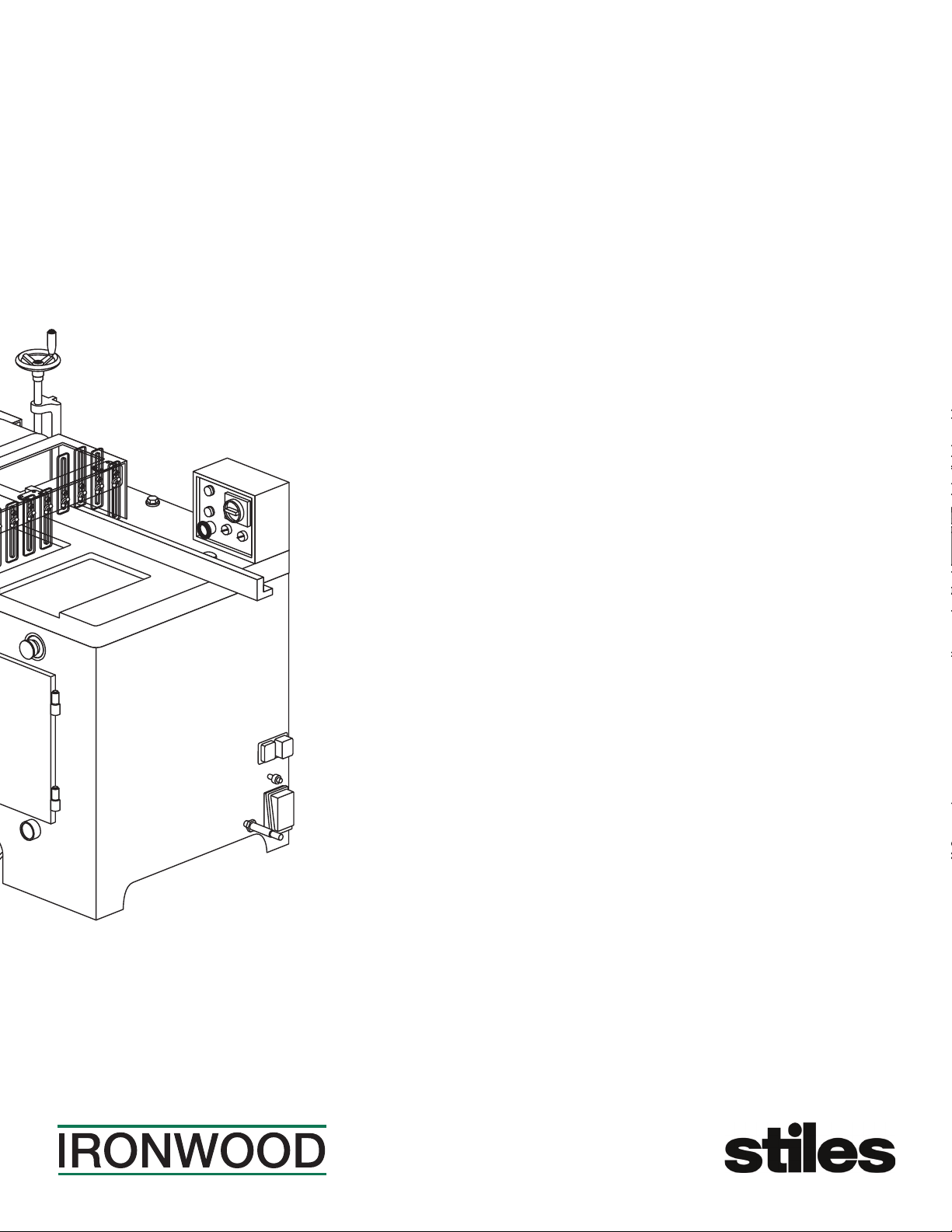

Convenient and

easy-to-use control

panel handles all

control functions

Adjustable ngers

on the fence protect

the operator from the

cutter and add

support for the

workpiece.

Safety guard

for improved

operator safety

Generous table size

provides support for

larger workpieces

Large, cast iron,

ground and polished

table is rugged and

stable, with maximum

rigidity for heavy

cutting operations

Door lock safety switch Foot pedal for pneumatic

operation of saw

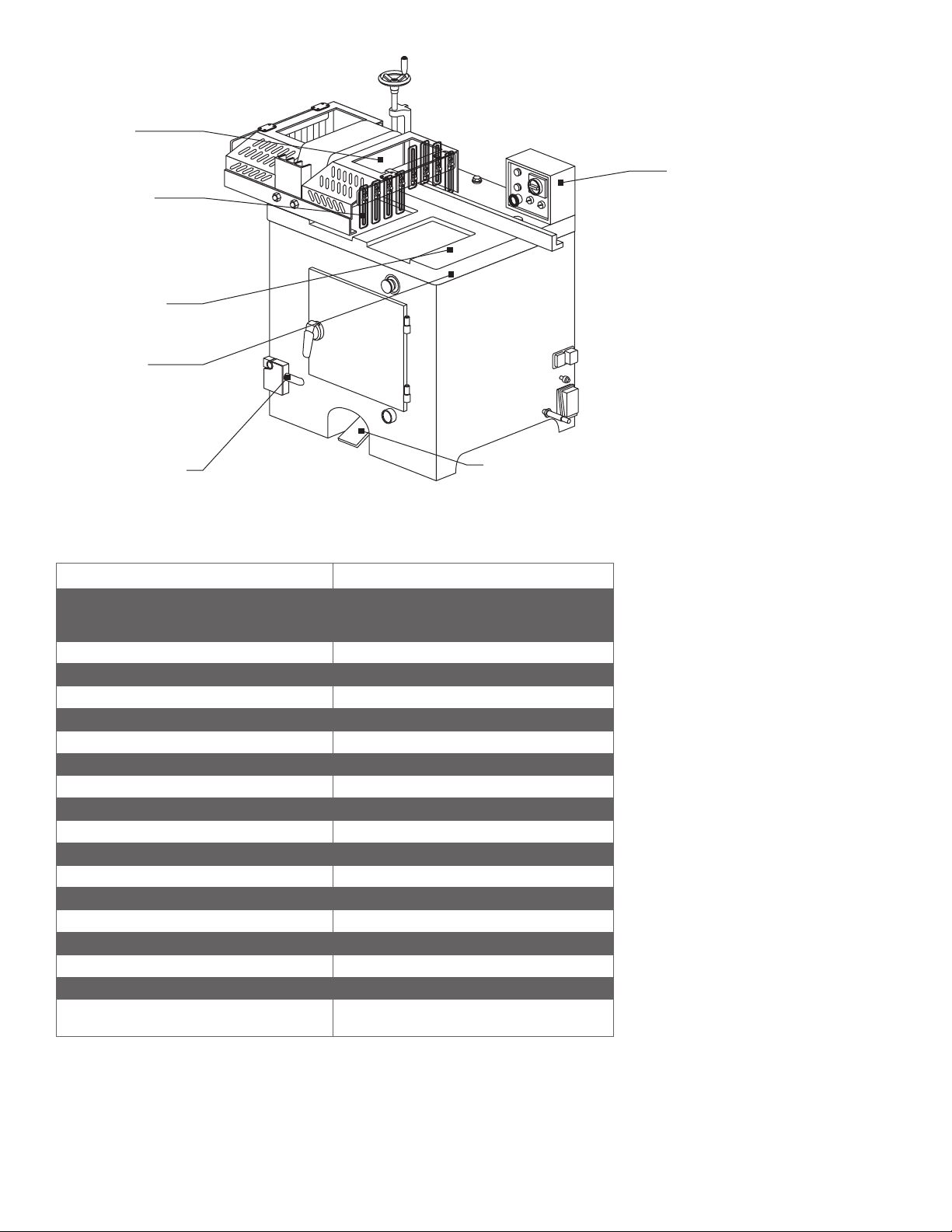

1.5 Technical Specifications

Description Ironwood CUT 18

Cutting capacity (thickness x width)

2" x 12", 3" x 11", 4" x 10"

(51mm x 305mm, 76mm x 280mm,

102mm x 254mm)

Cycle speed 45 cpm (cuts/min)

Cycle operation Pneumatic

Air pressure requirement 80-90 psi

Air consumption 12 cfm @ 45 cpm

Saw blade size 18" (457mm)

Saw arbor diameter 1" (25.4mm)

Saw blade speed 3,200 rpm

Dust port diameter 4" (102mm)

Dust extraction requirements 450 cfm @ 4,500 feet/min.

Motor 10 hp

Power 230 v (3 phase) 460 v (3 phase)

Amperage 25 amps (@ 230 v) / 12.5 amps (@460 v)

Table size 26" x 27

1⁄2" (660mm x 700mm)

Working table height 34¼" (870mm)

Net weight 771 lbs. (350 kgs)

Gross weight 903 lbs. (410 kgs)

Packing dimensions (L x W x H) 35 1⁄2" x 31

1⁄2" x 53⁄2"

(900mm x 800mm x 1,350 mm)

Ironwood CUT 18 | User Manual 5

1.6 Safety Considerations

For your safety, read these instructions thoroughly before you install

and operate this machine. Always have these instructions available

at the machine for reference.

Observe all codes and regulations that apply to the installation and

operation of this machine.

Keep visitors at a safe distance from the workspace.

Keep children away from this and all machines. Childproof your

work area!

Familiarize yourself with the safety notices used in this manual.

Caution

If cautions are ignored, personal injury and/or machine damage

may result.

WaRninG

If warnings are ignored, serious injury or death may result.

Warning Labels

This machine has warning labels attached to ensure safe operation.

These warning labels are very important and should be kept clean

and never be removed. If warning labels become damaged or lost,

contact Stiles Machinery immediately for replacements.

Label 1 Keep hands out of this area

Label 2 Do not operate the CUT 18 when the saw blade access

door is open

Label 3 Always wear ear and eye protection

Label 4 Safety instructions for operating the CUT 18

LABEL NO. 1 LABEL NO. 2

LABEL NO. 3 LABEL NO. 4

WaRninG

Never use the CUT 18 for purposes other than its intended use. Do

not modify or remove any guards or other safety features. Improper

use or modifications may affect your warranty or result in serious

injury or death.

Training

This machine is intended for use by authorized, well-trained

operators only.

Do not operate this machine until you have a complete working

knowledge of this saw and have been properly trained for its

safe operation, correct adjustment, and use. All operators should

thoroughly read and understand this manual and the workings of

this machine prior to operation.

It is essential that all operators be aware of the following:

• The dangers associated with the operation of this machine.

• The use of personal protective equipment for ear and eye

protection.

• The proper positioning of the operator and operator’s hands

relative to the saw blade and pneumatic hold down clamp.

• The principles of machine operation, and proper use and

adjustment of the fence, jigs, safety guards, extension tables and

end stops.

• The correct selection of tooling for each operation.

• The safe handling of the workpiece when cutting.

• The safe stacking of the workpiece before and after cutting.

NOTE: Dust extraction equipment must be connected and turned on

before starting all machine operations.

This manual suits for next models

2

Table of contents

Other Stiles Saw manuals