ALCOHOL DISTILLATION

You can use the still to produce your own alcoholic sprits and liqueurs at a fraction of the retail price. This can become a

fascinating hobby and you will be able to amaze your family and friends with the quality of the drinks you have produced.

The “ART” of distilling has been known for many centuries but has been surrounded by much secrecy and mythology.

With scientific advances in understanding the process, we are now able to understand exactly what happens and Still

Spirits have been able to reduce this to four simple steps for producing your own drinks.

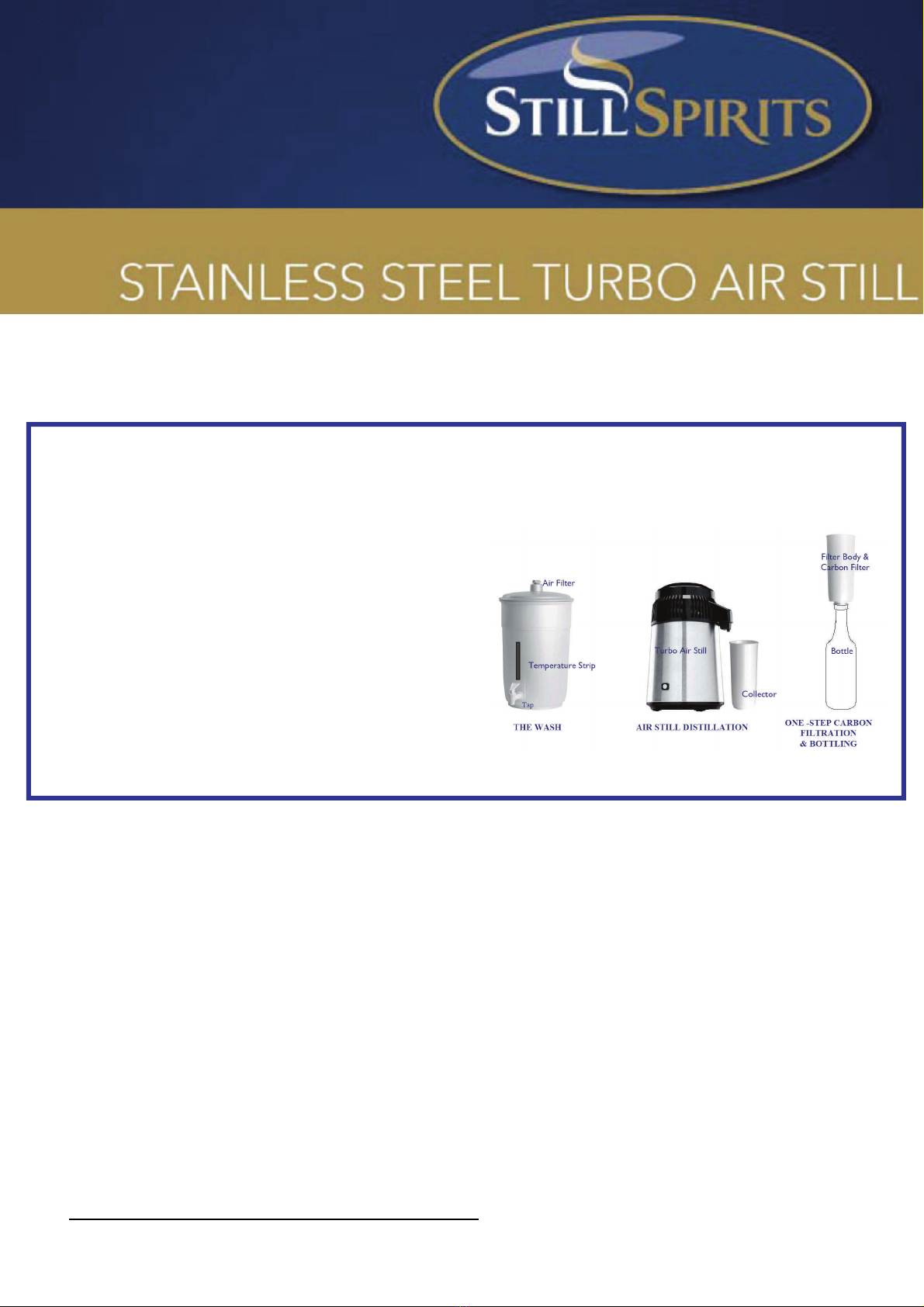

MAKING THE WASH (Instructions for use—to produce 2 litres (½US Gallon)

We recommend that you use an Air Still Fermenter and an Air Still Production Pack, which contains Still Spirits Triple Dis-

tilled Turbo Yeast, Still Spirits Turbo Carbon and Still Spirits Turbo Clear for 9 litres (2½US Gallons). Before you start

make sure the tap is securely fitted to the bucket and fill with 7.5 litres (2 US Gallons) warm water to ensure that the unit

is water tight. Once you have confirmed that the unit is water tight, sprinkle in the sachet of No Rinse Steriliser. Carefully

swirl this around so that it contacts all the internal surface. Discard water.

1. In the Fermenter prepare 7.5 litres (2 US Gallons) of water at 30°C

2. Add 2.2 kg (4 lbs 13 oz) Turbo Sugar (or 2.4 kg (5lb 8oz) Dextrose AKA. Corn Sugar) and stir until dissolved.

3. First massage the sachet containing the Turbo Carbon and then add it to the Fermenter and stir.

4. Sprinkle the yeast from the yeast sachet on top of the sugar/water/carbon solution (wash).

5. Fit the Carbon Cartridge to the Air Filter in the Fermenter lid and then fit the lid to the Fermenter.

6. Let this sit in a place where the air temperature is between 18 and 24°C (64 -75°F) for 7 days.

7. When fermentation is completed the wash will stop bubbling. To confirm fermentation is complete the wash can be

tested with a Beer, Wine and Spirit (Wash) Hydrometer. The wash has completed fermenting when the Specific

Gravity (S.G.) is below 990 on your hydrometer.

8. Once the wash has finished fermenting it is important to de-gas the wash. This is done by stirring briskly until all

fizzing stops. This will likely take a few minutes. Start slowly to avoid a sudden release of the gas. Once all the gas

has been removed, add in sachet A and stir well.

9. One hour later, carefully sprinkle Sachet B on the surface of the wash and evenly distribute. Do not stir vigorously

at this stage.

10. Leave to stand for 24 hours. During this time the wash should become clear ready for distilling.

IMPORTANT TIPS

If you already own a 30 litre (8 US Gallon) Fermenter we recommend you use Still Spirits Triple Distilled Turbo

Yeast, as it will give you the best quality wash for your distillation. The Triple Distilled Yeast has been formulated to

produce a very clean alcohol and eliminates the need to collect the “heads” (first portion) at the start of the distilla-

tion.

If you choose to use an alternate yeast variety you will have to carry out trials to determine what quantity of heads

must be removed at the start of the distillation.

It is essential that the wash is fully fermented and has been cleared, using finings, before distilling. We recommend

you use Still Spirits Turbo Clear Finings.

It is better to allow an extra day or so to be sure that the wash is fully fermented before distilling.

DISTILLING THE WASH

Read the safety instructions for your still BEFORE you use it. These are set out on page 4.

Once your wash is ready, clean the inside of the still and fill it to the 4 litre (1 US Gallon) line marked on the inside.

1. Make sure that no wash is spilt on the outside of the body.

2. Add the Ceramic Boil Enhancers and one capful of Distillers Conditioner to the still. These are used to reduce the

risk of surge boiling, which can happen occasionally.

3. Make sure that both electrical sockets are clean and dry.

4. Fit the top cover of the still in place and plug the fan lead into the socket in the still body.

5. Place a collector under the outlet nozzle. This should have a useable capacity of at least 800 ml (27 fl oz US).

6. Connect the main power cord between the still and the mains power socket and turn on the mains power socket

switch. You will hear the fan in the top cover of the still start immediately.

7. The wash will take just over an hour to heat up. Once distillation begins you will see the alcohol starting to drip into

the collector.

8. Allow the still to run until you have collected 700ml (23 fl oz US) of alcohol. This will be at a strength of 60% ABV

and you can use this to make up a 1 litre bottle at 38 - 40 % alcohol. This should take just over a further hour (that’s

two hours from start to finish). After you have collected 700ml (23 fl oz US) turn off the still. If you wish to produce

1125ml (38 fl oz US) collect 800ml (27 fl oz US) but the quality will be slightly reduced. Do not try to collect more

alcohol than this, as the quality will drop away quickly.

9. Allow the still to cool before removing the top cover. Empty out the remaining wash and clean the inside with clean

warm water. Dry the still thoroughly and put away for next time.