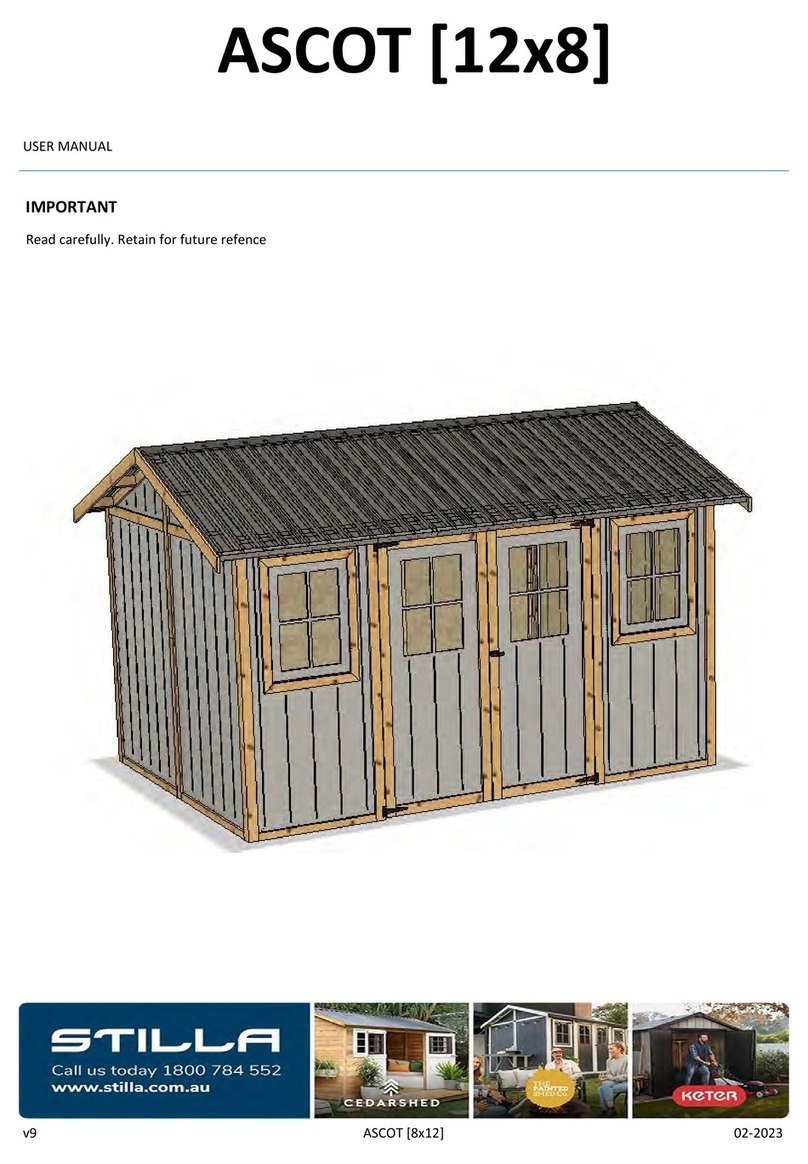

STILLA Birch 6x3 User manual

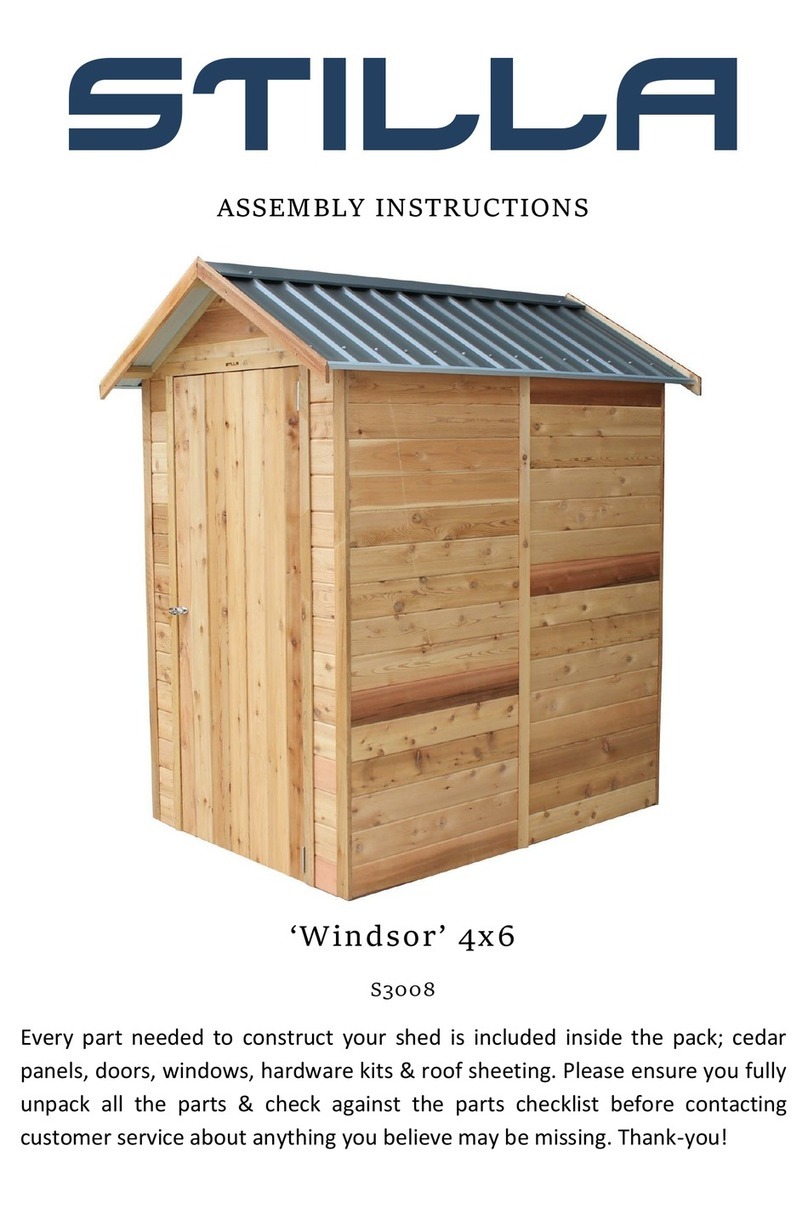

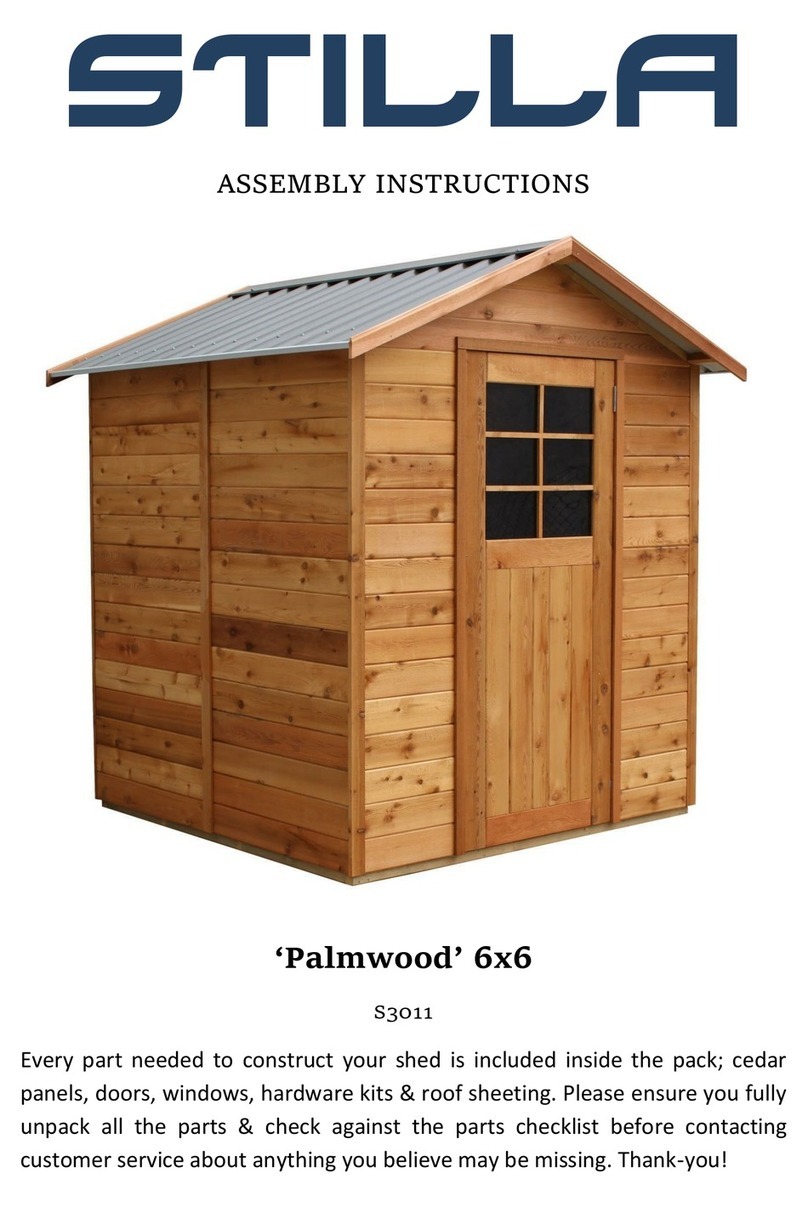

STILLA

ASSEMBLY INSTRUCTIONS

‘Birch’6x3

S3001

Every part needed to construct your shed is included inside the pack; cedar

panels, doors, windows, hardware kits & roof sheeting. Please ensure you fully

unpack all the parts & check against the parts checklist before contacting

customer service about anything you believe may be missing. Thank-you!

Caution

1 | P a g e

Please be careful when handling all components, some parts have sharp metal edges.

Always wear work gloves, eye protection and long sleeves when assembling or maintaining

your shed.

Tools required for assembly

•Level

•Drill

•Hammer

•Ladder

•Phillips head drive

•Hex Head Drive (5/16’)

•Safety glasses

•Gloves

Before assembly

•Remove all parts from packages and place in a safe place close to assembly area.

•Review all instructions; continue to refer to instructions throughout assembly –step

by step.

Preparing your site

•Choose your site carefully, site surface must be level (unless an Elevation kit or

Heavy duty floor kit option has been purchased with your product)

2 | P a g e

BIRCH 6x3 PARTS CHECKLIST

Part Code

Checked

Part Description

Qty

P

Cedar Clad Panel 900x1890mm

2

LP

Tapered Panel (Left) 900x1875mm

1

RP

Tapered Panel (Right) 900x1875mm

1

FP

Cedar Clad Front Panel 195x1805mm

2

D

6x3 Door 700x1770mm (Full Cedar)

2

C

1970mm Channel

1

L

1970mm L Flashing –ZINC

1

L

1040mm L Flashing –ZINC

2

RS

1040mm Roof Sheeting

3

HK

6x3 Hardware Kit

1

CP

Corner Post 2x1805 2x1890

4

CS

Cover Strip 1890x40x7mm

1

DS

Door Step 1410x42x19mm

1

DH

6x3 Door Head 1800mm

1

IM

6x3 Instruction Manual

1

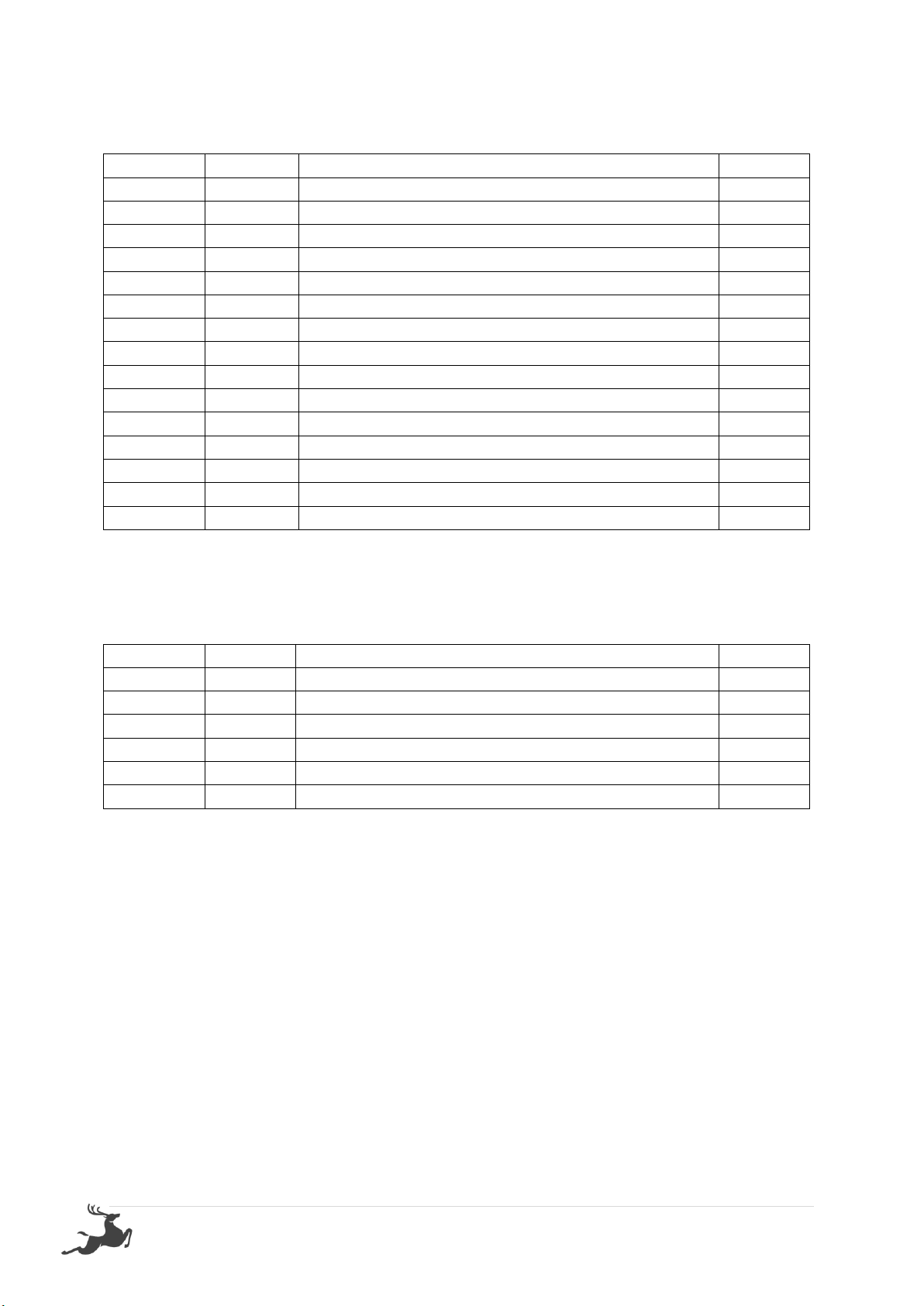

Floor Kit –Option

Floor Frame - (Rebated Floor 70x35mm/Heavy Duty Floor 140x35mm)

Part Code

Checked

Part Description

Qty

EP

End Plate 1870mm

2

DJ

Double Joist 830mm

2

SJ

Single Joist 830mm

3

L

Logs (light duty floor does not come with logs)

4

FB

1798mm x 485mm

1

FB

1798mm x 326mm

1

3 | P a g e

If no floor option was purchased, go to step 2.0 (Wall Assembly)

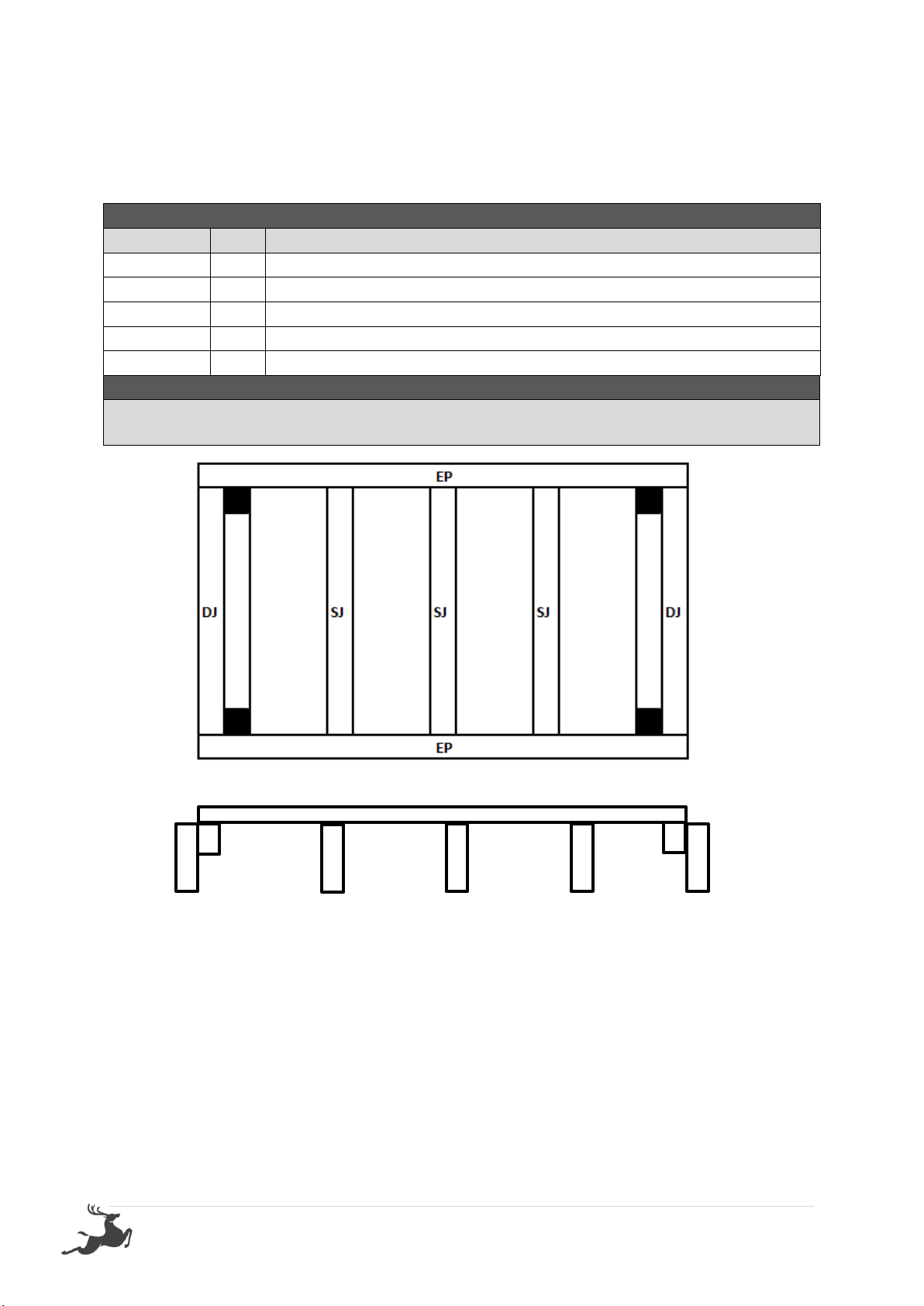

STEP 1.0

FLOOR KIT

1.0 –FLOOR KIT

PART CODE

QTY

DESCRIPTION

EP

2

End Plate 1870mm

SJ

3

Single Joist 830mm

DJ

2

Double joist 830mm (42x35mm part of DJ goes at the top inside)

100BS

24

100mm Batten screw (Heavy Duty Floor Only)

75N

24

75mm Nail (Rebated Floor Only)

1.0 –FLOOR FRAME

Fasten through EP into DJ using 3 x 100BS per join (75N on Rebated Floor)

Fasten Through EP into SJ using 2 x 100BS per join (75N on Rebated Floor)

HEAVY DUTY FLOOR KIT

Heavy duty floor can be installed on unlevelled ground –use supplied logs to level your floor

by digging them into the ground.

Install heavy duty floor kit using 4 logs –1 in each corner (position shown above) screw

through frame into log using 4 x 100BS per corner.

Ensure floor frame is square by measuring from corner to corner diagonally prior to

installing flooring.

Yellow Tongue

DJ

DJ

SJ

SJ

SJ

4 | P a g e

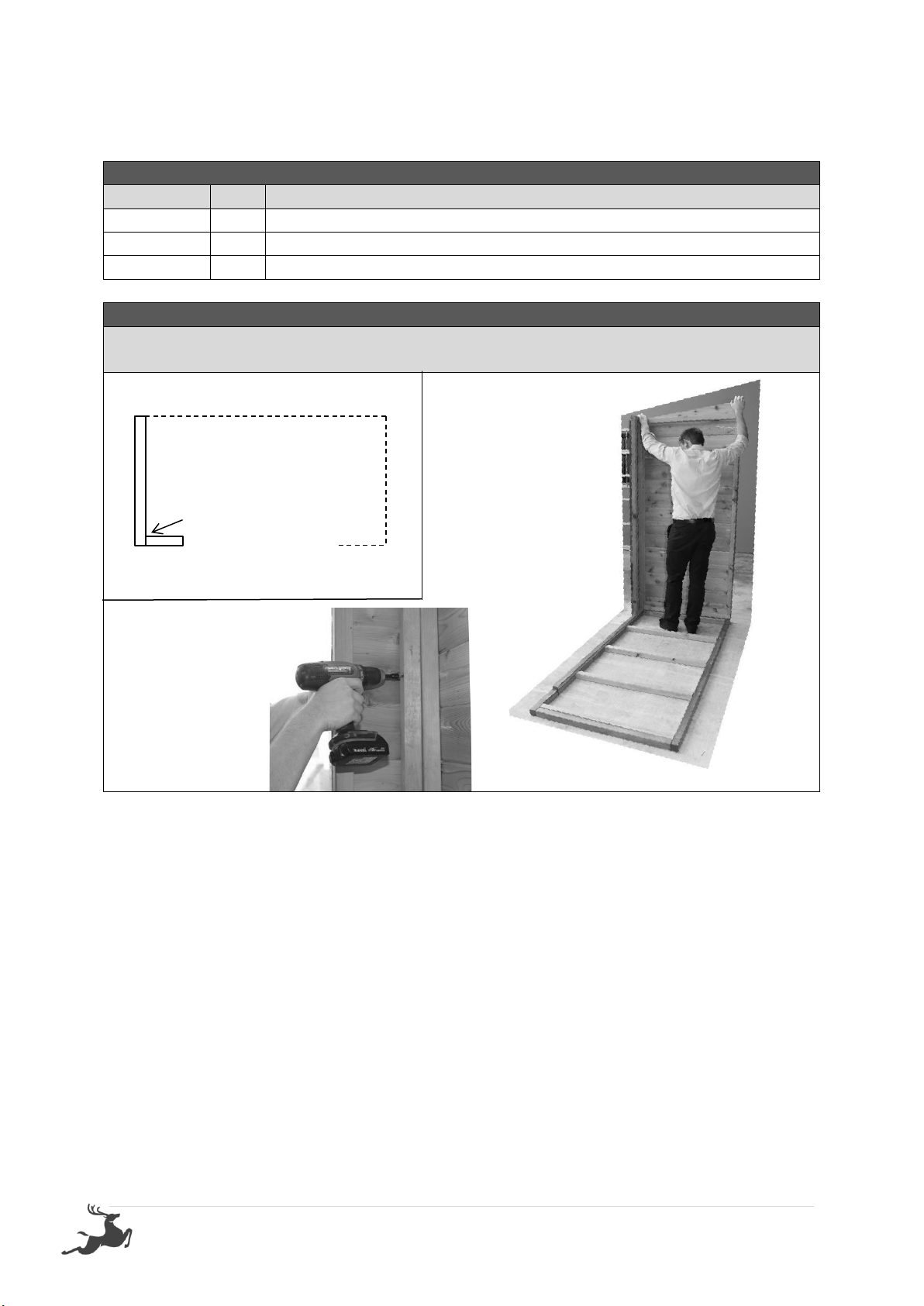

STEP 1.1

FLOORING INSTALLATION

1.1 –FLOOR INSTALLATION

PART CODE

QTY

DESCRIPTION

FB

1

Floor Board 1798x485mm

FB

1

Floor Board 1798x326mm

50PS

20

50mm Phillips Screw

1.1 –FLOOR SHEETS

Fasten floor sheet to floor frame as shown below using 50PS

5 | P a g e

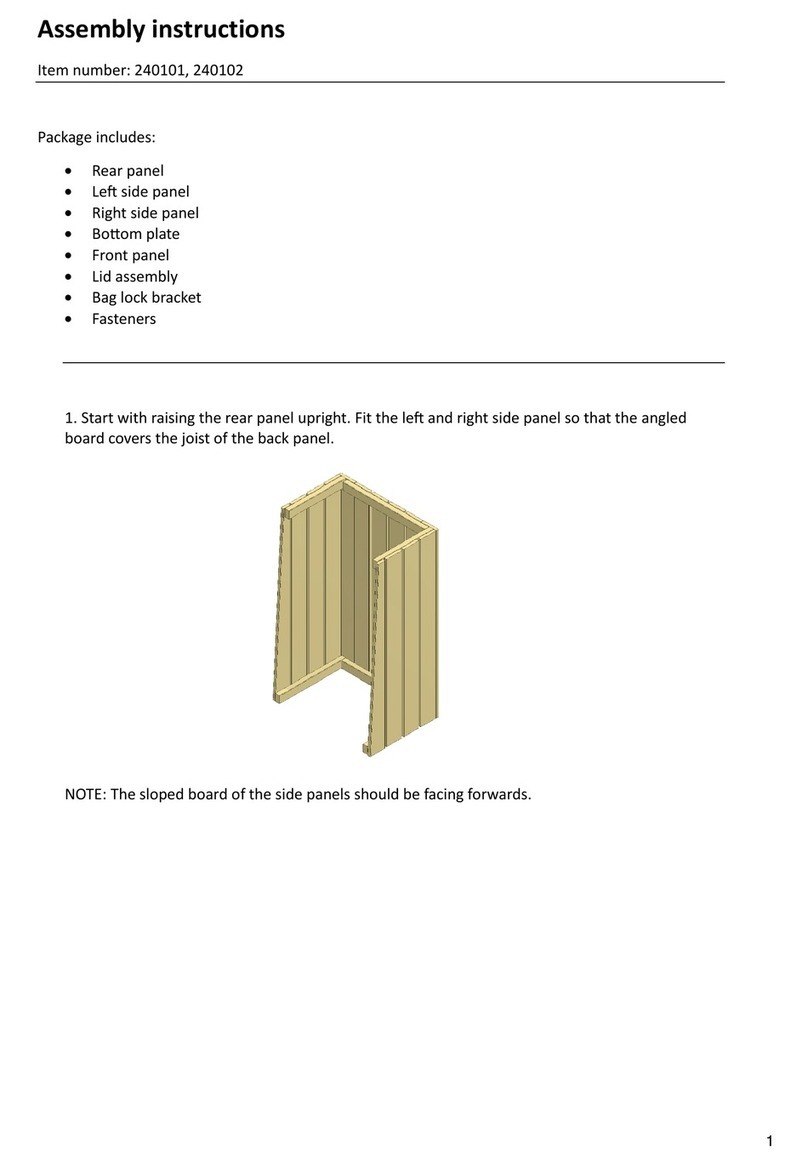

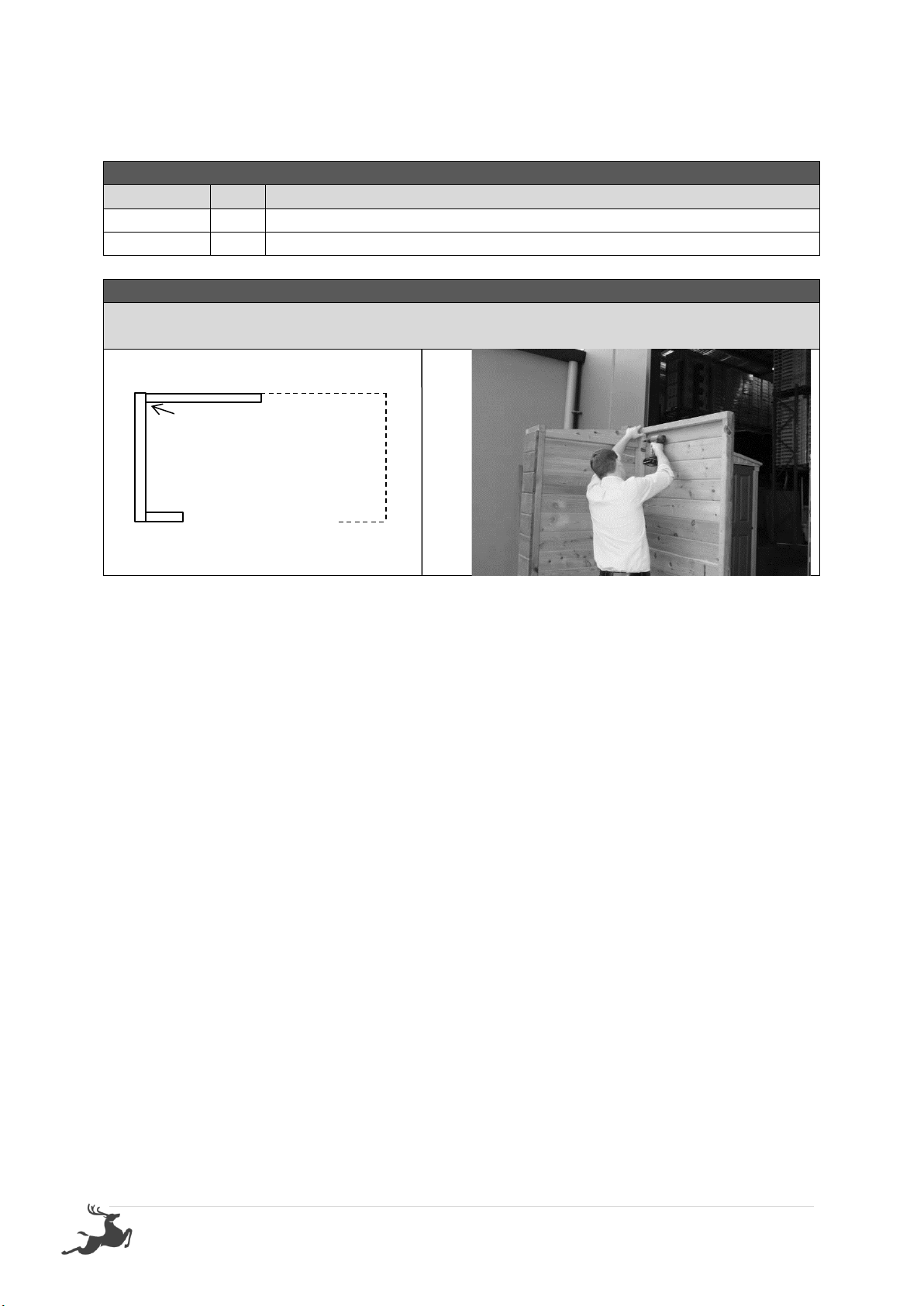

STEP 2.0

WALL ASSEMBLY

2.0 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

FP

1

Front panel

LP

1

Tapered panel left

65HHS

3

65mm hex head screw

2.0 - ASSEMBLY –WALL ASSEMBLY

Screw through FP into LP (top, centre & bottom) using 3 x 65HHS. (Holding studs flush on

the outside)Note –ensure tongue of cedar cladding is at the top on all panels.

LP

Screw 3 x 65HHS (Top,

centre & bottom)

FP

6 | P a g e

STEP 2.1

WALL ASSEMBLY

2.1 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

P

1

900mm panel

65HHS

3

65mm hex head screw

2.1 - ASSEMBLY –WALL ASSEMBLY

Screw through P into LP (Top, centre & bottom) using 3 x 65HHS, holding studs flush on the

outside.

P

LP

Screw 3 x 65HHS (Top,

centre & bottom)

7 | P a g e

STEP 2.2

WALL ASSEMBLY

2.2 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

P

1

900mm panel

65HHS

3

65mm hex head screw

2.2 - ASSEMBLY –WALL ASSEMBLY

Screw through P into P (Top, centre & bottom) using 3 x 65HHS, holding studs flush on the

inside.

P

Screw 3 x 65HHS (Top,

centre & bottom)

P

8 | P a g e

STEP 2.3

WALL ASSEMBLY

2.3 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

RP

1

Tapered panel right

65HHS

3

65mm hex head screw

2.3 - ASSEMBLY –WALL ASSEMBLY

Screw through P into RP (top, centre & bottom) using 3 x 65HHS holding studs flush on the

outside.

STEP 2.4

WALL ASSEMBLY

2.4 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

FP

1

Front panel

65HHS

3

65mm hex head screw

2.4 - ASSEMBLY –WALL ASSEMBLY

Screw through FP into RP (top, centre & bottom) using 3 x 65HHS holding studs flush on the

outside.

P

Screw 3 x 65HHS (Top,

centre & bottom)

P

RP

P

Screw 3 x 65HHS

(Top, centre &

bottom)

P

FP

RP

9 | P a g e

STEP 2.5

DOOR STEP INSTALLATION

2.5 - ASSEMBLY PARTS –DOOR INSTALLATION

PART CODE

QTY

DESCRIPTION

DS

1

Door Step

40N

3

40mm Nail

2.5 - ASSEMBLY –DOOR INSTALLATION

Nail through DS into floor frame (if floor option was not chosen fasteners are not supplied)

DS

10 | P a g e

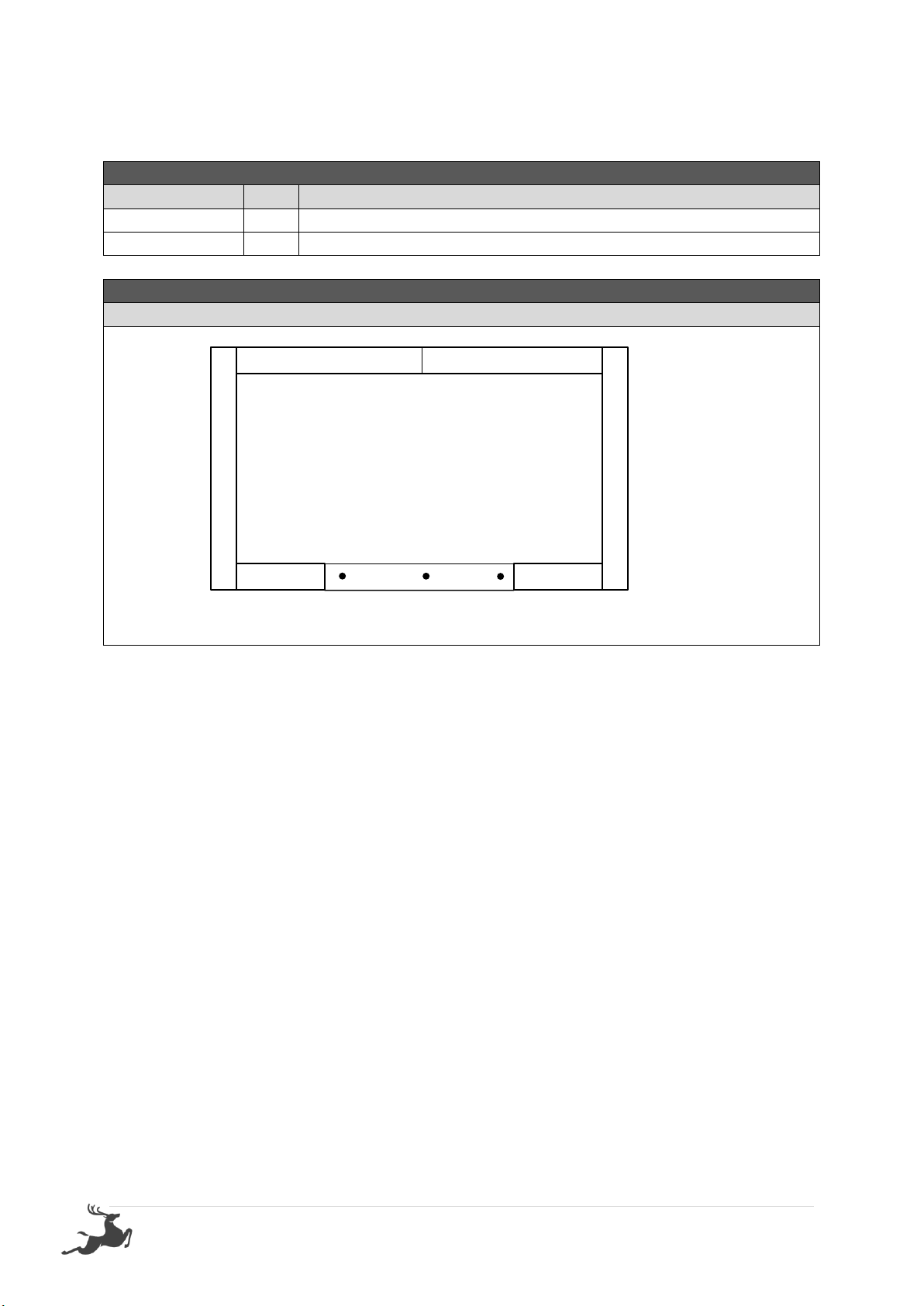

STEP 2.6

FASTENING WALLS TO FLOOR

2.6 - ASSEMBLY PARTS –FASTENING WALLS TO FLOOR

PART CODE

QTY

DESCRIPTION

65HHS

7

65mm hex head screw

2.6 - ASSEMBLY –FASTENING WALLS TO FLOOR

Ensure walls are in correct position and straight.

Fasten through wall bottom plate in positions shown below.

If floor option not chosen, fasteners are not supplied.

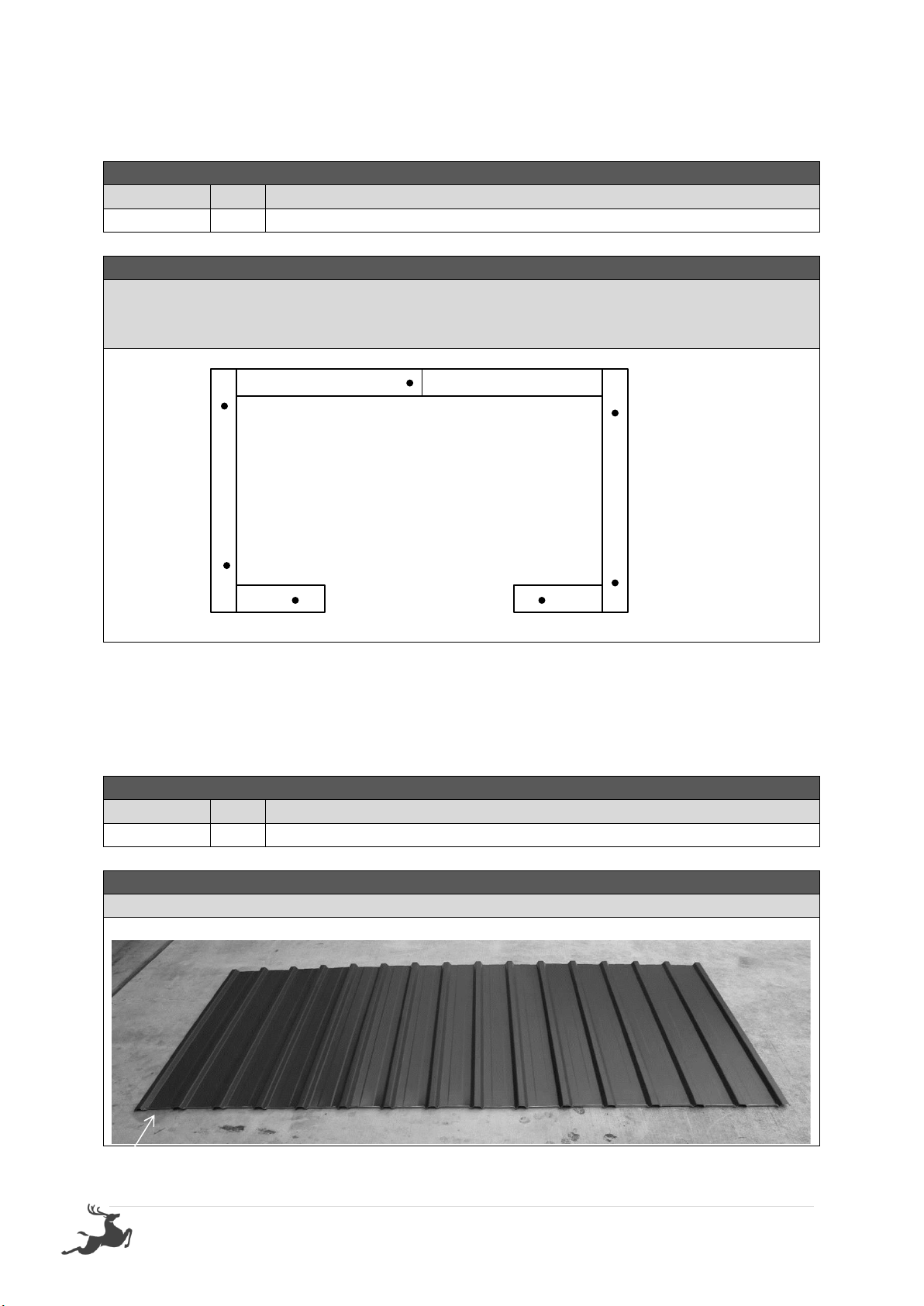

STEP 3.0

ROOF ASSEMBLY

3.0 - ASSEMBLY PARTS –ROOF ASSEMBLY

PART CODE

QTY

DESCRIPTION

RS

3

1040mm roof sheet

3.0 - ASSEMBLY –ROOF ASSEMBLY

Lay RS x 3 down on a flat hard surface and overlap until full measurement is 1970mm.

Bent up edge goes at the back of the shed.

11 | P a g e

STEP 3.1

ROOF ASSEMBLY

3.1 - ASSEMBLY PARTS –ROOF ASSEMBLY

PART CODE

QTY

DESCRIPTION

L

1

1970mm L flashing

C

1

1970mm C channel

ST

8

Self-tapping screw

3.1 - ASSEMBLY –ROOF ASSEMBLY

Place L on RS (Roof Sheets) as shown in picture. Screw through top, 1 Rib in from each end

and into each join of sheet (4 times all up) using ST x 4.

Slide C into place and repeat process.

Screw

Screw

Back

Front

Bent up edge

L

C

12 | P a g e

STEP 3.2

ROOF ASSEMBLY

3.2 - ASSEMBLY PARTS –ROOF ASSEMBLY

PART CODE

QTY

DESCRIPTION

L

2

1040mm L flashing

ST

6

Self-tapping screw

3.2 - ASSEMBLY –ROOF ASSEMBLY

Place L into position, as shown in picture. Screw through L into L at back and 1970C at front.

Screw threw L into roof sheet (RS) in centre. (repeat at both ends of the roof)

STEP 3.3

DOOR HEAD ASSEMBLY

3.3 - ASSEMBLY PARTS –DOOR HEAD ASSEMBLY

PART CODE

QTY

DESCRIPTION

DH

1

Door head

40N

4

40mm Nail

3.3 - ASSEMBLY –DOOR HEAP ASSEMBLY

Place DH in position and fasten through DH into FP using 2 x 40N at each end.

Screw

Screw

(Note: This drawing does not show the right number of ribs)

L

L

13 | P a g e

STEP 3.4

ROOF INSTALLATION

3.4 - ASSEMBLY PARTS –ROOF INSTALLATION

PART CODE

QTY

DESCRIPTION

1

Assembled Roof

40RS

24

40mm Roof screw

3.4 - ASSEMBLY –ROOF INSTALLATION

Slide roof into position with L at back. Roof must hang over back walls by 20mm and even

hangover on side walls. Screw through roofing rib into top plate of front and back wall

panels starting in four corners on 2nd rib in.

Note: Use a straight edge to keep screws in line.

STEP 3.5

DOOR HINGE ASSEMBLY

3.5 - ASSEMBLY PARTS –DOOR HINGE ASSEMBLY

PART CODE

QTY

DESCRIPTION

H

4

Hinge

HS

12

Hinge Screw

D

2

Door

3.5 - ASSEMBLY –DOOR HINGE ASSEMBLY

Place door on back and hold hinge (H) in position. Fasten hinges to door using 3 x hinge

screws (HS) per hinge –Predrilling these screws is recommended.

Position: Hinges are to be placed at top and bottom of door. They are to be centralised over

bracing on back of door (as per second and third image below)

14 | P a g e

STEP 3.6

DOOR INSTALLATION

3.6 - ASSEMBLY PARTS –DOOR INSTALLATION

PART CODE

QTY

DESCRIPTION

D

2

Door

HS

12

Hinge screw

3.6 - ASSEMBLY –DOOR INSTALLATION

Hold door in position, 3mm down from top. Front of the door when closed will be flush with

front of VJ cladding- Predrilling is recommended.

Screw through hinge into front wall (as pictured).

STEP 3.7

PAD BOLT INSALLATION

3.7 - ASSEMBLY PARTS –PAD BOLT INSTALLATION

PART CODE

QTY

DESCRIPTION

PB

2

Pad bolt

3.7 - ASSEMBLY –PAD BOLT INSTALLATION

Hold PB in position and fasten to door. Mark centre of bolt (while closed) and drill 12mm

hole in marked position. Repeat for bottom pad bolt- Fasten Padbolts to Door

15 | P a g e

STEP 3.8

PAD BOLT INSALLATION

STEP 4.0

CORNER POSTS

4.0 - ASSEMBLY PARTS –CORNER POSTS

PART CODE

QTY

DESCRIPTION

CP

4

2 x 1890 –2 x 1805

40N

24

40mm Nail

4.0 - ASSEMBLY –CORNER POSTS

Hold CP in position nail through corner post into wall stud. (6 x 40N per corner) Repeat on

all corners using1890mm at back and 1805 mm at front.

3.8 - ASSEMBLY PARTS –PAD BOLT INSTALLATION

PART CODE

QTY

DESCRIPTION

PB

1

Pad bolt (fasten to door that is not pad bolted inside)

3.8 - ASSEMBLY –PAD BOLT INSTALLATION

Holding doors in closed position. Hold PB centre of the door as shown in picture. Screw

through PB into door. Hold clasp in position and fasten to door.

16 | P a g e

STEP 4.1

COVER STRIPS

4.1 - ASSEMBLY PARTS –COVER STRIPS

PART CODE

QTY

DESCRIPTION

CS

1

Cover strip

40N

6

40mm Nail

4.1 - ASSEMBLY –COVER STRIPS

Hold CS in position, covering join on back wall.

Using 6 x 40N, nail in position.

17 | P a g e

TO REGISTER YOUR WARRANTY

Thank-you for purchasing a STILLA product. To register your 10 year product

warranty, please go to www.stilla.com.au/warranty and complete the online

form. We recommend that you complete this step once you have finished

installing your product.

PLEASE NOTE THAT IF YOU DO NOT COMPLETE THIS WARRANTY

REGISTRATION FORM –YOUR PRODUCT IS NOT COVERED BY WARRANTY.

PRODUCT MAINTENANCE

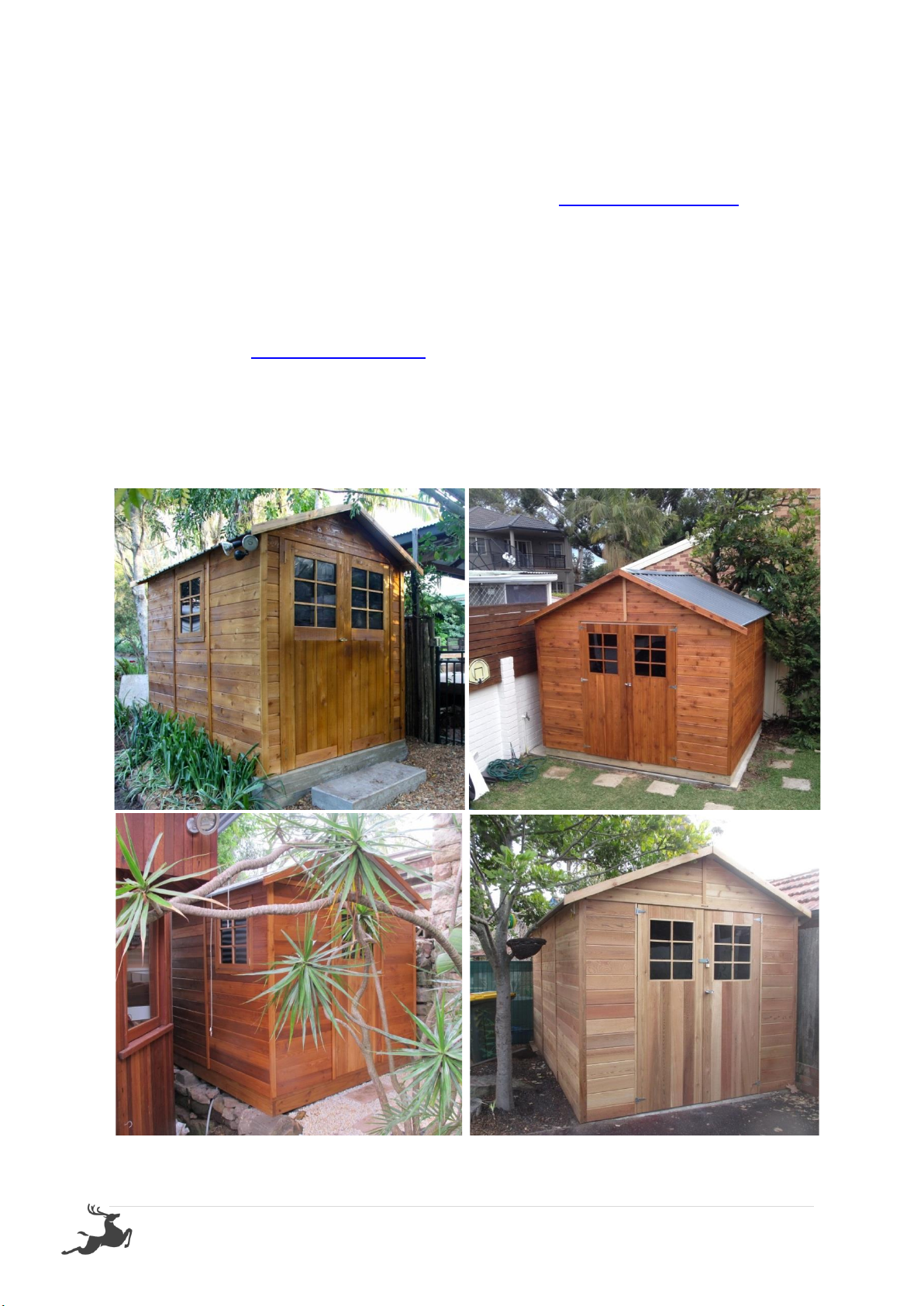

We highly recommend you coat the external of your product with Intergrain

Stain –Light Oak. This product cannot be bought off the shelf but is a known

mix of Ultra Deck Intergrain Cedar/Cypress and a black paint. This can be

purchased from Dulux paint store or the paint section at Bunnings.

18 | P a g e

19 | P a g e

SHOW US YOUR SHED

We would love to see a photo of your STILLA product installed in your

backyard. Please upload this image when completing the warranty registration.

Alternatively, you can send the photos by email to sales@stilla.com.au.

If you require any assistance, please feel free to call or email.

Kind regards,

STILLA Customer Support

This manual suits for next models

2

Table of contents

Other STILLA Outdoor Storage manuals

Popular Outdoor Storage manuals by other brands

X-METAL

X-METAL 4065 owner's manual

Gardiun

Gardiun Glasgow KIS12992 instruction manual

ABSCO SHEDS

ABSCO SHEDS 45302WK Assembly & instruction manual

Backyard Products

Backyard Products YardLine SOMERFIELD GABLE manual

ABSCO SHEDS

ABSCO SHEDS J30232G Assembly instructions

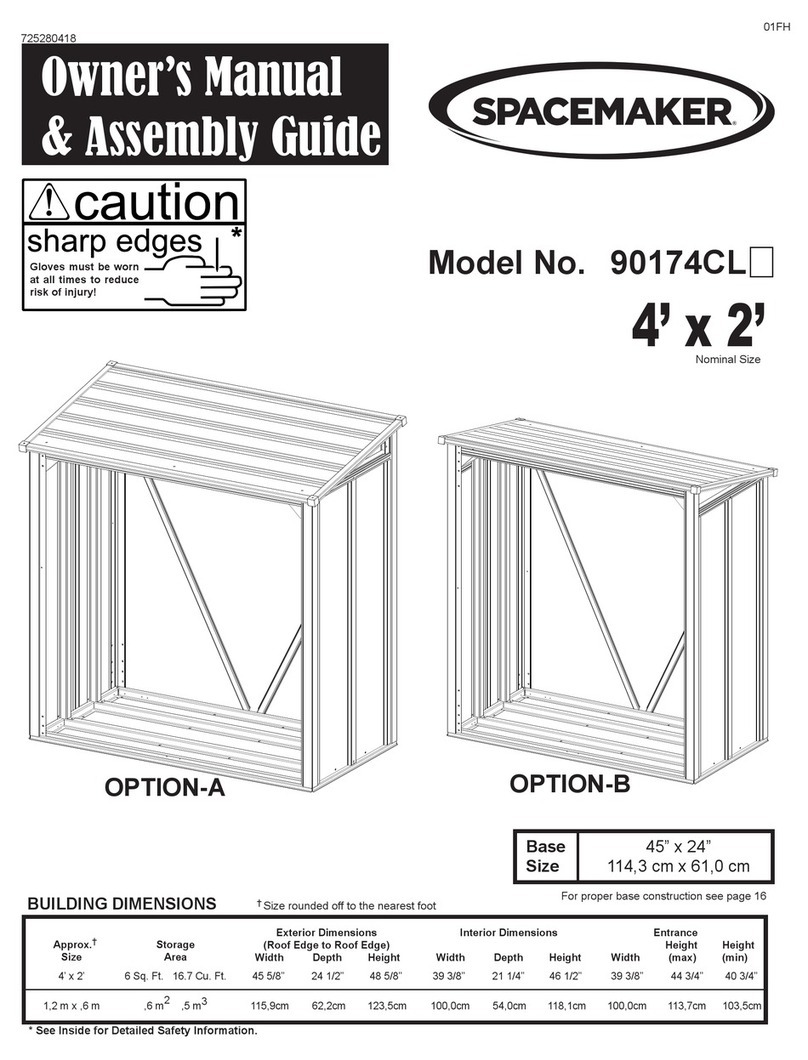

SPACEMAKER

SPACEMAKER 90174CL Series Owner's manual & assembly guide

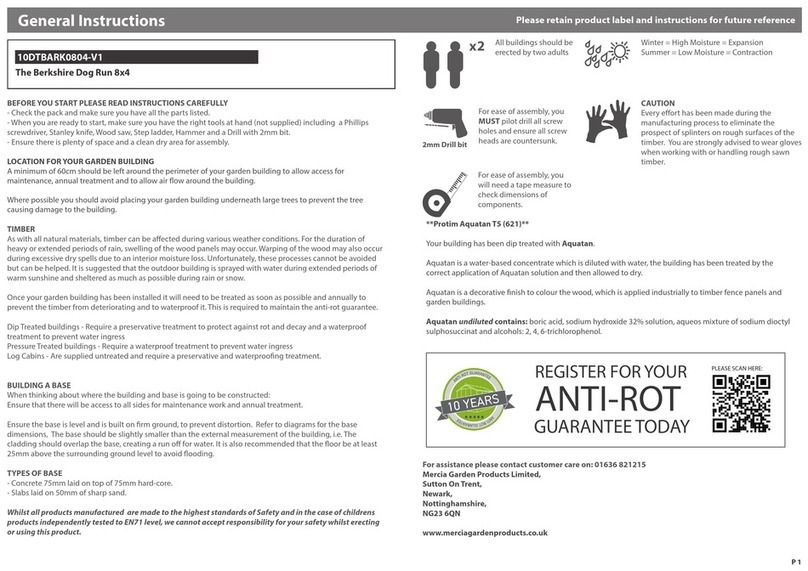

Mercia Garden Products

Mercia Garden Products 10DTBARK0804-V1 Assembly instructions

Fishers Woodscraft

Fishers Woodscraft Home Garden Pub Assembly instructions

garofalo

garofalo BAULE WOODY GREY 80 user manual

Lifetime

Lifetime 6418 Assembly instructions and owner's manual

Keter

Keter OAKLAND 7511 user manual

USP

USP Duramax Palladium manual