1 | P a g e

Caution

Please be careful when handling all components, some parts have sharp metal edges.

Always wear work gloves, eye protection and long sleeves when assembling or maintaining

your shed.

Tools required for assembly

•Level

•Drill

•Hammer

•Ladder

•12mm Drill bit

•6mm Drill bit

•Phillips head drive

•Hex Head Drive (5/16’)

•Safety glasses

•Gloves

Before assembly

•Remove all parts from packages and place in a safe place close to assembly area.

•Review all instructions; continue to refer to instructions throughout assembly –step

by step.

Preparing your site

•Choose your site carefully, site surface must be level (unless an Elevation kit or

Heavy duty floor kit option has been purchased with your product)

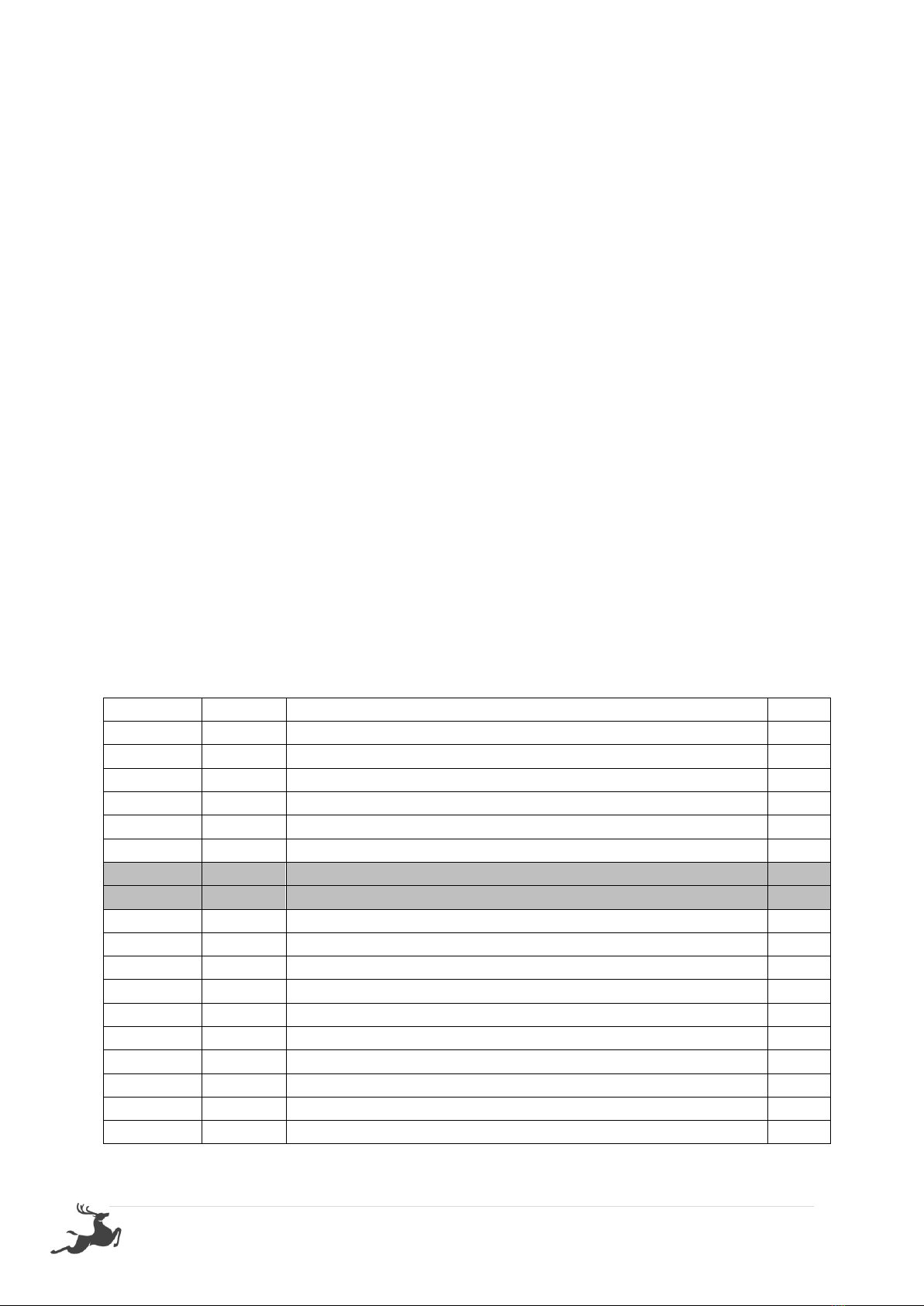

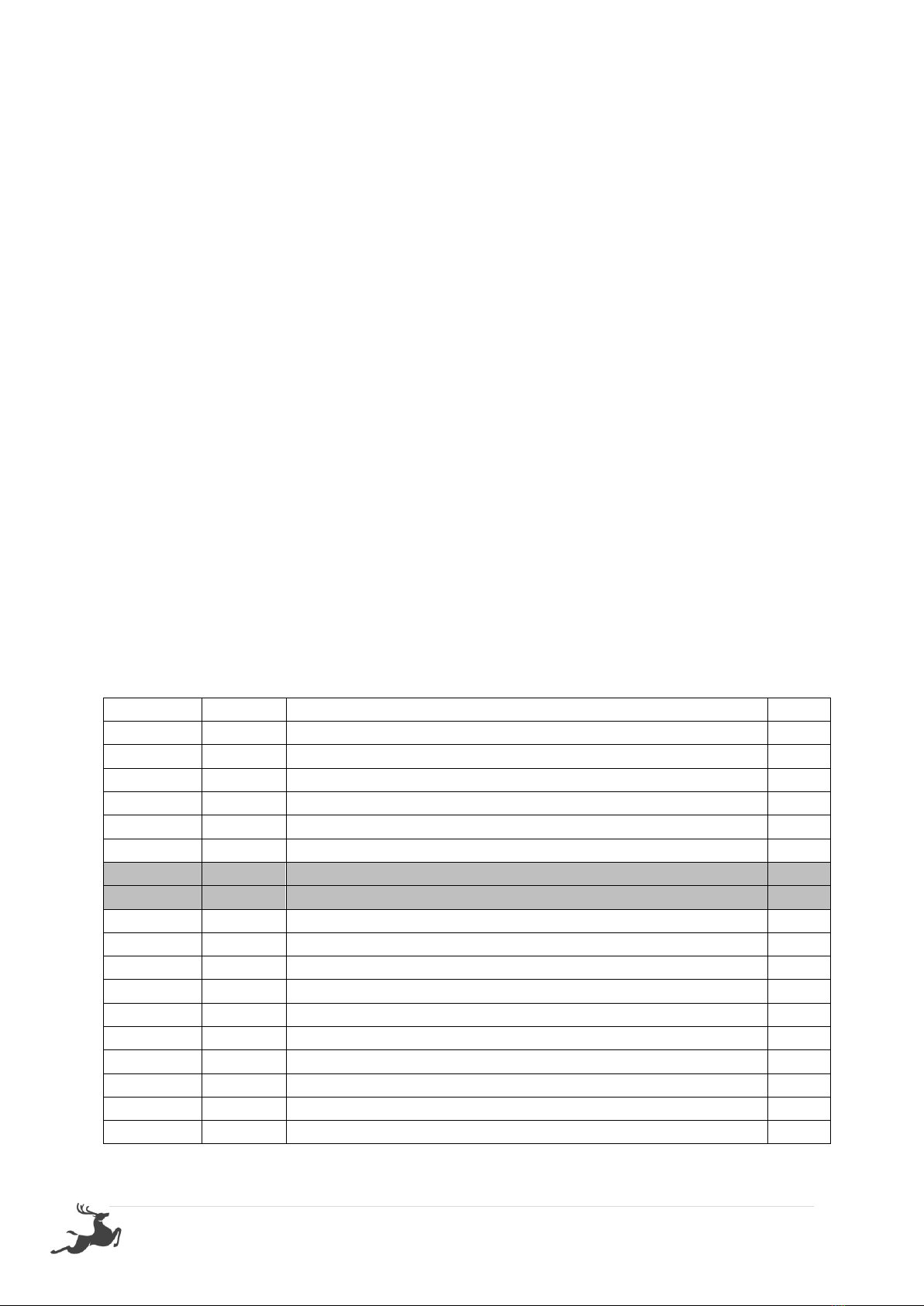

PALMWOOD 6x6 PARTS CHECKLIST

Cedar Clad Panel 900x1890mm

Cedar Clad Panel 480x1890mm (180x1890 if Double Doors)

Single Colonial Door 830x1875mm

Top Batten/Bottom Batten 2115mm

1890x61x18mm Corner Posts

840mm Door Head (1440x42x35mm if Double Doors)

840mm Door Step (1440x42x19mm if Double Doors)