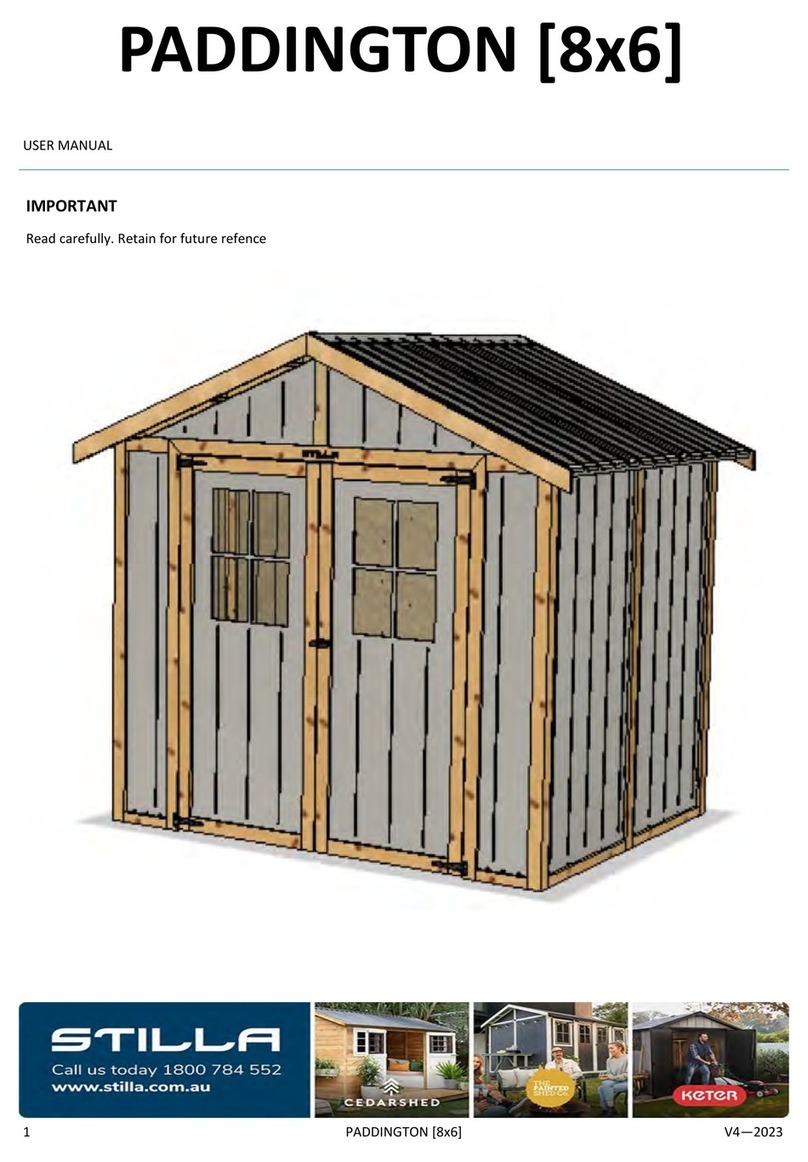

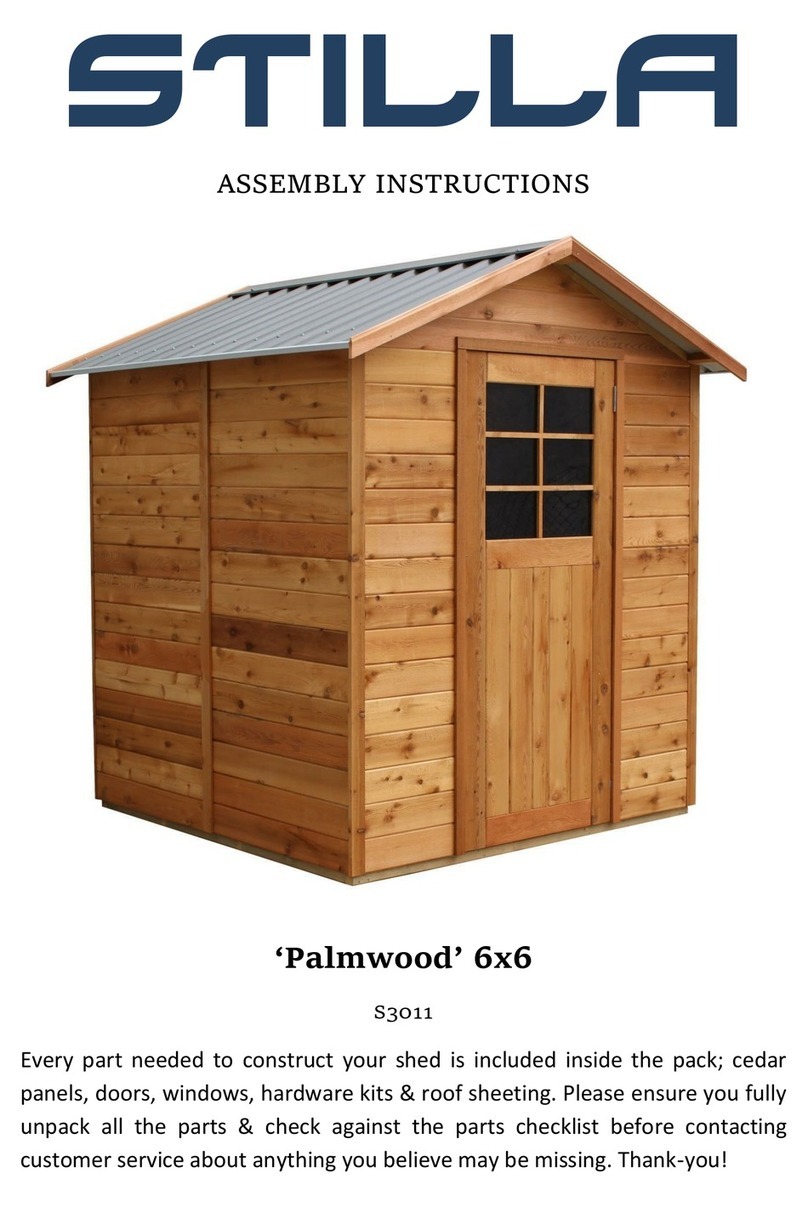

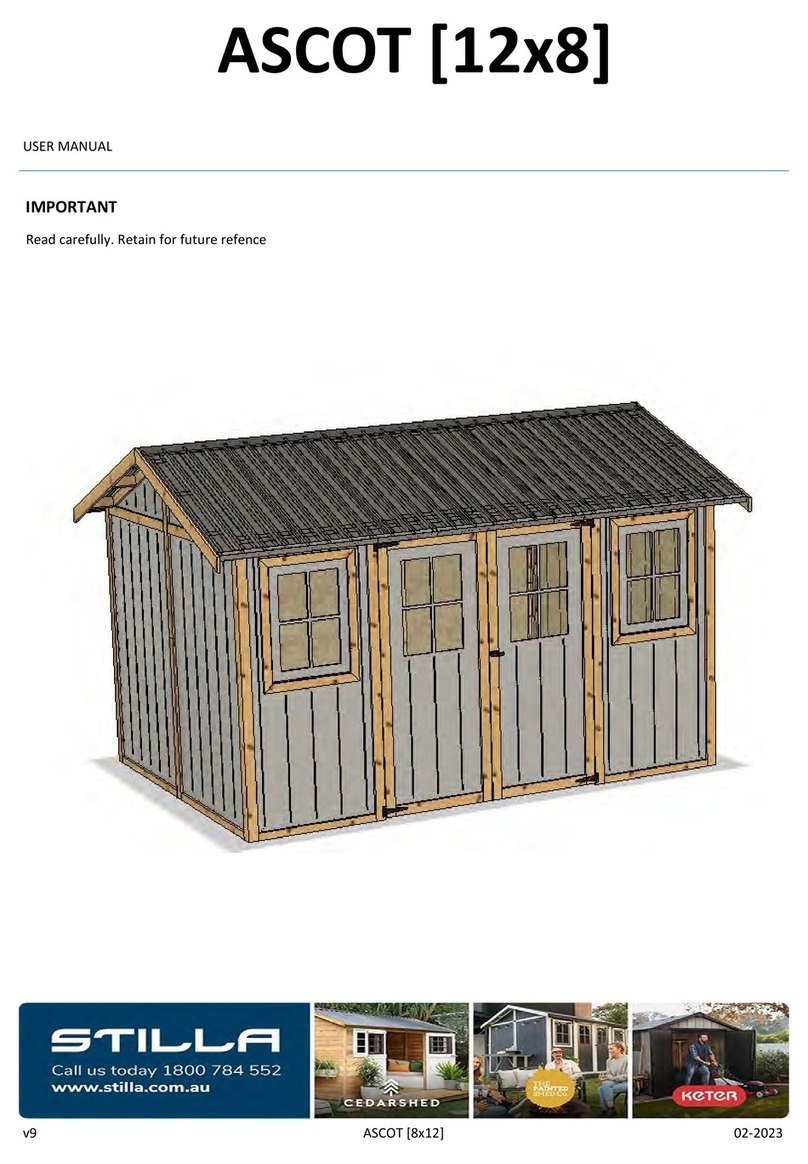

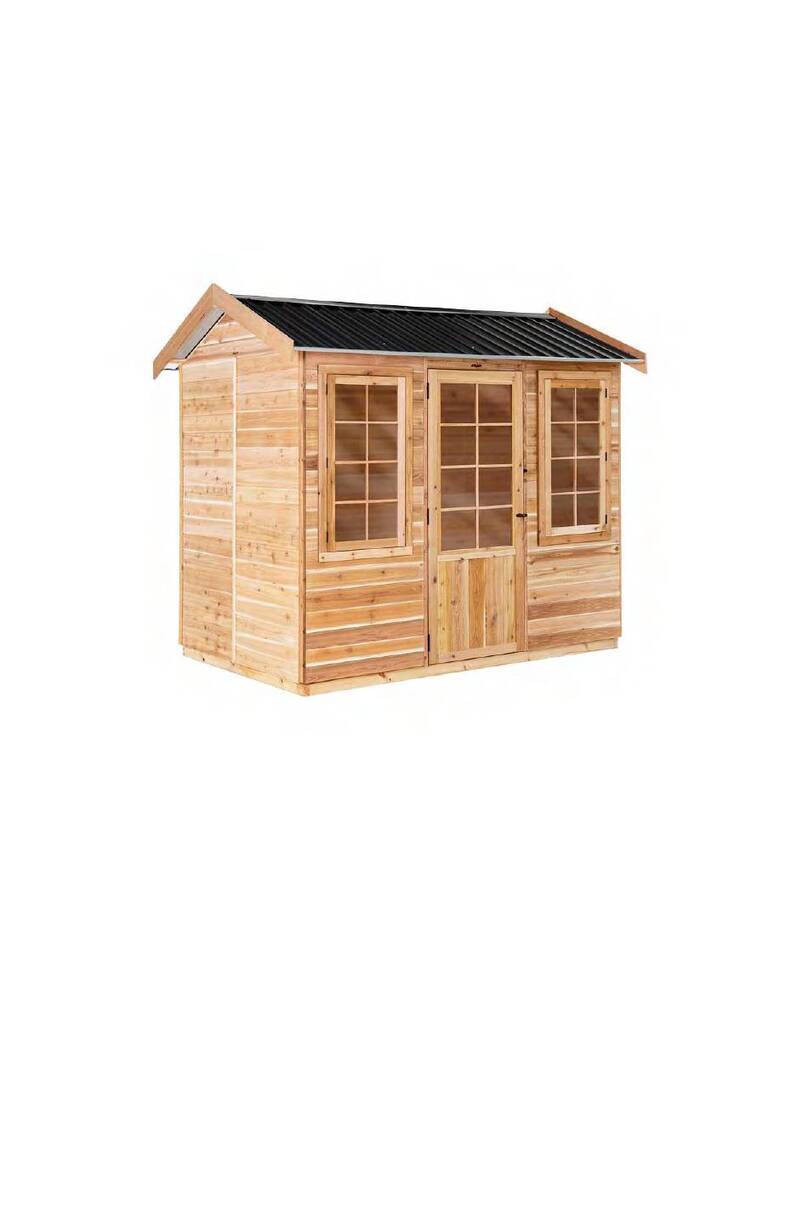

STILLA Windsor User manual

This manual suits for next models

1

Table of contents

Other STILLA Outdoor Storage manuals

Popular Outdoor Storage manuals by other brands

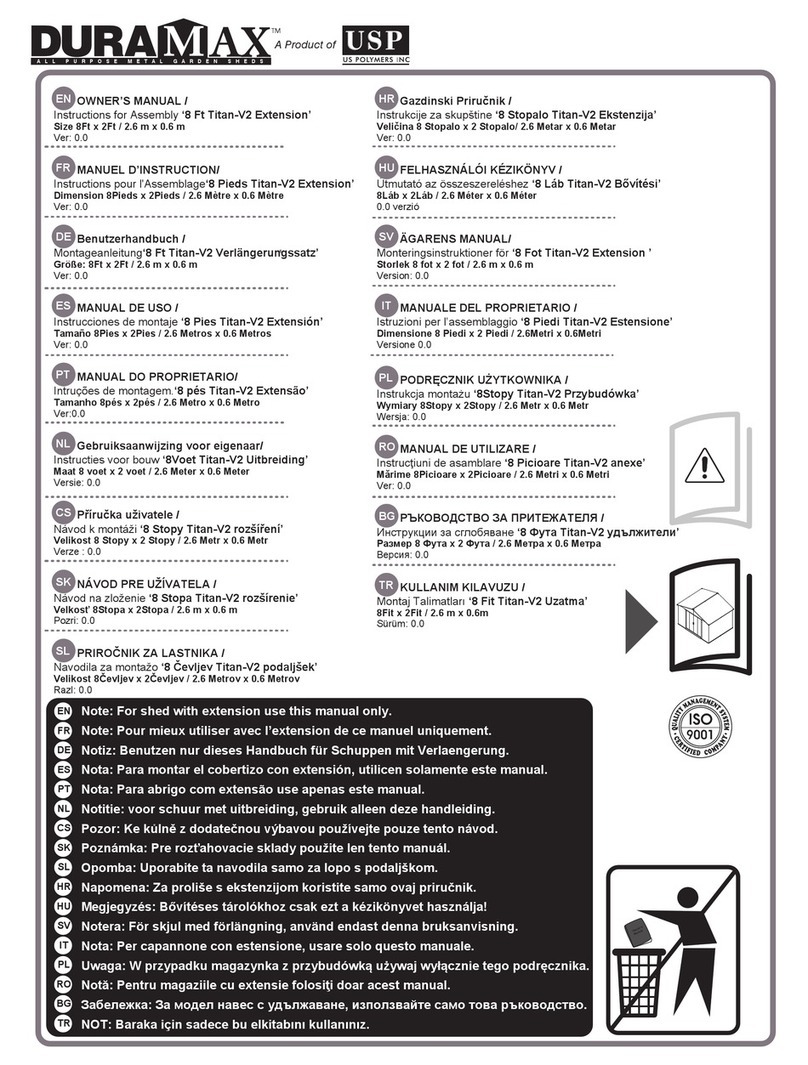

USP

USP DuraMax Titan-V2 owner's manual

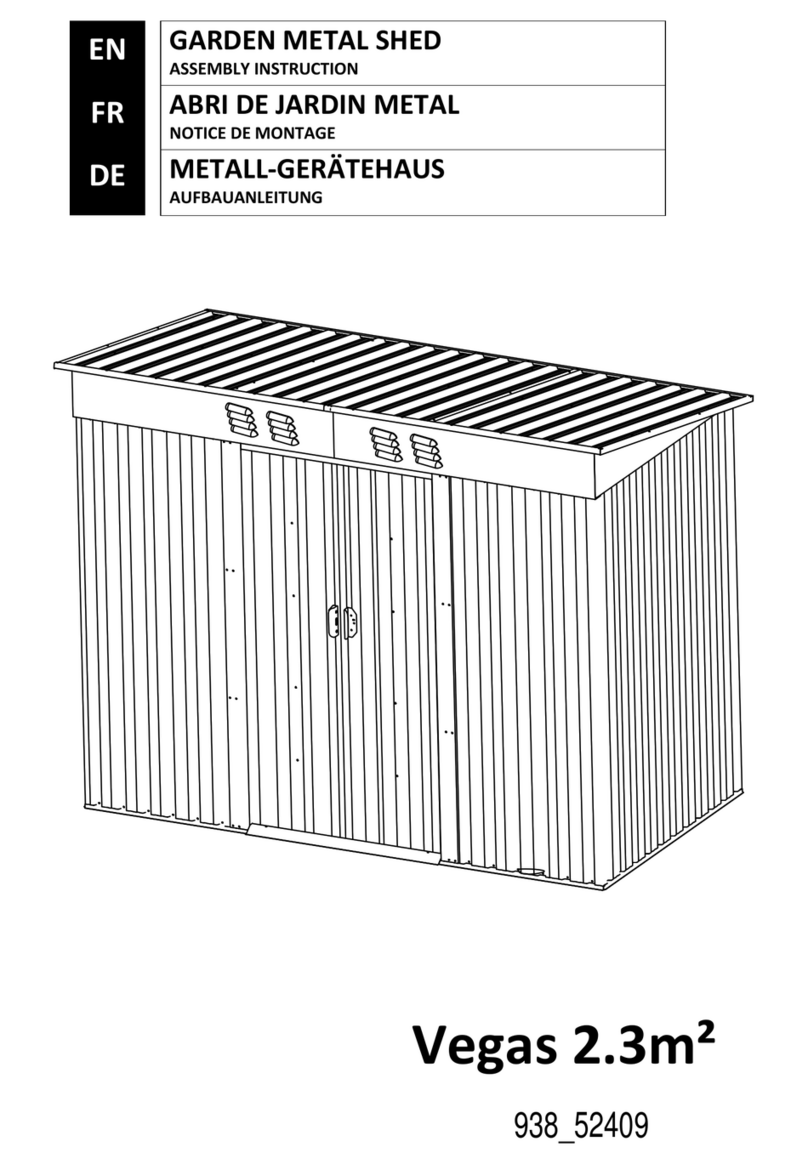

habitat et jardin

habitat et jardin Vegas 938 52409 Assembly instruction

Suncast

Suncast 774098 Assembly manual

Lifetime

Lifetime 60186 Assembly instructions

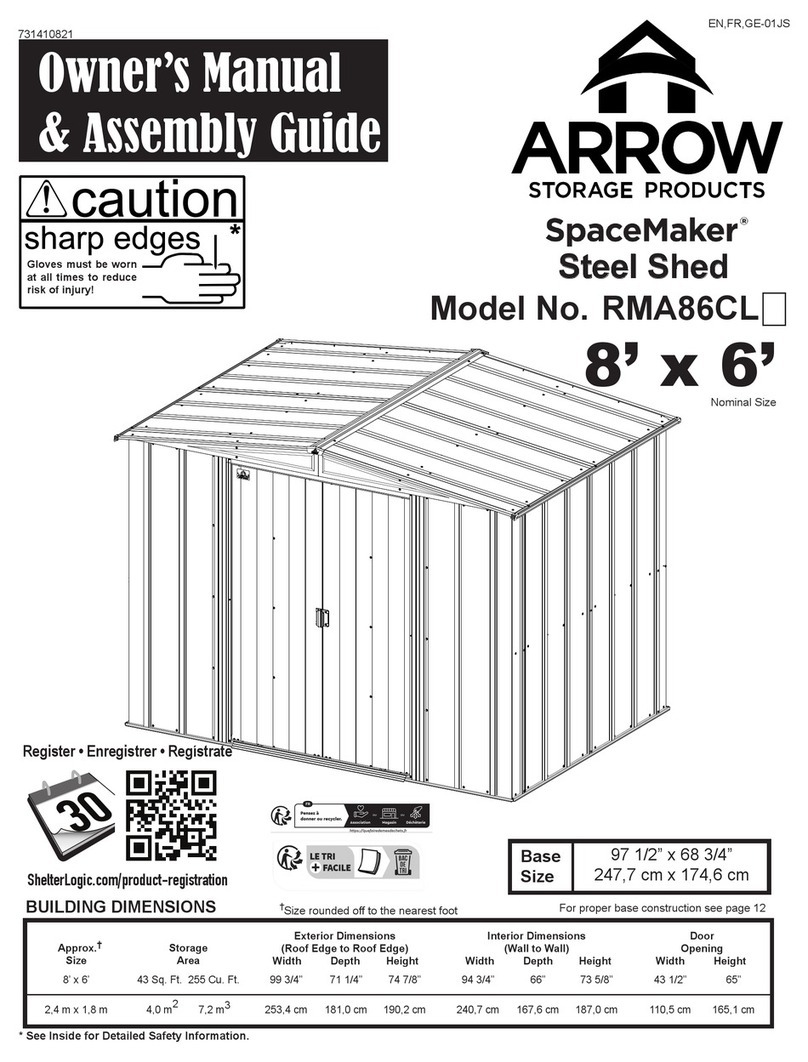

Arrow Storage Products

Arrow Storage Products ENFRGE-01JS Owner's manual & assembly guide

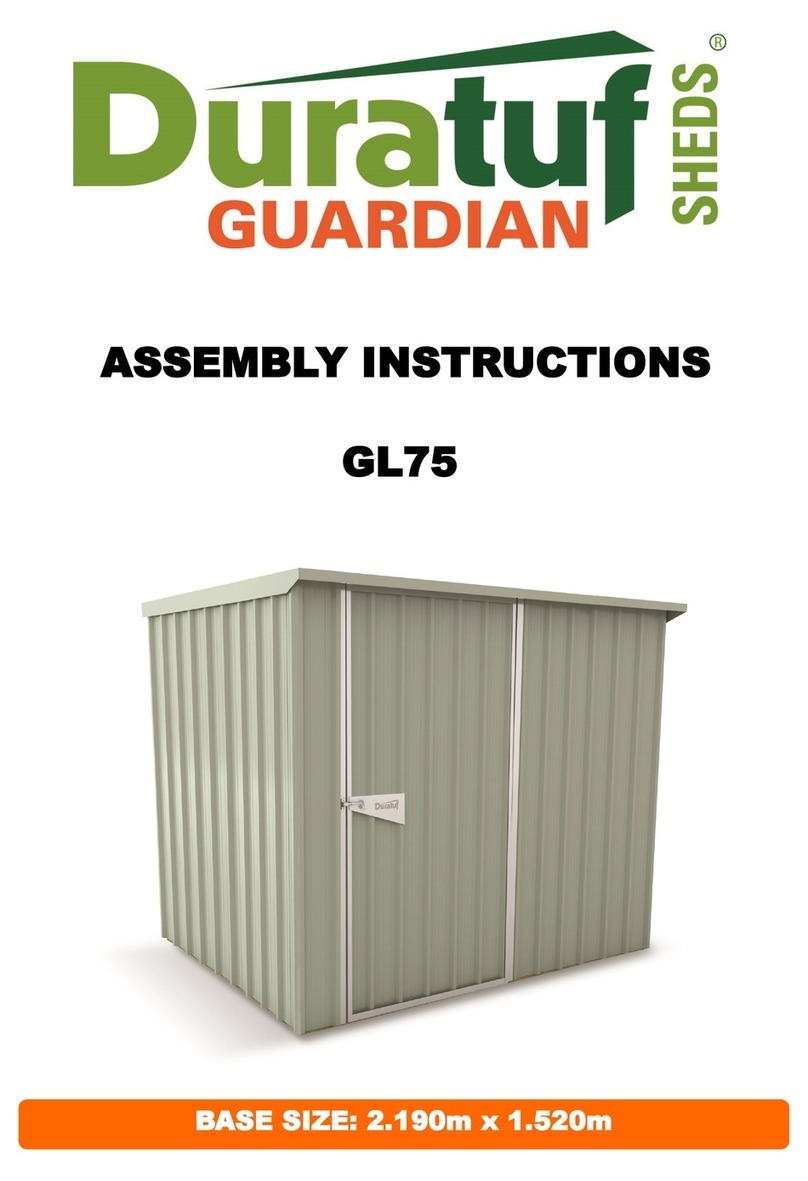

Duratuf

Duratuf GL75 Assembly instructions

ABSCO SHEDS

ABSCO SHEDS BUSH RANGER 3023BRK manual

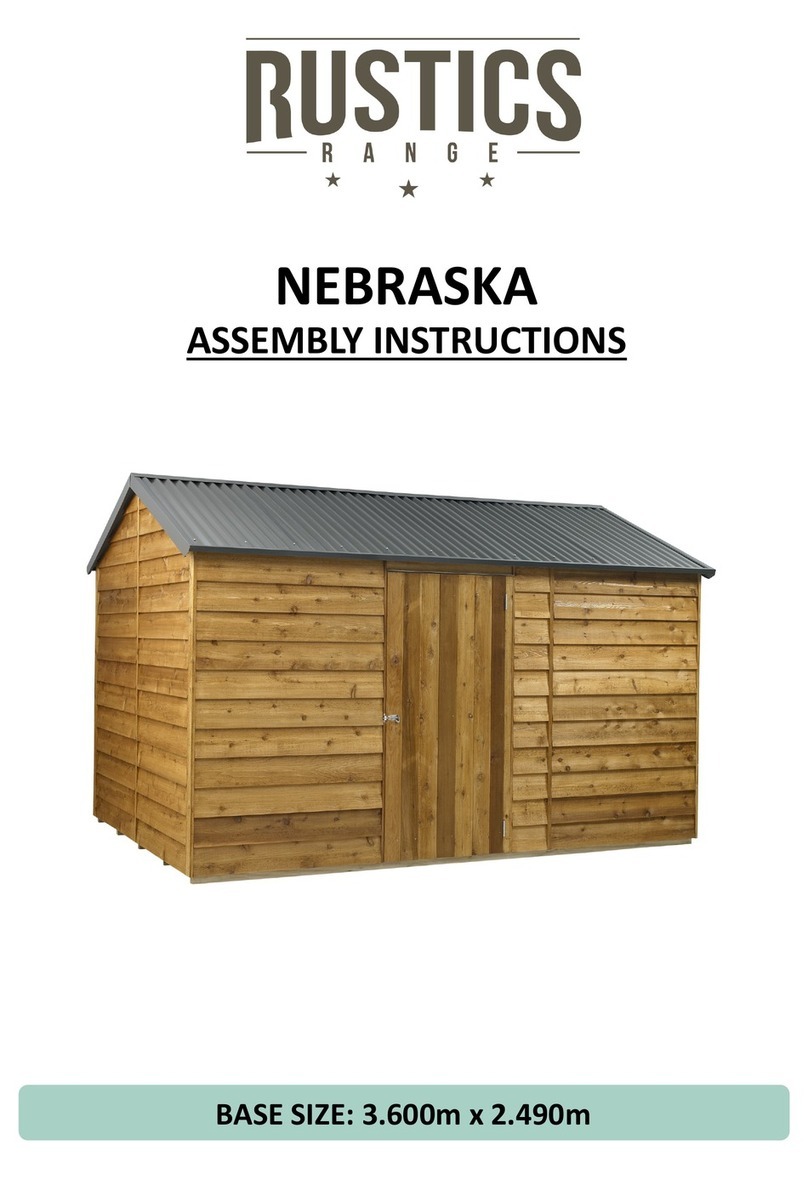

Riverlea

Riverlea Rustics NEBRASKA Assembly instructions

Asgard

Asgard TROJAN PLUS quick start guide

Arrow Storage Products

Arrow Storage Products WR86 Owner's manual & assembly guide

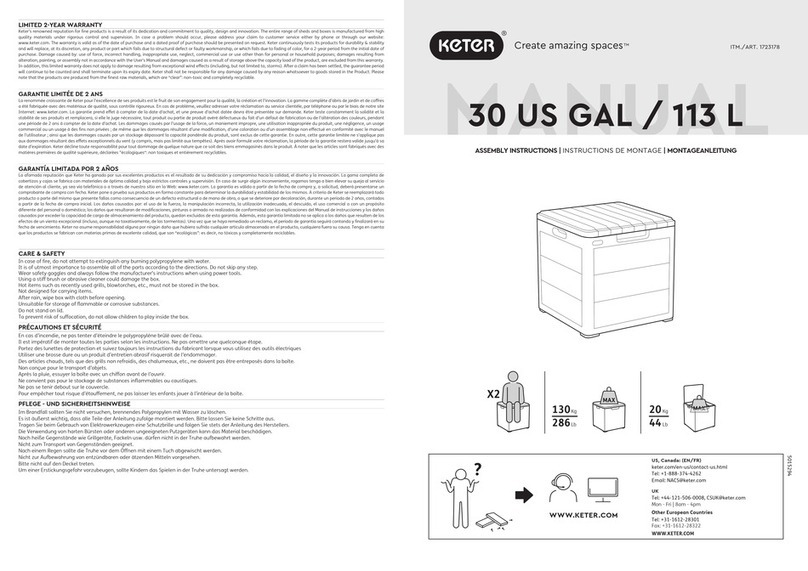

Keter

Keter Cortina 1723178 Assembly instructions

Keter

Keter HOLLYWOOD 270 L Assembly instructions

US Polymers

US Polymers Duramax 10 Ft Eco owner's manual

Dancover

Dancover Garden Locker Shed manual

Duratuf

Duratuf SG2520 Assembly instructions

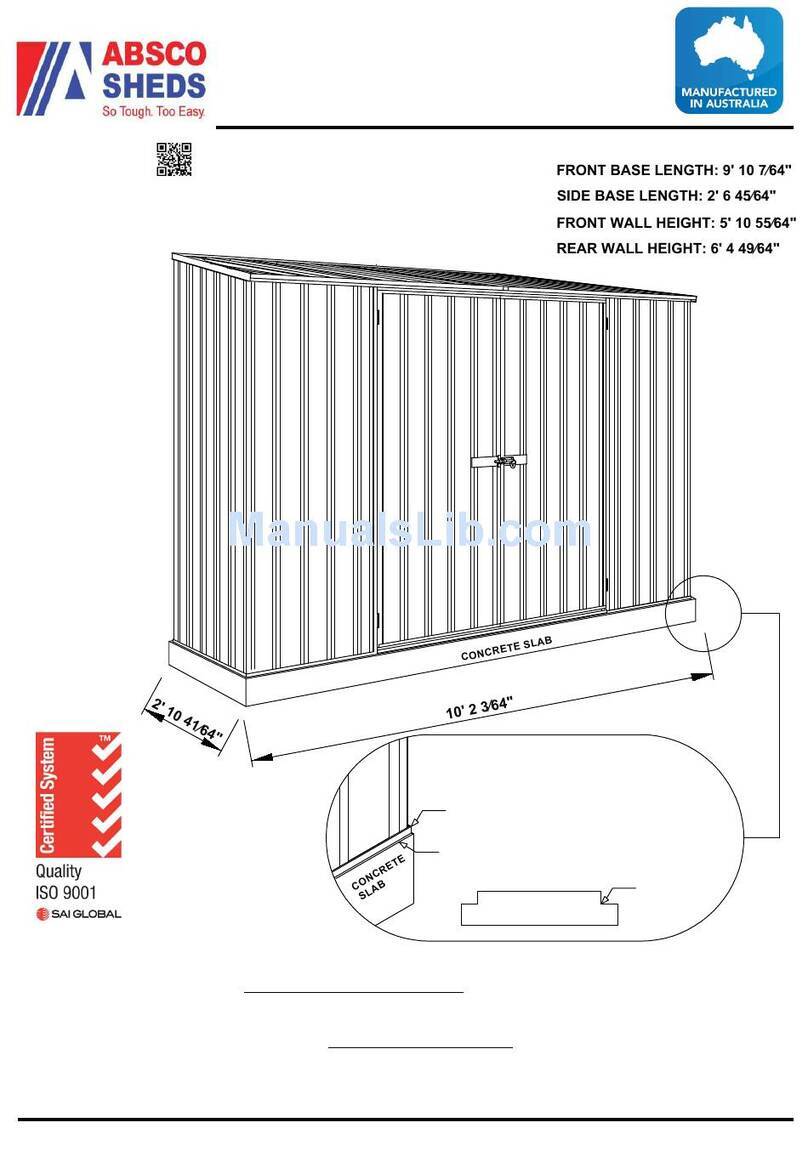

Absco

Absco J30082S Assembly instructions

Arrow Storage Products

Arrow Storage Products EG1216AB owner's manual

Feider Machines

Feider Machines FAJ200A owner's manual