STILLA Peppertree 9x6 User manual

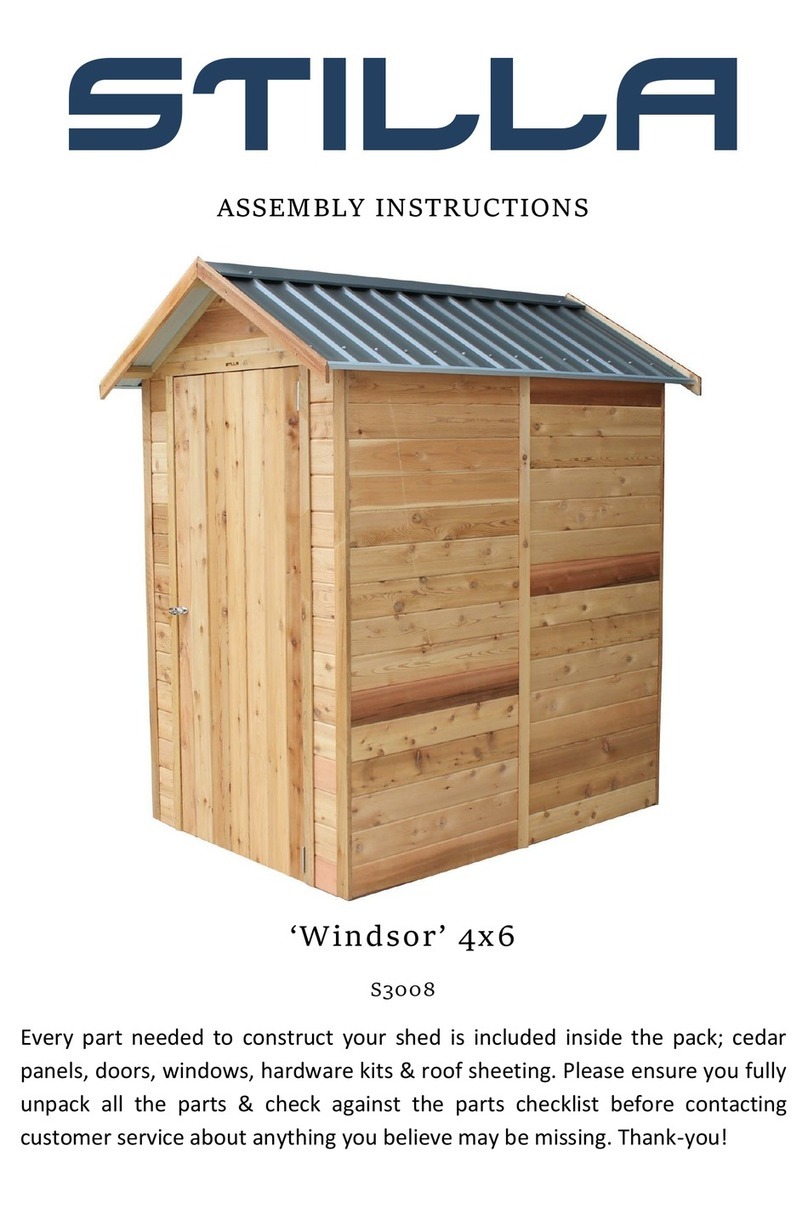

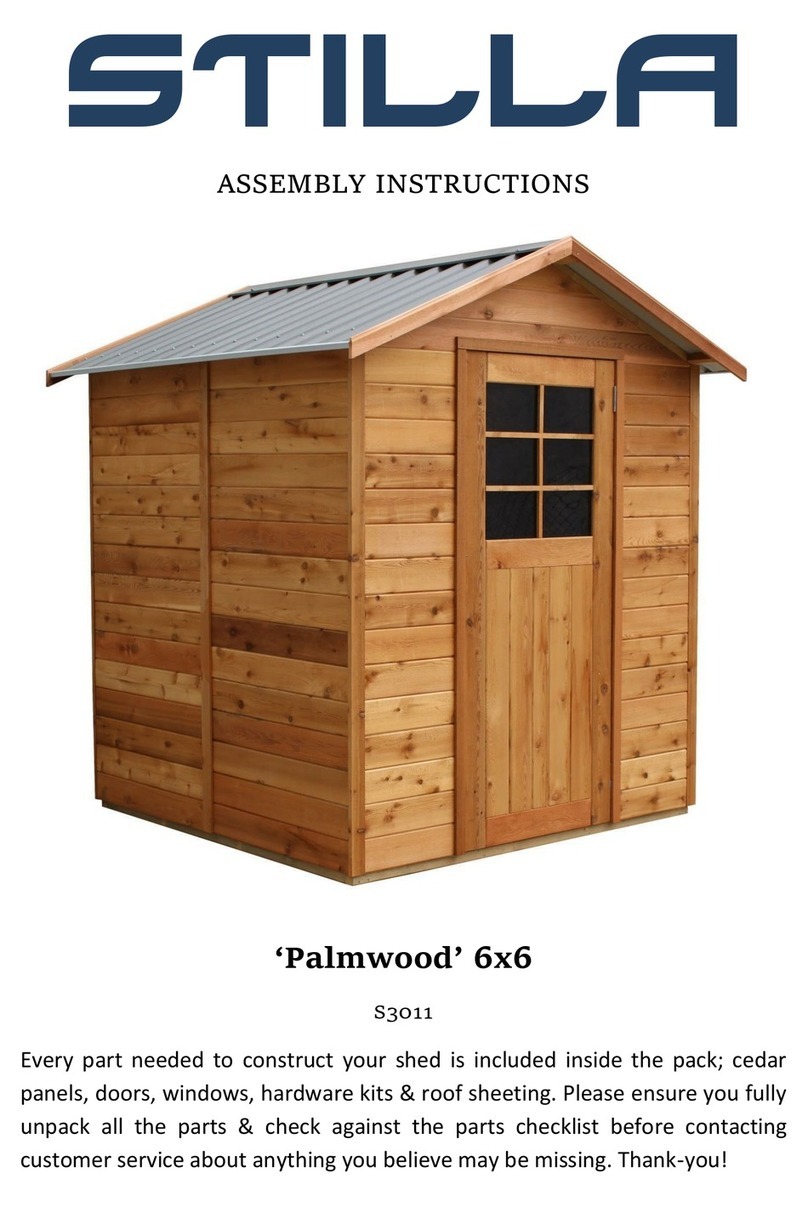

STILLA

ASSEMBLY INSTRUCTIONS

‘Peppertree’9x6

S3081

Every part needed to construct your shed is included inside the pack; cedar

panels, doors, windows, hardware kits & roof sheeting. Please ensure you fully

unpack all the parts & check against the parts checklist before contacting

customer service about anything you believe may be missing. Thank-you!

24/10/2023

1 | P a g e

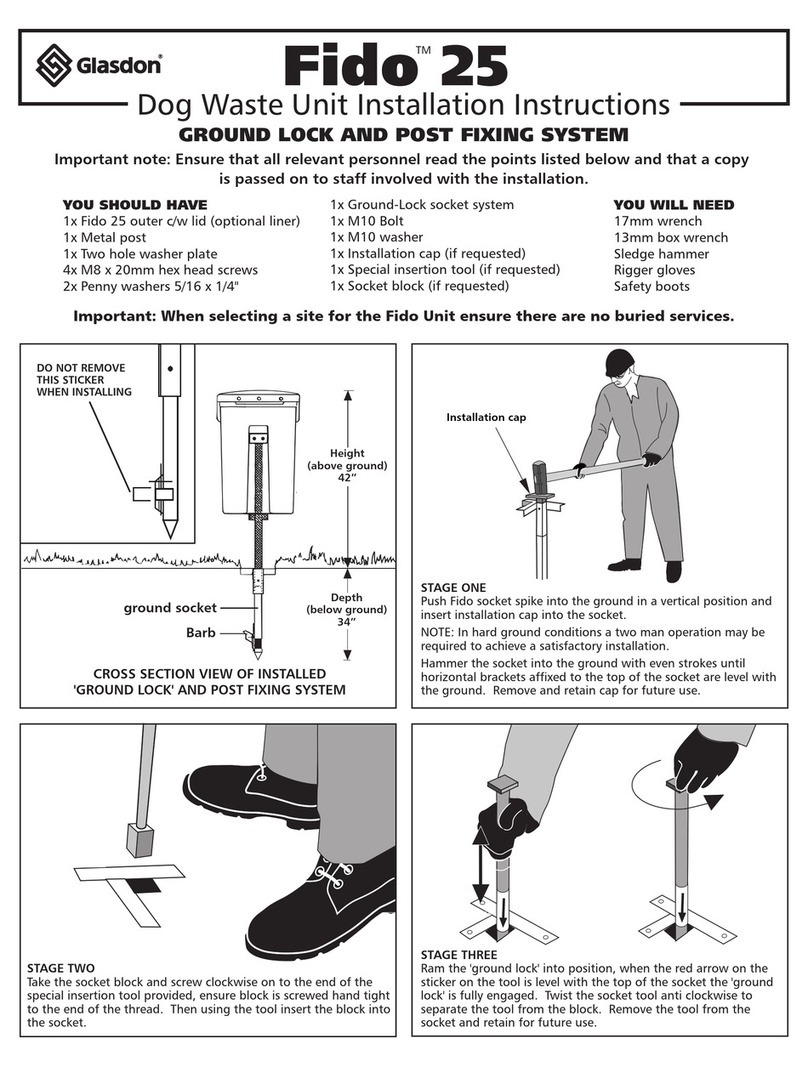

Caution

Please be careful when handling all components, some parts have sharp metal edges.

Always wear work gloves, eye protection and long sleeves when assembling or maintaining

your shed.

Tools required for assembly

•Level

•Drill (capable of driving 100mm

Batten Screw)

•Hammer

•Ladder

•10mm Drill bit

•6mm Drill bit

•Tape measure

•Phillips head drive

•Hex Head Drive (5/16’)

•Safety glasses

•Gloves

•Circular/power saw (if heavy duty

floor was chosen)

•4mm Alan key

•Batten screw drive

Before assembly

•Before proceeding with installation, we recommend viewing the Cedar Studio video

at www.stilla.com.au/installation/ or search Stilla Cedar Studios on Youtube. This

doesn’t show the installation in detail however it could give you some handy tips.

Please note we haven’t videoed the assembly of each shed however the video online

is the Pioneer 20x10 and will give you an overall idea on how the installation process

is completed.

•Remove all parts from packages and place in a safe place close to assembly area.

•Review all instructions; continue to refer to instructions throughout assembly –step

by step.

Preparing your site

•If you are installing your shed on the Stilla heavy duty floor, this can be placed on

unlevelled surfaces and levelled up by using the 100x100 stumps provided.

24/10/2023

2 | P a g e

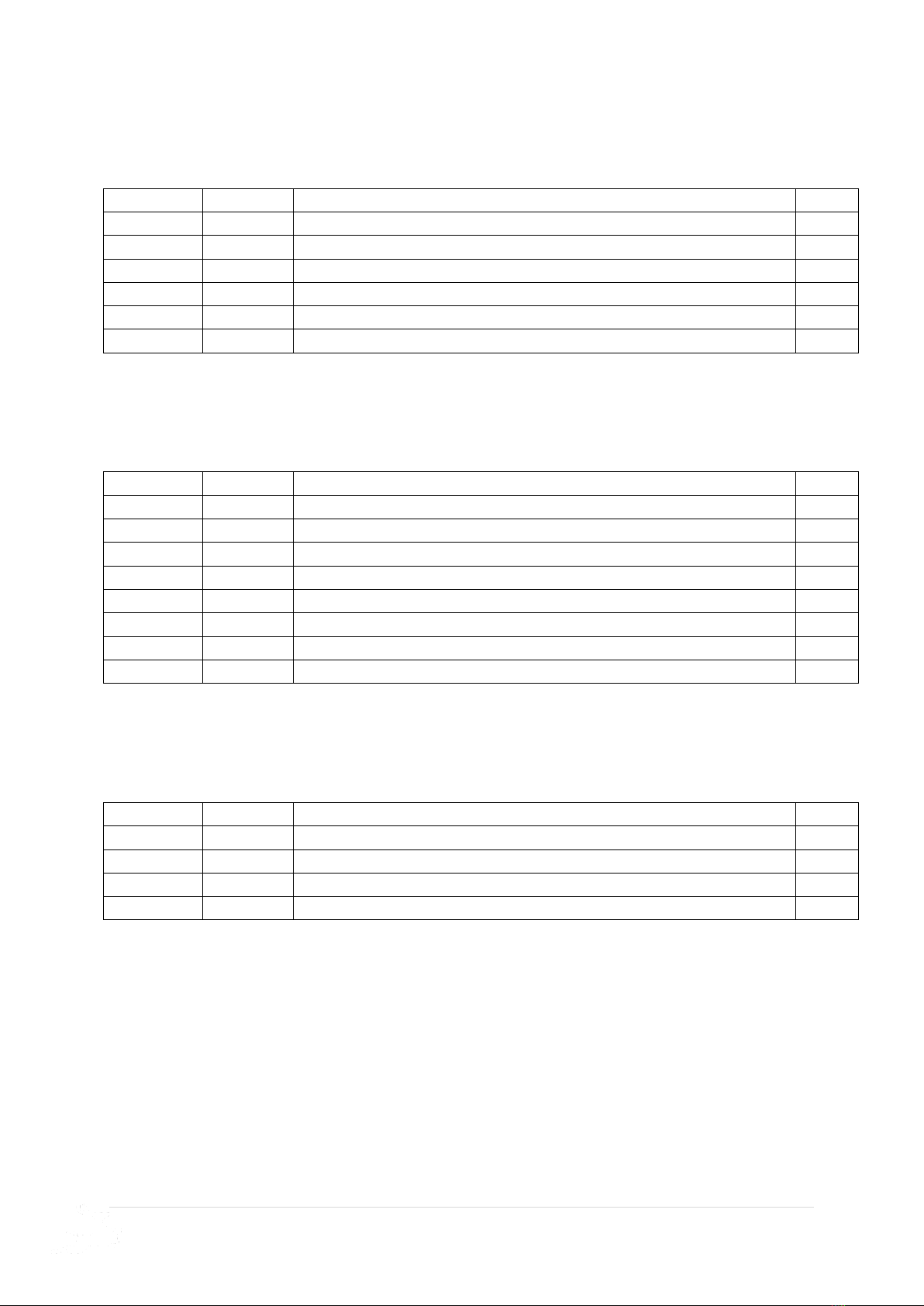

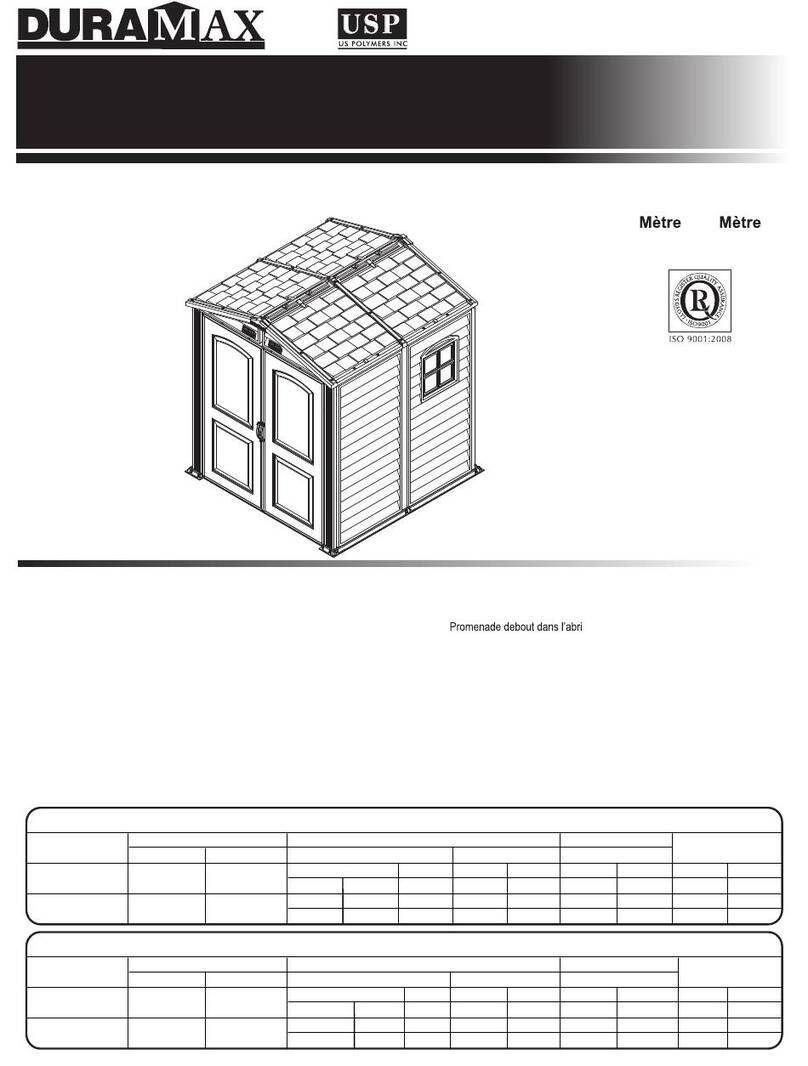

PEPPERTREE 9X6 PARTS CHECKLIST

Part Code

Checked

Part Description

Qty

P

Cedar Clad Ply Panel 900x2020mm (remove 2 if DD)

7

WP

Cedar Clad Ply Window Panel 930x2020mm

2

SWA

Cedar Studio Window Assembly (add per additional WP)

2

SCD

Single Colonial Door 825x1885mm

1

G

6ft Gable

2

FP

Cedar Clad Ply Front Panel 180x2020mm (add if DD option)

2

DCD

Double Colonial Door 710x1885mm (add if DD option)

2

CP

Corner Post 2015x65x20mm

4

CS

Cover Strip 2015x40x7mm

6

CS

Fixed Cover Strip 2015x40x7mm (4x per added fixed window)

SF

6ft Studio Fascia Pack (4pcs) –140x20mm

1

R

Roof Rafter 870x70x45mm

8

CT

Collar Tie

2

SDH

Single Door Head 840x123x45mm

1

SDSS

Single Door Surround Set –2@ 840mm, 2@ 1870mm (17x17)

1

DDH

Studio Double Door Head 1440x123x45mm (add if DD option)

1

DDSS

Double Door Surround Set –2@ 1440mm, 2@ 1870mm (17x17)

(add if DD option)

1

DDS

Double Door Vertical Seal –1855x55x20mm (add if DD option)

1

SIWS

Studio Internal Window Strip Set –2@ 770mm, 2@ 1240mm

(add per additional WP)

2

E

Roof End Piece 203x70x30mm

12

RS

1120mm Roof Sheeting

8

Sky

1120mm Skylight (option- swap with 1120 RS)

RC

1800mm Ridge Cap

2

C

1520mm Channel

4

HK

9x6 Hardware Kit

1

IM

9x6 Instruction Manual

1

REP

Roof End Plate 1304x70x45mm

8

JP

Joining Plate 812x70x45mm

4

RI (option)

Roof Insulation 2700x1300mm

2

24/10/2023

3 | P a g e

Floor Kit –Option (add screws)

Floor Frame –140x35

Part Code

Checked

Part Description

Qty

EP

End Plate 1884x140x38mm

4

DJ

Double Joist 1280x140x38mm

4

SJ

Single Joist 1280x140x38mm

6

L

Logs 750mm

6

FB

1798x800mm

3

FB

1798x206mm

1

Annex Kit –Option (add screws)

3020mm x 1450mm

Part Code

Checked

Part Description

Qty

VBJ

Veranda Beam Joiner 700x70x45mm

1

VOBJ

Veranda Outer Beam Joiner 700x140x35mm

1

VB

Veranda Beam 1510x70x45mm

2

VOB

Veranda Outer Beam 1510x140x35mm

2

VR

Veranda Rafter 1320x70x45mm

4

VF

Veranda fascia 1350x140x20 block cedar

2

VRS

1450mm Veranda Roof Sheet

4

VP

Veranda Posts 2400x90x90mm

2

Annex Deck Kit –Option (add screws)

3600mm x 1420mm

Part Code

Checked

Part Description

Qty

VEP

Veranda End Plate 2700x140x35mm

2

VJ

Veranda Joists 1350x140x35

7

VFB

Veranda Floorboards 2750x140x20mm

11

VL

Veranda Logs 750x100x100mm

3

24/10/2023

4 | P a g e

If no floor option was purchased, go to step 2.0 (Wall Assembly)

SKIP TO BACK FOR IMAGES TO HELP WITH FLOOR INSTALL

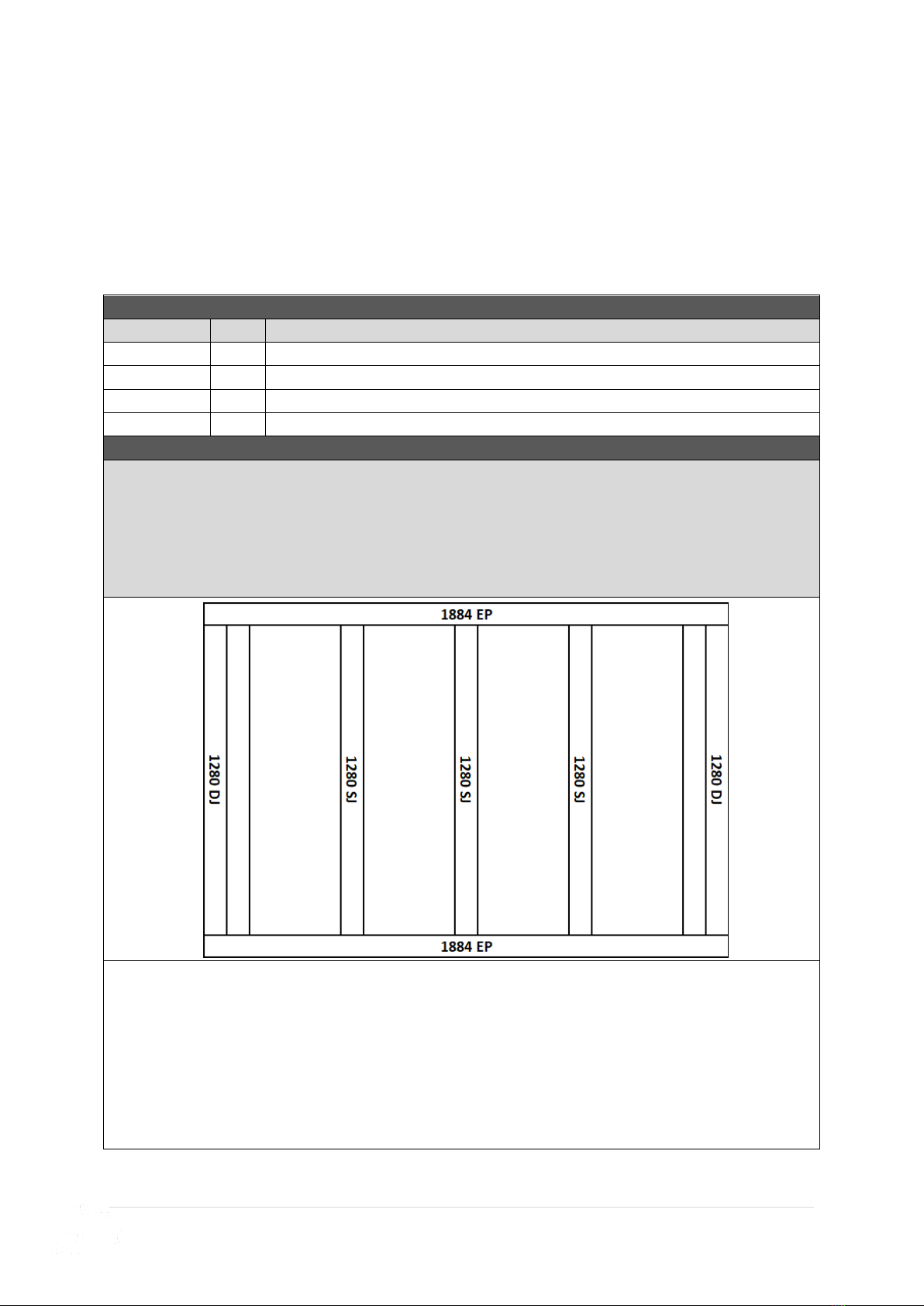

STEP 1.0

FLOOR KIT

1.0 –FLOOR KIT (1 of 2 floor frames)

PART CODE

QTY

DESCRIPTION

EP

2

End Plate 1884mm

SJ

3

Single Joist 1280mm

DJ

2

Double Joist 1280mm

100BS

24

100mm Batten Screw

1.0 –FLOOR FRAME (1 of 2 floor frames)

Fasten floor frame together as indicated in diagram below, using lines and predrilled holes.

Screw through EP into DJ using 3x 100BS.

Screw through EP into SJ using 2 x 100BS per join.

Ensure frame is square by measuring from corner to corner diagonally, frame will be square

when both diagonal measurements equal the same.

REPEAT THIS PROCESS FOR FASTENING 1 MORE FLOOR FRAME.

ENSURE 42x35 side of the DJ sits at top.

FRONT

24/10/2023

5 | P a g e

STEP 1.1

FLOOR FRAME INSTALLATION

The 9x6 floor frame comes in two parts. Install first floor frame in desired position at

desired height and fasten to logs once level and square, then join and fasten next frame

and repeat.

1.1 –FLOOR FRAME INSTALLATION

PART CODE

QTY

DESCRIPTION

L

6

Logs 750x100x100mm

100BS

24

100mm batten screws

65BS

8

65mm Batten Screws

200PB

6

200mm M12 Post Bolt

W

12

M12 Washers

1.1 –FLOOR FRAME INSTALLATION

Repeat the steps below for each floor frame, joining the floor frames together as you go in

order displayed in diagram below.

1. Lay out frame in desired position and mark holes to dig, as indicated on diagram

below (use shovel or marking paint).

2. Dig and place logs in holes (using concrete if you wish).

3. Fasten floor frame to logs at desired height, using 4x 100BS per log, ensuring frame is

level*.

4. Butt next floor frame into installed frame and join using 8x 65BS evenly spaced along

the EP.

5. Repeat process until all frames are joined.

* Fasten frame to logs when roughly level and then critique by hammering in or adding dirt

(or concrete) to corners until perfectly level at every post.

Once all frames are joined, predrill holes (using a 13mm drill bit) and bolt each log to the

floor frame in spots indicated with 200PB, using washers on both sides.

FRONT

FRONT

FRONT

24/10/2023

6 | P a g e

STEP 1.2

FLOOR INSTALLATION

1.2 –FLOORING INSTALLATION

PART CODE

QTY

DESCRIPTION

FB

3

Floor Board 1798x800mm

FB

1

Floor Board 1798x206mm

50PS

75

50mm Philips Screw

1.2–FLOORING INSTALLATION

Fasten floor sheets to floor frame as shown in diagram below using 50PS.

Bring Floor sheets in 47mm on two EP sides from the outside of the floor frame and 44mm

from the two DJ sides as seen below.

Note- The x marked on the floor sheets do not line up with our joists.

24/10/2023

7 | P a g e

STEP 2.0

SINGLE DOOR WALL PANEL LAYOUT

The 9x6 Peppertree comes standard with a single door in the non-gable end of the shed

with two window panels either side, as seen in the plan below. Follow the steps outlined

in the following pages to assemble this plan in the correct order.

Note: Any additional window panels purchased can be positioned and replace any of the

900 panels (9P) seen on this plan.

24/10/2023

8 | P a g e

STEP 2.1

WALL ASSEMBLY

2.1 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

WP

1

930mm Window Panel

P

1

900mm Panel

65HHS

3

65mm Hex head screw

2.1 - ASSEMBLY –WALL ASSEMBLY

Screw through WP into P (top, centre & bottom) using 3 x 65HHS*. Cedar strip on FWP or FP

should be on the door side.

* It helps to have one person adjusting from the outside and one person screwing on the inside.

Note: Ensure tongue on cedar cladding is at top.

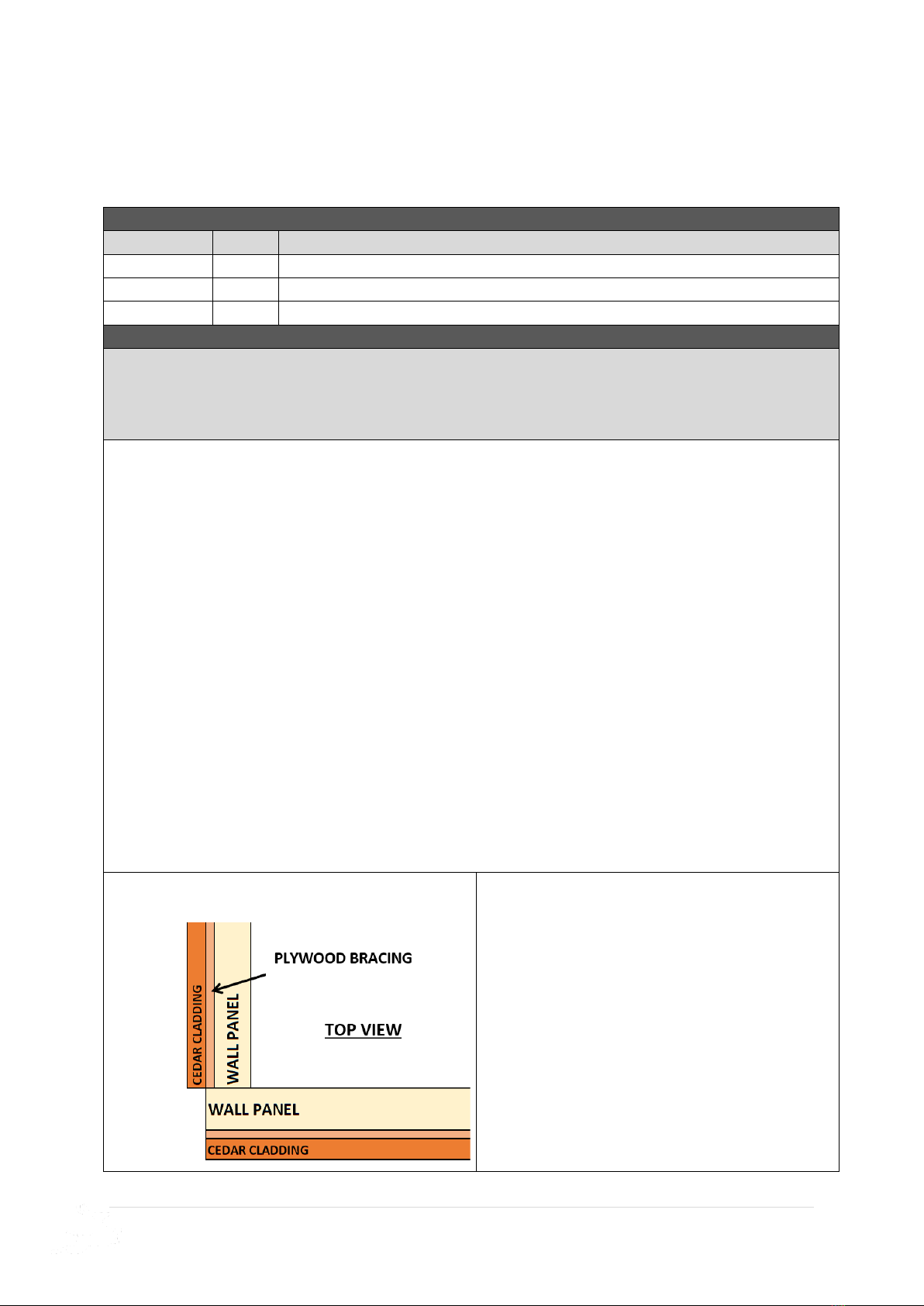

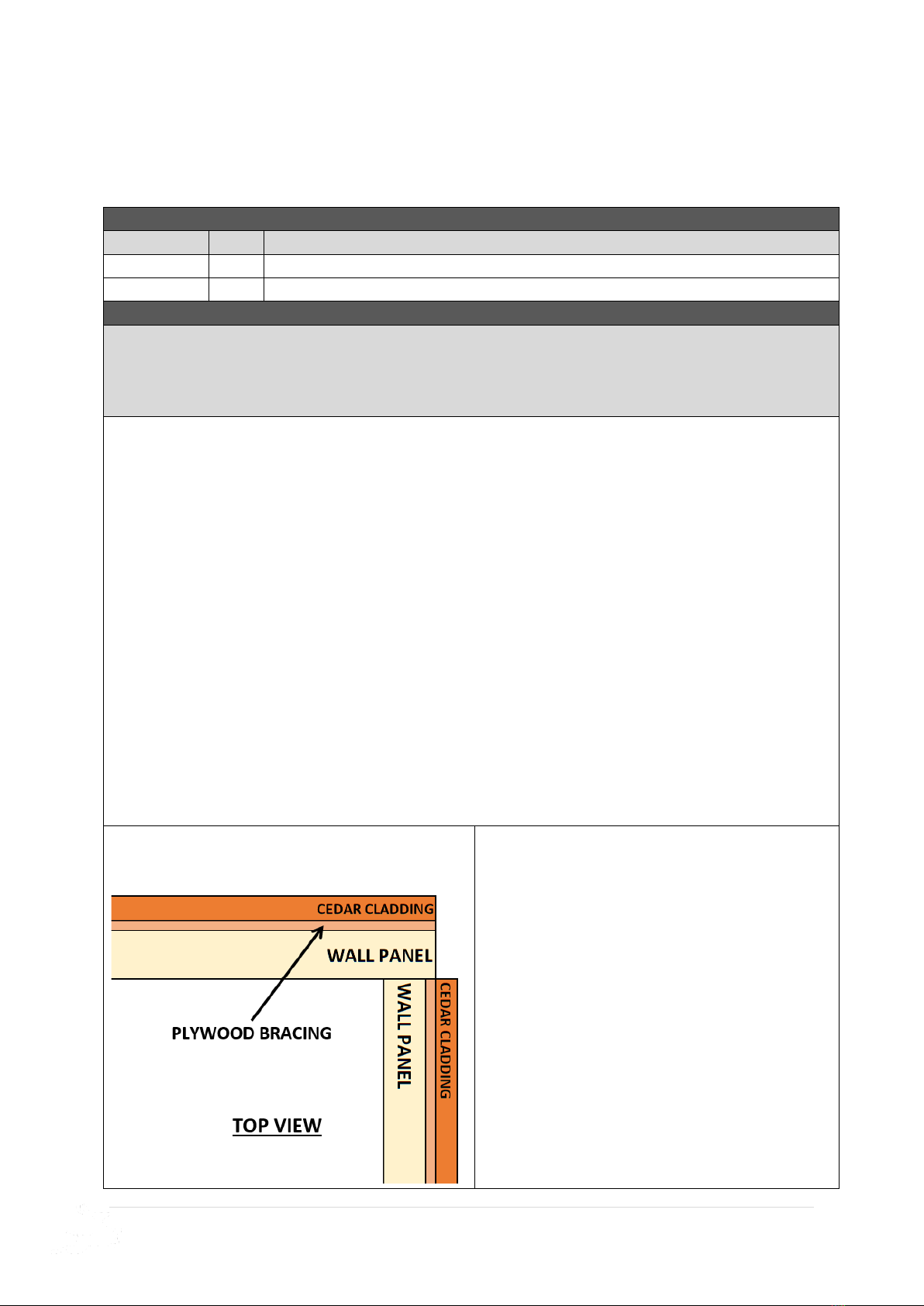

IMPORTANT CORNER DETAIL:

Install frame flush on the outside of plywood

bracing.

24/10/2023

9 | P a g e

STEP 2.2

WALL ASSEMBLY

2.2 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

P

1

900mm Panel

65HHS

3

65mm Hex head screw

2.2- ASSEMBLY –WALL ASSEMBLY

Screw through P into P (top, centre & bottom) using 3 x 65HHS*.

* It helps to have one person adjusting from the outside and one person screwing on the inside.

Note: Ensure tongue on cedar cladding is at top.

24/10/2023

10 | P a g e

STEP 2.3

WALL ASSEMBLY

2.3 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

P

1

900mm Panel

65HHS

3

65mm Hex head screw

2.3- ASSEMBLY –WALL ASSEMBLY

Screw through P into P (top, centre & bottom) using 3 x 65HHS*.

* It helps to have one person adjusting from the outside and one person screwing on the inside.

Note: Ensure tongue on cedar cladding is at top.

IMPORTANT CORNER DETAIL:

Install frame flush on the outside of plywood

bracing.

24/10/2023

11 | P a g e

STEP 2.4

WALL ASSEMBLY

2.4 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

P

1

900mm Panel

65HHS

3

65mm Hex head screw

2.4- ASSEMBLY –WALL ASSEMBLY

Screw through P into P (top, centre & bottom) using 3 x 65HHS*.

* It helps to have one person adjusting from the outside and one person screwing on the inside.

Note: Ensure tongue on cedar cladding is at top.

24/10/2023

12 | P a g e

STEP 2.5

WALL ASSEMBLY

2.5 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

P

1

900mm Panel

65HHS

3

65mm Hex head screw

2.5- ASSEMBLY –WALL ASSEMBLY

Screw through P into P (top, centre & bottom) using 3 x 65HHS*.

* It helps to have one person adjusting from the outside and one person screwing on the inside.

Note: Ensure tongue on cedar cladding is at top.

24/10/2023

13 | P a g e

STEP 2.6

WALL ASSEMBLY

2.6 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

P

1

900mm Panel

65HHS

3

65mm Hex head screw

2.6- ASSEMBLY –WALL ASSEMBLY

Screw through P into P (top, centre & bottom) using 3 x 65HHS*.

* It helps to have one person adjusting from the outside and one person screwing on the inside.

Note: Ensure tongue on cedar cladding is at top.

IMPORTANT CORNER DETAIL:

Install frame flush on the outside of plywood

bracing.

24/10/2023

14 | P a g e

STEP 2.7

WALL ASSEMBLY

2.7 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

P

1

900mm Panel

65HHS

3

65mm Hex head screw

2.7 - ASSEMBLY –WALL ASSEMBLY

Screw through P into P (top, centre & bottom) using 3 x 65HHS*.

* It helps to have one person adjusting from the outside and one person screwing on the inside.

Note: Ensure tongue on cedar cladding is at top.

24/10/2023

15 | P a g e

STEP 2.8

WALL ASSEMBLY

2.8 - ASSEMBLY PARTS –WALL ASSEMBLY

PART CODE

QTY

DESCRIPTION

WP

1

930mm Front Window Panel

65HHS

3

65mm Hex head screw

2.8- ASSEMBLY –WALL ASSEMBLY

Screw through WP into P (top, centre & bottom) using 3 x 65HHS*. Cedar strip on FWP or FP

should be on the door side.

* It helps to have one person adjusting from the outside and one person screwing on the inside.

Note: Ensure tongue on cedar cladding is at top.

IMPORTANT CORNER DETAIL:

Install frame flush on the outside of plywood

bracing.

24/10/2023

16 | P a g e

STEP 2.9

DOOR HEAD INSTALL (Non-Gable end)

2.9 - ASSEMBLY PARTS –DOOR HEAD INSTALL

PART CODE

QTY

DESCRIPTION

SDH

1

840x123x45mm Double Door Head

MP

2

Mending Plate

32PS

8

32mm Phillips Screw

2.9 - ASSEMBLY –DOOR HEAD INSTALL

1. Mark 75mm either side on top of door head (tongue is on top).

2. Screw Mending Plate to top of either side of Door Head using 2x 32PS.

3. Place Door Head in position. Ensure back of Door Head sits flush with back frame

of front panel.

4. Fasten Door Head by screwing 2x 32PS through mending plate into front panel.

Ensure Door Head sits hard against side of front panel.

1.

2.

3.

Ensure Door Head sits hard

against side of front panel

and flush with back frame.

4.

24/10/2023

17 | P a g e

STEP 3.0

DOOR HEAD INSTALL (non-Gable End)

3.0 - ASSEMBLY PARTS –DOOR HEAD INSTALL

PART CODE

QTY

DESCRIPTION

100BS

2

100mm batten screw

3.0 - ASSEMBLY –DOOR HEAD INSTALL

Secure Door Head by screwing 1x 100BS through front panel into bottom of Door Head, as

seen below*.

* Predrill a 4mm hole before screwing.

24/10/2023

18 | P a g e

STEP 3.1

DOOR SURROUND INSTALL

3.1 - ASSEMBLY PARTS –DOOR SURROUND INSTALL

PART CODE

QTY

DESCRIPTION

SDSS

1

Double Door Surround Set –2@ 840mm, 2@ 1870mm (DD option)

40N

20

40mm Nail

3.1 - ASSEMBLY –DOOR SURROUND INSTALL

1. Nail top 1440mm Door Surround to bottom of door head (flush with back) using 4x 40N.

2. Nail bottom 1440mm door surround to floor frame (hard against flooring) using 4x 40N*.

Ensure wall panels are tight against surround (there should be a 1440mm gap).

3. Measure and cut side 1870mm Door Surrounds to fit between top and bottom.

4. Nail side Door Surrounds, flush with back of wall panels, using 6x 40N per side.

* If floor frame was not purchased, secure bottom piece using silicone and concrete nails (not

supplied).

Nail surround flush

with back of frame

using 40N.

24/10/2023

19 | P a g e

STEP 3.2

GABLE INSTALL

3.2 - ASSEMBLY PARTS –GABLE INSTALL (1 of 2 Gables)

PART CODE

QTY

DESCRIPTION

G

1

6ft Gable

65HHS

4

65mm Hex head screw

3.2 - ASSEMBLY –GABLE INSTALL (1 of 2 Gables)

Carefully place gable on back wall, ensuring groove on gable slots into the tongue on the wall,

as seen below. Ensure end of gable sits flush with side of back wall panel and fasten by

screwing 4x 65HHS through panels into gable- 2 screws either side of join.

REPEAT THIS PROCESS FOR INSTALLING OTHER SIDE GABLE.

Ensure groove slots into tongue

Screw upwards through

wall panel into gable

This manual suits for next models

1

Table of contents

Other STILLA Outdoor Storage manuals

Popular Outdoor Storage manuals by other brands

Arrow Storage Products

Arrow Storage Products SpaceMaker RMA108CL owner's manual

ABSCO SHEDS

ABSCO SHEDS 23151SK-PTX manual

Backyard Products

Backyard Products HANDY HOME PRODUCTS MARCO Series Assembly manual

Duratuf

Duratuf PG66 Assembly instructions

Yardline

Yardline RIDGEPOINTE Assembly manual

USP

USP DURAMAX 6 Ft WoodSide owner's manual