StoneAge AUTOSTROKE AST-200-V2 User manual

AUTOSTROKE™(AST-200-V2)

FOR USE WITH THE AUTOBOX®PRODUCT LINE

USER MANUAL

PL 629-V2 REV E

(02/2019)

2866-795-1586 • WWW.STONEAGETOOLS.COM

MANUFACTURER’S INFORMATION................................................................ 2

SPECIFICATIONS ........................................................................................ 3

DESCRIPTION OF EQUIPMENT AND INTENDED USE ................................... 3

KEY FEATURES........................................................................................... 3

CE DECLARATION OF INCORPORATION ..................................................... 4

WARNING AND SAFETY INSTRUCTIONS ....................................................... 6

OPERATOR TRAINING................................................................................. 6

PERSONAL PROTECTIVE EQUIPMENT REQUIREMENTS.............................. 6

PRE-RUN SAFETY CHECK .......................................................................... 7

SYSTEM ASSEMBLY - OVERVIEW .................................................................. 8

ABX-2L AND ABX-2L-V2 MANIFOLD UPGRADE............................................. 10

AUTOSTROKE AIR MANIFOLD CONVERSION OVERVIEW ............................ 10

REMOVAL OF MANIFOLD AND INSTALLATION OF CONVERSION ................. 11

SPLICING THE TUBING FOR THE T-FITTINGS .............................................. 12

ABX-2L AND ABX-2L-V2 AUTOSTROKE SET-UP ............................................ 13

ABX-3L AND ABX-3L-V2 AUTOSTROKE SET-UP ............................................ 15

OPERATION...................................................................................................... 17

MAINTENANCE ................................................................................................ 18

STORAGE, TRANSPORTATION, AND HANDLING ........................................... 18

AIR MOTOR GENERATOR REPLACEMENT INSTRUCTIONS.......................... 19

PART DIAGRAMS ............................................................................................. 22

TERMS AND CONDITIONS .............................................................................. 26

TABLE OF CONTENTS

3

866-795-1586 • WWW.STONEAGETOOLS.COM

DESCRIPTION OF EQUIPMENT AND

INTENDED USE

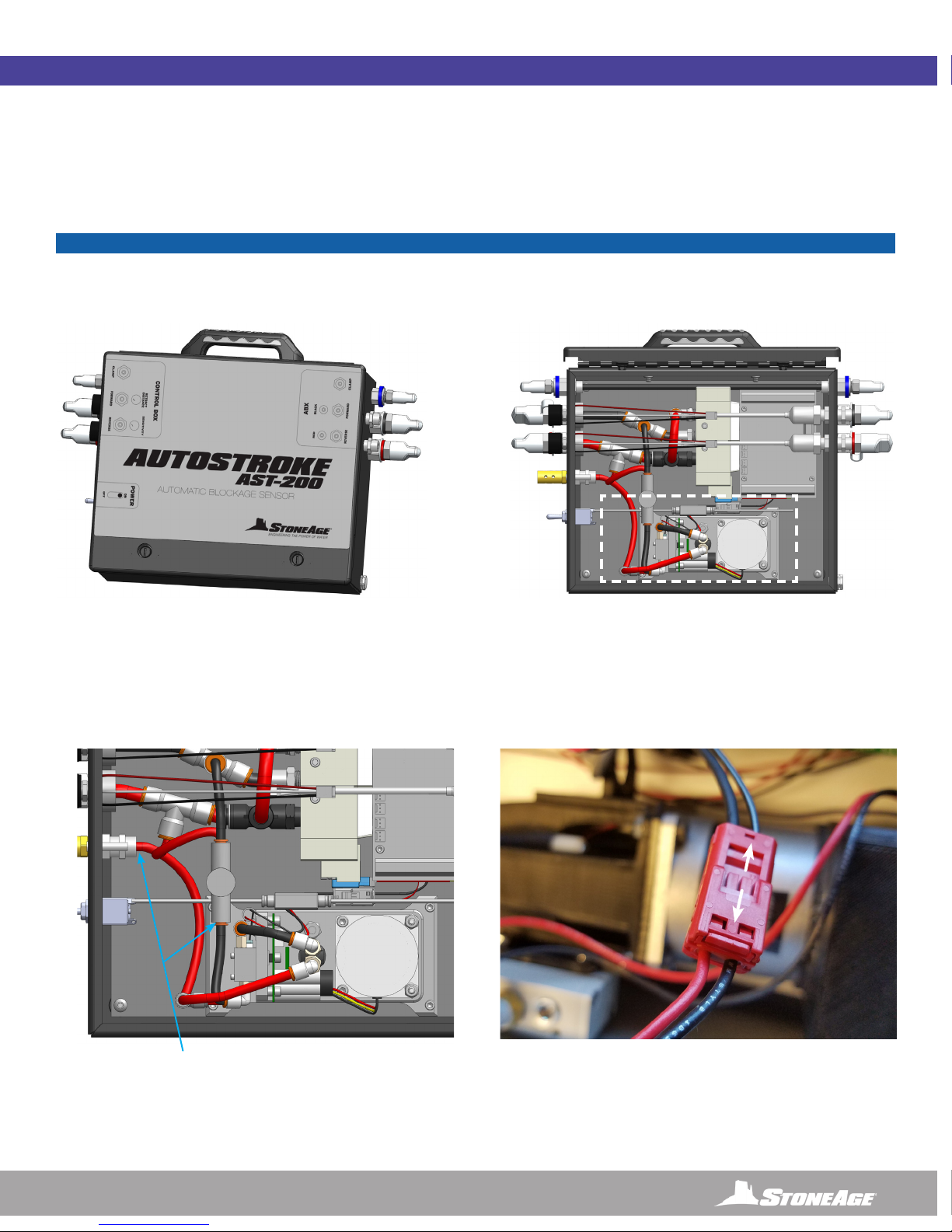

The AutoStroke (AST-200-V2) is an accessory for the Autobox®ABX-

2L, ABX-2L-V2, ABX-3L, and ABX-3L-V2, that can be mounted to

both Autobox®Control Boxes. The AutoStroke detects when the

lance encounters a blockage in a tube and retracts the lance for a

set time before continuing forward again, allowing the banshee to

continue to rotate and reducing potential hose damage.

KEY FEATURES:

• Air motor generator allows operation with compressed air as

opposed to batteries.

• Automatically retracts lance when blockage is encountered.

• Adjustable hose push force.

• Adjustable retract time.

• Switch allows disabling functionality when not desired.

• Mounts on CB stand and connects in line with Autobox®ABX-

2L, ABX-2L-V2, ABX-3L, and ABX-3L-V2L forward, reverse,

and clamp, airlines with two additional signal lines from the ABX

unit.

SPECIFICATIONS

AutoStroke (AST-200-V2)

Weight:

18 lbs

(8.2 kg)

AutoStroke (AST-200-V2)

Dimensions:

16.9” Long x 11.7” Tall x 7.9” Wide

(429 mm x 297mm x 201mm)

Air Pressure: 40 to 125 psi

(2.8 to 8.6 bar)

Air Consumption: 3 CFM

(5 m³/hr)

StoneAge Inc.

466 S. Skylane Drive

Durango, CO 81303, USA

Phone: 970-259-2869

Toll Free: 866-795-1586

www.stoneagetools.com

StoneAge Europe

Unit 2, Britannia Business Centre

Britannia Way

Malvern WR14 1GZ

United Kingdom

Phone: +44 (0) 1684 892065

This manual must be used in accordance with all applicable national laws. The manual shall be regarded as a part of the machine

and shall be kept for reference until the nal dismantling of the machine, as dened by applicable national law(s).

Updated manuals can be downloaded at:

https://www.stoneagetools.com/manuals

MANUFACTURER’S INFORMATION

4866-795-1586 • WWW.STONEAGETOOLS.COM

EU DECLARATION OF CONFORMITY

Manufacturer: StoneAge Incorporated

466 South Skylane Drive

Durango, CO 81303

USA

Authorized Representative: StoneAge Europe

Unit 2, Britannia Business Centre

Britannia Way

Malvern WR14 1GZ

United Kingdom

Steve Ellis, Director StoneAge Europe

Declare that: AutoStroke (AST-200-V2) blockage detector accessory

for high pressure water cleaning of system parts.

Is compliant with the following Directives and Standards:

Directive 2006/42/EC (Machinery Directive)

EN ISO 12100:2010 (E) Safety of machinery – General principles for design – Risk assessment and risk reduction

2011/65/EU Restriction of Hazardous Substances (RoHS2) Directive.

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use - EMC requirements-Part 1:General requirements

The Technical File for AutoStroke (AST-200-V2) is maintained at:

StoneAge Incorporated, 466 South Skylane Drive, Durango, CO 81303, USA and was compiled by the Engineering Manager.

The Technical File is available through the Authorized Representative.

This Declaration of Conformity is issued under the exclusive responsibility of StoneAge Incorporated.

________________________________________ 02/11/2019

StoneAge Incorporated, Durango, CO, USA Date

Adam Markham, Engineering Manager, Robotics

5

866-795-1586 • WWW.STONEAGETOOLS.COM

NOTES

This page is intentionally left blank.

6866-795-1586 • WWW.STONEAGETOOLS.COM

PERSONAL PROTECTIVE EQUIPMENT REQUIREMENTS

Use of Personal Protective Equipment (PPE) is dependent on

the working pressure of water and the cleaning application.

Managers, Supervisors, and Operators MUST carry out a job

specic risk assessment to dene the exact requirements for

PPE. See Protective Equipment for Personnel (Section 6) of

WJTA-IMCA’s Recommended Practices For The Use Of High-

pressure Waterjetting Equipment for additional information.

Hygiene - Operators are advised to wash thoroughly after all

waterjetting operations to remove any waterblast residue which

may contain traces of harmful substances.

First aid provision - users MUST be provided with suitable rst

aid facilities at the operation site.

PPE may include:

• Eye protection: Full face visor

• Foot protection: Kevlar® brand or steel toe capped,

waterproof, non-slip safety boots

• Hand protection: Waterproof gloves

• Ear protection: Ear protection for a minimum of 85 dBA

• Head protection: Hard hat that accepts a full face visor

and ear protection

• Body protection: Multi-layer waterproof clothing approved

for waterjetting

• Hose protection: Hose shroud

• Respiratory protection: May be required; refer to job

specic risk assessment

OPERATOR TRAINING

Managers, Supervisors, and Operators MUST be trained in Health

and Safety Awareness of High-pressure Water Jetting and hold

a copy the Water Jetting Association (WJA) Code of Practice, or

equivalent (see www.waterjetting.org.uk).

Operators MUST be trained to identify and understand all applicable

standards for the equipment supplied. Operators should be trained

in manual handling techniques to prevent bodily injury.

Operators MUST read, understand, and follow the Operational and

Training Requirements (Section 7.0) of WJTA-IMCA’s Recommended

Practices For The Use Of High-pressure Waterjetting Equipment, or

equivalent.

Operators MUST read, understand and follow the Warnings,

Safety Information, Assembly, Installation, Connection, Operation,

Transport, Handling, Storage, and Maintenance Instructions detailed

in this manual.

StoneAge has designed and manufactured this equipment

considering all hazards associated with its operation. StoneAge

assessed these risks and incorporated safety features in the design.

StoneAge WILL NOT accept responsibility for the results of misuse.

IT IS THE RESPONSIBILITY OF THE INSTALLER/OPERATOR

to conduct a job specic risk assessment prior to use. Job specic

risk assessment MUST be repeated for each different set up,

material, and location.

The risk assessment MUST conform to the Health and Safety at

Work Act 1974 and other relevant Health and Safety legislation.

The risk assessment MUST consider potential material or substance

hazards including:

• Aerosols

• Biological and microbiological (viral or bacterial) agents

• Combustible materials

• Dusts

• Explosion

• Fibers

• Flammable substances

• Fluids

• Fumes

• Gases

• Mists

• Oxidizing Agents

WARNING AND SAFETY INSTRUCTIONS

7

866-795-1586 • WWW.STONEAGETOOLS.COM

WARNING AND SAFETY INSTRUCTIONS

WARNING

Operations with this equipment can be potentially hazardous.

Caution MUST be exercised prior to and during machine and water

jet tool use. Please read and follow all of these instructions, in addition

to the guidelines in the WJTA Recommended Practices handbook,

available online at www.wjta.org. Deviating from safety instructions

and recommended practices can lead to severe injury and/or death.

• Do not exceed the maximum operating pressure specied for

any component in a system.

• The immediate work area MUST be marked off to keep out

untrained persons.

• Inspect the equipment for visible signs of deterioration,

damage, and improper assembly. Do not operate if damaged,

until repaired.

• Make sure all threaded connections are tight and free of leaks.

• The AutoStroke (AST-200-V2) is an accessory to the

AUTOBOX

®

ABX-2L, ABX-2L-V2, ABX-3L, and ABX-3L-V2.

Users of the AUTOBOX

®

ABX-2L, ABX-2L-V2, ABX-3L, and

ABX-3L-V2 MUST be trained and/or experienced in the use

and application of high-pressure technology and cleaning,

as well as all associated safety measures, according to the

WJTA Recommended Practices for the use of High-pressure

Waterjetting Equipment.

• The Control Box should be located in a safe location where the

Operator has good visibility of the AUTOBOX

®

ABX-2L, ABX-

2L-V2, ABX-3L, and ABX-3L-V2.

• The AUTOBOX

®

ABX-2L, ABX-2L-V2, ABX-3L, ABX-3L-V2,

AutoStroke (AST-200-V2), and Control Box MUST be

supervised at all times and should never be left unattended.

• Test the Control Box before operating the AUTOBOX

®

ABX-2L,

ABX-2L-V2, ABX-3L, ABX-3L-V2, and AutoStroke (AST-200-V2)

with high-pressure water to verify the control valves move the

hose in the intended direction, and that the dump valve and

hose clamp are working properly. See the “Operation” section

of this manual for adjustment settings.

• Always de-energize the system before opening the door to

service or replace any parts. Failure to do so can result in severe

injury and/or death.

PRE-RUN SAFETY CHECK

Refer to WJTA-IMCA’s, Recommended Practices For The Use Of

High-pressure Waterjetting Equipment and/or The Water Jetting

Association’s, WJA Code of Practice for additional safety information.

• Complete a job specic risk assessment and act on the resulting

actions.

• Adhere to all site specic safety procedures.

• Ensure the waterblasting zone is properly barricaded and that

warning signs are posted.

• Ensure the work place is free of unnecessary objects (e.g. loose

parts, hoses, tools).

• Ensure all Operators are using the correct Personal Protective

Equipment (PPE).

• Check that the air hoses are properly connected and tight.

• Check all hoses and accessories for damage prior to use. Do

not use damaged items. Only high quality hoses intended for

waterblast applications should be used as high-pressure hoses.

• Check all high-pressure threaded connections for tightness.

• Test the Control Box before operating the AUTOBOX

®

ABX-2L

ABX-2L-V2, ABX-3L, ABX-3L-V2, and AutoStroke (AST-200-V2)

with high-pressure water to verify the control valves move the

hose in the intended direction, and that the dump valve and

hose clamp are working properly. See the “Operation” section

of this manual for adjustment settings.

• Ensure that Operators never connect, disconnect, or tighten

hoses, adapters, or accessories with the high-pressure water

pump unit running.

• Ensure no personnel are in the hydroblasting zone.

WARNING AND SAFETY INSTRUCTIONS

8866-795-1586 • WWW.STONEAGETOOLS.COM

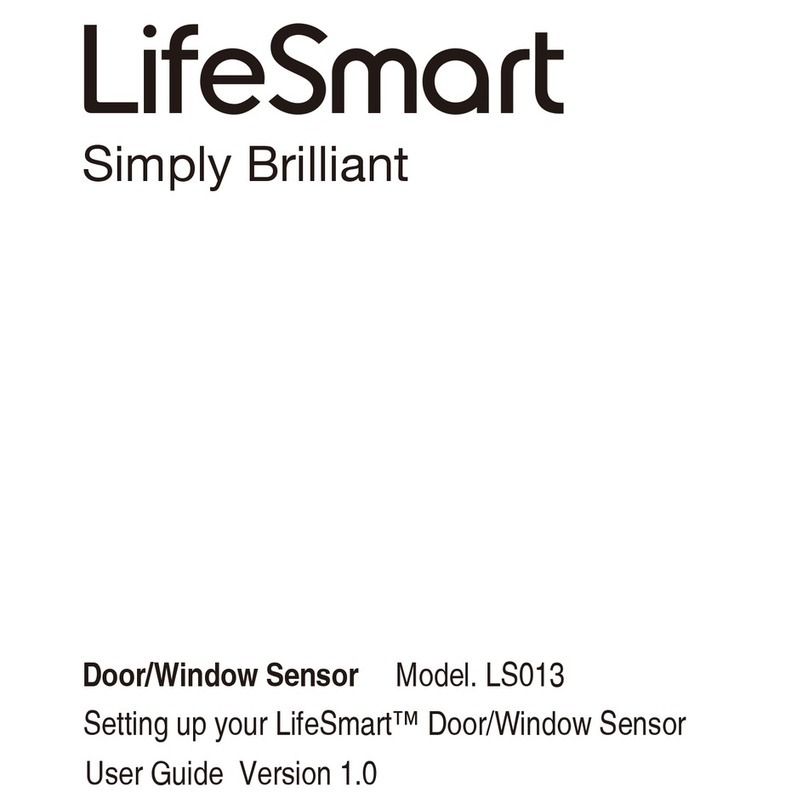

SYSTEM ASSEMBLY - OVERVIEW

TOOLS REQUIRED FOR INSTALLATION

TOOL SIZE WHERE USED

ALLEN WRENCH HEX KEY 5/32” FLAT HEAD CAP SCREWS

CLOSED END BOX WRENCH 7/16” HEX HEAD BOLTS AND QUICK DISCONNECT FITTINGS

OPEN END BOX WRENCH 9/16” 1/4 JIC FITTINGS ON HOSE ENDS

OPEN END BOX WRENCH 3/4” JIC FITTING ASSEMBLIES ON MANIFOLD

OPEN END BOX WRENCH 7/8” 1/2 JIC FITTINGS ON HOSE ENDS

LOCTITE®567 PIPE DOPE OR TAPE - ALL NEW OR REPLACED TAPERED PIPE FITTINGS

NOTE: THIS COLOR CODE

SYSTEM IS USED THROUGH THE

SYSTEM FOR TUBE AND HOSE

CONNECTIONS AND COLOR I.D.

FORWARD

REVERSE

# DESCRIPTION QTY

1AST 277-25 AUTOSTROKE™ UMBILICAL ASSEMBLY 1

2 AST 301-V2 AUTOSTROKE™ BOX WITH GENERATOR 1

3 AST 340 AUTOSTROKE™ HOSE BUNDLE ASSY 1

AUTOSTROKE™(AST-200-V2)

AUTOMATIC BLOCKAGE SENSOR

9

866-795-1586 • WWW.STONEAGETOOLS.COM

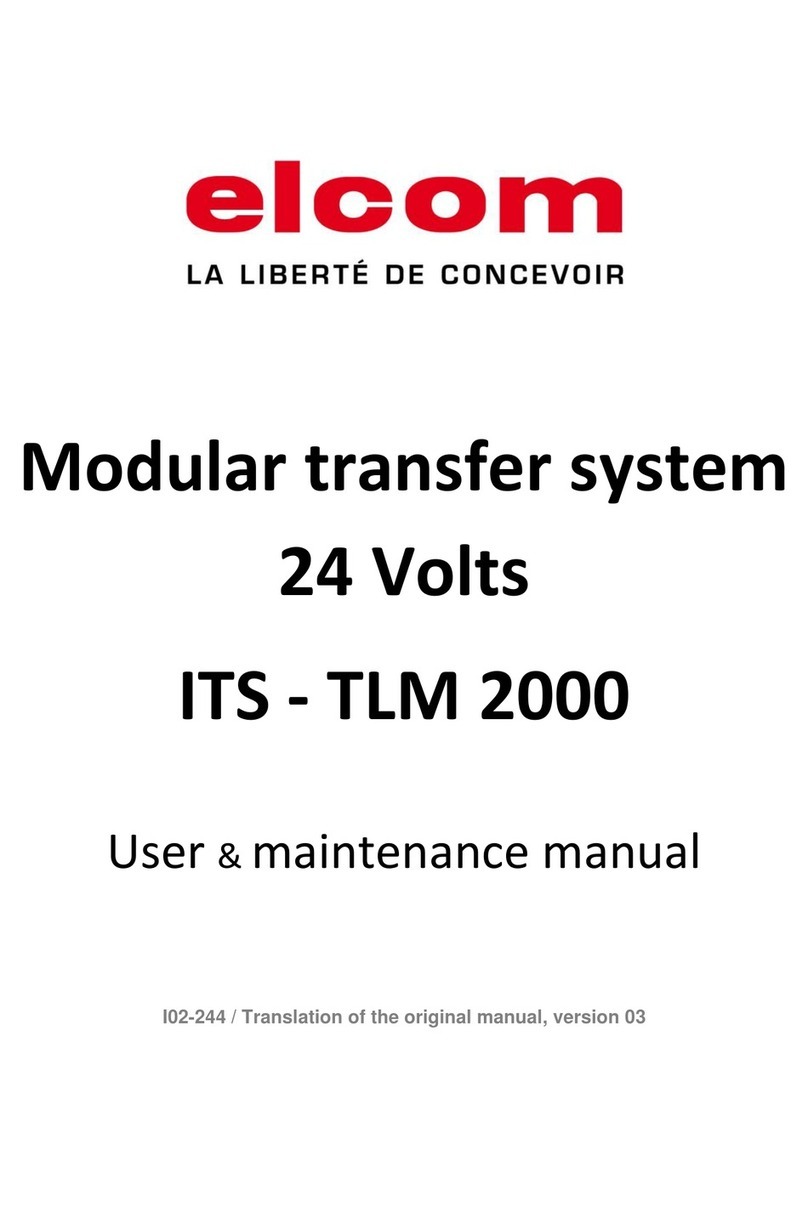

SYSTEM ASSEMBLY - OVERVIEW

AUTOSTROKE™

(AST 275)

MANIFOLD

ASSEMBLY

AUTOSTROKE™

(AST-200-V2)

ASSEMBLY

AUTOSTROKE™

(AST-200-V2)

HOSE, FORWARD

AUTOSTROKE™

(AST-200-V2)

HOSE, REVERSE

1/4” TUBING LINES

(COME BUNDLED IN NYLON SHEATH)

AUTOSTROKE™(AST-200-V2)

SHOWN WITH AUTOBOX® ABX-2L AND CB-ABX ASSEMBLY

10 866-795-1586 • WWW.STONEAGETOOLS.COM

ABX-2L AND ABX-2L-V2 MANIFOLD UPGRADE

THE AUTOSTROKE AIR MANIFOLD CONVERSION OVERVIEW

This conversion guide describes how to replace the Air Manifold and add T-connections in order to provide necessary air signals from the

ABX-2L and ABX-2l-V2 to the AutoStroke. This rst step is mandatory to allow the AutoStroke AST-200-V2 to function with the Autobox®

ABX-2L and ABX-2L-V2.

THE AUTOSTROKE AIR MANIFOLD CONVERSION PARTS KIT

The parts below are included in the AST 275 AutoStroke Air Manifold Conversion Kit.

ORIGINAL

AIR MANIFOLD

ABX-2L AND

ABX-2L-V2

BEFORE

ABX-2L AND

ABX-2L-V2

AFTER

AUTOSTROKE

AIR MANIFOLD

AUTOSTROKE Air Manifold Assembly

Quick Disconnect Fittings

NOTICE

The Autobox® ABX-3L and ABX-3L-V2 come ready to hook-up to the AutoStroke and therefore this upgrade is NOT necessary for the

Autobox® ABX-3L and ABX-3L-V2.

11

866-795-1586 • WWW.STONEAGETOOLS.COM

FIGURE 1

ABX-2L AND ABX-2L-V2 MANIFOLD UPGRADE

REMOVING THE ABX-2L AIR MANIFOLD

1. Remove the 4 at head cap screws from the Top Plate using a 5/32 Allen wrench hex key. Set the Top Plate and screws aside, and open

the Side Door. (FIGURE 1)

2. Unplug the three tubes from the bottom of the manifold (FIGURE 2) and remove the 2 hex head bolts using a 7/16 socket driver or box

wrench. Remove and retain the top 3 JIC tting assemblies, and disconnect the 3 air tubes from the bottom of the Air Manifold. Discard

the old manifold. (FIGURE 3)

FIGURE 2

INSTALLING THE AUTOSTROKE AIR MANIFOLD CONVERSION

1. Install the 3 JIC tting assemblies to the new AutoStroke Air Manifold. Use pipe dope or tape on the NPT tapered threads. Re-attach the

air manifold using the 2 hex head bolts that were reserved from the original manifold assembly. (FIGURE 1)

2. Reconnect the 3 air tubes (blue, red, and black) to the push-to-connect ttings on the bottom of the air manifold. (FIGURE 2)

FIGURE 3

FIGURE 2FIGURE 1

DISCONNECT

12 866-795-1586 • WWW.STONEAGETOOLS.COM

ABX-2L AND ABX-2L-V2 MANIFOLD UPGRADE

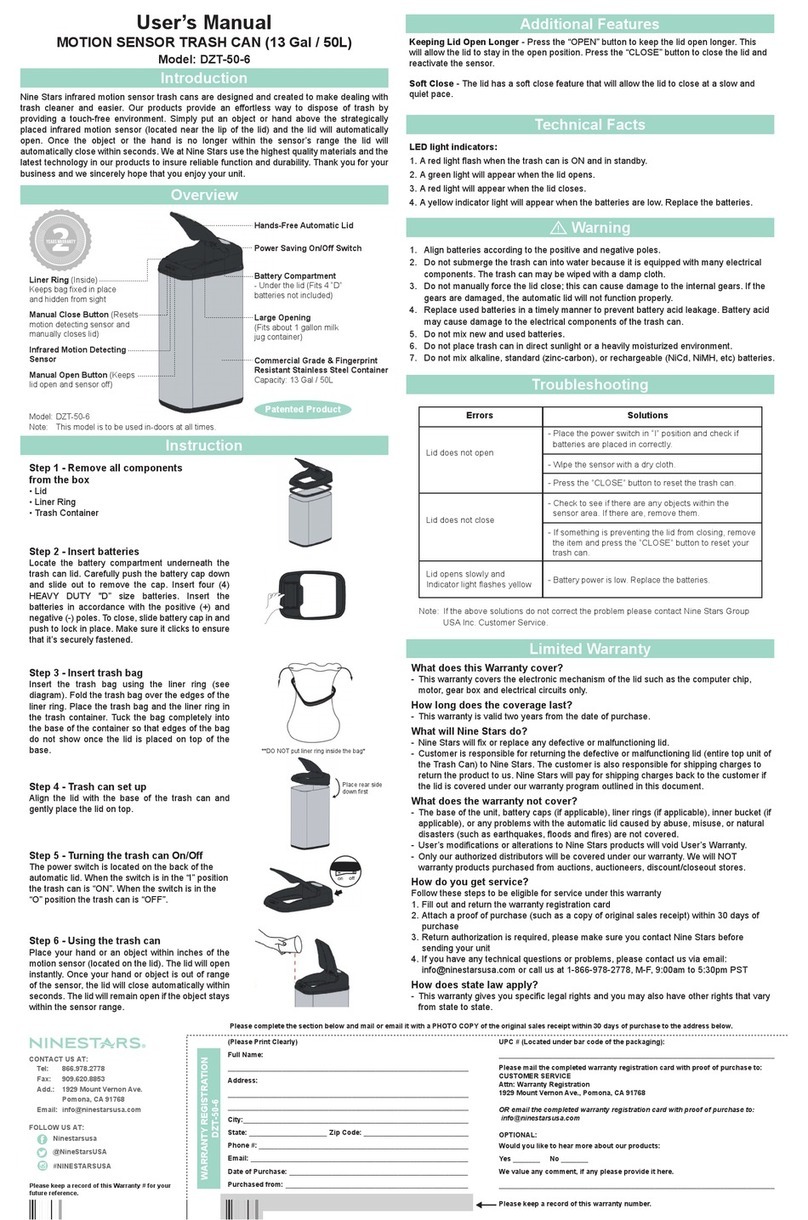

SPLICING THE TUBING FOR THE T-FITTINGS

1. Disconnect the red and black air tubes from the ttings on the left side of the ow controls. (FIGURE 1) Cut exactly 2 inches off the end of

the red tube and 3 inches off the black tube. (FIGURE 2)

2. Connect the red and black tubes with the T-ttings from the manifold to the ttings on the left side of the ow controls. Connect the

other end of the T-ttings to the end of the cut tubing. The tubes from the manifold assembly should lie between the ow control knobs.

(FIGURE 3)

3. Attach the Top Plate and close the Side Door Assembly. (FIGURE4)

4. Install the two Quick Disconnect Fittings to the brass elbows using pipe dope or tape on the tapered threads. (FIGURE 5)

FIGURE 1 FIGURE 2

FIGURE 4

FIGURE 3

FIGURE 5

COMPLETED

OR

Remove 3”

Remove 2”

CONNECT T-FITTINGS

13

866-795-1586 • WWW.STONEAGETOOLS.COM

FIGURE 2

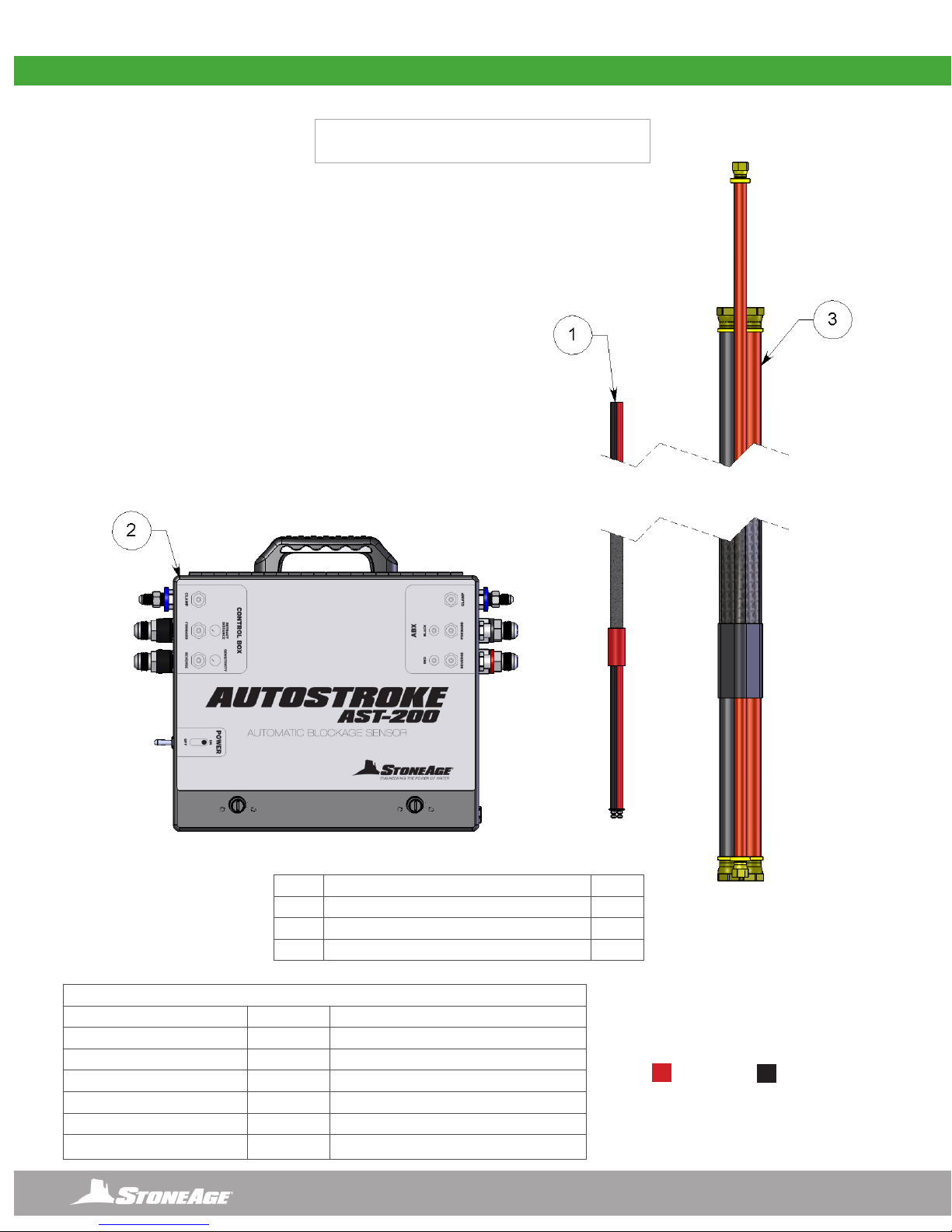

ABX-2L AND ABX-2L-V2 AUTOSTROKE SET-UP

CONNECTING THE AST-200-V2 AUTOSTROKE TO THE CB-ABX CONTROL BOX

1. Disconnect the air hose from the back of the Control Assembly. Loosen the Thumb Screw on the Pole Mount on the Control Assembly.

Carefully lift the Control Assembly off of the Mounting Pole and put aside. (Figure 1)

2. Slide the AutoStroke Assembly onto the Mounting Pole and hand tighten the Thumb Screw. Then slide the Control Assembly back

onto the Mounting Pole. Align the Thumb Screw with the top hole on the Mounting Pole and hand tighten. (Figure 2)

3. Connect the air hose from the FRL to the back of the Control Assembly. (Figure 3)

DISCONNECT

FIRST

THUMB

SCREW

POLE

MOUNT

MOUNTING

POLE

THUMB

SCREW

CONTROL

ASSEMBLY

AUTOSTROKE

ASSEMBLY

FIGURE 1 FIGURE 2 COMPLETE

FIGURE 3

14 866-795-1586 • WWW.STONEAGETOOLS.COM

HOSE CONNECTIONS

1. Connect the BLACK and RED 1/2” lines from the AutoStroke “Forward” and “Reverse” connections to the “Forward” and “Reverse”

connections on the back of the CB-ABX. Connect the SHORT 1/4” I.D. Hose to the tting marked “CLAMP” on the left side of the

AutoStroke to the “CLAMP” tting on the Control Box. (Figure 1)

2. Connect the LONG 1/4” I.D. Hose to the tting marked “CLAMP” on the right side of the AutoStroke and the opposite end to the

“CLAMP” tting on the ABX-2L or ABX-2L-V2. Insert the ends of the 1/4” BLACK and RED tubing into the press lock ttings on the

right side of the AutoStroke. Push the opposite ends of each tube into the color labeled, press lock, ttings on the manifold atop the

ABX-2L or ABX-2L-V2. Connect the BLACK and RED 1/2” lines to the right side of the AutoStroke marked “Forward” and “Reverse”

and connect the opposite ends to the manifold on the ABX-2L or ABX-2L-V2. (Figure 2 & 3)

3. Skip to the “OPERATIONS” page of this manual.

FIGURE 2

CORRECT AUTOSTROKE CONNECTION TO ABX-2L

ABX-2L AND ABX-2L-V2 AUTOSTROKE SET-UP

FIGURE 1

FORWARD

REVERSE

CLAMP TO

AUTOSTROKE

FORWARD

REVERSE

CLAMP TO

ABX-2L

FIGURE 3

NOTICE

The AutoStroke and the CB-ABX are labeled “Forward” and “Reverse”and color coded. Make sure the hoses mate to their corresponding

labeled connections on both ends.

CORRECT AUTOSTROKE CONNECTION TO CONTROL BOX

15

866-795-1586 • WWW.STONEAGETOOLS.COM

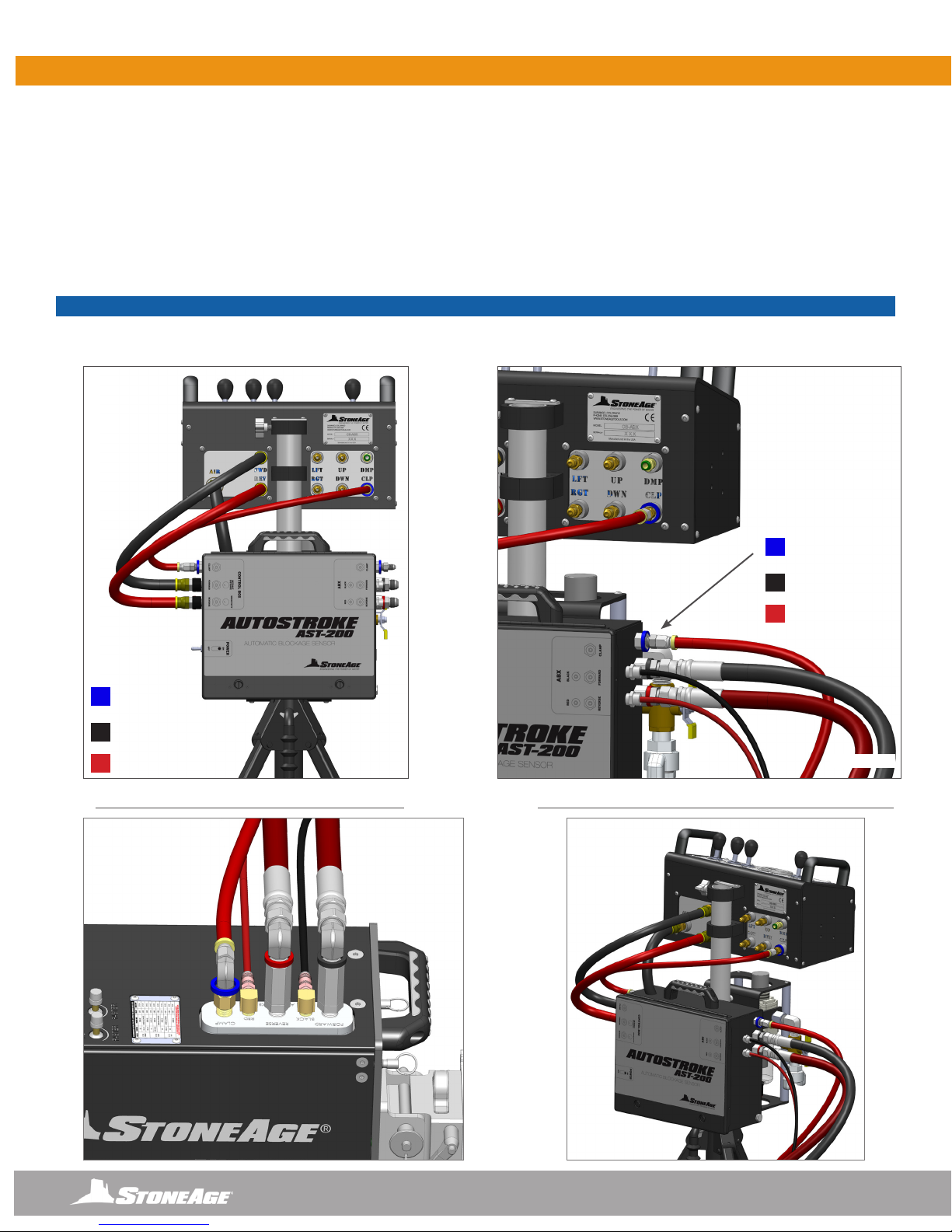

ABX-2L AND ABX-2L-V2 AUTOSTROKE SET-UP ABX-3L AND ABX-3L-V2 AUTOSTROKE SET-UP

CONNECTING THE AST-200-V2 AUTOSTROKE TO THE CBX-ABX CONTROL BOX

1. Disconnect the air hose from the back of the Control Assembly. Loosen the Thumb Screw on the Pole Mount and carefully lift the

Control Assembly off of the Mounting Pole. Put the Control Assembly aside. (Figure 1)

2. Slide the AutoStroke Assembly onto the Mounting Pole, with the Decal side facing away from the FRL. Then hand tighten the Thumb

Screw. Then slide the Control Assembly back onto the Mounting Pole. Then hand tighten the Thumb Screw to secure the Control

Assembly to the Mounting Pole. (Figure 2)

3. Connect the air hose from the FRL to the back of the Control Assembly. (Figure 3)

DISCONNECT

FIRST

THUMB

SCREW

POLE

MOUNT

MOUNTING

POLE

THUMB

SCREW

CONTROL

ASSEMBLY

AUTOSTROKE

ASSEMBLY

FIGURE 1 FIGURE 2 COMPLETE

FIGURE 3

16 866-795-1586 • WWW.STONEAGETOOLS.COM

CORRECT AUTOSTROKE

CONNECTION TO CONTROL BOX

CORRECT AUTOSTROKE

CONNECTION TO ABX-3L OR ABX-3L-V2

FIGURE 3

ABX-3L AND ABX-3L-V2 AUTOSTROKE SET-UP

NOTICE

The AutoStroke and the CBX-ABX are labeled “Forward” and “Reverse”and color coded. Make sure the hoses mate to their corresponding

labeled connections on both ends.

FIGURE 2

FORWARD

REVERSE

CLAMP TO

CONTROL BOX

FIGURE 1

FORWARD

REVERSE

CLAMP TO

CONTROL BOX

HOSE CONNECTIONS

1. Connect the BLACK and RED 1/2” lines from the AutoStroke “Forward” and “Reverse” connections to the “Forward” and “Reverse”

connections on the back of the CBX-ABX. Connect the SHORT 1/4” I.D. Hose to the tting marked “CLAMP” on the left side of the

AutoStroke to the “CLAMP” tting on the Control Box. (Figure 1)

2. Connect the LONG 1/4” I.D. Hose to the tting marked “CLAMP” on the right side of the AutoStroke and the opposite end to the

“CLAMP” tting on the ABX-3L or ABX-3L-V2. Insert the ends of the 1/4” BLACK and RED tubing into the press lock ttings on the

right side of the AutoStroke. Push the opposite ends of each tube into the color labeled, press lock, ttings on the manifold atop the

ABX-3L or ABX-3L-V2. Connect the BLACK and RED 1/2” lines to the right side of the AutoStroke marked “Forward” and “Reverse”

and connect the opposite ends to the manifold on the ABX-3L or ABX-3L-V2. (Figure 2 & 3)

17

866-795-1586 • WWW.STONEAGETOOLS.COM

OPERATION

AUTOSTROKE AST-200-V2 FUNCTIONS

• With the AutoStroke in the “OFF” Position, run the Autobox Tractor in Reverse until the Air Motor Generator goes silent. This may take up

to one minute and will allow the Air Motor Generator to charge.

• Turn the AutoStroke toggle to the “ON” Position and make sure the power light comes on.

• To setup the AutoStroke turn the SENSITIVITY knob all the way in the counter-clockwise direction. (Increase turn clockwise, Decrease

turn counter-clockwise)

• Next position your nozzles so they hit the tube sheet face and run them into the tube sheet. While holding the feed in lever increase the

sensitivity until it just starts to peck at the tube sheet face.

• Adjust the RETRACT DISTANCE (Increase turn clockwise, Decrease turn counter-clockwise) until you like how far it is retracting the

nozzles.

• The AutoStroke is now operational.

+ -

+ -

18 866-795-1586 • WWW.STONEAGETOOLS.COM

The AutoStroke™ (AST-200-V2) should be stored in a dry location between jobs. Before storing the unit, use compressed air to blow out

any debris and moisture. Use mild soapy water to clean the machine in order to remove corrosive materials. Apply a small amount of air

tool oil directly into the forward and reverse ttings. Install the dust caps onto all ttings to keep moisture and dirt out.

STORAGE, TRANSPORTATION, AND HANDLING

Contact StoneAge for Safety Data Sheets for material usage and any other pertinent information that may be required.

MAINTENANCE

Maintenance Item Frequency Maintenance Required

Air Motor Generator Replacement When Needed If the Air Motor Generator fails on the AutoStroke, it is possible to replace

it. Please call your StoneAge Customer Service Representative to order

part number AMG-100-V2 AIR MOTOR GENERATOR, WITH FITTINGS.

Follow the Air Motor Generator Replacement instructions located in this

manual

All Air Fittings After each use Reinstall all dust caps to protect from dirt and moisture.

Air Lines Before each use Blow out before making connections to the AutoStroke

Electrical Connections Frequently Visually inspect for corrosion.

MAINTENANCE

NOTICE

Electronic components are not user serviceable. If troubleshooting the system fails it must be sent back to StoneAge Tools for service.

Contact your customer service representative. 1-866-795-1586

Problem Solution

AST-200 is not functioning -Check that airlines are connected properly

-Check that switch is on and red LED is lit while feeding forward

-Increase sensitivity

-Verify that fuse is not blown

AST-200 continues to reverse feed -Check that hose is not getting hung up behind the ABX

-Reduce sensitivity

-Reduce hose drag

AST-200 power light is not coming on but the

switch is in the “ON” positon

- Toggle rhe AutoStroke to the “OFF” Position, run the Autobox Tractor in Reverse until the

Air Motor Generator goes silent. This may take up to one minute and will allow the Air Motor

Generator to charge. The charge time could be longer with lower pressures.

TROUBLESHOOTING

19

866-795-1586 • WWW.STONEAGETOOLS.COM

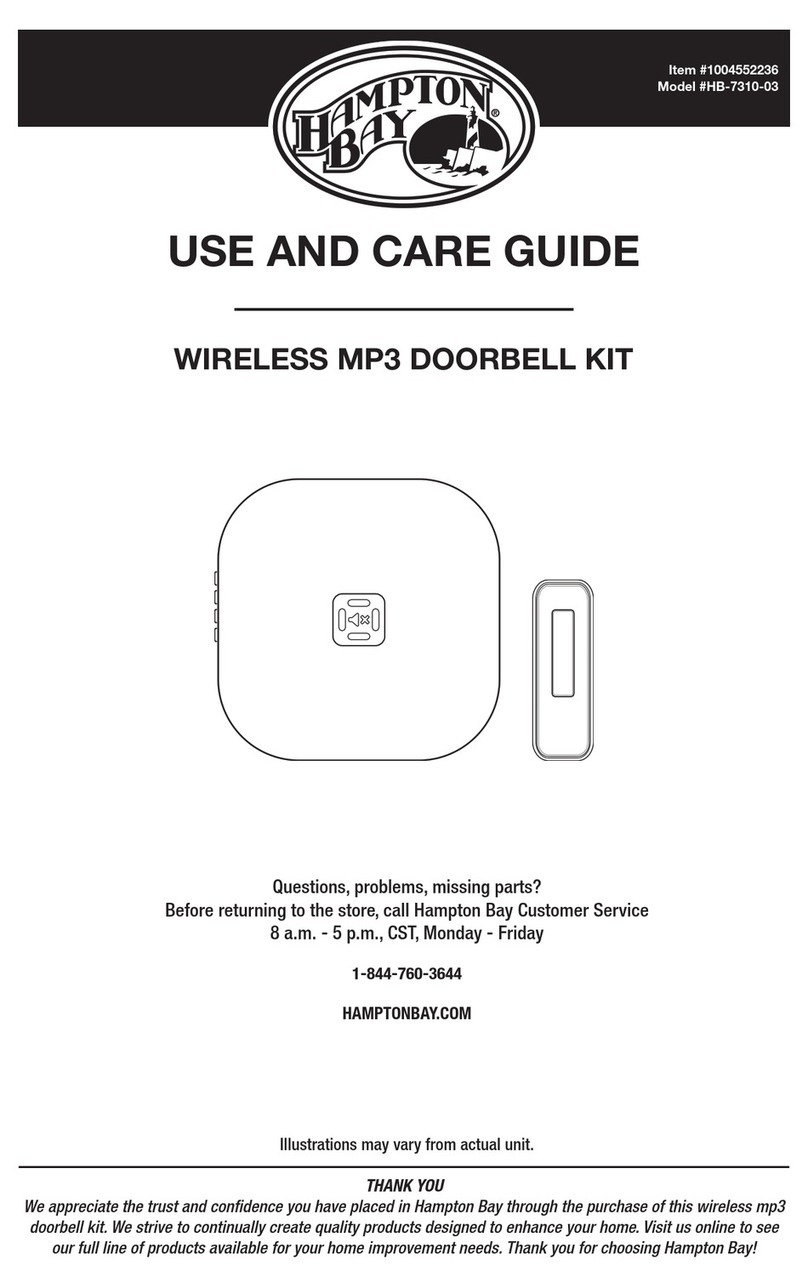

AIR MOTOR GENERATOR REPLACEMENT INSTRUCTIONS

These replacement instructions describe how to replace an air motor generator within an AST-200-V2 AutoStroke.

AIR MOTOR GENERATOR REMOVAL INSTRUCTIONS

AIR MOTOR GENERATOR REPLACEMENT

NOTICE

Airline connections should be removed at least 10 minutes before servicing to allow time for stored electrical energy to dissipate.

1. Using a at screwdriver, turn the quarter turn latches

counterclockwise 90 degrees and open the AutoStroke

enclosure.

2. Disconnect the 2 air tubes from the air motor generator

AST-200-V2 AUTOSTROKE shown without cover

Air Motor Generator location

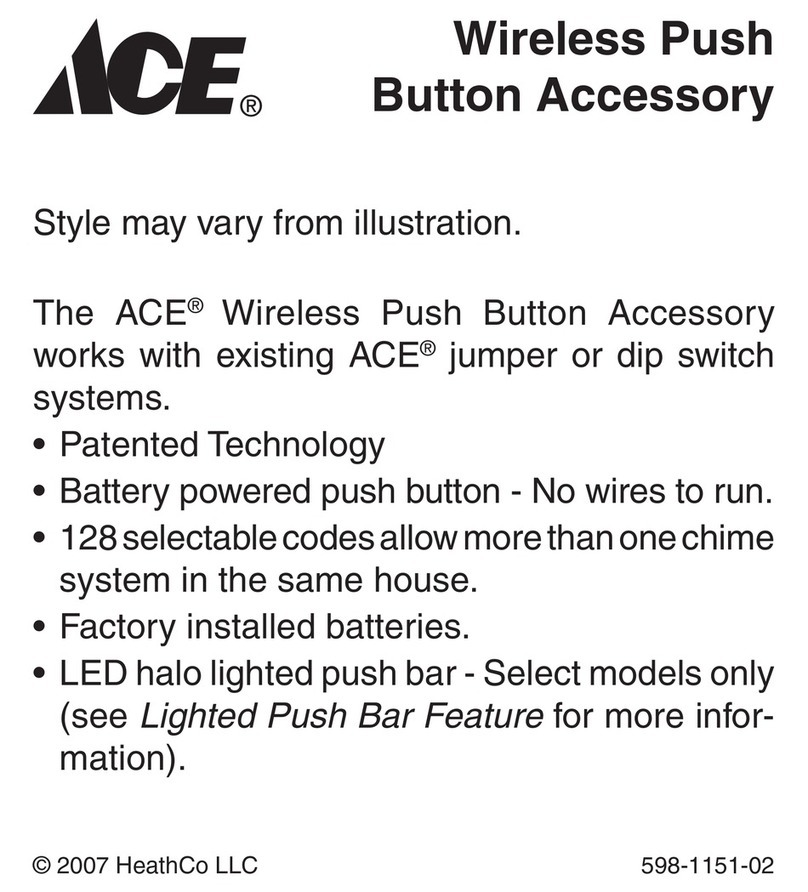

3. Depress the tab on the back of the electrical

connector and carefully separate the electrical

connection.

20 866-795-1586 • WWW.STONEAGETOOLS.COM

AIR MOTOR GENERATOR REPLACEMENT

4. Remove the four screws securing the Air Motor

Generator with a 9/64” Hex Key

5. Remove the Air Motor Generator from the AutoStroke enclosure.

AIR MOTOR GENERATOR REMOVAL INSTRUCTIONS.....CONTINUED

AIR MOTOR GENERATOR INSTALLATION INSTRUCTIONS

1. Install the replacement Air Motor Generator into the AutoStroke

enclosure as shown.

2. Install the four screws securing the air motor generator

with a 9/64” Hex Key.

3. Carefully reconnect he electrical connection.

Table of contents

Popular Accessories manuals by other brands

HAMPTON BAY

HAMPTON BAY HB-7310-03 Use and care guide

BM PRO

BM PRO SmartSense Installing

Audio Control

Audio Control The Epicenter Plus owner's manual

Master cool

Master cool MMBT12 Installation and operation manual

Silvercrest

Silvercrest HG02989A Operation and safety notes

Ninestars

Ninestars DZT-50-6 user manual

RAISE 3D

RAISE 3D N2 installation guide

Heath Zenith

Heath Zenith Wireless Push Button Accessory 598-1151-02 owner's manual

Life Smart

Life Smart LS086WH quick start guide

Best Choice Products

Best Choice Products SKY5472 instruction manual

MD SPORTS

MD SPORTS Meijer Assembly instructions

BJ Live

BJ Live BJ-234 user guide