StoneAge SPINCAT SC-125 User manual

PL 625 REV B

(05/2018)

SPINCAT SC 125

ROTARY NOZZLE

USER MANUAL

2866-795-1586 • WWW.STONEAGETOOLS.COM

TABLE OF CONTENTS

MANUFACTURER’S INFORMATION ...........................................................3

SPECIFICATIONS..........................................................................3

DESCRIPTION OF EQUIPMENT AND INTENDED USE ....................................3

KEY FEATURES ...........................................................................3

SYSTEM ASSEMBLY - OVERVIEW ............................................................4

PRE-RIH CHECKLIST ..........................................................................5

LUBRICANT REPLACEMENT INSTRUCTIONS ................................................6

HIGH PRESSURE SEAL REPLACEMENT ......................................................7

DISASSEMBLY .................................................................................8

ASSEMBLY .....................................................................................10

TROUBLESHOOTING ..........................................................................12

TOOL STORAGE................................................................................12

REPLACEMENT PART WEAR INFORMATION .................................................14

MAINTENANCE, PARTS, AND OVERHAUL KITS ..............................................15

TERMS AND CONDITIONS AND WARRANTY .................................................16

3

866-795-1586 • WWW.STONEAGETOOLS.COM

MANUFACTURER’S INFORMATION

SPECIFICATIONS

Tool Family: SpinCat

Tool Model: SC-125

Pressure Range: 1-5k psi (70-340 bar)

Flow Range: .5 to 1.5 bpm (21 to 63 gpm)

Flow Rating: 2.3 Cv

Rotation Speed: 10-50 rpm

Inlet Connection: 7/8" AMMT

PSI Loss (@ 1 bpm): 330 psi (23 bar)

Tension (pull): Safe load to 8500 lbs (3856 kg)

Compression (set down): Safe load to 12000 lbs (5443 kg)

Outside Diameter: 1.25 in. 32 mm

Overall Length: 8.3 in. 203 mm

Weight: 1.9 lbs .9 kg

Maximum Temperature: 390° F 200° C

StoneAge Inc.

466 S. Skylane Drive

Durango, CO 81303, USA

Phone: 970-259-2869

Toll Free: 866-795-1586

www.stoneagetools.com

StoneAge Europe

Unit 2, Britannia Business Centre

Britannia Way

Malvern WR14 1GZ

United Kingdom

Phone: +44 (0) 1684 892065

This manual must be used in accordance with all applicable national laws. The manual shall

be regarded as a part of the machine and shall be kept for reference until the nal dismantling

of the machine, as dened by applicable national law(s).

Updated manuals can be downloaded at:

https://www.stoneagetools.com/manuals

DESCRIPTION OF EQUIPMENT AND

INTENDED USE

The SC-125 provides well intervention

teams with an advanced solution for 1 1/4”

CT BHA’s requiring a “slick” or Slimhole

prole. Proven effective in wells with small

ID restrictions, heavy scale deposition, and

a history of entry challenges, the SC-125’s

smooth prole aids reaching target depths

the rst time then delivers powerful impact

force and dwell time to enhance perf

stimulation and clean-out objectives.

KEY FEATURES:

• Recessed head ensures rotation to

continue when tool is against well bore

wall and contributes to “slick” prole

• Constructed of hardened stainless

steel for strength, durability & chemical

resistance

• Effectively cuts scale in HCL acid clean-

out jobs

• Drilled head sized for nominal ow rates

of .5 to 1.5 bpm

• Viscous speed control

• Field serviceable

JETTING

The SC-125 has two drilled head options for nominal ow rates of .5 to 1.5 bpm

4866-795-1586 • WWW.STONEAGETOOLS.COM

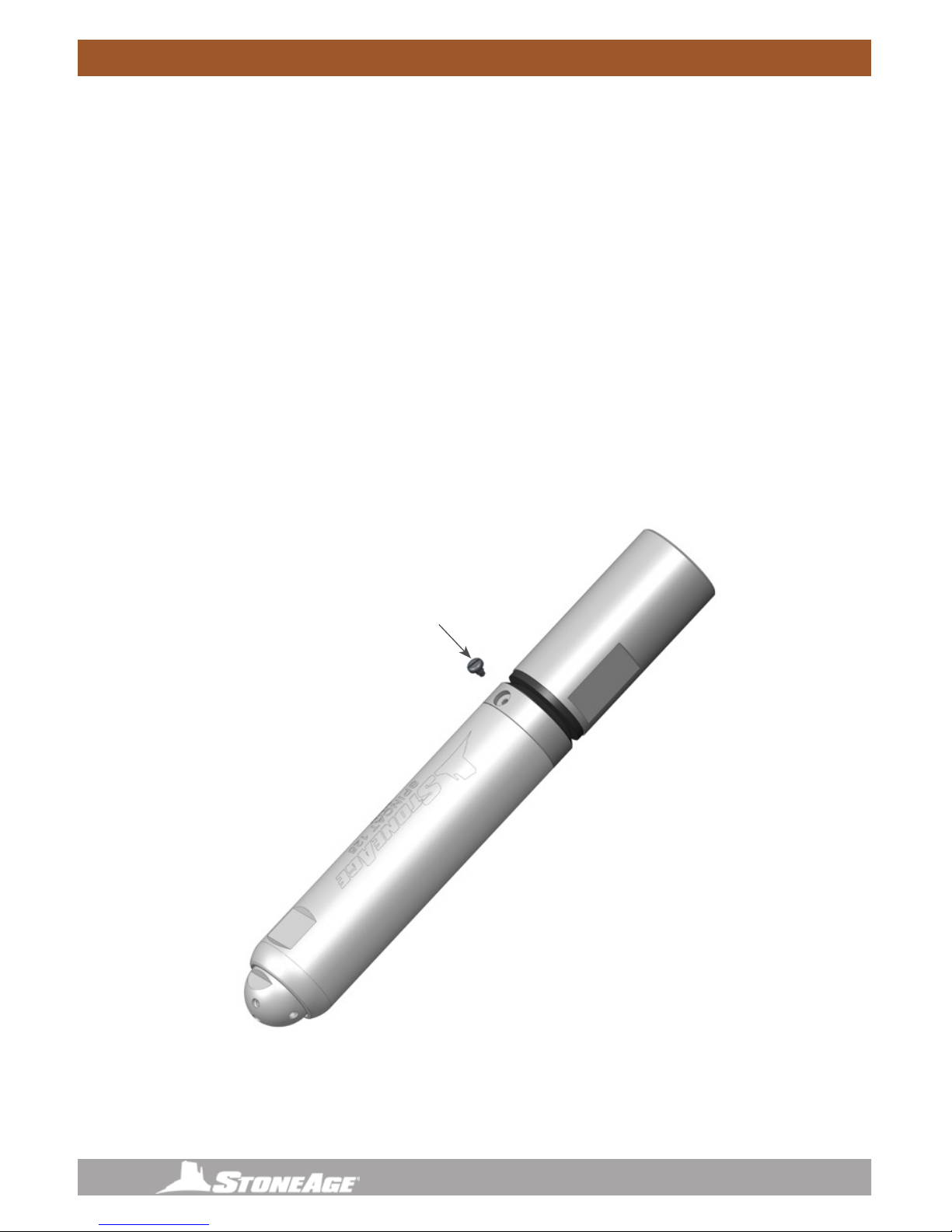

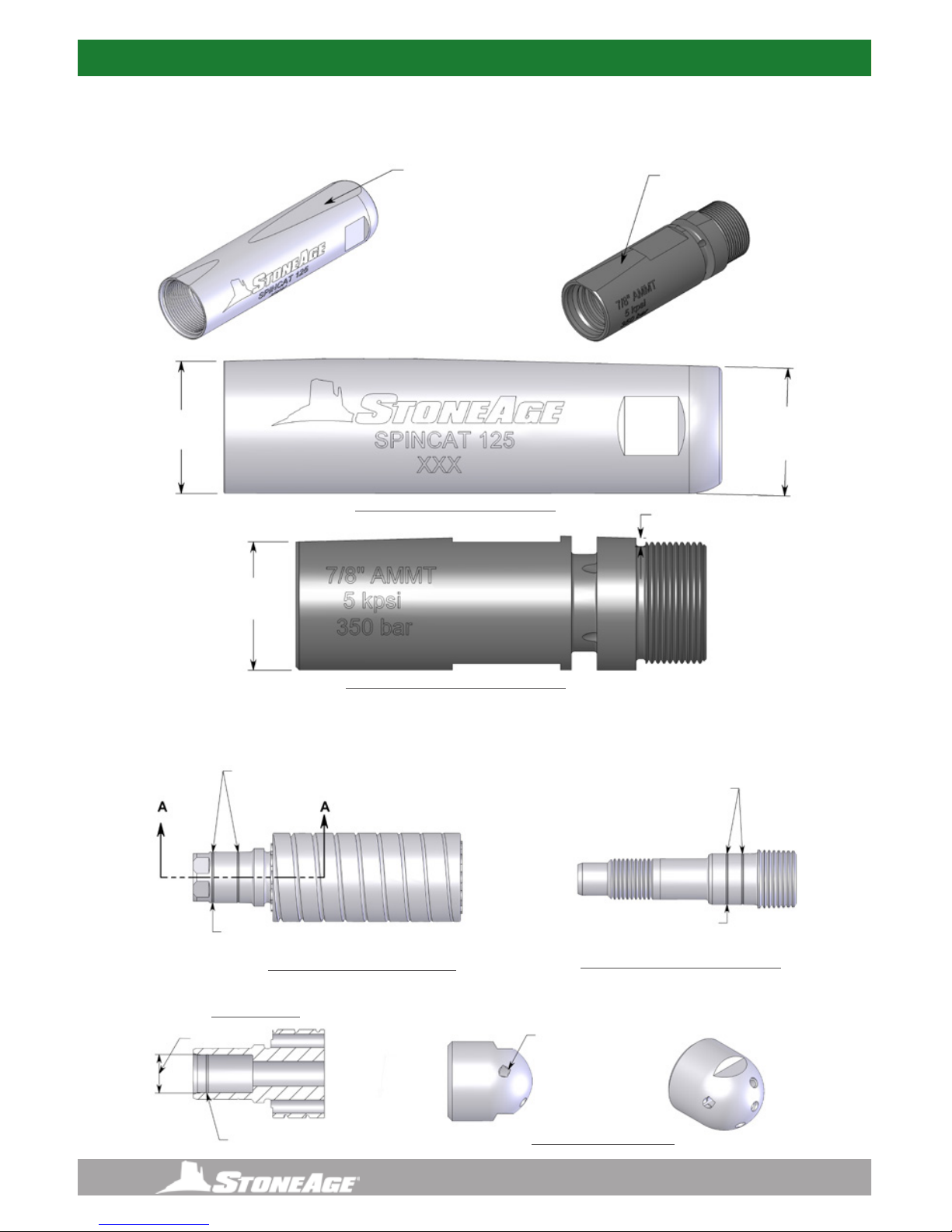

OVERVIEW

DESCRIPTION:

The Spincat is a self-rotating swivel designed for coil tubing well service. The powerful

rotating jets cover a large area for efcient cleaning. Jet reaction force powers rotation

of the head. An internal uid speed control maintains rotation speeds of 10 to 50 rpm.

The Spincat uses a synthetic silicone viscous uid for lubrication. The uid is available

from StoneAge as part number BJ 048-S.

The tool has a straight ow-through design with a leak-free high pressure seal so pump

power is not wasted. It has a 7/8" AMMT box inlet thread. The tool can be used at

temperatures up to 200°C (392°F), and can be used with up to 30% HCL and Nitrogen

injection. (Note: if used with HCL, ush tool with clean water after use.)

If the SpinCat™ will be used with high external borehole pressures, make certain that the

body of the tool is completely full of lubricating uid; air pockets are compressible and

this could lead to oil seal failure and loss of lubrication.

The SpinCat™ can be used at operating pressures of 1000 to 5000 psi and ow rates of

0.5 to 1.5 bpm (21 to 63 gpm) with standard head porting.

The standard nozzle head has ve drilled ports; one at 15 degrees forward, two at 45

degrees forward and two at 90 degrees to the axis of rotation. Customized heads

are available with variable drilled patterns to concentrate the ow in a particular direction.

FLOW RANGE

PRESSURE

1000-5000 PSI .5 -1.5 BPM

DANGER

Operations with this equipment can be potentially hazardous. Caution must be exercised

prior to and during machine and water jet tool use. Please read and follow all of these

instructions, in addition to the guidelines in the WJTA Recommended Practices handbook,

available online at www.wjta.org. Deviating from safety instructions and recommended

practices can lead to severe injury and/or death.

5

866-795-1586 • WWW.STONEAGETOOLS.COM

PRE-RIH CHECKLIST

PRE-RIH CHECKLIST:

• After receipt on location, visually inspect the SpinCat™ to ensure no small debris

has entered the tool. NOTE: The SpinCat™ package includes a briefcase size

Pelican® case. We recommend keeping the SpinCat™ and spare set screws and

other parts inside the case.

• Verify there is no oil leaking from the set screw or body. If the set screw is missing

and oil has leaked out then perform the Lubrication procedure in this manual.

• Turn the SpinCat™ head by hand. It should rotate very smoothly but not spin freely.

There should not be any stoppage or feeling of binding or catching internally.

• Ensure the Weep seal on the inlet nut is in place. The function of this seal is to

prevent debris from plugging the vent holes. The vent hole’s function is to vent

internal pressure build-up should the high pressure (HP) tungsten impregnated seal

fail or leak intermittently while reseating itself. If the wiper seal is lost or missing it

can be replaced with a suitable size Viton® O-Ring as a temporary measure.

• The SpinCat™ is made of hardened stainless steel for long service life with strong

acids, chemicals and solvents. We recommend you do not use pipe wrenches

on the SpinCat™. Customers who have SpinCats™ 2-4 years old and are still in

excellent condition, NEVER use pipe wrenches on their SpinCats™. Over time

teeth cuts accumulate on the inlet nut, the body and head and “chew up” the tool.

Eventually these parts have to be replaced unnecessarily. Some customers do not

feel this is of signicant importance and if replacement parts becomes necessary

we can supply them.

• When function testing, watch for leakage along the body and behind the head. This

indicates an improperly redressed tool. Also watch for leakage from around the

Weep seal, the high pressure seal might leak during initial pressurization but should

stop once enough pressure to achieve rotation has been reached. The only place

water should be exiting the tool is through the nozzles. The head should rotate

slowly and smoothly.

• If the head does not rotate during a function test but it rotates easily by hand, it

could be the pump rate and pressure must be increased or the tool is simply “tight”

or “cold,” or there is very heavy oil in the tool and it will loosen up in the hole, or the

SpinCat™ may be jetted improperly. Check the SpinCat™ Jetting App. A simple

but frequent problem in function tests is the test uid does not contain viscosity

reducer but the job requires it due to extremely high friction pressures.

6866-795-1586 • WWW.STONEAGETOOLS.COM

LUBRICANT FILL INSTRUCTIONS

TOPPING OFF LUBRICANT:

The Spincat uses synthetic silicone viscous uid for a lubricant. To top off the

tool with lubricant, follow steps below. If the tool is being rebuilt or the seal

replaced, the lubricant should be poured directly into the body around the shaft

before the inlet nut is installed. To replace the high pressure seal, follow the steps

on the right.

1. Remove the Port Plug Assembly (FT 026).

2. Remove the Inlet Nut.

3. Rell the Body with viscous uid to 1/4" above the top of the upper Bearing.

4. Hold the Inlet nut at an angle with the Port Plug hole facing up. Thread Body onto Inlet Nut

and tighten to 50 ft-lb.

5. Install Port Plug

FT 026

Port Plug

with O-Ring

7

866-795-1586 • WWW.STONEAGETOOLS.COM

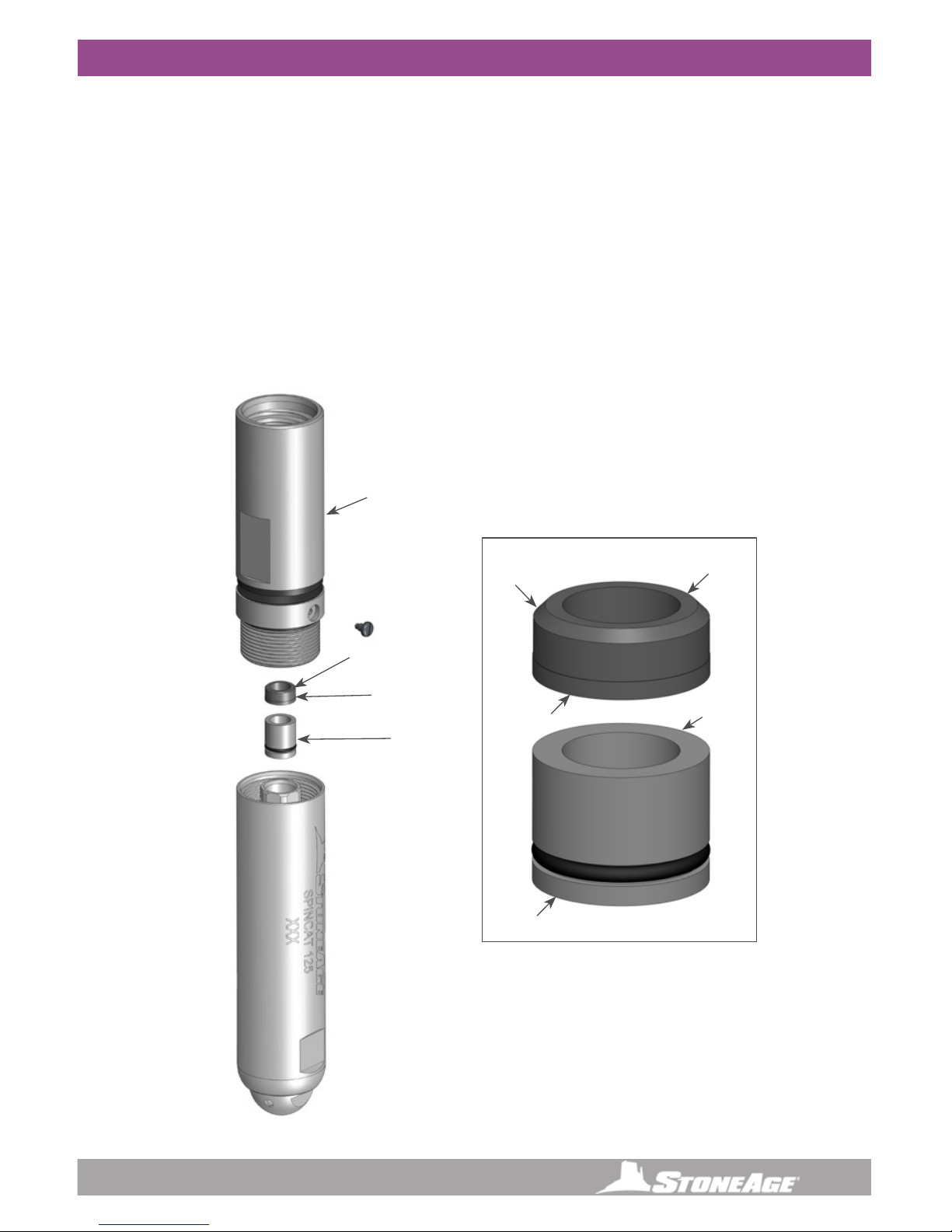

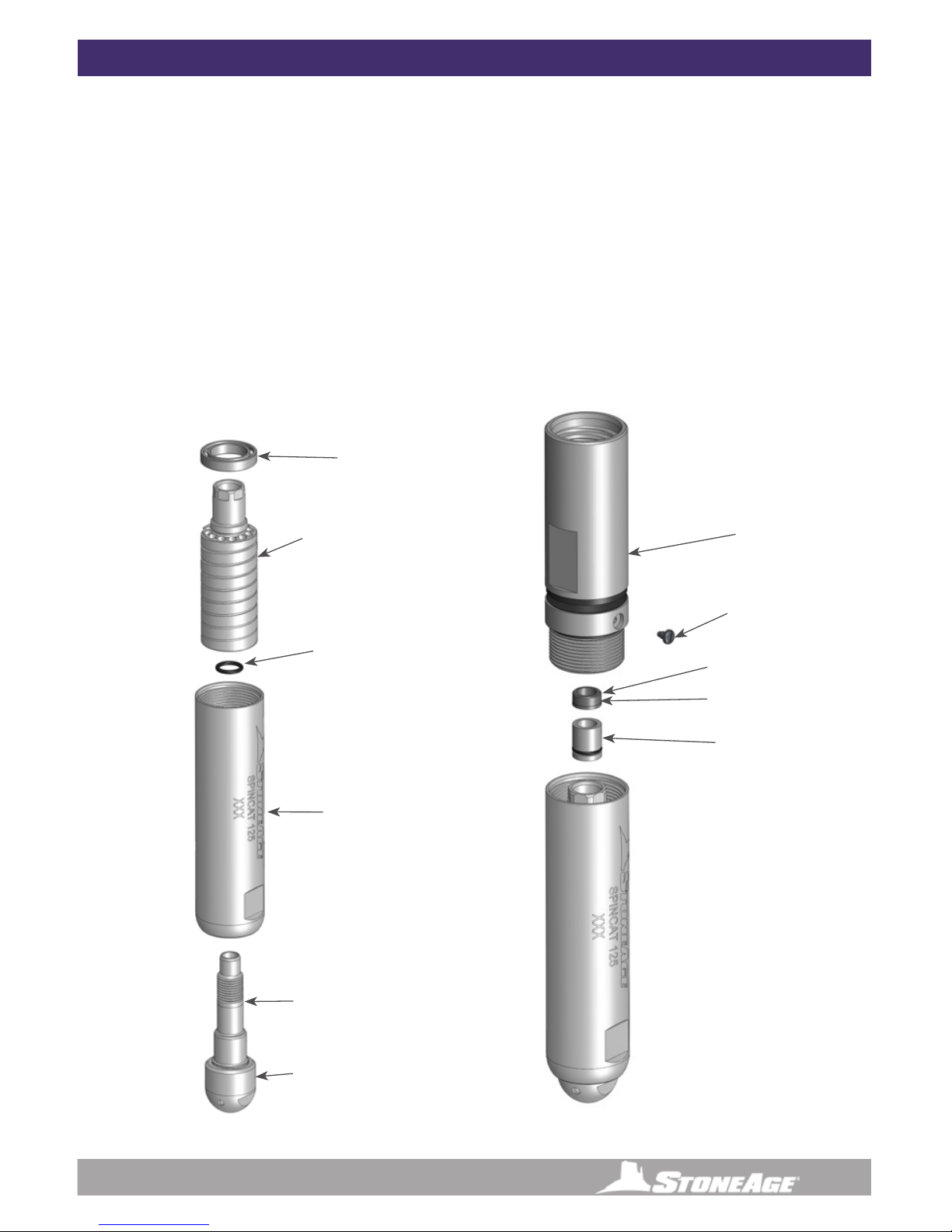

TO REPLACE THE HIGH PRESSURE SEAL:

1. Unscrew the Inlet Nut (SC125 002-AMMT) and remove the Port Plug Assembly (FT 026).

2. Remove the old Seat (SC168 011-C) and H.P. Seal (SC168 012-O).

3. Apply grease to and install new H.P. Seal into the shaft with the O-Ring groove end going

in rst. Do not press all the way into the shaft bore.

4. Install new Seat (SC168 011-C) with the chamfered face toward Inlet Nut. Press in just far

enough so that the seat is captured in the shaft bore.

5. Fill the body with viscous uid to 1/4" above the top of the upper bearing.

6. Hold the Inlet nut at an angle with the Port Plug hole facing up. Thread Body onto Inlet Nut

and tighten to 50 ft-lb.

7. Install Port Plug with O-Ring.

HIGH PRESSURE SEAL REPLACEMENT

SC125 002-AMMT

Inlet Nut

DETAIL VIEW OF H.P. SEAL & SEAT

CHAMFERED

FACE UP

CHAMFERED

FACE

FL AT FACE

O-RING

GROOVE END

SC168 011- C

Seat, Carbide

SC168 011- C

Seat, Carbide

SC168 012-O

H.P. Seal

SC168 012

H.P. Seal

Assembly

8866-795-1586 • WWW.STONEAGETOOLS.COM

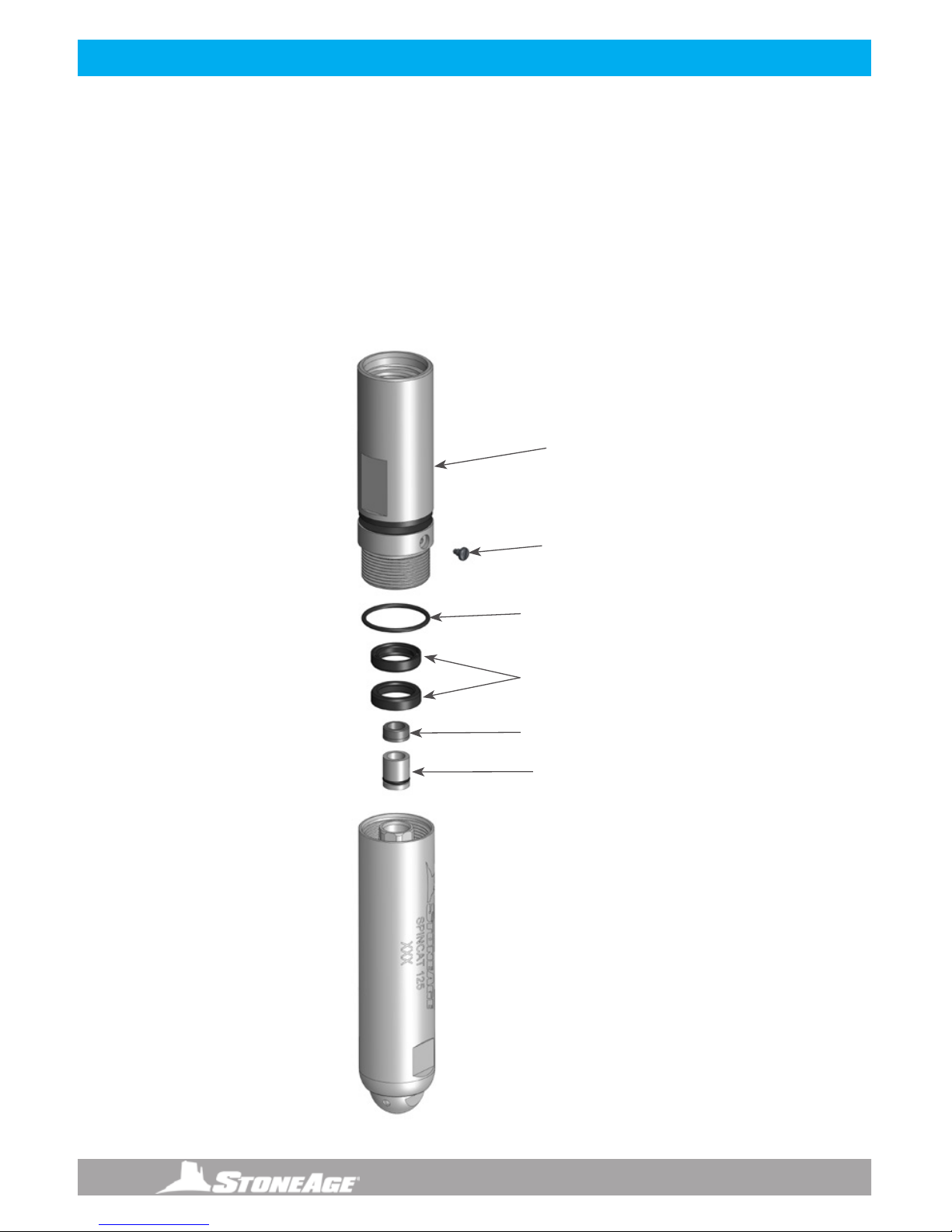

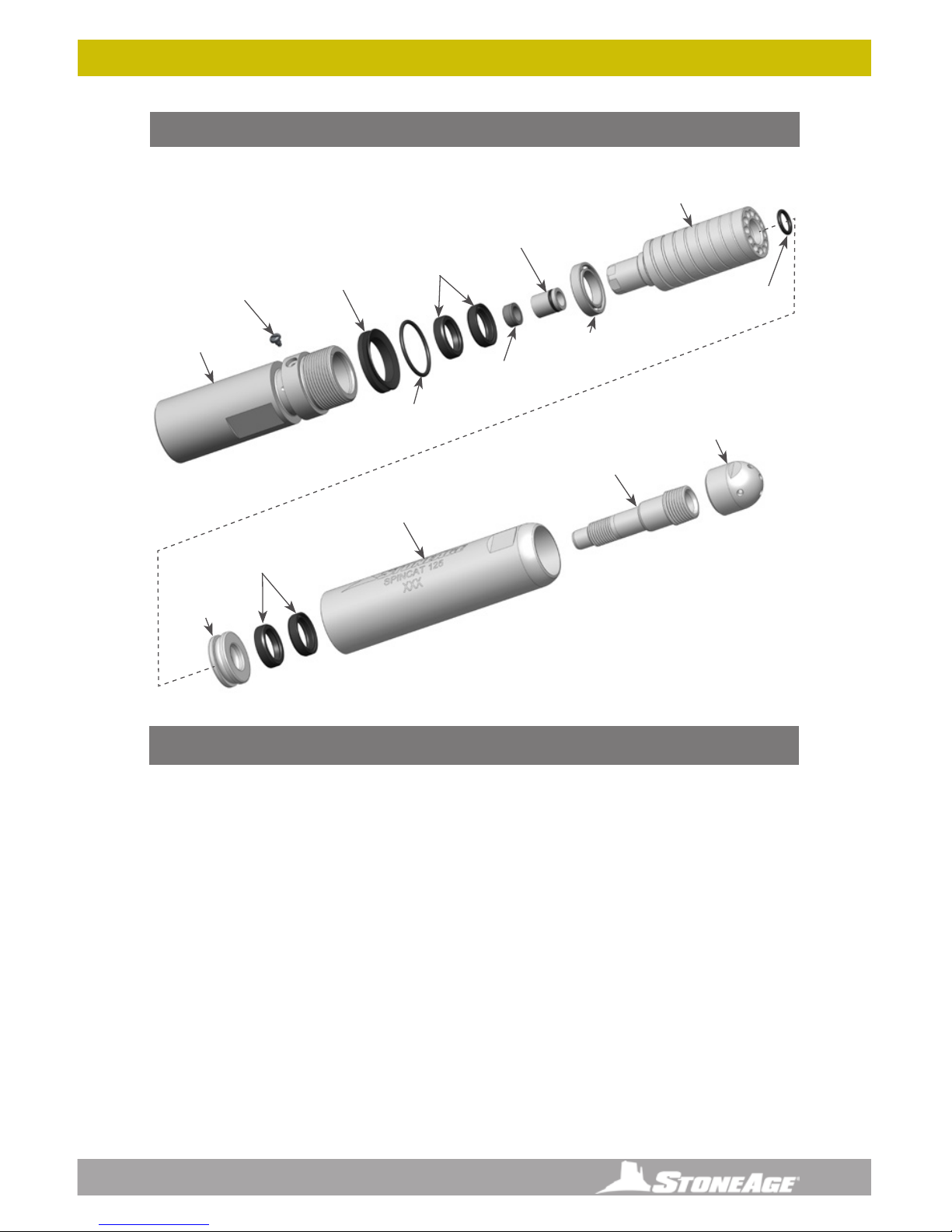

DISASSEMBLY

TO DISASSEMBLE THE SPINCAT SC-125:

1. Unscrew the Inlet Nut (SC125 002-AMMT) from the body.

2. Remove the Port Plug Assembly (FT 026) from the Nut.

3. Remove the Seat (SC168 011-C) and the H.P. Seal (SC168 012-O) from the bore of the shaft.

4. If the Shaft Seals (SC125 006) are damaged, remove them from the Nut using snap ring

pliers.

5. If the O-Ring (SC125 008) is damaged, remove it from the Nut.

6. If the Weep Seal (SC125 021) is damaged, removed it from the Nut.

SC125 002-AMMT

Inlet Nut

SC168 011- C

Seat, Carbide

SC125 006

Shaft Seal (2)

SC125 008

O-Ring, Viton

FT 026

Port Plug

Assembly

SC168 012-O

H.P. Seal

Assembly

9

866-795-1586 • WWW.STONEAGETOOLS.COM

DISASSEMBLY

SC125 009

Bearing

SC125 007

Thrust Bearing

SC125 003

Body

SC125 016

O-Ring, Viton

SC125 006

Shaft Seal (2)

SC125 001.1

Shaft, Inlet End

SC125 043-.5

or

SC125 043-1.0

Head

7. Unscrew the Inlet End Shaft (SC125 001.1) from the Outlet End Shaft/Head assembly

and remove both from the Body.

8. Pull the Bearing (SC125 009) from the Inlet End Shaft.

9. If the O-Ring (SC125 016) is damaged, remove it from the bore of the Inlet End Shaft.

10. Remove the Thrust Bearing (SC125 007) from the Body.

11. If the Shaft Seals (SC125 006) are damaged, remove them from the Body.

SC125 001.2

Shaft, Outlet End

10 866-795-1586 • WWW.STONEAGETOOLS.COM

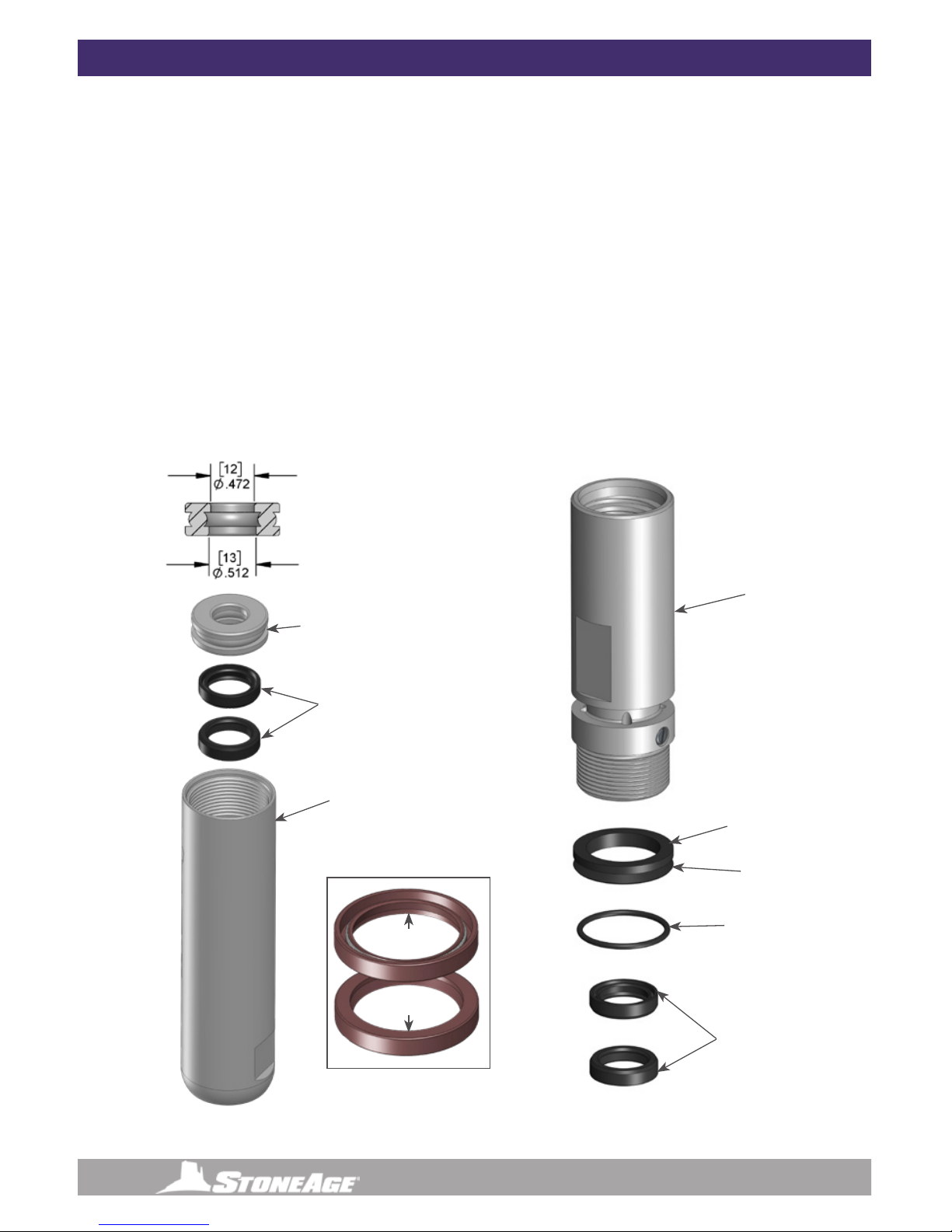

TO ASSEMBLE THE SPINCAT SC-125:

A StoneAge Seal Tool (SC125 050) is available to aid in installing the Seals in the Body and

Nut.

1. Install Shaft Seals (SC125 007) into Body (SC125 003). Note direction of lip with spring on

each Seal. Apply Armour-All to lips of seals.

2. Install Thrust Bearing (SC125 007) into Body. The end of the Bearing with the slightly

larger bore (13mm) should go in facing down and towards the Seals as shown in detail.

3. Install Weep Seal (SC125 021) into deep groove of Inlet Nut (SC125 002-AMMT).

Angled lip should be towards Port Plug hole.

4. Install O-Ring (SC125 008) onto relief groove behind threads of Inlet Nut (SC125 002-

AMMT).

5. Install Shaft Seals (SC125 006) into Inlet Nut. Note direction of lip with spring on each

Seal. Apply anti-seize to Inlet Nut threads. Apply Armour-All to lips of seals.

SC125 007

Thrust Bearing

SC125 003

Body

SC125 006

Shaft Seal (2)

SC125 002-AMMT

Inlet Nut

SC125 006

Shaft Seal (2)

SC125 021

Weep Seal

ANGLED

LIP SIDE

DOWN

SC125 008

O-Ring, Viton

DETAIL VIEW OF SHAFT SEALS

LIP WITH

SPRING UP

LIP WITH

SPRING DOWN

ASSEMBLY

11

866-795-1586 • WWW.STONEAGETOOLS.COM

ASSEMBLY

6. Thread the Head (SC125 043-X) onto Outlet End Shaft (SC125 001.2). Use Threadmate

and uorocarbon tape on the pipe threads.

NOTE: there is a 1/4" hex on the inside diameter of the Shaft for holding the

Shaft when tightening. Tighten to 30 ft-lbs. Apply anti-seize to straight threads of the

Shaft.

7. Install O-Ring (SC125 016) into internal groove in outgoing bore of the Inlet End Shaft

(SC125 001.1). Apply grease to O-Ring.

8. Slide Head/Shaft assembly into the rounded end of the Body. Slide the Inlet End Shaft

into the threaded end of the body and tighten shafts together to 30 ft-lbs.

9. Slide Bearing (SC125 009) into inlet end of Body.

10. Fill the tool with silicone lubricant to 1/4" above top of Bearing.

11. Install the H.P. Seal and Seat as shown in the Maintenance Section and thread the

Body onto the Inlet Nut. Tighten to 50 ft-lbs.

12. Install Port Plug.

SC125 009

Bearing

SC125 003

Body

SC125 016

O-Ring, Viton

SC125 001.1

Shaft, Inlet End

SC125 043-.5 or 1.0

Head

SC125 001.2

Shaft, Outlet End

SC125 002-AMMT

Inlet Nut

CHAMFERED

FACE UP

SC168 011- C

Seat, Carbide

SC125 026

Port Plug

Assembly

SC168 012-O

H.P. Seal

Assembly

12 866-795-1586 • WWW.STONEAGETOOLS.COM

TROUBLESHOOTING

HIGH-PRESSURE SEAL LEAK:

• The high pressure seal may leak initially at lower pressures, but should pop closed as

pressure is increased. A continuous leak at operating pressure from the weep holes

indicates the need to replace the HP Seal and Seat. HP Seals wearing out too quickly

can be an indication that the HP Seat is installed upside-down, or the tool is rotating

too fast. If the tool is leaking, but not over rotating, the SC125 602 Seal Kit is required.

TOOL WILL NOT ROTATE:

• Check the nozzles for plugging or wear (nozzles have to be removed to check for

obstructions).

• Check that the nozzle sizes are correct for the desired ow and that the desired ow

matches the head ow range.

• Check that the nozzle sizes are installed in a balanced conguration.

• If the tool feels rough when manually rotating the head, this indicates internal

damage and SC125 610 Overhaul Kit will be required.

• Check head by hand to make sure it rotates freely. If it does not rotate freely by hand,

the tool needs to be disassembled and repaired. Research from eld reports show

that exceeding set-down weight may bend the headshaft ever so slightly and prevent

rotation.

TOOL ROTATES TOO FAST:

• If the head rotates too fast, clean out old lubricating uid and replace with fresh

lubricant.

• If tool is showing heavy scufng damage to body, we suggest that the customer

install an available uted body on the SpinCat™.

STORAGE

TOOL STORAGE:

The SpinCat™ should NOT be stored in a used condition with wellbore and pumped uids

possibly migrating into the lubricant chamber. Flush with fresh water and perform a seal

redress after HCL, Xylene or Toluene chemical treatment jobs. Downhole tools, especially

thru tubing tools tend to be stored upside down in tool racks with threaded stubs welded

to rack base. Storing the SpinCat™ in this manner allows air to collect at the top of the

lubricant chamber. We recommend the SpinCat™ be stored with inlet nut facing up to avoid

this air pocket. The SpinCat™ may also be stored horizontally.

NOTES

13

866-795-1586 • WWW.STONEAGETOOLS.COM

NOTES

THIS PAGE LEFT INTENTIONALLY BLANK

14 866-795-1586 • WWW.STONEAGETOOLS.COM

MAINTENANCE PARTS & OVERHAUL KITSREPLACEMENT PART WEAR INFORMATION

SC125 003 Body Scufng Wear

Ø 1.182

Minimum at

head end

Ø 1.225

Minimum at

inlet nut end

Ø 1.189

Minimum

.080 Minimum Allowable

Common scufng

wear pattern on Inlet

Nut

Common scufng

wear pattern on

Body

SC125 002 Inlet Nut Scufng Wear

• BODY AND INLET NUT WEAR:

Follow these wear dimension guidelines to determine when to replace parts.

SC125 001.1 Shaft, Inlet Wear SC125 001.2 Shaft, Outlet Wear

SC125 043 Head Wear

SECTION A-A

NOTE: Inspect nozzle

orices for wear out

of round. Replace if

visibly worn.

Potential wear groove

by high pressure seal.

Ø .578 Minimum

Allowable

Ø .578 Minimum

Allowable

Potential wear groove

by shaft seal lips.

Potential wear groove

by shaft seal lip.

Ø.447

Maximum

• SHAFT/HEAD WEAR:

Follow these wear dimension guidelines to determine when to replace parts.

15

866-795-1586 • WWW.STONEAGETOOLS.COM

MAINTENANCE PARTS & OVERHAUL KITS

MAINTENANCE & OVERHAUL KIT PARTS

SC125 600 – LUBRICATION KIT

1 BJ 048 -S Viscous Fluid, Slow - 6oz

1 BJ 062-S Anti-seize, 2g

1 PL 625 SC-125 Manual Insert

1 SC125 026 Port Plug Assembly

SC125 602 -SEAL REDRESS KIT

1 BJ 048 -S Viscous Fluid, Slow - 6oz

1 BJ 062-S Anti-seize, 2g

1 PL 625 SC-125 Manual Insert

4 SC125 006 Shaft Seal

1 SC125 008 O-Ring, Viton

1 SC125 016 O-Ring

1 SC125 021 Weep Seal

1 SC125 026 Port Plug Assembly

1 SC168 011-C Carbide Seat

1 SC168 012-O HP/ High Temp Seal Assembly

SC125 610 - OVERHAUL KIT

1 BJ 048 -S Viscous Fluid, Slow - 6oz

1 BJ 062-S Anti-seize, 2g

1 GPT 022-250 Hex Key, 1/4", Standard L

1 PL 625 SC-125 Manual Insert

4 SC125 006 Shaft Seal

1 SC125 007 Thrust Bearing

1 SC125 008 O-Ring, Viton

1 SC125 009 Bearing

1 SC125 016 O-Ring

1 SC125 021 Weep Seal

1 SC125 026 Port Plug Assembly

1 SC125 050 Tool, Seal Installer

1 SC168 011-C Carbide Seat

1 SC168 012-O HP/ High Temp Seal Assembly

SC125 612 - TOOL KIT

1 SC125 050 Tool, Seal Installer

1 GPT 022-250 Hex Key, 1/4", Standard L

SC125 026 Port Plug

Assembly

SC125 009

Bearing

SC125 007

Thrust Bearing

SC125 003

Body

SC125 016

O-Ring, Viton

SC125 021

Weep Seal

SC125 006

Shaft Seal

SC125 006

Shaft Seal

SC125 001.1

Shaft, Inlet End

SC125 001.2

Shaft, Outlet End

SC125 043-.5

or

SC125 043-.1.0

Head

SC168 012-O

H.P. Seal

Assembly

SC168 011-C

Seat, Carbide

SC125 008

O-Ring, Viton

SC125 002-AMMT

Inlet Nut

PARTS OVERVIEW

16 866-795-1586 • WWW.STONEAGETOOLS.COM

TERMS AND CONDITIONS AND WARRANTY INFORMATION TERMS AND CONDITIONS AND WARRANTY INFORMATION

1. Acceptance of Terms and Conditions. Receipt

of these Terms and Conditions of Sale (“Terms and

Conditions”) shall operate as the acceptance by

StoneAge, Inc. (“Seller”) of the order submitted by

the purchaser (“Buyer”). Such acceptance is made

expressly conditional on assent by Buyer to these Terms

and Conditions. Such assent shall be deemed to have

been given unless written notice of objection to any of

these Terms and Conditions (including inconsistencies

between Buyer’s purchase order and this acceptance) is

given by Buyer to Seller promptly on receipt hereof.

Seller desires to provide Buyer with prompt and efcient

service. However, to individually negotiate the terms

of each sales contract would substantially impair

Seller’s ability to provide such service. Accordingly, the

product(s) furnished by Seller are sold only according

to the terms and conditions stated herein and with the

terms and conditions stated in any effective StoneAge

Dealer Agreement or StoneAge Reseller Agreement, if

applicable. Notwithstanding any terms and conditions

on Buyer’s order, Seller’s performance of any contract

is expressly made conditional on Buyer’s agreement

to these Terms and Conditions unless otherwise

specically agreed to in writing by Seller. In the absence

of such agreement, commencement of performance,

shipment and/or delivery shall be for Buyer’s

convenience only and shall not be deemed or construed

to be an acceptance of Buyer’s terms and conditions.

2. Payment/Prices. Unless other arrangements have

been made in writing between Seller and Buyer, payment

for the product(s) shall be made upon receipt of invoice.

The prices shown on the face hereof are those currently

in effect. Prices invoiced shall be per pricelist in effect

at the time of shipment. Prices are subject to increase

for inclusion of any and all taxes which are applicable

and which arise from the sale, delivery or use of the

product(s), and the collection of which Seller is or may

be responsible to provide to any governmental authority,

unless acceptable exemption certicates are provided

by Buyer in accordance with applicable law. Buyer

shall pay all charges for transportation and delivery

and all excise, order, occupation, use or similar taxes,

duties, levies, charges or surcharges applicable to the

product(s) being purchased, whether now in effect

or hereafter imposed by any governmental authority,

foreign or domestic.

3. Warranty. SELLER MAKES NO WARRANTIES OR

REPRESENTATIONS AS TO THE PERFORMANCE

OF ANY PRODUCT EXCEPT AS SET FORTH IN THE

STONEAGE LIMITED WARRANTY PROVIDED WITH THE

PRODUCT.

4. Delivery. Seller is not obligated to make delivery by

a specied date, but will always use its best efforts to

make delivery within the time requested. The proposed

shipment date is an estimate. Seller will notify Buyer

promptly of any material delay and will specify the

revised delivery date as soon as practicable. UNDER

NO CIRCUMSTANCES SHALL SELLER HAVE ANY

LIABILITY WHATSOEVER FOR LOSS OF USE OR

FOR ANY DIRECT OR CONSEQUENTIAL DAMAGES

RESULTING FROM DELAY REGARDLESS OF THE

REASON(S).

All product(s) will be shipped F.O.B. point of origin,

unless specically agreed otherwise, and Buyer shall

pay all shipping costs and insurance costs from that

point. Seller, in its sole discretion, will determine and

arrange the means and manner of transportation of the

product(s). Buyer shall bear all risk of loss commencing

with the shipment or distribution of the product(s) from

Seller’s warehouse. Order shortages or errors must be

reported within fteen (15) business days from receipt of

shipment to secure adjustment. No product(s) may be

returned without securing written approval from Seller.

5. Modication. These Terms and Conditions are

intended by Seller and Buyer to constitute a nal,

complete and exclusive expression of agreement

relating to the subject matter hereof and cannot be

supplemented or amended without Seller’s prior written

approval.

6. Omission. Seller’s waiver of any breach or Seller’s

failure to enforce any of these Terms and Conditions

at any time, shall not in any way affect, limit or waive

Seller’s right thereafter to enforce and compel strict

compliance with every term and condition hereof.

7. Severability. If any provision of these Terms and

Conditions is held to be invalid or unenforceable, such

invalidity or unenforceability shall not affect the validity

or enforceability of the other portions hereof.

17

866-795-1586 • WWW.STONEAGETOOLS.COM

TERMS AND CONDITIONS AND WARRANTY INFORMATION

8. Disputes. Seller and Buyer shall attempt in good

faith to promptly resolve any dispute arising under

these Terms and Conditions by negotiations between

representatives who have authority to settle the

controversy. If unsuccessful, Seller and Buyer shall

further attempt in good faith to settle the dispute

by nonbinding third-party mediation, with fees and

expenses of such mediation apportioned equally to

each side. Any dispute not so resolved by negotiation

or mediation may then be submitted to a court of

competent jurisdiction in accordance with the terms

hereof. These procedures are the exclusive procedures

for the resolution of all such disputes between the Seller

and Buyer.

9. Governing Law. All sales, agreements for sale, offers

to sell, proposals, acknowledgments and contracts

of sale, including, but not limited to, purchase orders

accepted by Seller, shall be considered a contract under

the laws of the State of Colorado and the rights and

duties of all persons, and the construction and effect of

all provisions hereof shall be governed by and construed

according to the laws of such state.

10. Jurisdiction and Venue. Seller and Buyer agree

that the state or federal courts located within the City

and County of Denver, Colorado shall have sole and

exclusive jurisdiction over any litigation concerning any

dispute arising under these Terms and Conditions not

otherwise resolved pursuant to Section 9 as well as any

alleged defects of any Products or damages sustained

as a result of such alleged defects. Seller and Buyer

further agree that should any litigation be commenced

in connection with such a dispute, it shall only be

commenced in such courts. Seller and Buyer agree to

the exclusive jurisdiction of such courts and neither will

raise any objection to the jurisdiction and venue of such

courts, including as a result of inconvenience.

11. Attorney’s Fees. If any litigation is commenced

between Seller and Buyer, or their personal

representatives, concerning any provision hereof,

the party prevailing in the litigation shall be entitled,

in addition to such other relief that is granted, to a

reasonable sum as and for their attorneys’ fees and

costs in such litigation or mediation.

STONEAGE TRADEMARK LIST

View the list of StoneAge’s trademarks and service marks and learn how the trademarks should be used. Use of

StoneAge trademarks may be prohibited, unless expressly authorized.

http://www.StoneAgetools.com/trademark-list/

STONEAGE PATENT DATA

View the list of StoneAge’s current U.S. patent numbers and descriptions.

http://www.sapatents.com

STONEAGE TERMS AND WARRANTY

View StoneAge’s Terms and Warranty Conditions online.

http://www.stoneagetools.com/terms

http://www.stoneagetools.com/warranty

18 866-795-1586 • WWW.STONEAGETOOLS.COM

TERMS AND CONDITIONS AND WARRANTY INFORMATION TERMS AND CONDITIONS AND WARRANTY INFORMATION

Warranties set forth herein extend only to End-Users,

meaning customers acquiring, or that have previously

acquired, a product manufactured by StoneAge

(“Product”) for their own use and not for resale, either

directly from StoneAge Inc. (“StoneAge”) or from a

StoneAge Authorized Dealer or Reseller (“Dealer”). No

warranty of any kind or nature is made by StoneAge

beyond those expressly stated herein.

1. LIMITED WARRANTY PERIOD. Subject to

the limitations and conditions hereinafter set forth,

StoneAge warrants its Product to be free from defects

in workmanship and material for a period of one (1) year

from the date of purchase by the End-User, provided that

the end of the limited warranty period shall not be later

than eighteen (18) months from the date of shipment of

the Product to the Dealer or the End-User by StoneAge

(“Limited Warranty Period”). All replacement parts which

are furnished under this Limited Warranty and properly

installed shall be warranted to the same extent as the

original Product under this Limited Warranty if, and only

if, the original parts were found to be defective within the

original Limited Warranty Period covering the original

Product. Replacement parts are warranted for the

remainder of the original Limited Warranty Period. This

Limited Warranty does not cover any component part of

any Product not manufactured by StoneAge. Any such

component part is subject exclusively to the component

manufacturer’s warranty terms and conditions.

2. LIMITED WARRANTY COVERAGE. StoneAge’s

sole obligation under this Limited Warranty shall be, at

StoneAge’s option and upon StoneAge’s inspection, to

repair, replace or issue a credit for any Product which is

determined by StoneAge to be defective in material or

workmanship. StoneAge reserves the right to examine

the alleged defective Product to determine whether this

Limited Warranty is applicable, and nal determination

of limited warranty coverage lies solely with StoneAge.

No statement or recommendation made by a StoneAge

representative, Dealer or agent to End-User shall

constitute a warranty by StoneAge or a waiver or

modication to any of the provisions hereof or create any

liability for StoneAge.

3. WARRANTY SERVICE PROVIDERS. Service

and repair of the Product is to be performed only by

StoneAge authorized service representatives, including

Dealers who are authorized repair centers, with

StoneAge approved parts. Information about StoneAge

authorized service representatives can be obtained

through the StoneAge website at www.stoneagetools.

com/service. Unauthorized service, repair or

modication of the Product or use of parts not approved

by StoneAge will void this Limited Warranty. StoneAge

reserves the right to change or improve the material and

design of the Product at any time without notice to End-

User, and StoneAge is not obligated to make the same

improvements during warranty service to any Product

previously manufactured.

4. WARRANTY EXCLUSIONS. This Limited Warranty

does not cover, and StoneAge shall not be responsible

for the following, or damage caused by the following:

(1) any Product that has been altered or modied in any

way not approved by StoneAge in advance in writing;

(2) any Product that has been operated under more

severe conditions or beyond the rated capacity specied

for that Product; (3) depreciation or damage caused

by normal wear and tear, failure to follow operation or

installation instructions, misuse, negligence or lack

of proper protection during storage; (4) exposure to

re, moisture, water intrusion, electrical stress, insects,

explosions, extraordinary weather and/or environmental

conditions including, but not limited to lightning, natural

disasters, storms, windstorms, hail, earthquakes, acts

of God or any other force majeure event; (5) damage to

any Product caused by any attempt to repair, replace,

or service the Product by persons other than StoneAge

authorized service representatives; (6) costs of normal

maintenance parts and services; (7) damage sustained

during unloading, shipment or transit of the Product;

or (8) failure to perform the recommended periodic

maintenance procedures listed in the Operator’s Manual

accompanying the Product.

5. REQUIRED WARRANTY PROCEDURES. To be

eligible for warranty service, the End-User must: (1)

report the Product defect to the entity where the Product

was purchased (i.e. StoneAge or the Dealer) within

the Limited Warranty Period specied in this Limited

Warranty; (2) submit the original invoice to establish

ownership and date of purchase; and (3) make the

Product available to a StoneAge authorized service

representative for inspection to determine eligibility

for coverage under this Limited Warranty. This Limited

Warranty shall not extend to any person or entity who

fails to provide proof of original purchase from StoneAge

or a Dealer. No Product may be returned for credit

or adjustment without prior written permission from

StoneAge.

WARRANTY:

19

866-795-1586 • WWW.STONEAGETOOLS.COM

TERMS AND CONDITIONS AND WARRANTY INFORMATION

6. DISCLAIMER OF IMPLIED WARRANTIES AND OTHER

REMEDIES. EXCEPT AS EXPRESSLY STATED HEREIN

(AND TO THE FULLEST EXTENT ALLOWED UNDER

APPLICABLE LAW), STONEAGE HEREBY DISCLAIMS

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING WITHOUT LIMITATION ALL IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, AND ANY AND ALL

WARRANTIES, REPRESENTATIONS OR PROMISES

AS TO THE QUALITY, PERFORMANCE OR FREEDOM

FROM DEFECT OF THE PRODUCT COVERED BY

THIS LIMITED WARRANTY. STONEAGE FURTHER

DISCLAIMS ALL IMPLIED INDEMNITIES.

7. LIMITATION OF LIABILITY. End-User specically

acknowledges that the Product may be operated at

high speeds and/or pressures, and that as such it may

be inherently dangerous if not used correctly. End-

User shall familiarize itself with all operation materials

provided by StoneAge and shall at all times use and

require its agents, employees and contractors to use

all necessary and appropriate safety devices, guards

and proper safe operating procedures. In no event shall

StoneAge be responsible for any injuries to persons or

property caused directly or indirectly by the operation

of the Product if End-User or any agent, employee, or

contractor of End-User: (1) fails to use all necessary

and appropriate safety devices, guards and proper

safe operating procedures; (2) fails to maintain in good

working order such safety devices and guards; (3) alters

or modies the Product in any way not approved by

StoneAge in advance in writing; (4) allows the Product to

be operated under more severe conditions or beyond the

rated capacity specied for the Product; or (5) otherwise

negligently operates the Product. End-User shall

indemnify and hold StoneAge harmless from any and all

liability or obligation incurred by or against StoneAge,

including costs and attorneys’ fees, to or by any person

so injured.

TO THE FULL EXTENT ALLOWED BY APPLICABLE

LAW, STONEAGE SHALL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL,

OR PUNITIVE DAMAGES (INCLUDING WITHOUT

LIMITATION, LOSS OF PROFITS, LOSS OF GOODWILL,

DIMINUTION OF VALUE, WORK STOPPAGE,

INTERRUPTION OF BUSINESS, RENTAL OF

SUBSTITUTE PRODUCT, OR OTHER COMMERCIAL

LOSS EVEN TO THE EXTENT SUCH DAMAGES WOULD

CONSTITUTE DIRECT DAMAGES), WITH RESPECT TO

THE COVERED STONEAGE PRODUCT, OR OTHERWISE

IN CONNECTION WITH THIS LIMITED WARRANTY,

REGARDLESS OF WHETHER STONEAGE HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

IT IS UNDERSTOOD THAT STONEAGE’S LIABILITY,

WHETHER IN CONTRACT, IN TORT, UNDER ANY

WARRANTY, IN NEGLIGENCE, OR OTHERWISE SHALL

NOT EXCEED THE AMOUNT OF THE PURCHASE

PRICE PAID BY THE END-USER FOR THE PRODUCT.

STONEAGE’S MAXIMUM LIABILITY SHALL NOT

EXCEED, AND END-USER’S REMEDY IS LIMITED

TO EITHER (1) REPAIR OR REPLACEMENT OF THE

DEFECTIVE WORKMANSHIP OR MATERIAL OR, AT

STONEAGE’S OPTION, (2) REFUND OF THE PURCHASE

PRICE, OR (3) ISSUANCE OF A CREDIT FOR THE

PURCHASE PRICE, AND SUCH REMEDIES SHALL BE

END-USER’S ENTIRE AND EXCLUSIVE REMEDY.

YOU, THE END-USER, UNDERSTAND AND EXPRESSLY

AGREE THAT THE FOREGOING LIMITATIONS ON

LIABILITY ARE PART OF THE CONSIDERATION IN

THE PRICE OF THE STONEAGE PRODUCT YOU

PURCHASED.

Some jurisdictions do not allow the limitation or

exclusion of liability for certain damages, so the above

limitations and exclusions may not apply to you. This

Limited Warranty gives you specic legal rights, and you

may also have other rights which vary from jurisdiction

to jurisdiction. If any provisions of this Limited Warranty

is held to be invalid or unenforceable, such invalidity

or unenforceability shall not affect the validity or

enforceability of the other portions hereof.

1-866-795-1586 • www.STONEAGETOOLS.com

© 2015 StoneAge, Inc. All Rights Reserved

Table of contents

Other StoneAge Ultrasonic Jewelry Cleaner manuals

Popular Ultrasonic Jewelry Cleaner manuals by other brands

Aussie Pumps

Aussie Pumps Eco Clean Super Indy Operating & maintenance instructions

AL-KO

AL-KO MB 2010 Translation of the original instructions for use

RIDGID

RIDGID K-750 manual

Sanuvox

Sanuvox CoilClean IL installation manual

GILMAN

GILMAN gemini GUC30BMTS quick start guide

RugDoctor

RugDoctor FlexClean FCM-1 user manual