StoneAge Sentinel LWPS-100-X User manual

PL 690 REV B

(09/2021)

LIGHTWEIGHT POSITIONER

(LWPS-100-X)

USER MANUAL

2866-795-1586 • WWW.STONEAGETOOLS.COM

MANUFACTURER’S INFORMATION .......................................... 3

SPECIFICATIONS ........................................................................................ 3

DESCRIPTION OF EQUIPMENT AND INTENDED USE ................................... 3

KEY FEATURES........................................................................................... 3

EC AND UKCA DECLARATIONS OF CONFORMITY....................................... 4 - 5

WARNING AND SAFETY INSTRUCTIONS .................................... 6

OPERATOR TRAINING................................................................................. 6

PERSONAL PROTECTIVE EQUIPMENT REQUIREMENTS.............................. 6

SAFETY LABEL DEFINITIONS....................................................................... 6

PRE-RUN SAFETY CHECK .......................................................................... 7

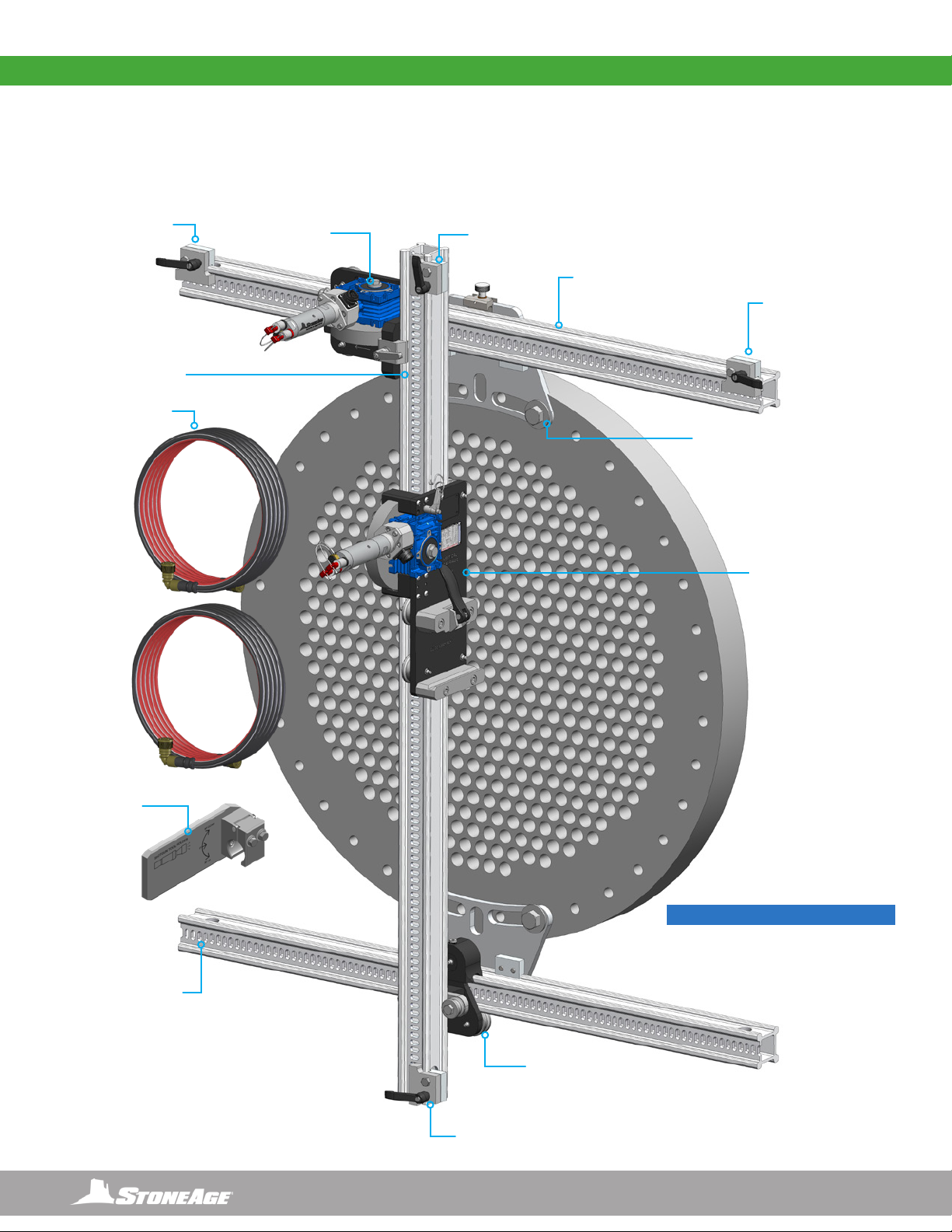

PRODUCT OVERVIEWS ....................................................... 8

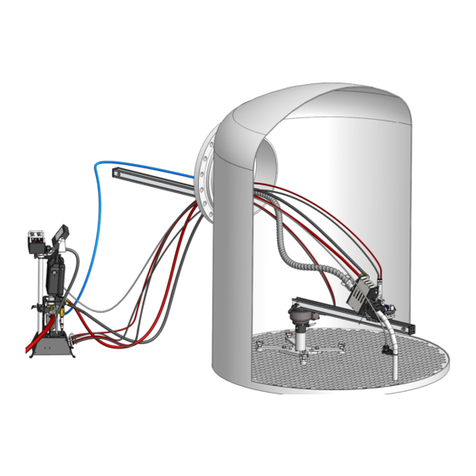

LIGHTWEIGHT POSITIONER SYSTEM.......................................................... 8

LIGHTWEIGHT POSITIONER AND ACCESSORIES ........................................ 9

LIGHTWEIGHT POSITIONER CLAMP STYLES .............................................. 10

LIGHTWEIGHT POSITIONER SET-UP ......................................... 11

LIGHTWEIGHT POSITIONER ASSEMBLY...................................................... 11

LIGHTWEIGHT POSITIONER CONNECTIONS TO POWER HUB..................... 13

SHOTGUN MOUNT INSTALLATION .............................................................. 14

MAINTENANCE................................................................ 15

STORAGE, TRANSPORTATION, AND HANDLING ............................ 15

PARTS DIAGRAMS ............................................................ 15

TERMS AND CONDITIONS.................................................... 28

WARRANTY ................................................................... 29

TABLE OF CONTENTS

3

866-795-1586 • WWW.STONEAGETOOLS.COM

MANUFACTURER’S INFORMATION

SPECIFICATIONS

Imperial Metric

Full Positioner Weight 120 lbs 54.4 kg

Vertical Carriage Weight 17 lbs 7.7 kg

Horizontal Carriage Weight 15.4 lbs 7 kg

Idler Carriage Weight 4.4 lbs 2 kg

Dimensions without extensions 6 x 6 ft 1829 x 1829 mm

Cleaning Window Dimensions for 6ft Rail Conguration See diagram below table

Optional Rail Extension lengths 2, 4, and 6 ft 607, 1219, and 1829 mm

DESCRIPTION OF EQUIPMENT

AND INTENDED USE

The Lightweight Positioner can be

mounted to a variety of heat exchanger

tube bundles and has pneumatic

powered horizontal and vertical drives.

It is intended to be used with these

AUTOBOX® Hose Tractors;

• ABXS-3L (3 Lance with Sentinel

Technology)

• ABX-3L (3 Lance)

• ABX-2L-B (2 Lance Belt Drive)

• ABX-PRO (Single Lance)

KEY FEATURES:

• Better positioning accuracy - reduced

backlash and clearance across the

system

• Completely tool free setup and

operation

• Drives locked in place by a pin for

visual conrmation of engagement

• Highly accurate position encoding

• Reduced component size and weight

• Larger usable widow size

• Push-to-Connect ttings

• Metric hardware and tube sizes

• Sensor can be replaced in minutes

• Same sensor used in both drives

• Carriages are interchangeable with

LWP-500

• Rail scraper on idler carriage

• Utilizes eld proven stainless steel air

motors

72.3in

(1837mm)

Vertical Rail

Length

72.3in

(1837mm)

Horizontal

Rail Length

53.5in

(1360mm)

Maximum

Vertical Travel

2.0in

(51mm) Lower Beam Offset to Insure Idler Carriage

Remains Fully Engaged on Lower Horizontal Rail

13.7in

(347mm)

18.8in

(478mm)

58.2in

(1478mm)

Maximum

Horizontal Travel

This manual must be used in accordance with all applicable national laws. The manual

shall be regarded as a part of the machine and shall be kept for reference until the nal

dismantling of the machine, as dened by applicable national law(s). Updated manuals can

be downloaded at: https://www.stoneagetools.com/manuals

StoneAge Inc.

466 S. Skylane Drive

Durango, CO 81303, USA

Phone: 970-259-2869

Toll Free: 866-795-1586

www.stoneagetools.com

StoneAge NL

Reedijk 7Q

3274 KE Heinenoord

Netherlands

(+31) (0) 85 902 73 70

StoneAge UK

Unit 3

Crucible Business Park

Woodbury Lane

Norton

Worcester

Worcestershire, WR5 2DQ

United Kingdom

+44 (0) 1684 892065

4866-795-1586 • WWW.STONEAGETOOLS.COM

EC DECLARATION OF CONFORMITY

Manufacturer: StoneAge Incorporated

466 South Skylane Drive

Durango, CO 81303

USA

Authorized Representative: StoneAge Europe

Reedijk 7Q

3274 KE Heinenoord

Netherlands

Bob Van Wordragen, Operations Manager StoneAge NL

Declare that: Light Weight Positioner (LWPS-100-X)

for mounting and positioning hose tractors to heat exchangers.

Is compliant with the following Directives and Standards:

EU- Machinery Directive (2006/42/EC)

EU- RoHS Directive (2011/65/EU)

EU- EMC Directive (2014/30/EU)

EN ISO 12100:2010 (e) Safety of machinery – General principles for design – Risk assessment and risk reduction

EN ISO 4414:2010 (en) Pneumatic Fluid Power – General rules and safety requirements for systems and components

EN 55011:2009 Industrial, scientic and medical equipment - Radio-frequency disturbance characteristics - Limits and methods of measurement

EN 60204-1:2018 Safety of machinery– Electrical equipment of machines

This device complies with part 15 of the FCC rules and Industry Canada ICES-003. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause

undesired operation.

The Technical File for Light Weight Positioner (LWPS-100-X) is maintained at: StoneAge Incorporated, 466 South Skylane Drive, Durango, CO

81303, USA and was compiled by the Director of Engineering and Technology. The Technical File is available through the Authorized Representative.

This Declaration of Conformity is issued under the exclusive responsibility of StoneAge Incorporated.

________________________________________ 09/29/2021

StoneAge Incorporated, Durango, CO, USA Date

Scott Howell, New Product Introduction Manager

5

866-795-1586 • WWW.STONEAGETOOLS.COM

UK DECLARATION OF CONFORMITY

Manufacturer: StoneAge Incorporated

466 South Skylane Drive

Durango, CO 81303

USA

Authorized Representative: StoneAge UK

Unit 3

Crucible Business Park

Woodbury Lane

Norton

Worcester

Worcestershire, WR5 2DQ

United Kingdom

Steve Ellis, Managing Directory StoneAge UK

Declare that: Light Weight Positioner (LWPS-100-X)

for mounting and positioning hose tractors to heat exchangers.

Is compliant with the following Directives and Standards:

S.I. 2008:1597 - Supply of Machinery (Safety) Regulations 2008

S.I. 2012:3032 - Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012

S.I. 2016:1091 - Electromagnetic Compatibility Regulations 2016

S.I. 2008:1597 Safety of machinery – General principles for design – Risk assessment and risk reduction

S.I. 2008:1597 Pneumatic Fluid Power – General rules and safety requirements for systems and components

S.I. 2016:1091 Industrial, scientic and medical equipment - Radio-frequency disturbance characteristics - Limits and methods of measurement

S.I. 2016:1091 Safety of machinery– Electrical equipment of machines

S.I. 2016:1091 Electromagnetic Compatibility (EMC) standard for radio equipment and services; Part 1: Common technical requirements;

Harmonized Standard for Electromagnetic Compatibility

The Technical File for Light Weight Positioner (LWPS-100-X) is maintained at:

StoneAge Incorporated, 466 South Skylane Drive, Durango, CO 81303, USA and was compiled by the Engineering Manager.

The Technical File is available through the Authorized Representative.

This Declaration of Conformity is issued under the exclusive responsibility of StoneAge Incorporated.

________________________________________ 09/29/21

StoneAge Incorporated, Durango, CO, USA Date

Scott Howell, New Product Introduction Manager

6866-795-1586 • WWW.STONEAGETOOLS.COM

WARNING AND SAFETY INSTRUCTIONS

OPERATOR TRAINING

Managers, Supervisors, and Operators MUST be trained in Health

and Safety Awareness of High-pressure Water Jetting and hold

a copy the Water Jetting Association (WJA) Code of Practice, or

equivalent (see www.waterjetting.org.uk).

Operators MUST be trained to identify and understand all applicable

standards for the equipment supplied. Operators should be trained

in manual handling techniques to prevent bodily injury.

Operators MUST read, understand, and follow the Operational and

Training Requirements (Section 7.0) of WJTA-IMCA’s Recommended

Practices For The Use Of High-pressure Waterjetting Equipment, or

equivalent.

Operators MUST read, understand and follow the Warnings,

Safety Information, Assembly, Installation, Connection, Operation,

Transport, Handling, Storage, and Maintenance Instructions detailed

in this manual.

StoneAge has designed and manufactured this equipment

considering all hazards associated with its operation. StoneAge

assessed these risks and incorporated safety features in the design.

StoneAge WILL NOT accept responsibility for the results of misuse.

IT IS THE RESPONSIBILITY OF THE INSTALLER/OPERATOR

to conduct a job specic risk assessment prior to use. Job specic

risk assessment MUST be repeated for each different set up,

material, and location.

The risk assessment MUST conform to the Health and Safety at

Work Act 1974 and other relevant Health and Safety legislation.

The risk assessment MUST consider potential material or substance

hazards including:

• Aerosols

• Biological and microbiological (viral or bacterial) agents

• Combustible materials

• Dusts

• Explosion

• Fibers

• Flammable substances

• Fluids

• Fumes

• Gases

• Mists

• Oxidizing Agents

WARNING AND SAFETY INSTRUCTIONS

PERSONAL PROTECTIVE EQUIPMENT REQUIREMENTS

Use of Personal Protective Equipment (PPE) is dependent on

the working pressure of water and the cleaning application.

Managers, Supervisors, and Operators MUST carry out a job

specic risk assessment to dene the exact requirements for PPE.

See Protective Equipment for Personnel (Section 6) of WJTA-

IMCA’s Recommended Practices For The Use Of High-pressure

Waterjetting Equipment for additional information.

Hygiene - Operators are advised to wash thoroughly after all

waterjetting operations to remove any waterblast residue which may

contain traces of harmful substances.

First aid provision - users MUST be provided with suitable rst aid

facilities at the operation site.

PPE may include:

• Eye protection: Full face visor

• Foot protection: Kevlar® brand or steel toe capped,

waterproof, non-slip safety boots

• Hand protection: Waterproof gloves

• Ear protection: Ear protection for a minimum of 85 dBA

• Head protection: Hard hat that accepts a full face visor and

ear protection

• Body protection: Multi-layer waterproof clothing approved for

waterjetting

• Hose protection: Hose shroud

• Respiratory protection: May be required; refer to job specic

risk assessment

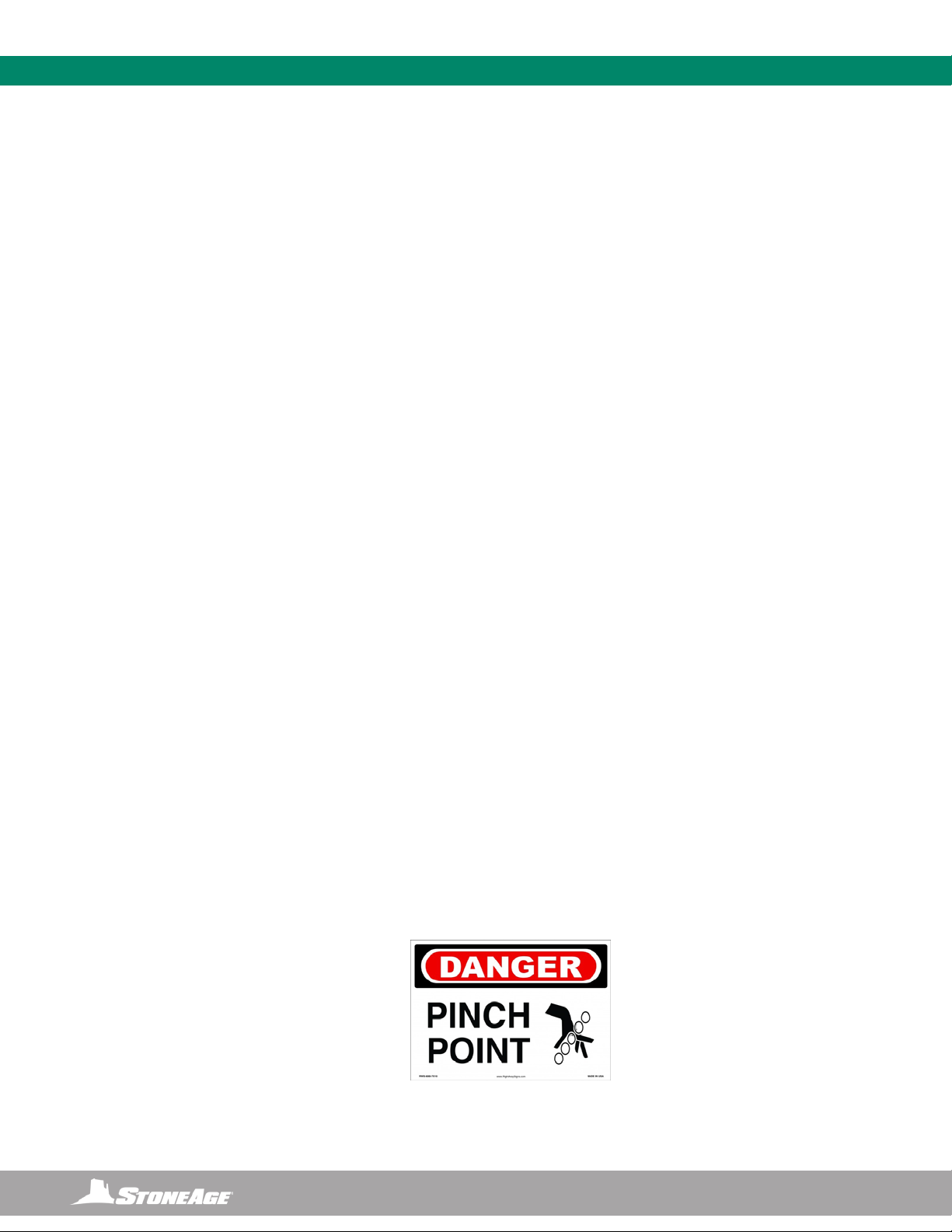

SAFETY LABEL DEFINITION

The Lightweight Positioner (LWPS-100-X) has the

potential to cause serious injury if ngers, hair, or

clothing become caught between the rollers and the

rails.

7

866-795-1586 • WWW.STONEAGETOOLS.COM

WARNING

Operations with this equipment can be potentially hazardous.

Caution MUST be exercised prior to and during machine and water

jet tool use. Please read and follow all of these instructions, in addition

to the guidelines in the WJTA Recommended Practices handbook,

available online at www.wjta.org. Deviating from safety instructions

and recommended practices can lead to severe injury and/or death.

• Do not exceed the maximum operating pressure specied for

any component in a system.

• The immediate work area MUST be marked off to keep out

untrained persons.

• Inspect the equipment for visible signs of deterioration,

damage, and improper assembly. Do not operate if damaged,

until repaired.

• Make sure all threaded connections are tight and free of leaks.

• Users of the Lightweight Positioner (LWPS-100-X) MUST be

trained and/or experienced in the use and application of high-

pressure technology and cleaning, as well as all associated

safety measures, according to the WJTA Recommended

Practices for the use of High-pressure Waterjetting Equipment.

• An anti-withdrawal device (back-out preventer) MUST be used

at all times. The back-out prevention device is the Hose Stop

Collet located within the Hose Guide Assembly. StoneAge

offers several different size Hose Stop Collets. The Collet Size

Reference guide is located on the Hose Guide Assembly.

• The Control Box should be located in a safe location where

the Operator has good visibility of the pipe and hose. The

Lightweight Positioner (LWPS-100-X) and Control Box MUST

be supervised at all times and should never be left unattended.

• Always de-energize the system before servicing or replacing any

parts. Failure to do so can result in severe injury and/or death.

• When moving the Lightweight Positioner (LWPS-100-X) lift with

care to prevent bodily injury.

PRE-RUN SAFETY CHECK

Refer to WJTA-IMCA’s, Recommended Practices For The Use Of

High-pressure Waterjetting Equipment and/or The Water Jetting

Association’s, WJA Code of Practice for additional safety information.

• Complete a job specic risk assessment and act on the resulting

actions.

• Adhere to all site specic safety procedures.

• Ensure the waterblasting zone is properly barricaded and that

warning signs are posted.

• Ensure the work place is free of unnecessary objects (e.g. loose

parts, hoses, tools).

• Ensure all Operators are using the correct Personal Protective

Equipment (PPE).

• Check that the air hoses are properly connected and tight.

• Check all hoses and accessories for damage prior to use. Do

not use damaged items. Only high quality hoses intended for

waterblast applications should be used as high-pressure hoses.

• Check all high-pressure threaded connections for tightness.

• **Ensure that a anti-withdrawal device (back-out

preventer), whip checks (hose whips), and all other

applicable safety devices are installed and set-up

properly.**

• Ensure the doors of the Lightweight Positioner (LWPS-100-X)

are closed and securely latched.

• Test the Control Box before operating the Lightweight Positioner

(LWPS-100-X) with high-pressure water to verify the control

valves move the hose in the intended direction, and that the

dump valve and hose clamp are working properly.

• Ensure that Operators never connect, disconnect, or tighten

hoses, adapters, or accessories with the high-pressure water

pump unit running.

• Ensure no personnel are in the hydroblasting zone.

WARNING AND SAFETY INSTRUCTIONSWARNING AND SAFETY INSTRUCTIONS

8866-795-1586 • WWW.STONEAGETOOLS.COM

LIGHTWEIGHT POSITIONER ASSEMBLY

(LWPS-100-X)

SYSTEM ASSEMBLY - OVERVIEW

RAIL STOP

RAIL STOP

RAIL STOP

HORIZONTAL DRIVE

ASSEMBLY

SHOT GUN

MOUNT

VERTICAL DRIVE

ASSEMBLY

IDLER

CARRIAGE

ASSEMBLY

RAIL STOP

CLAMP (SEE THE NEXT

PAGE FOR ALTERNATE

CLAMP STYLES)

2.5” SLOTTED RAIL

2.5” SLOTTED RAIL

POSITIONER

CONTROL LINES

2.5” SLOTTED RAIL

NOTICE

Heat exchanger tube bundle face,

shown for graphic representation only.

Not included in assembly

9

866-795-1586 • WWW.STONEAGETOOLS.COM

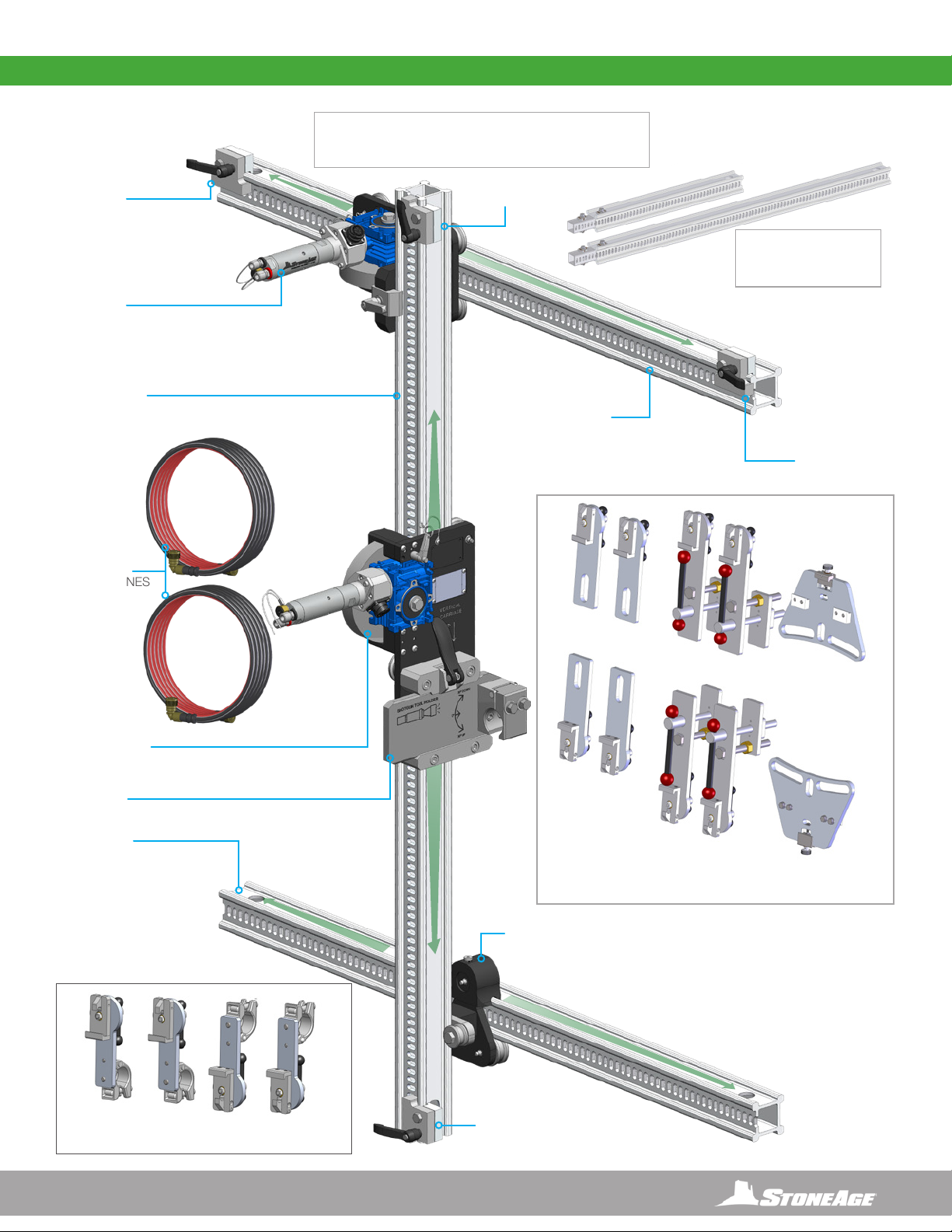

LIGHTWEIGHT POSITIONER

WITH SENTINEL TECHNOLOGY

AND ACCESSORIES

HORIZONTAL DRIVE

ASSEMBLY

VERTICAL DRIVE

ASSEMBLY

VERTICAL

SLOTTED RAIL HORIZONTAL

SLOTTED RAIL

HORIZONTAL

SLOTTED RAIL

SHOT GUN

MOUNT

RAIL STOP

ASSEMBLY

RAIL STOP

ASSEMBLY

RAIL STOP

ASSEMBLY

RAIL STOP

ASSEMBLY

IDLER CARRIAGE

ASSEMBLY

RAIL EXTENSIONS

(2,4, OR 6 FT LENGTHS)

(.61 m, 1.2 m, OR 1.8 m)

LIGHTWEIGHT POSITIONER - OVERVIEW

SLOTTED

QUICK CLAMP

(LWP 620 KIT

CONTAINS 4)

QUICK CLAMP

(LWP 621 KIT

CONTAINS 4)

PLATE CLAMP

(LWP 622 KIT

CONTAINS 2)

CLAMP TYPES

(LWP 625 KIT

INCLUDES ALL KITS

SHOWN HERE)

15ft (4.572m)

POSITIONER

CONTROL LINES

SCAFFOLD QUICK CLAMP

(LWP 554-K KIT CONTAINS 4)

10 866-795-1586 • WWW.STONEAGETOOLS.COM

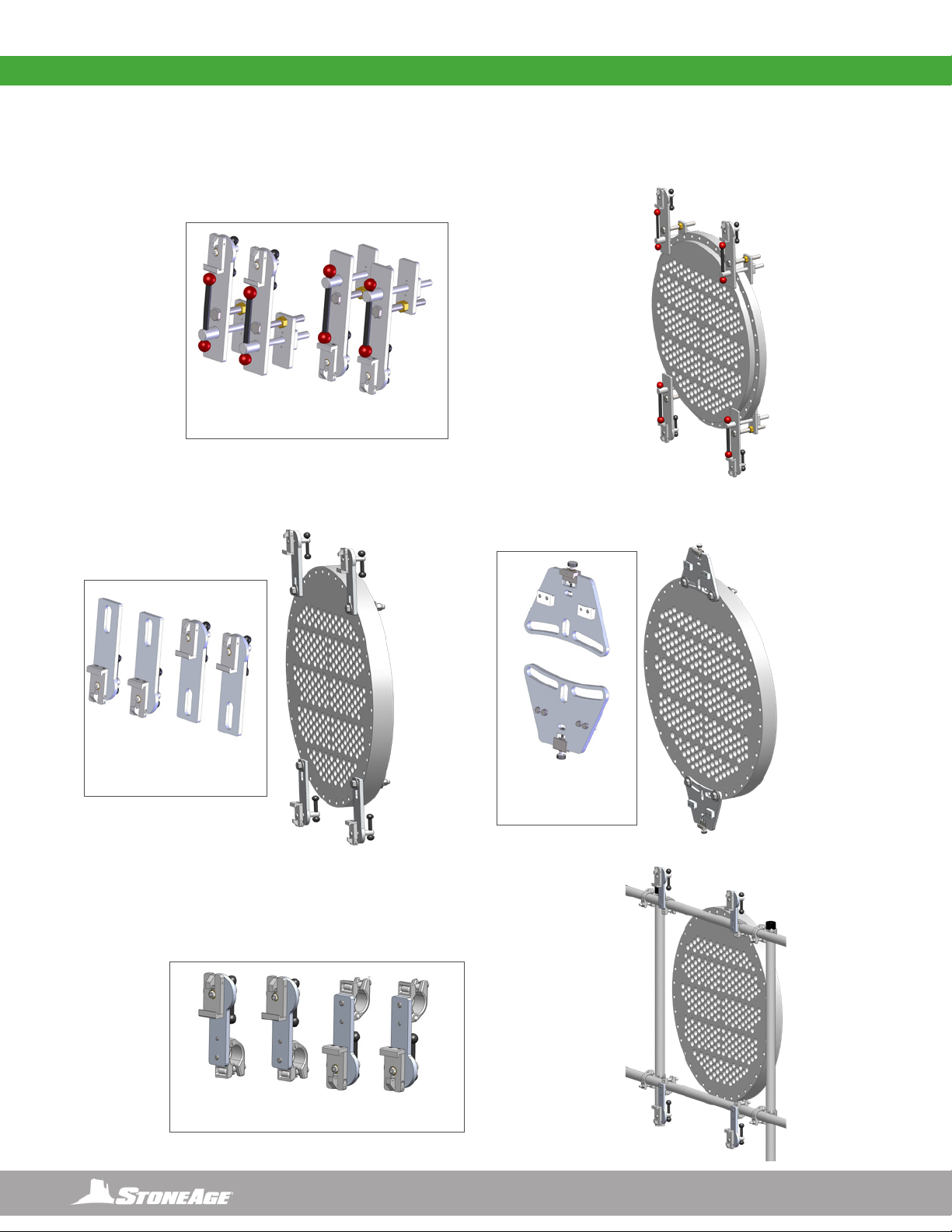

CLAMP SELECTION is dependent upon the heat exchanger geometry, bolt holes, hole spacing, and ange accessibility.

QUICK CLAMPS (LWP 518) are for use with heat exchanger anges that provide a robust clamping surface or if ange holes are

inaccessible. Align clamps on the surface of the ange to maximize ange engagement to clamps. (Figure 1)

SLOTTED QUICK (LWP 552) AND PLATE CLAMPS (LWP 519) are for use with heat exchanger anges that have easily accessible

bolt holes. Use quick clamps or plate clamps, depending on the spacing of the hole pattern. (Figures 1 & 3)

SCAFFOLD QUICK CLAMPS (LWP 554) are for use with scaffolding in situations

where they may be no way to clamp directly onto the heat exchanger. (Figure 4)

FIGURE 1

FIGURE 2 FIGURE 3

FIGURE 4

LIGHTWEIGHT POSITIONER CLAMP STYLES

SLOTTED QUICK CLAMP

(LWP 620 KIT CONTAINS 4)

SCAFFOLD QUICK CLAMP

(LWP 554-K KIT CONTAINS 4)

QUICK CLAMP

(LWP 621 KIT CONTAINS 4)

PLATE CLAMP

(LWP 622 KIT

CONTAINS 2)

11

866-795-1586 • WWW.STONEAGETOOLS.COM

LIGHTWEIGHT POSITIONER STEP BY STEP SET-UP

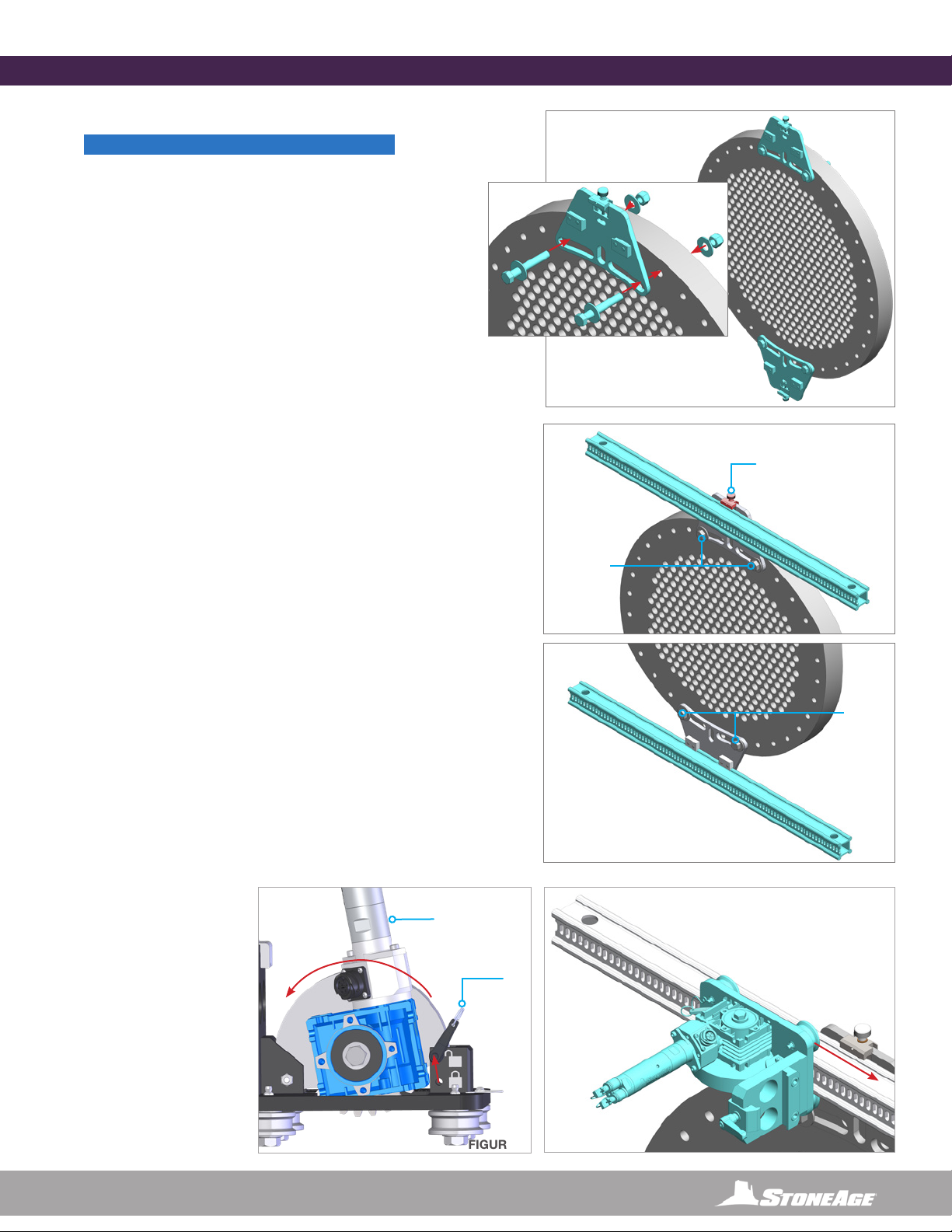

1. Mount the appropriate frame Positioner Clamps to

the tube bundle as shown in Figure 1. (Shown with

Plate Clamps) Positioner Clamps should be Parallel to

the direction of the tube rows. (Figure 1)

2. Loosen the Rail Clamp Tensioner on the top

Positioner Clamp and insert the Top Rail (slots

facing out) into the upper rail clamps. Tighten the Rail

Clamp Tensioner securing the rail to the Positioner

Clamp. Check Rail Clamp bolts to ensure they are

secured to the tube bundle ange. (Figure 2)

3. Loosen the Rail Clamp Tensioner on the bottom

Positioner Clamp and insert the Lower Rail into the

lower rail clamps. It is not critical that this rail is aligned

as precisely as the top rail, but it should be close to

parallel with the top rail for best performance. Tighten

the Rail Clamp Tensioner securing the rail to the

Positioner Clamp. Check Rail Clamp bolts to ensure

they are secured to the tube bundle ange. (Figure 3)

4. Remove the Quick Release Pin from the locked

position, pull back on the air motor to lift the gear, and

insert the Quick Release

Pin into the unlocked

position. This will allow the

Horizontal Drive Carriage

to slide onto the rail without

pneumatic power. Center

the carriage on the top rail,

pull out the Quick Release

Pin, let the gear drop into

place and verify the gear

is engaging the slotted rail

correctly. Replace the Quick

Release Pin into the locked

postion. (Figures 4 & 5)

LIGHTWEIGHT POSITIONER SET-UP

FIGURE 1

FIGURE 5

LIGHTWEIGHT POSITIONER SET-UP

FIGURE 2

Rail Clamp

Tensioner

CHECK

FIGURE 3

CHECK

FIGURE 4

UNLOCK

Quick Release

Pin

Gear

LOCK

Air Motor

NOTICE

Heat exchanger tube bundle face, shown for

graphic representation only. Not included in

assembly

12 866-795-1586 • WWW.STONEAGETOOLS.COM

5. Angle the Idler Carriage as shown to allow the

Idler Carriage to engage with the lower rail properly.

Rotate it back to the vertical position and slide it

towards the lower Rail Clamp. (Figure 6)

6. Loosen the Rail Clamp Handle on the Horizontal

Drive.Align the Idler Carriage on the lower rail so

the Vertical Rail can slide into it. Slide the Vertical

Rail with (slots facing out) down through the

Horizontal Drive clamp and between the rollers

on the idler carriage. Adjust the position of the

vertical rail as required and secure the rail in place

by tightening the Rail Clamp Handle on the

Horizontal Drive. (Figure 7)

7. Remove the Quick Release Pin from the locked

position, pull back on the air motor to lift the

gear, and insert the Quick Release Pin into the

unlocked position. This will allow the Vertical

Drive Carriage to slide onto the rail without

pneumatic power. Center the carriage on the

vertical rail, pull out the Quick Release Pin, let

the gear drop into place and verify the gear is

engaging the slotted rail correctly. Replace the

Quick Release Pin into the locked position.

(Figures 8 & 9)

8. Loosen the handles on the four Rail Stops and

slide one onto both ends of the top horizontal rail

and both ends of the vertical rail. Rotate all the

handles so they face away from Horizontal and

Vertical Drives (as shown) and ensure that they are

securely fastened. (Figure 10)

LIGHTWEIGHT POSITIONER SET-UP

FIGURE 9

FIGURE 6

FIGURE 7

Rail

Clamp

Handle

Rail

Scraper

FIGURE 10

UNLOCK

Quick Release

Pin

Air Motor

Gear

LOCK

FIGURE 8

CAUTION

Verify the Positioner Clamps and Rail Clamps are

securely fastened and both drive carriages are

securely engaged and the pinned in the locked

position.

Never unlock the vertical drive once the guide

assembly and tractor are installed, as it may result

in the carriage sliping down the vertical rail and

may cause damage and/or injury.

WARNING

Failure to secure the Rail Clamps could result in

the carriages driving off the rails. This will create a

hazardous situation which, if not avoided, could

result in death or serious injury

TECH TIP:

The rail scraper is spring loaded to t closely against

the rail to remove debris ahead of the idler roller.

Pulling up on the rail scraper or tilting the idler carriage

during installation will increase clearance and simplify

installation.

13

866-795-1586 • WWW.STONEAGETOOLS.COM

POWER HUB

VERTICAL

DRIVE

HORIZONTAL

DRIVE

90° ELECTRIC

CABLE END

90° ELECTRIC

CABLE END

LIGHTWEIGHT POSITIONER CONNECTIONS TO THE POWER HUB

CONTROL LINE CONNECTIONS

1. Remove the dust caps from all ttings of the Horizontal and

Vertical Drives.

2. Connect control lines to the front of the Power Hub

• Two Straight Electric Cable Ends ( , )

• Two 8mm diameter tubing for the Horizontal Drive ( )

• Two 8mm diameter tubing for the Vertical Drive. ( )

3. Blow out all control lines. Use of dirty or contaminated

pneumatic hoses will cause component damage and

malfunction

4. Connect control lines to the Horizontal Drive

• Connect the two 8mm diameter tubing from the Power Hub

( ) to the corresponding color coded ttings on the

Horizontal Drive.

• Connect the 90Pot Plug from the Power Hub ( ) to

the resceptacle on the sensor.

5. Connect control lines to the Vertical Drive

• Connect the two 8mm diameter tubing from the Power Hub

( ) to the corresponding color coded ttings on the

Vertical Drive.

• Connect the 90Pot Plug from the Power Hub ( ) to the

resceptacle on the sensor.

Straight Electric Cable End

and (2) 8mm diameter tubing 90° Electric Cable End and

(2) 8mm diameter tubing

CONTROL LINE ENDS

14 866-795-1586 • WWW.STONEAGETOOLS.COM

MAINTENANCE

SHOTGUN MOUNT INSTALLATION

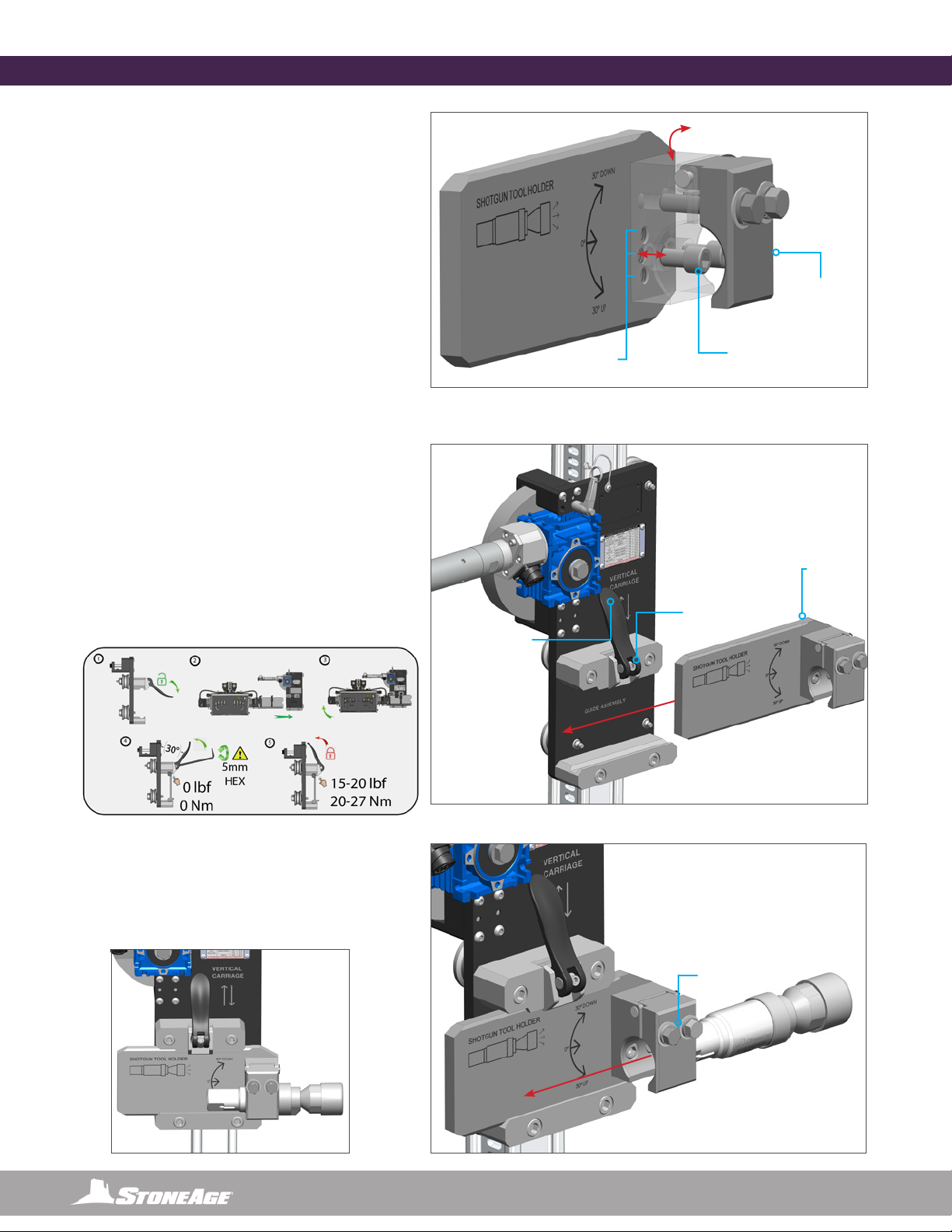

INSTALL SHOTGUN MOUNT

(FOR USE WITH BARRACUDA OR SPITFIRE TOOL)

1. Set the desired Clamp Angle.

• The Clamp Assembly on the Shotgun Mount can

be rotated 30° Up or Down by removing the two

SHCS Screws with a 5/16” Allen Key, rotating the

Clamp into the desired position, and fastening the

Screws in the desired location.

• Make sure these screws are tightened

before operation.

2. Install Shotgun Mount onto the Vertical Carriage.

• Pull to open the Clamp Handle on the Vertical

Carriage and slide the Shotgun Mount in back to

front.

• The mount will stop when it reaches the chamfers

at the front. This is a safety feature.

• Lock the Clamp Handle in place when the mount

is in position.

• If the Clamp Handle feels too loose or too tight, it

can be adjusted with a 5mm Allen Key. Follow the

instructions on the decal on the Vertical Drive.

3. Fasten the Shotgun tool in the Clamp.

• Loosen the two Hex Bolts on the Clamp with a

9/16” Hex Wrench.

• Slide the tool in back to front and securely

tighten the Hex Bolts.

5/16” ALLEN

KEY

MOUNTING

POSITIONS

TENSION

ADJUSTABLE

WITH 5mm

ALLEN KEY

CHAMFER

STOP

PULL OPEN /

PUSH CLOSED

9/16” HEX

INSTALLED

CLAMP

ASSEMBLY

15

866-795-1586 • WWW.STONEAGETOOLS.COM

Contact StoneAge for Safety Data Sheets for material usage, a complete list of spare part numbers, and service instructions for the

Lightweight Positioner.

MAINTENANCE

Return the plugs into all push connect ttings to keep water away from the connectors during cleaning. Use mild soapy water to clean the

machine in order to remove corrosive materials. Before storing the unit, use compressed air to lightly blow off debris and moisture. Apply a

small amount of air tool oil directly into the Horizontal and Vertical Drive ttings. Then, briey operate the controls at slow speed for a short

duration in each direction to coat the interior parts of the motor. Install the dust caps onto all ttings to keep moisture and dirt out.

DO NOT SPRAY WATER DIRECTLY AT OR SUBMERGE THE AIR MOTOR BREATHER PORTS OR ELECTRONIC COMPONENTS.

MAKE SURE ALL DUST CAPS ARE IN PLACE AND ELECTRICAL SENSOR CONNECTIONS ARE TIGHT PRIOR TO CLEANING.

The Lightweight POSITIONER (LWPS-100-X), can be broken down into smaller components that should be stored in a clean and dry area.

Maintenance Item Frequency Maintenance Required

Forward, reverse, and clamp ttings Before each use Inspect threads for wear or damage.

Carriage rollers Every 100 Hours of use Lubricate Zerks on all Carriage Rollers using any multipurpose

NLGI 2 grease.

Vertical and Horizontal Rails As Needed Inspect for wear that would allow Carriage Rollers to slip off.

Replace Rail as needed.

Quick Release Handles When loose or too tight 5mm hex to tighten. When it’s set correctly it should take 15-

20lbs of force to close the lever

PARTS DIAGRAM

STORAGE, TRANSPORTATION, AND HANDLING

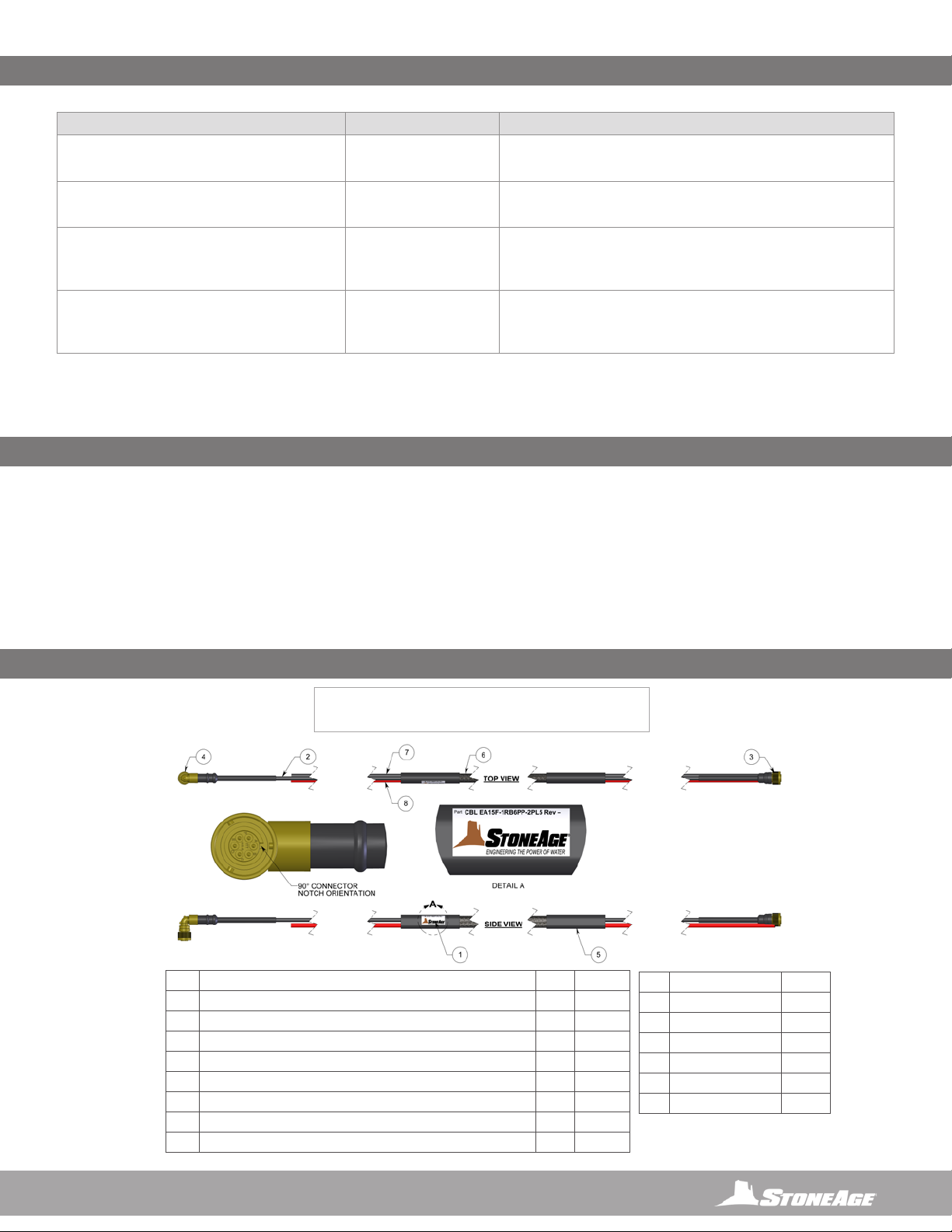

LIGHTWEIGHT POSITIONER

(CBL EA15F-1RB6PP-2LPL5)

POSITIONER CONTROL LINE ASSEMBLY

# PART NUMBER QTY OAL EACH

1 CBL EA15F-1RB6PP-2PL6.1 LABEL 1

2 CBL EA15F.1 WIRE, 1X4 PAIR, 24 (7/32_ AWG COPPER ALLOY, .011” POLYPLEFIN 1 15’-0”

3 EE CN-RB-PF6PS-14S-0001 PLUG, POT AND HEATSHRINK ENDBELL 1

4 EE CN-RB-PF6PS-14S-90-0001 PLUG, 90 DEG POT AND HEATSHRINK ENDBELL 1

5 GPHS 1100-OLE-A-BK HEAT SHRINK, 1.1” ID , BLACK 2 5”

6 GPSL 0750-NYL-G-BK HOSE BUNDLE SLEEVE 1 11’-4”

7 GPTB 8MM6-PUR95A-BK 8MM OD X 6MM ID URETHANE TUBING, BLACK 1 14’-2”

8 GPTB 8MM6-PUR95A-RD 8MM OD X 6MM ID URETHANE TUBING, RED 1 14’-2”

PIN WIRE

A BROWN / BROWN WHITE 12V

BGREEN WHITE 485-B

C GREEN 485-A

D BLUE / BLUE WHITE GND

E ORANGE SFT-A

FORANGE WHITE SFT-B

16 866-795-1586 • WWW.STONEAGETOOLS.COM

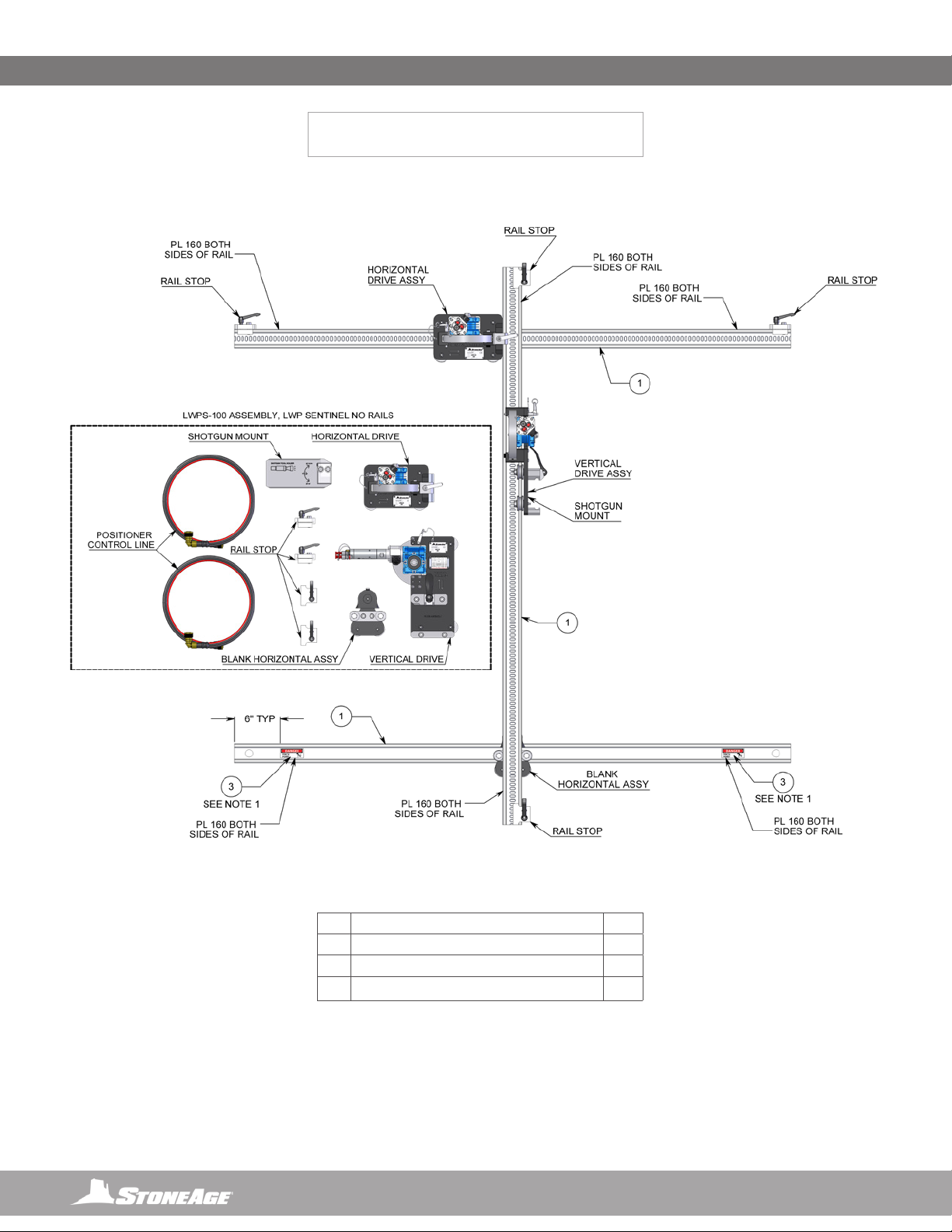

LIGHTWEIGHT POSITIONER ASSEMBLY

(LWPS-100-X)

# PART NUMBER QTY

1 BU 002-6-001 2.5” BOX RAIL EXTRUSION, SLOTTED 3

2 LWPS-100 ASSEMBLY, LWP SENTINEL NO RAILS 1

3 PL 160 WARNING PINCH POINT 1.25 X 3.0 DECAL 12

PARTS DIAGRAM

17

866-795-1586 • WWW.STONEAGETOOLS.COM

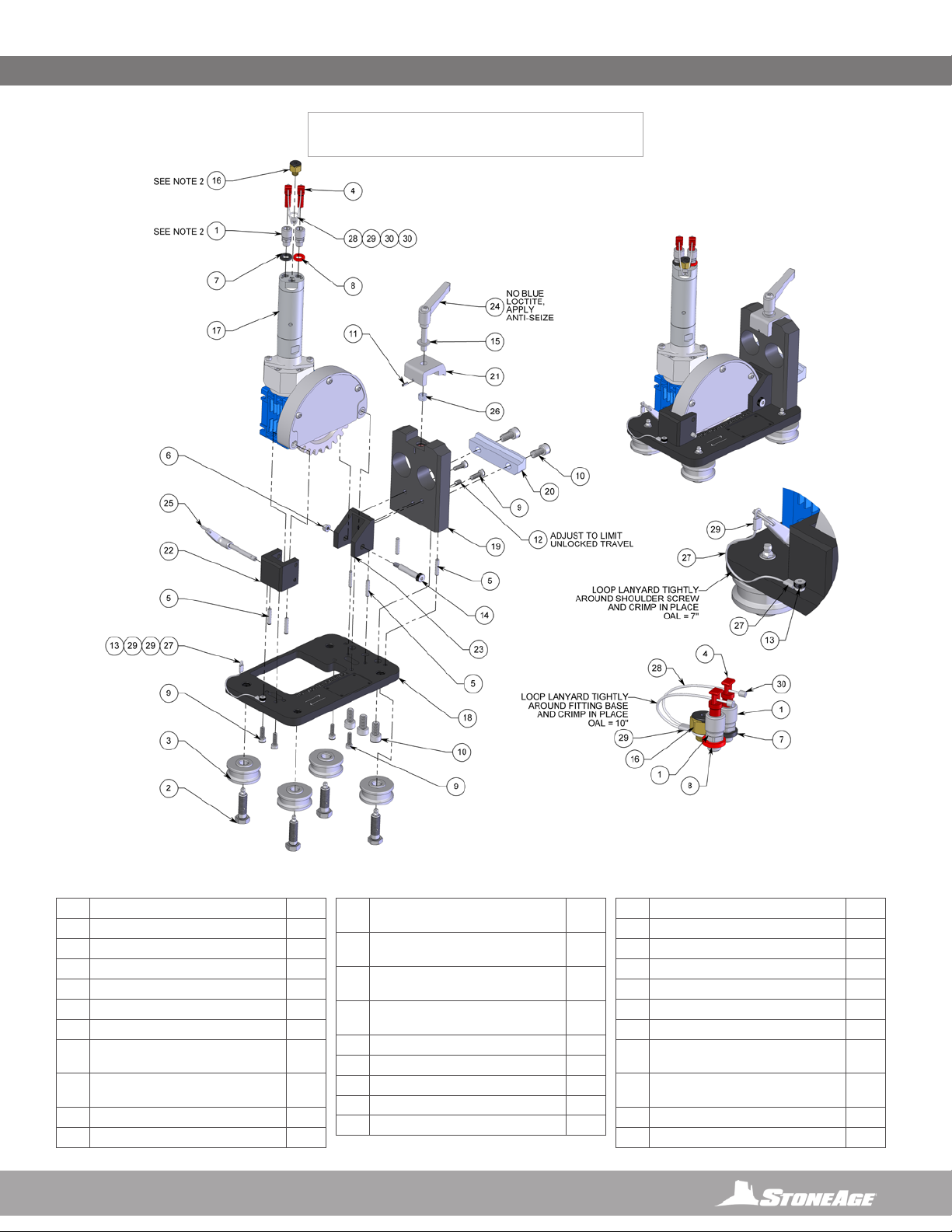

LIGHTWEIGHT POSITIONER (LWPS 140)

HORIZONTAL POSITIONER

NOTE:

1. APPLY BLUE LOCTITE (242 OR EQUIVALENT) TO THREAD OF ALL

HARDWARE, EXCEPT IF NOTED.

2. APPLY LOCTITE THREAD SEALANT (567 OR EQUIVALENT) AND/OR

TEFLON TAPE TO THREADS OF ALL PIPE FITTINGS.

PARTS DIAGRAM

# PART NUMBER QTY

1 ABXS 277 FTG, ADAPTER P2M PL5 EISELE 2

2BR 051-1.5-0 AXLE-ZERK 4

3 BR 055-SS ROLLER ASSY 4

4 CB 499 FTG, STEM PLUG PL5 MODIFIED 2

5 GDP 3M5-26 PIN, DOWEL M5 x 26 SS 6

6 GN 3M6-1.0-L NUT, NYLOK M6x1.0 SS 1

7 GP 014-BK ID WASHER, RUBBER, EXTRA

SMALL, BLACK

1

8 GP 014-R ID WASHER, RUBBER, EXTRA

SMALL, RED

1

9 GS 3M6-18-1.0 SHCS M6x1.0 x 18 SS 6

10 GS 3M10-20-1.5 SHCS M10x1.5 x 20 SS 5

11 GSP 3M3-10 SLOTTED SPRING PIN M3 X

10 SS

1

12 GSS 3M6-1.0-10CU SET SCREW, CUP PT

M6x1.0 x 10 SS

1

13 GSSH M5-4-SS SHOULDER SCREW M5 X

4 SS

1

14 GSSH M8-40-SS SHOULDER SCREW M8 X

40 SS

1

15 GW 525-F WASHER, FLAT .25 1

16 LWP 557 FTG, EXHAUST PROTECTOR P2M 1

17 LWPS 110 ASSY, GEAR DRIVE 1

18 LWPS 141 PLATE, HORIZONTAL CARRIAGE 1

19 LWPS 143 PLATE, RAIL BASE 1

20 LWPS 144 CLAMP, RAIL 1

21 LWPS 145 JAW, ADJUSTABLE CLAMP 1

22 LWPS 148 MOUNT, HORIZONTAL GEAR LEFT 1

23 LWPS 149 MOUNT, HORIZONTAL GEAR RIGHT 1

24 LWPS 151 LEVER, HAND SS 1

25 LWPS 152 PIN, QUICK-RELEASE .25 X 1.75 1

26 PROP 335 SPRING, COMPRESSION 1

27 SRT 209.1.1 WIRE ROPE FOR LWPS 140 (CUT

TO 7IN)

1

28 SRT 209.1.1 WIRE ROPE FOR LWPS AIR

MOTOR (CUT TO 10IN)

1

29 SRT 209.1.3 ALUMINUM SLEEVE 3

30 SRT 209.1.4 ALUMINUM STOP SLEEVE 2

18 866-795-1586 • WWW.STONEAGETOOLS.COM

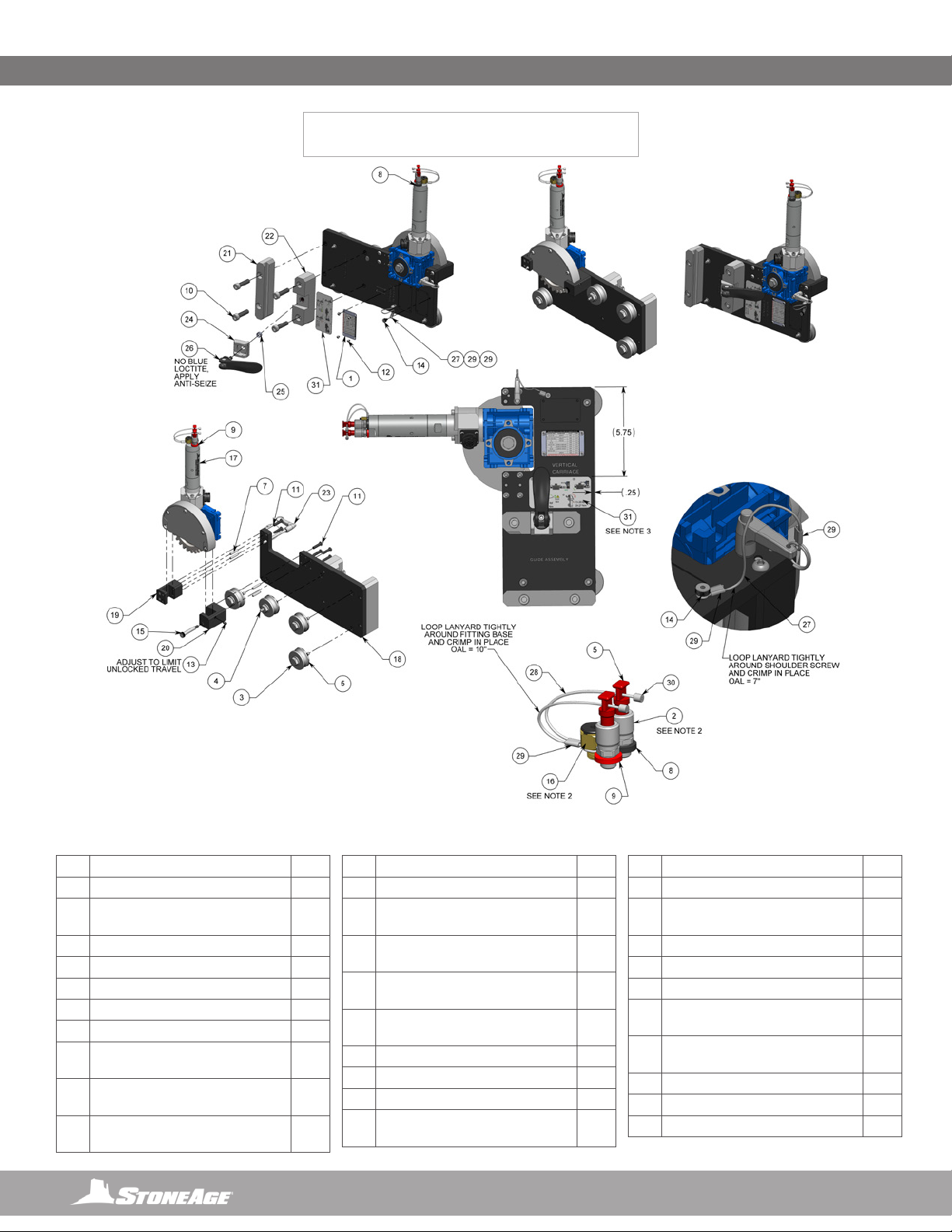

NOTES:

1. APPLY BLUE LOCTITE (242 OR EQUIVALENT) TO THREADS OF ALL HARDWARE,

EXCEPT IF NOTED.

2. APPLY LOCTITE THREAD SEALANT (567 OR EQUIVALENT) AND / OR TEFLON TAPE

TO THREADS OF ALL PIPE FITTINGS.

3. CLEAN SURFACE WITH ISOPROPYL ALCOHOL BEFORE INSTALLING DECAL. LOCATE

APPROX. WHERE SHOWN.

LIGHTWEIGHT POSITIONER (LWPS 160)

VERTICAL POSITIONER

PARTS DIAGRAM

# PART NUMBER QTY

1 ABX 139 COLLET REFERENCE PLATE 1

2 ABXS 277 FTG, ADAPTER P2M PL5

EISELE

2

3BR 051-1.5-0 AXLE-ZERK 3

4BR 052-1.5 AXLE-ZERK 1

5 BR 055-SS ROLLER ASSY 4

6 CB 499 FTG, STEM PLUG PL5 MODIFIED 2

7 GDP 3M5-26 PIN, DOWEL M5 X 26 SS 4

8 GP 014-BK ID WASHER, RUBBER, EXTRA

SMALL, BLACK

1

9 GP 014-R ID WASHER, RUBBER, EXTRA

SMALL, RED

1

10 GS 3M10-40-1.5 SHCS M10X1.5 X 40

SS

4

11 GSB 3M6-25-1.0 BHCS M6X1.0 X 25 SS 6

12 GSB 313-0075 BHCS 6-32 X .19 SS 4

13 GSS 3M6-1.0-10CU SET SCREW, CUP PT

M6X1.0 X 10 SS

1

14 GSSH M5-4-SS SHOULDER SCREW M5

X 4 SS

1

15 GSSH M8-40-SS SHOULDER SCREW M8

X 40 SS

1

16 LWP 557 FTG, EXHAUST PROTECTOR

P2M

1

17 LWPS 110 ASSY, GEAR DRIVE 1

18 LWPS 161 PLATE, VERTICAL CARRIAGE 1

19 LWPS 163 MOUNT, VERTICAL GEAR LEFT 1

20 LWPS 164 MOUNT, VERTICAL GEAR

RIGHT

1

21 LWPS 166 CLAMP, LOWER RAIL 1

22 LWPS 167 CLAMP, UPPER RAIL 1

23 LWPS 171 PIN, QUICK-RELEASE

.25X2.75

1

24 PROP 334 TAB, CLAMP 1

25 PROP 335 SPRING, COMPRESSION 1

26 PROP 336 HANDLE ASSY 1

27 SRT 209.1.1 WIRE ROPE FOR LWPS 160

(CUT TO 7IN)

1

28 SRT 209.1.1 WIRE ROPE FOR LWPS AIR

MOTOR (CUT TO 10IN)

1

29 SRT 209.1.3 ALUMINUM SLEEVE 3

30 SRT 209.1.4 ALUMINUM STOP SLEEVE 2

31 PL 211 LWPS CLAMP DECAL 1

19

866-795-1586 • WWW.STONEAGETOOLS.COM

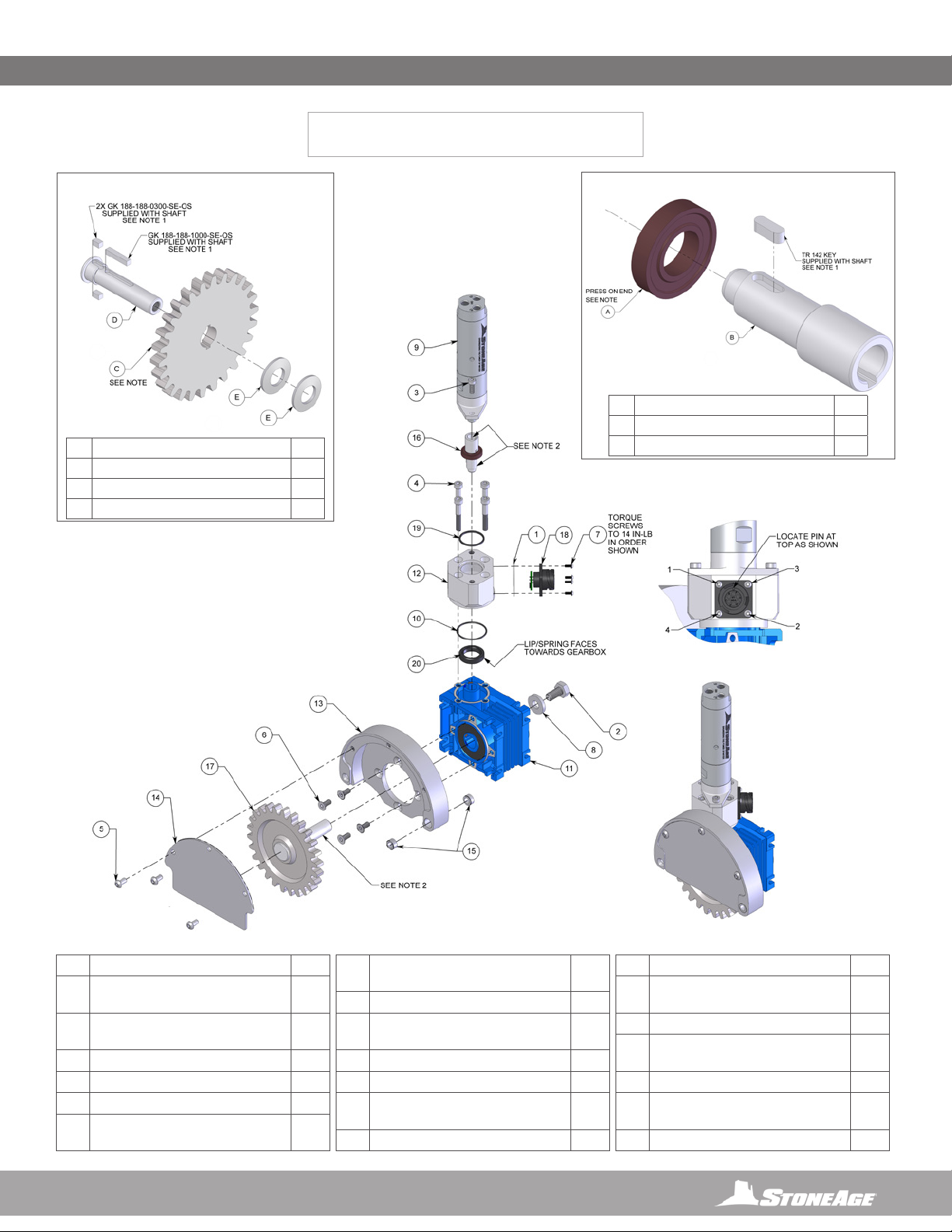

LIGHTWEIGHT POSITIONER (LWPS 110)

GEAR DRIVE ASSEMBLY

NOTE:

1. APPLY BLUE LOCTITE (242 OR

EQUIVALENT) OR EQUIVALENT TO

THREADS OF ALL HARDWARE,

EXCEPT WHERE NOTED.

2. APPLY SILVER BOSTIK NEVER SEEZ

(OR EQUIVALENT) AS NOTED.

# PART NUMBER QTY

1 EE CN-RB-G-14S-F-AX GASKET,

CONNECTOR

1

2 GB 3M10-20-1.25 BOLT, HEX M10x1.25

x 20 SS

1

3 GS 3M5-14-0.8 SHCS M5x0.8 x14 SS 2

4 GS 3M6-40-1.0 SHCS M6x1.0 x 40 SS 4

5 GSB 3M6-12-1.0 BHCS M6x1.0 x 12 SS 3

6 GSF 3M6-14-1.00 FHCS M6x1.00 x

14 SS

4

7 GTB 3M3-8-0.5 BHTS M3x0.5 x 8 Torx

SS

4

8 GW 3M10-F WASHER, FLAT M10x4mm 1

9 LWP 520-001 AIR MOTOR, SS, W/

FLANGE, LUBE FREE

1

10 LWP 538 O-RING 1

11 LWP 550 MOTOVARIO GEARBOX 1

12 LWPS 111 HUB, ENCODER MOTOR

MOUNT

1

13 LWPS 112 PLATE, DRIVE SPROCKET 1

14 LWPS 113 COVER, GEAR 1

15 LWPS 114 SLEEVE BEARING, OIL-

IMPREGNATED

2

16 LWPS 115 ASSY, STEP SHAFT 1

17 LWPS 120 ASSY, SHAFT KEYED

BELLEVILLE

1

18 LWPS 130 ASSY, LWPS SENSOR BOARD 1

19 LWPS 133 O-RING, DOUBLE SEAL

X-PROFILE

1

20 SL 010 SEAL 1

* APPLY LOCTITE RETAINING COMPOUND (680 OR

EQUIVALENT) TO COMPONENTS AS NOTED. BE SURE AND SET

MAGNET BEFORE KEY. BE SURE TO SET KEY AND MAGNET

COMPLETELY AND SECURELY WHILE LETTING LOCTITE CURE

FOR 5 HRS. WIPE EXCESS LOCTITE (ESPECIALLY SHAFT).

# PART NUMBERS QTY.

A EE MG-0001 MULTIPOLE RING 1

B LWPS 116 STEP SHAFT 1

LWPS 115 STEP SHAFT ASSEMBLY

*

*

# PART NUMBERS QTY.

C LWPS 121 GEAR, SPUR SS 3.25 CBORE 1

D LWPS 122 SHAFT, KEYED BELLEVILLE 1

E LWPS 123 WASHER, BELLEVILLE .625 X .098 2

LWPS 120 SHAFT KEYED BELLEVILLE ASSEMBLY

*

PARTS DIAGRAM

20 866-795-1586 • WWW.STONEAGETOOLS.COM

LIGHTWEIGHT POSITIONER (LWPS 180)

IDLER CARRIAGE ASSEMBLY

LIGHTWEIGHT POSITIONER (BU 152)

RAIL STOP ASSEMBLY

# PART NUMBER QTY.

1 BU 149 PLATE, RAIL STOP 1

2 BR 060 RAIL CLAMP 1

3 GB 537-05 BOLT, HEX .37-16 X 1.25 1

4 BU 151 HANDLE 1

# PART NUMBER QTY

1BR 051-1.5-0 AXLE-ZERK 3

2 BR 055-SS ROLLER ASSY 3

3 GB 3M10-30-1.5 BOLT, HEX M10x1.5 X 30 SS 2

4 GS 3M10-20-1.5 SHCS M10x1.5 x 20 SS 4

5 GSSH M8-12-SS SHOULDER SCREW M8 X 12 SS 1

6 LWPS 181 PLATE, IDLER CARRIAGE 1

7 LWPS 182 BLOCK, SPACER 1

8 LWPS 183 PLATE, GUIDE 1

9 LWPS 185 SCRAPER, RAIL 1

10 LWPS 186 STUD, VERTICAL RAIL GUIDE 2

11 LWPS 188 SPRING, WAVE 1

PARTS DIAGRAM

Table of contents

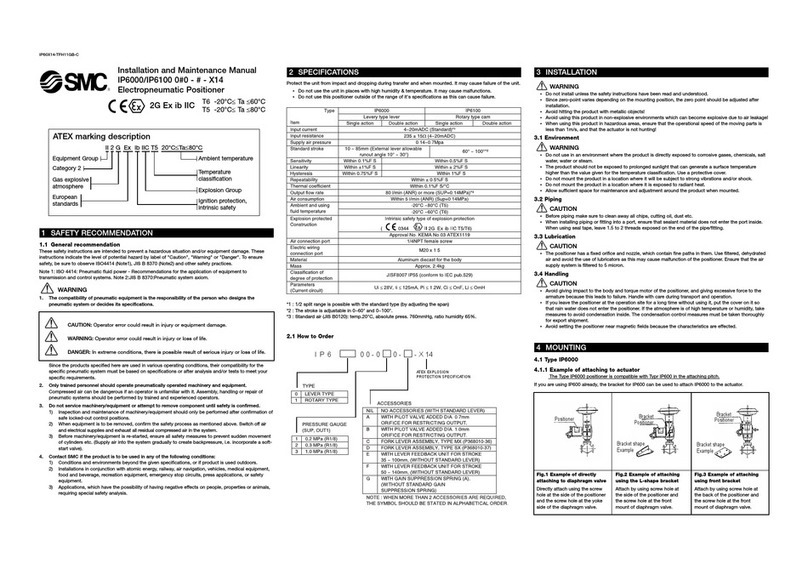

Other StoneAge Valve Positioner manuals

Popular Valve Positioner manuals by other brands

Emerson

Emerson Fisher 3610J Errata sheet

SMC Networks

SMC Networks IP6000 Installation and maintenance manual

Samson

Samson FOUNDATION 3730-5 Mounting and operating instructions

ABB

ABB PositionMaster EDP300 Commissioning Instruction

Burkert

Burkert 8791 REV.2 operating instructions

Proval

Proval A236 Series Installation, operation and maintenance manual