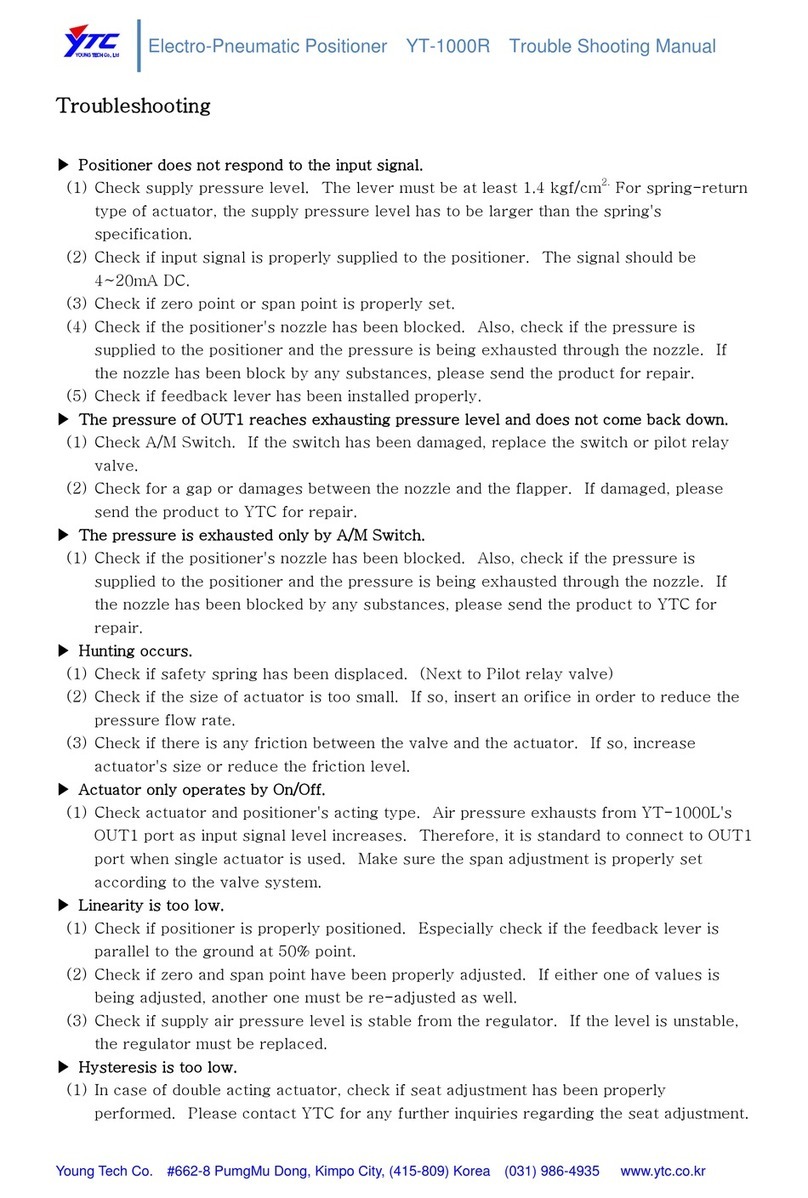

-19-

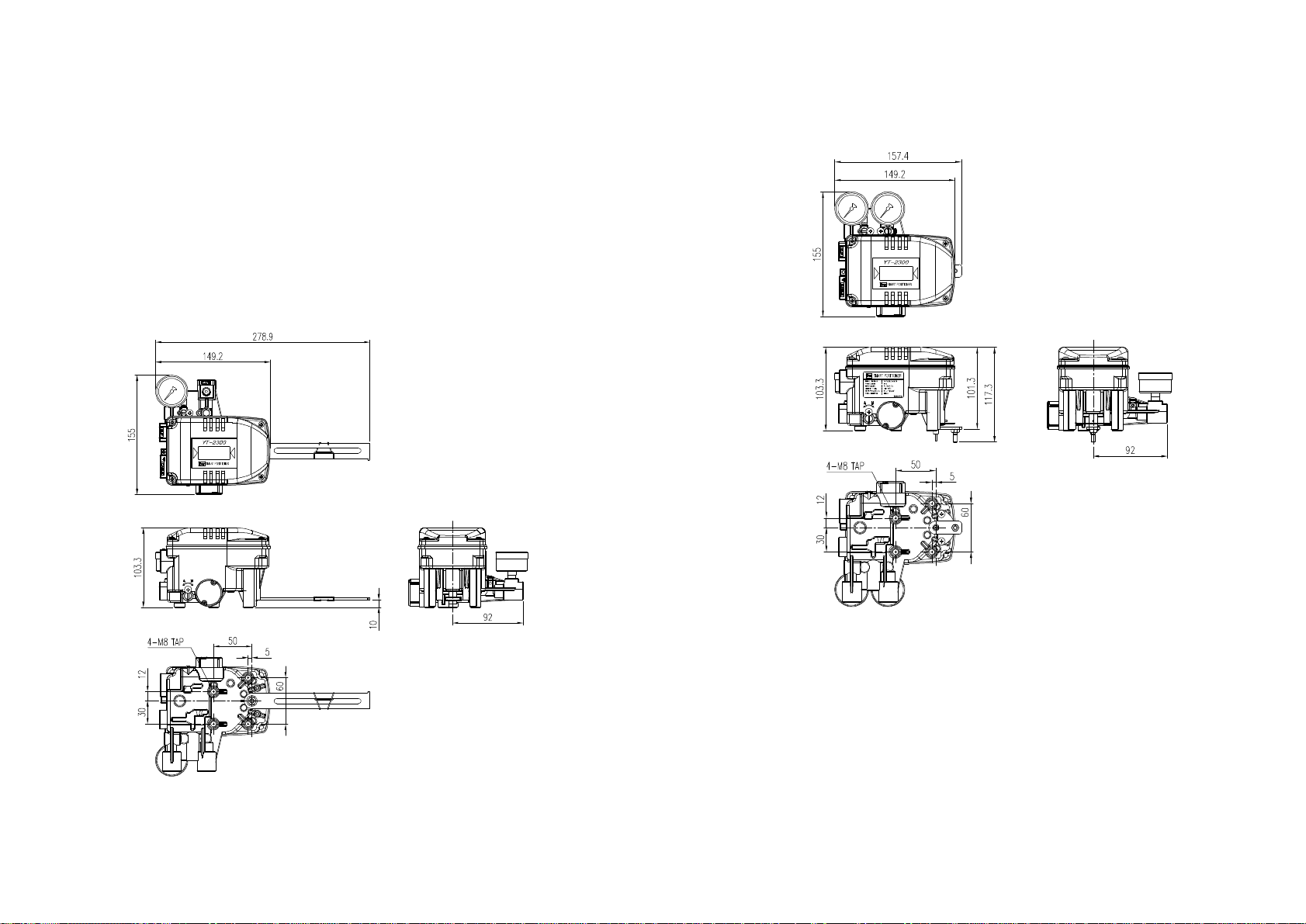

InstallingYT-2300Rwithbracket

YT-2300Rissuppliedwithstandardbracket.Thebracketisconsistsof2partandcan

beusedwithForkleverandNamurshaft.Thebracketisassembledinthefactoryas

basedon20mmofactuatorstemheight.Butifactuatorstemheightishigherthanthat

like30mm,50mm,reassemblethebracketadjustingtotheheight.Referringtothe

followingtable,checktheholepositions.

YT-2300RUpperbracketA

BottombracketBActuator

BracketassemblymethodbyactuatorstemheightH

Actuatorstem

height(H) Markingsofboltholes

A-L B-L A-R B-R

20mm H:20 H:20,30 H:20 H:20,30

30mm H:30 H:20,30 H:30 H:20,30

50mm H:50 H:50 H:50 H:50

Ex)IncasethatHis30mm,A-LshouldbelockedinH:30holeandB-LinH:20,30,A-R

inH:30,B-RinH:20,30withbolts.

-20-

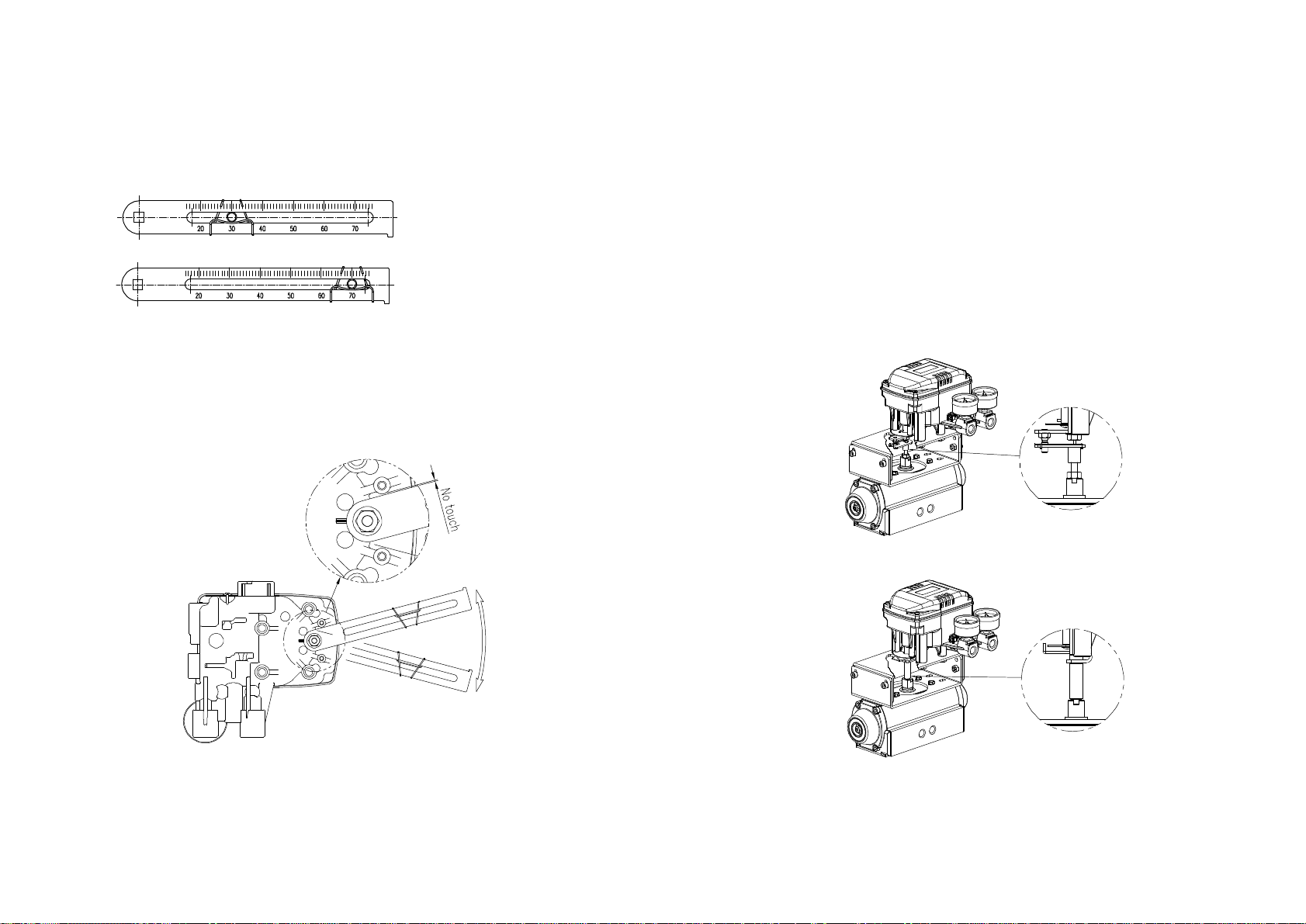

1.Usualtypesofactuatorstemheight(H)are20,30and50mm.AftercheckingH,

assemblebracketsasexplainedonthepreviouspage.Thebracketissetas20mmtype

inthefactory. Actuatorstem

Actuator

Actuatorstemheight(H=20mm)

2.Attachbrackettotheactuatorusinghexagonheadboltsorwrenchbolts.Diameterof

bracketboltholesis6mm.Usespringwashersoranyotherequipmentsoasthebolts

nottobeloosenedbyvibrationorimpact.Thedirectionofbracketisdifferentby

operatingconditions,butnormaldirectionisasfollowingpicture.Thatis,whenthepiping

ofactuatorandYT-2300RisdirectionA,bracketholeandindicatorattachedonthe

bottomofYT-2300Rmainshaftshouldbesamedirectionasbeinghalfcircle.

DirectionA

Attachmentdirectionofbracketandactuator

3.Setrotationpositionofactuatorstemasinitialzeropointwhichisstroke0%.Incase

ofspringreturntypesingleactuator,sincetheactuatorstemisalwaysrotatedatzero

pointwithoutsupplypressure,itiseasytocheckzeropoint.Iftheactuatorisdouble

acting,checkthatwhetheritisclockwiseorcounterclockwiseortherotationdirectionof

actuatorstemwithusingsupplypressure.

4.Setactuatorstemasinitialzeropointandinstallforkleverasthefollowingpicture.

Ensurethepositionofinitialzeropointwhenactuatorstemisclockwiseorcounter

clockwise.Installationangleofforklevershouldbeabout45degreebasedonthelinear

shaft.ButtheangleisnotrelatedtoNamurshaft.