3610J and 3620J Positioners

Instruction Manual

June 2008

2

Contents (continued)

Changing Positioner Action 23. . . . . . . . . . . . . . .

Changing to Direct Action 23. . . . . . . . . . . . . . . .

Changing to Reverse Action 24. . . . . . . . . . . . .

Split Range Operation 24. . . . . . . . . . . . . . . . . . . .

Characterized Cams for 3610J, 3610JP,

3620J, and 3620JP Positioners 25. . . . . . . . .

Principle of Operation 26. . . . . . . . . . . . . . . . . . . . .

Maintenance 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioner Disassembly 30. . . . . . . . . . . . . . . . . . .

Removing the Positioner from the Actuator 30

Disassembling the Bypass Valve 30. . . . . . . . .

Disassembling the Gauge Block 31. . . . . . . . . .

Disassembling the 3622

Electro-Pneumatic Converter 32. . . . . . . . . .

Disassembling the Feedback

Lever Assembly 32. . . . . . . . . . . . . . . . . . . . . .

Disassembling the Reversing

Plate and Gasket 32. . . . . . . . . . . . . . . . . . . .

Disassembling the Relay 32. . . . . . . . . . . . . . . .

Disassembling the Summing Beam

Assembly 33. . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembling the Nozzle Assembly 33. . . . . .

Disassembling the Input Module 34. . . . . . . . . .

Positioner Reassembly 34. . . . . . . . . . . . . . . . . . .

Assembling the Input Module 34. . . . . . . . . . . .

Assembling the Nozzle Assembly 35. . . . . . . . .

Assembling the Summing Beam Assembly 35

Assembling the Relay 36. . . . . . . . . . . . . . . . . . .

Assembling the Reversing Plate

and Gasket 37. . . . . . . . . . . . . . . . . . . . . . . . . .

Assembling the Gauge Block 37. . . . . . . . . . . . .

Assembling the 3622

Electro-Pneumatic Converter 37. . . . . . . . . .

Assembling the Feedback Lever Assembly 38

Assembling the Bypass Valve Assembly 38. . .

Changing Positioner Types 38. . . . . . . . . . . . . . .

Parts Ordering 40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Kits 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioner Common Parts 41. . . . . . . . . . . . . . .

3622 Electro-Pneumatic Converter 43. . . . . . .

Diagnostic Connections 44. . . . . . . . . . . . . . . . .

Loop Schematics/Nameplates 53. . . . . . . . . . . . . .

Introduction

Scope of Manual

This instruction manual includes installation,

operation, calibration, maintenance, and parts

ordering information for 3610J and 3620J Series

positioners. (i.e. 3610J, 3610JP, 3611JP,

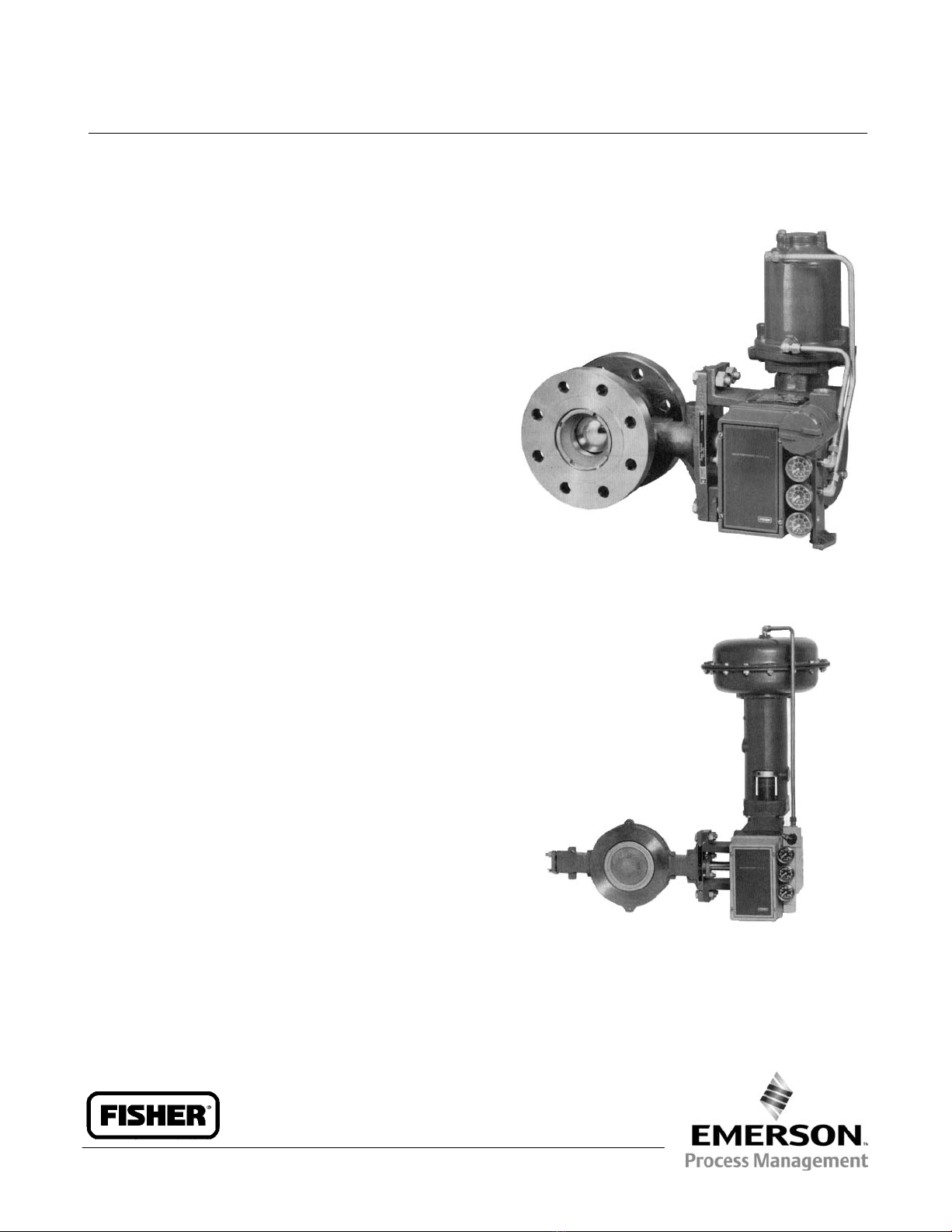

W6594 / IL

Figure 2. 3621JP Positioner with 585C Actuator

3620J, 3620JP, and 3621JP). This manual also

provides field installation information for the 3622

electro-pneumatic converter. Refer to separate

instruction manuals for information on the actuator

and control valve. Contact your Emerson Process

Managementtsales office if assistance is needed

in obtaining actuator or control valve instruction

manuals.

Do not install, operate or maintain a 3610J or 3620J

Series positioner without first Dbeing fully trained

and qualified in valve, actuator and accessory

installation, operation and maintenance, and D

carefully reading and understanding the contents of

this manual. If you have any questions about these

instructions, contact your Emerson Process

Management sales office.

Description

3610J or 3610JP pneumatic positioners and 3620J

or 3620JP electro-pneumatic positioners are used

with diaphragm rotary actuators and piston rotary

actuators as shown in figure 1. 3611JP and 3621JP

positioners are used with 585, 585R, 585C, or

585CR sliding stem actuators as shown in figure 2.

The positioner mounts integrally to the actuator

housing and provides a valve ball, disk, or plug

position for a specific input signal. The positioner

accepts either a pneumatic or milliampere input

signal. Refer to the Type Number Description for a

detailed explanation of type numbers.