M-Pac PLT2

The semi-automatic strapping machine M-Pac PLT2 is specially made for manual horizontal strapping of pallets. It can be

used in many dierent branches of industry. The M-Pac PLT2 is distinguished by reliability, easy operation and low

maintenance.

Semi-automatic horizontal strapping

Operation

The placing of the strapping is easy

to adjust by the lever. The strapping

cycle is started by a push button on

the control panel.

Strap tensioning

By means of a selector switch it is

possible to choose from manual or

automatic tensioning of the

strapping.

Manual strap tensioningmode.

The strap tensioning can be adjusted

by push button on the control panel.

This gives time to place the strapping

exactly, so that an optimal pallet

stabilization can be achieved.

Automatic strap tensioningmode.

The strap tensioning will be

automatically increased during the

strapping cycle to the adjusted level,

after which the strapping will be

sealed.

Variable seal time

Pop open of seals on critical products is

now history. Selective timing for

increased seal eciency is possible via a

switch.

Flexible appication (option)

The M-Pac PLT2 is not dependent on a

xed point of the electricity grid. There

is a possibility to let the machine work

on battery. In consequence of this the

M-Pac PLT2 can be used almost

anywhere.

Internal reel

The reel is integrated in the machine,

resulting in a compact engineering.

The coil is simply pulled out of the

machine, changed and pushed back.

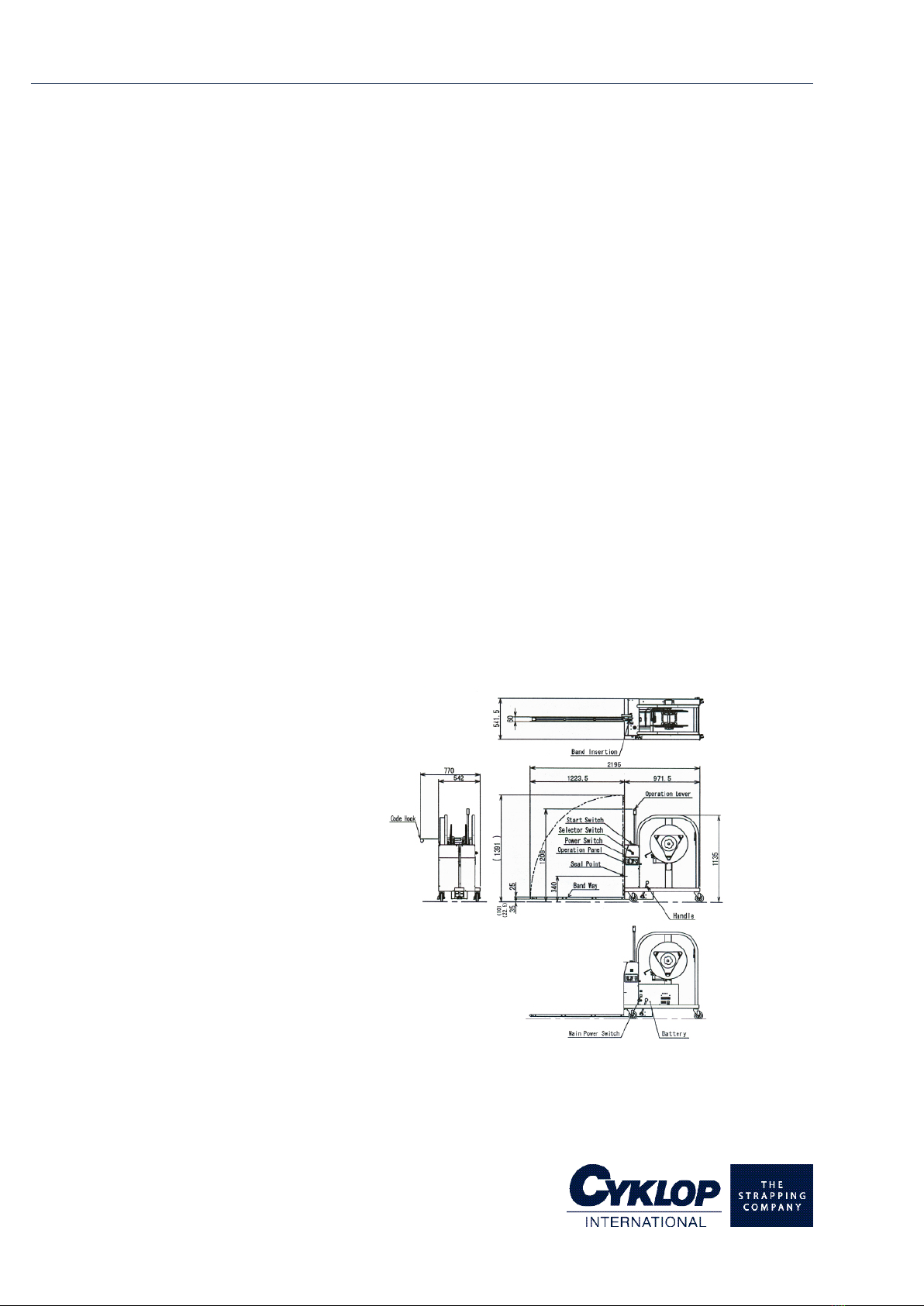

Working area

The M-Pac PLT2 is very deployable

with the 4 wheels, 230V power

supply.

Technical data:

Min. package: approx. 380 mm

Strap. material: Polystrap 12 or

15,5 mm

Coil: core diameter: 200 mm

outer diameter: 420 mm

width: 190 mm

Strap tension: max. 690 N

Heating time: approx. 30 sec.

Sealing: heat-seal

Power supply: 230 V, 50 Hz, 0,4 kVa

Machine weight: ca. 95 kg

Version 10/2008

Cyklop UK Limited

Unit 2, Generation Business Park

Barford Road

St. Neots, Cambridgeshire, PE19 6YQ

Phone: +44 (0)1480 216777

Fax: +44 (0)1480 216779

homepage: www.cyklop.co.uk

Subject to changes

Features