Copying all or part of this manual in any way or form is prohibited without prior written consent from its author. © 2012

website: www.fromm-pack.com

6

50302501manen.f

5 UNAUTHORIZED USE

This machine must be used for the manufacturer's intended use only.

In particular, it is prohibited to use even part of the system:

- Without guards and/or with disconnected, faulty or missing safety devices;

- If it has not been correctly installed;

- To handle materials having dimensions other than those specific in the technical data;

- Outdoors, where the machine may be exposed to rain or high levels of humidity;

- Under conditions in which the machine may be dangerous or may malfunction;

- For improper use of the machine or for use by untrained personnel;

- For use that does not comply with specific standards;

- In the event of power supply failure;

- In the event of irregular maintenance;

- Subsequent to unauthorized modifications or operations;

- Full or partial failure to comply with instructions;

- With accessories other than those recommended by the manufacturer;

The possible use of the machine under one or more of the following conditions is not foreseen:

- In environments at temperatures above +30°C.

A written statement from the manufacturer is required for exceptions to the above.

Modifications not authorized by the Manufacturer, which alter the machine's planned functions and modify risks

and/or create new risk, shall be the full responsibility of the party who performed these modifications.

Said modifications, when performed without prior manufacturer authorization, will nullify all forms of warranty

and invalidate the Declaration of Incorporation for the Machine Directive 2006/42/EC.

Use of this machine for other purposes than those recommended by the manufacturer in this manual are strictly

prohibited.

Consequently, the manufacturer shall not be held liable for injury to persons or animals or damage to property

caused by the improper or prohibited use of the machine.

6 RESIDUAL RISKS

a) Noise:

- though the machine is not in itself noisy, the use of noise protection may be requested due to the sound

pressure level (SPL) in the environment in which the machine is installed.

b) When, for operation or maintenance, the machine must be used in manual mode, the following Personal

Protective Equipment must be used:

- Gloves

c) Heat-related (burns): even though the machine features specific safety guards and signs to warn the

operator, a risk for burns exists when coming into contact or handling the heat-sealing elements;

d) Electricity-related (electrocution, burns):

- Risk created by the dangerous residual voltage and current inside the machine, even after the main

source of power has been disconnected.

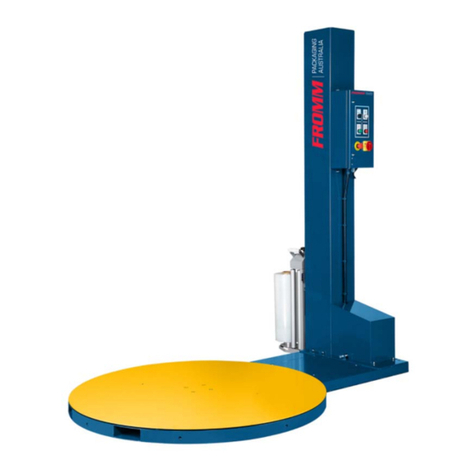

7 DESCRIPTION AND OPERATION

The AP250 is a machine designed to produce air pillows for product protection and void-filling. The machine

uses film supplied by FROMM or manufactured to its specifications. Heat seals are created using variable-heat

jaws. For each type of pillow, filling temperatures and pressures suited to that specific product are used.

Perforated mats of pillows (to optimize filling and facilitate separation) or singe pillows (according to the length

of the pillow itself) may be created to best suit customer needs. The use of this machine is reserved for

professional operators who have received appropriate instructions and training.