PART I

CONTENTS

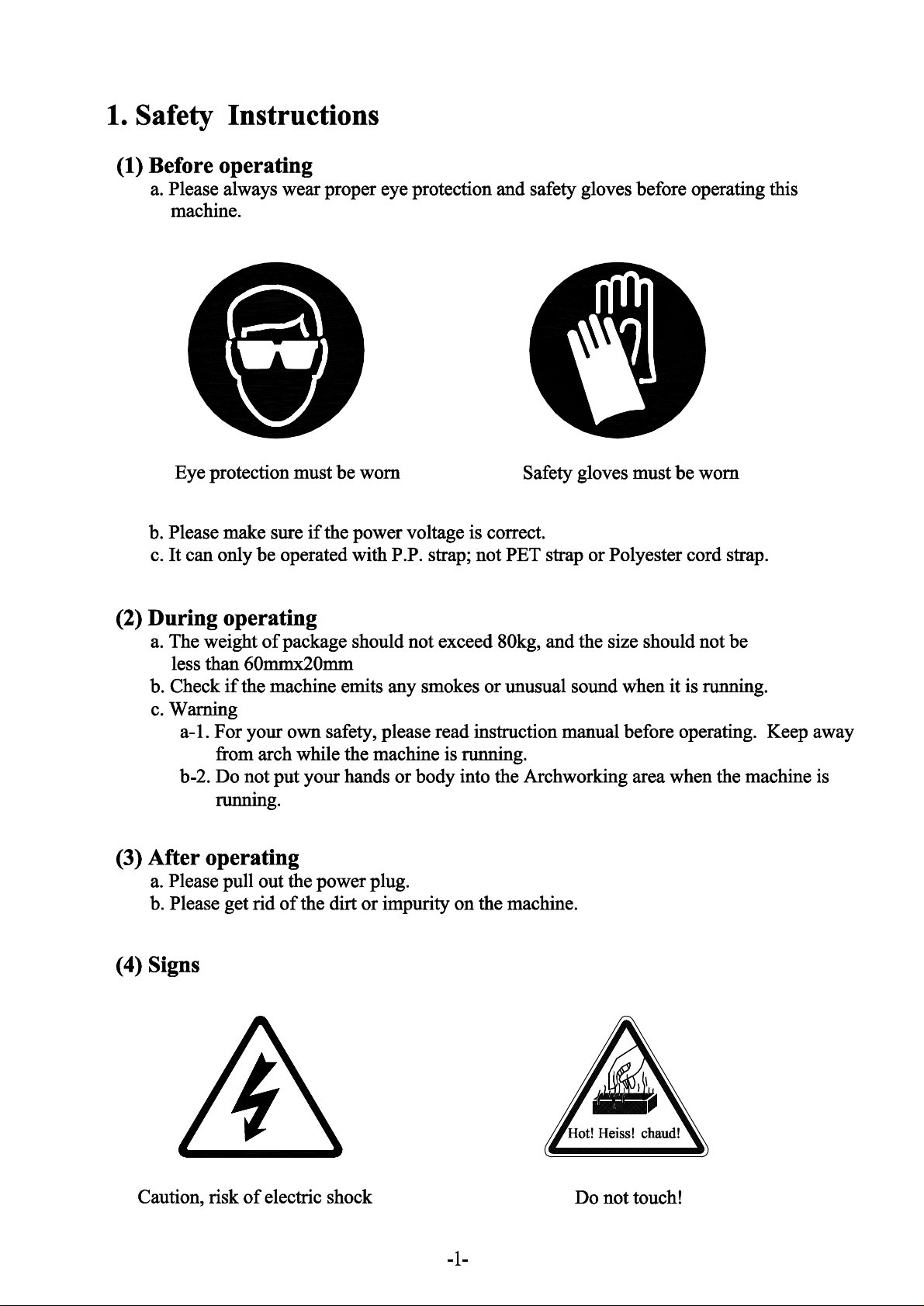

1. Safety Instructions…………………………………… 1~2

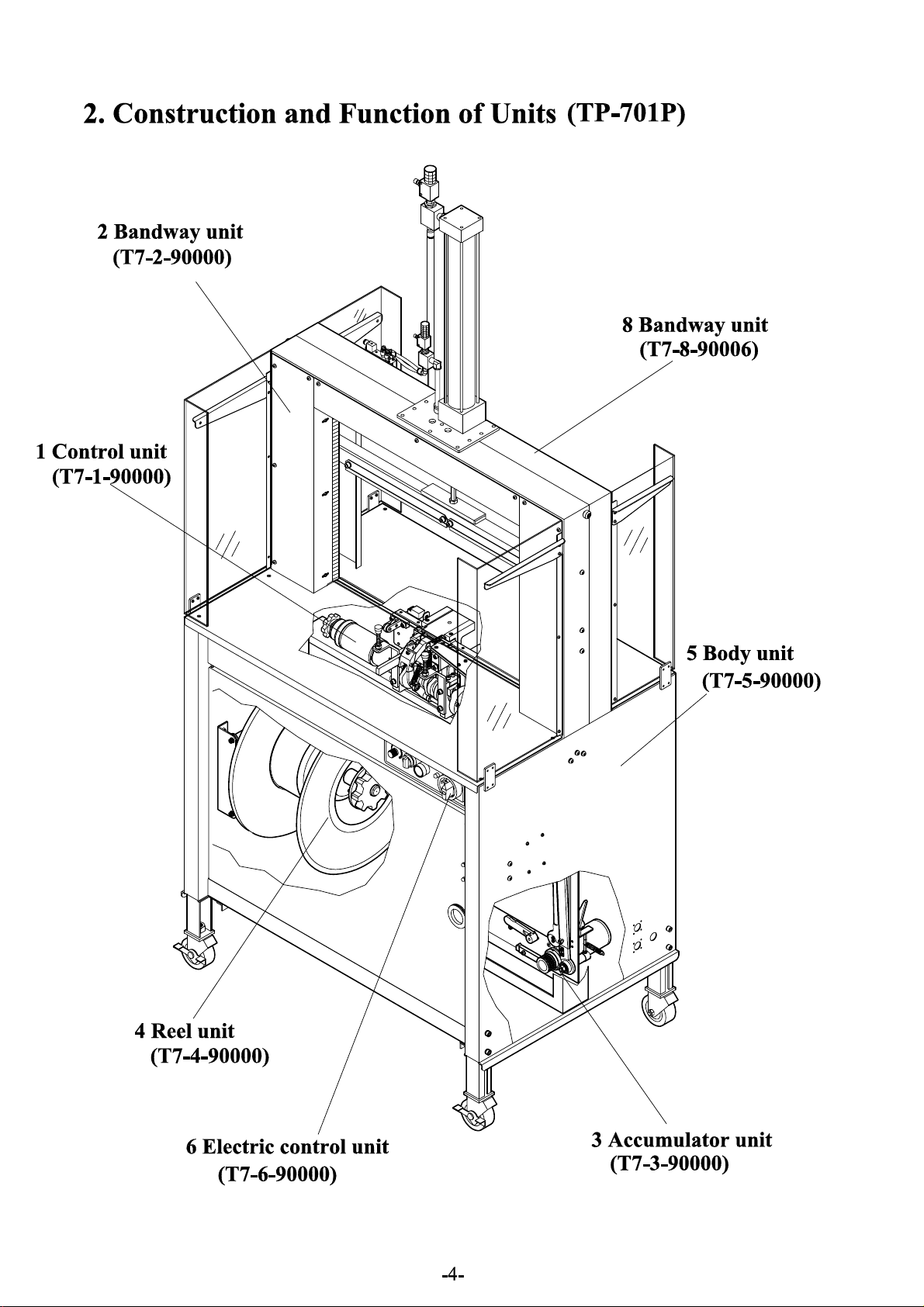

2. Construction and Function of Units…………………

3~4

3. General Safety Remarks………………………………………

5~8

( 1 ) Basic Operation…………………………………………………

5

( 2 ) Basic Safety Precautions…………………………………………5

( 3 ) Safety Instructions Governing Specific Operational Phases……

6

( 4 ) Warning of Electrical Dangers…………………………………

7

( 5 ) Grounding Instructions Shall Include the Following……………

7

( 6 ) Extension Cords…………………………………………………

8

4. Machine Information…………………………………………

8~17

( 1 ) Areas of Application and Machine Description………………… 8

( 2 ) Technical Safety Devices………………………………………

9

( 3 ) Electrical Specifications………………………………………… 10

( 4 ) Technical Data…………………………………………………

11~12

( 5 ) Machine and Operating Elements………………………………

13

( 6 ) Installation Diagram……………………………………………

14

( 7 ) Wiring Diagram…………………………………………………

15~16-3

( 8 ) Pneumatic System Diagram……………………………………

17

5. Operating the Machine………………………………………

18~26

( 1 ) How to Load and Thread P.P. Strap, and How to Operate……… 18

( 2 ) Strap Tension Adjustment………………………………………

19

( 3 ) How to Adjust the Right Strap Guide After Changing to a

Different Strap Width……………………………………….…

20

( 4 ) How to Adjust the Pressure Between the Feed Wheels of M2…

21~22

( 5 ) SQ2 Functioning………………...………………………………

23

( 6 ) How to Adjust the Strap Amount in the Accumulator Box……

24

( 7 ) Timer Box Functioning…………………………………………

25

( 8 ) Installation of Cylinder Unit……………………………………

26