Siebeck JET 2000 Operational manual

Translation of the original

operating manual

No. jet_in_bed_0315

Strapping machine JET 2000

Model JET IN

D - 69412 EBERBACH

ElektischerAnschlußwert Electricalsupply

KW

Volt Hz

Machinetype

Maschinentyp

Maschinen-Nr.

Machine-N°

Baujahr

Yearof constr.

Maschinenbez.

Masch.gewicht

Machineweight

Machinename

Verschnürungsmaschine/ Tyingmachine

Ph.AC

Internet:www.siebeck.de email:[email protected]

1

0

GMBH D - 69412 EBERBACH

Telephone 00496271-92080 Fax 00496271-920888

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 2

Table of contents

Page

Hazard warnings ………………………………………………………… 3

Foreword……………………………………………………………………4

Warranty…………………………………………………………………….5

EC Conformity declaration ………………………………………………..6

Technical data

Proper use ……………………………………….. 7

Safety…………………………………………………………………... 8

Set-up and commissioning ...………………………………………… 9

Inserting the string …………………………………………………….. 10

Correct positioning of the products to be wrapped……………… 11

Maintenance and care…………………………………………………… 12

Operating controls ……………………………………………………… 13

Aggregate zero point setting ………………………………………….. 14

Setting the stripper …………………………………………………….. 15

The story of knots ………………………………………………………. 16-17

Faults and their causes …… ………………………..………………….18

Residual risks and incorrect operation …………………………………19-20

Spare parts – list

Wiring and circuit plan

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 3

Hazard warnings

Hazard warnings are found in the respective position in the text.

They are denoted by this warning triangle and an

information text

Caution!

The technical manual must have been read and understood

before using the machine for the first time. For personal safety it

is important to follow all the instructions listed in it. The manual

must be kept bythe customer and must be handed over in case

the machine is passed on to third parties or a new user.

Caution!

Installation and repair must only be performed by qualified

persons who have the necessary experience and knowledge of

occupational and industrial safety and risks of accidents. If the

available staff do not have one or more of these qualifications,

specialist staff must be contracted.

Caution!

If it is necessary to replace a component, you must make

sure that only original spare parts are used. Improper repairs

or the use of non-original spare parts can cause

considerable damage and hazards for the user

In case of damage which has be caused by failure to observe this operating

manual, the warranty will be rendered null and void. No liability will be

assumed for consequential damages.

No liability will be assumed in case of material damages or personal injuries

which are caused by improper use or failure to adhere to the safety

instructions.

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 4

Introduction

This machine has been engineered in accordance with the recognised rules

of technology and in adherence to the regulations for occupational safety and

the prevention of accidents so that proper use cannot not cause any

hazards for the life and limb of the user or third parties.

Information on incorrect use and residual risks, which are still in place or

possible despite the integrated safety and technical protective

equipment, are described and illustrated on pages 43-47. These risks are

documented in a risk analysis and filed by the manufacturer.

Every person on the user's premises given the task of setting

up, commissioning, operating, maintaining and repairing this

machine must have read and understood this operating

manual, and in particular the chapter "Safety".

The customer's own changes, restrictions or upgrades and the resultant

safety-related consequences are at the expense and risk of the user.

If this machine is sold or set up at another location, this

operating manual must be handed over to the new owner or the

new user. Additional copies can be ordered from the address

given below, quoting article number 0914FRT-A-MKIVbed.

Friedrichsdorfer Landstrasse 65

D - 69412 Eberbach

Telephone 0049 6271-92080

Fax 00496271-920888

Internet: www.siebeck.de

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 5

WARRANTY

All machines which have been manufactured at our production

facilities are covered by a warranty of 12 months, starting from the

date of commissioning, or 18 months from the date of delivery. This

warranty covers material and manufacturing faults.

The warranty covers all parts, with the exception of

expendable parts and parts which are replaced due to normal wear

during maintenance. Under the terms and conditions of the

warranty we are not liable for working hours and downtimes.

If machine damage is caused due to the use of unsuitable tying

material or material not expressly recommended by us, the warranty

will be rendered null and void.

All claims must be asserted in writing. An exact description of the

cause of damage, the part number and machine number must be

enclosed. Once we have accepted your warranty claim, the faulty

part must be returned to us.

This warranty is only valid if

original parts without any form of modification are used.

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 6

EC - Declaration of conformity

We hereby declare that the following specified machinery

Make : SIEBECK

Model : JET IN

Serial No. :

complies with the following provisions applying to it:

EC Machinery Directive 2006/42/EC (valid from 29.12.2009)

Harmonised standards applied, in particular

EN ISO 12100 Part 1 and 2 ”Safety of machinery"

EN 60204-1 “Electrical equipment of machines"

89/336/EEC as amended 92/31/EEC “EMC Directive“

Eberbach, date 10.09.2014

Siebeck GmbH

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 7

Technical data

Machinery dimensions

D - 69412 EBERBACH

ElektischerAnschlußwert E lectricalsupply

KW

Volt Hz

Machinetype

Maschinentyp

Maschinen-Nr.

Machine-N°

Baujahr

Yearofconstr.

Maschinenbez.

Masch.gewicht

Machineweight

Machinename

Verschnürungsmaschine/ Tyingmachine

Ph.AC

Internet:www.siebeck.de email:[email protected]

SEW

1

0

122,5 - 222,5

450,0

275,0

1575,0 - 1675,0

310,0

2450,0 - 2550,0

250,0

560,0

850,0 - 950,0 410,0

690,0

200,0

105,0

120,0

All dims. in mm, changes reserved

Electrical connection values: 400 Volt, 3 phase power supply, 1 kW, 50 Hz

Machine performance: up to 40 cycles p. min. (based on product size)

Machine weight: 130 kg

Noise pressure level: < 79 dB(A) as per EN 11204

(without product / without string)

Proper use:

Solely commercial / strapping of preferably ring-shaped products

RING DIMENSIONS

AB

C

Ringabmessungen

maximal minimal

A

B

C

600 mm 80 mm

500 mm 70 mm

400 mm 5 mm

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 8

Safety!

The European standard EN 60204-1 requires the power supply

connection to be established by a suitable plug device. The

power supply cable must not be connected to a power distributor

directly by way of a terminal connection, without a plug

connector.

The safety limit switch below the table top prevents the machine

from starting up during maintenance work. This safety device

must be checked before putting the machine into operation each

time to make sure it is fully functional.

Procedure:

First switch on the machine and remove table top. Do not reach

into the machine (!), then press the foot pedal. The machine must

not start up.

Attention!

Risk of crushing! Checking protective device

The rack is secured electromechanically during the downward

motion. If the needle shoe hits an object above the table top, the

drive motor is reversed immediately and the rack runs upwards in

the initial position.

To check this protection device, place a box on the table top

opening and start the machine by pressing the foot switch. If the

box is damaged during this process, the protective device must be

checked. The manufacturer recommends carrying out this check

on a daily basis.

Always pull the mains plug before all maintenance and cleaning

work!!

When inserting a new string bobbin, and when threading the

string, always pull the mains plug.

A minimum of 500 lux is required for local lighting.

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 9

Set-up and commissioning

Erect the machine in the designated location and press the roller wheel locks

down so that the machine is stable.

To avoid collisions with other machines, as well as for adequate

access for the operating and maintenance personnel, there must

be a clearance of min. 1.5 metres around the machine.

If not otherwise stipulated, the machine is designed for 400 volt 3-phase

alternating current and 50 Hz, when supplied from the factory. Measure the

local mains voltage and compare the measurement with the value specified

on the type plate.

Check that the machine is correctly grounded. Adhere to the local electrical

engineering regulations. Maximum fuse protection 16 amperes.

Checking the motor direction of rotation

The machine comes with a rotation direction monitoring device (phase

sequence relay).

Connect the machine via the mains plug to the mains. Turn on main switch.

If the pilot light does not light up, then there is an incorrect phase sequence.

The monitoring device locks the power supply. Two phase wires must be

exchanged on the mains plug for the correct direction of rotation.

Strapping material

The knotting mechanism is designed for a maximum thickness of 900 linear

metres per kilogram (ELA-900). We recommend obtaining the material from

the machine manufacturer during the warranty period. This prevents the

possible loss of the warranty claim, which could be caused by the incorrect

use of the material.

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 10

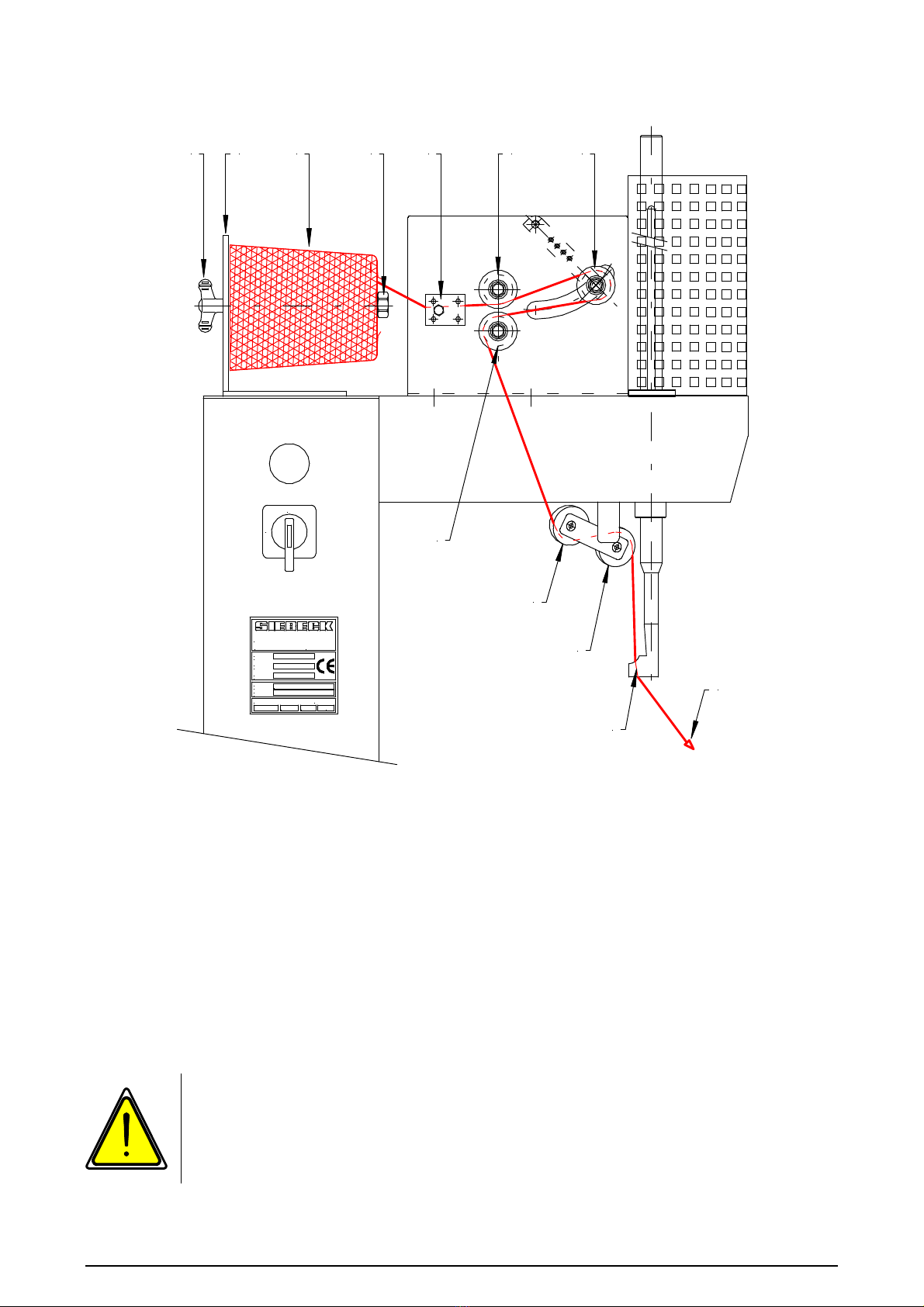

Inserting the string

D - 69412 EBERBACH

ElektischerAnschlußwert Electrical supply

KW

Volt Hz

Machinetype

Maschinentyp

Maschinen-Nr.

Machine-N°

Baujahr

Year o f co nstr.

Maschinenbez.

Masch.gewicht

Machineweight

Machinename

Verschnürungsmaschine / Tyingmachine

Ph.AC

Internet: www.siebeck.de email: info@sieb eck.de

1

0

BCD A E 21

3

4

5

FG

1. Insert bobbin holder (A) with string bobbin (B) into the pick-up (C)

and tighten with wing nut (D).

2. Thread string through between the brake plates (E)

3. Thread into the five string rollers reels starting at 1, and in the

sequence up to 5, and then through the hole (F) in the needle shoe

from top to bottom thread

4. Pull end of string (G) with your right hand as far as the right, rear

table top corner and hold there

5. Start the machine via the foot pedal. The string is then automatically

inserted underneath the table top and cut off

Attention Risk of crushing!

Make sure you keep the opening in the middle of the table top

clear.

When inserting the needle here, there is a considerable risk of

injury.

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 11

Correct positioning of the products to be strapped

1. The products to be wrapped (ring) should be run in each case for

the first and any other binding up across the contact surface

marked on the table top (see figure below).

2. After the first binding, the product is run further to the right and

again to just over the contact surface.

If two strappings are not enough, the process must be repeated.

3. If the product is pushed beyond the contact surface, the wrapping

becomes loose. If the product is run just in front of the contact

surface, then there is a fault in the binding, or the string tears.

Kordel

Kordel

Anlegekante

Anlegekante

Nadelschuh Nadelschuh

Tischplatte Tischplatte

Anlegekante

Anlegekante

Ring

Ring

1 2

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 12

Service and maintenance of the machine

To prevent accidents when cleaning and servicing the machine, it

is essential to make sure that the main switch is turned off, or the

machine power supply is switched off. The manufacturer of the

machine is released from any liability if this mandatory

requirement is not observed.

Cleaning the machine

After a running time of approximately 40 hours, the machine must be

cleaned thoroughly. The table top must be removed so that the

knotting aggregate is exposed and can be easily cleaned. Clean with

a vacuum cleaner and do not use compressed air.

Lubrication schedule

After a running time of approximately 40 hours, all lubrication nipples

must be lubricated (use only oil, no grease). All lubrication points

marked in red must be lubricated with an oil can twice a week. All

moving parts must be oiled once a week.

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 13

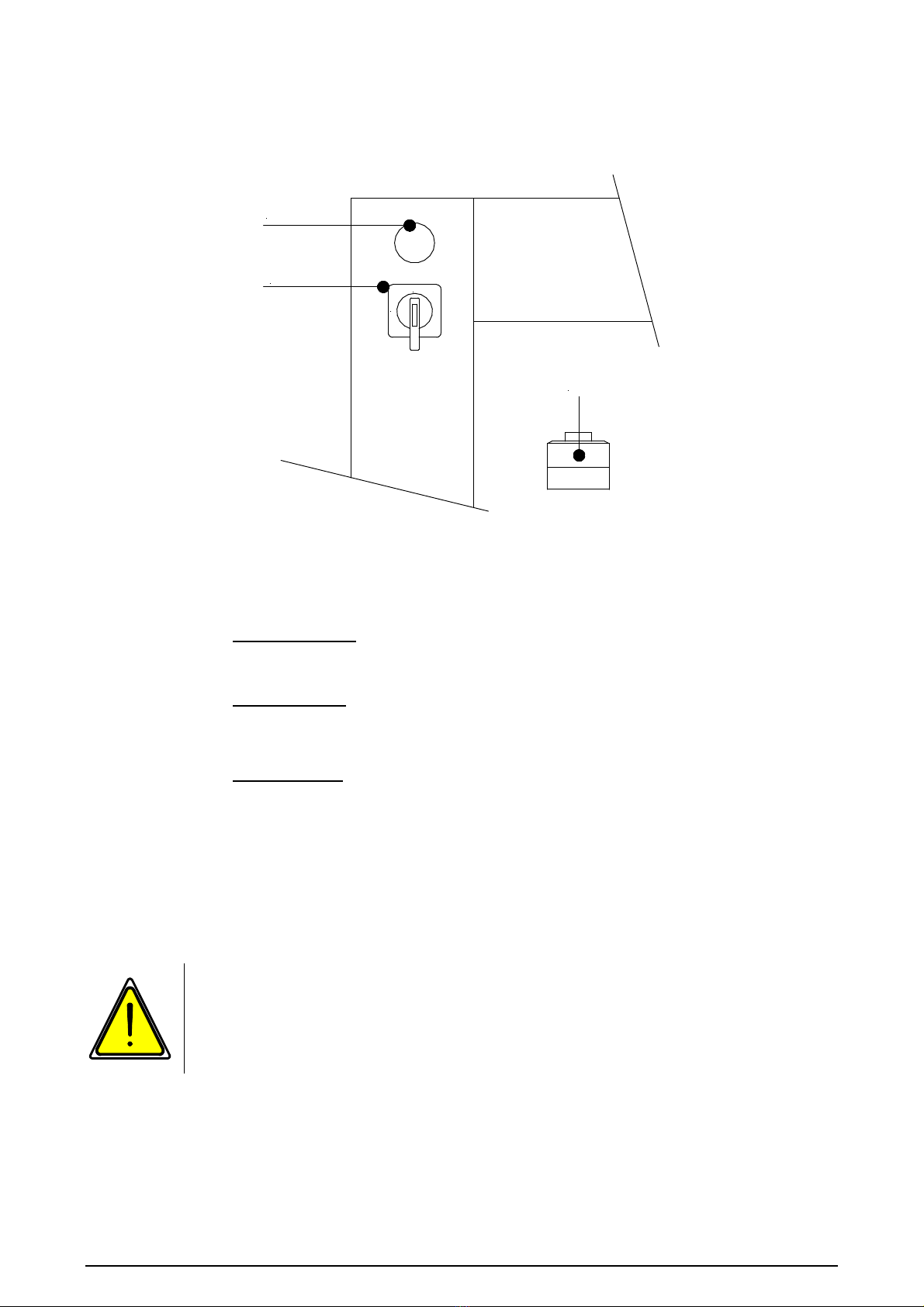

Operating controls

1

0

1

2

3

1 Control lamp

2 Main switch = O / off I / on

3 Pushbutton

(under the table top )

- press intermittently = Move aggregate forward in

stages

- press repeatedly = Aggregate runs to

neutral position

Jog mode via pushbutton:

Only authorised and trained staff are allowed to perform this

procedure!

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 14

Adjusting the zero position on the aggregate

JAG-07-050

-S3 -S2

"O"

-S10

-M2

The correct zero point (“O“) is achieved if the inserting lever JAG-07-

050 has reached its furthest left position.

The zero point is adjusted by sliding the end switch -S3.

Only authorised and trained staff are allowed to perform this

setting!!

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 15

Stripper setting

The side setting for the stripper "C" is made using the threaded pin No. 9

(group M4).

When the knotter "A" moves back, the stripper "C" must rest on knotter "A"

with pressure.

The height is set is using the rod end No. 2 (group M4).

The correct height of the stripper slot "B" to the knotter is shown in the figure

below.

A B C

Only authorised and trained staff are allowed to perform this

setting!

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 16

The story of knots

Incorrect knotting patterns and their causes

Short loops

The knotter opens too early. Shift the mount for the

cam roller for opening the knotter backwards

towards the chain wheel. The stripper does not rest

on the knotter. The string is too thin.

Knots not strong enough

Stripper slot too large. The knotter opens too early.

The string is too thin.

String not cut cleanly

The string knife is blunt. Flip or replace the knife.

String break before the knot

Sharp edges on the stripper, drawslide head, tip

up lever or knife lever.

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 17

One normal length and one short loop

The knotter is not closing properly. Tension

spring for the knotting lock is too weak. The

stripper does not rest on the knotter.

Single loop

The knot has only a single loop. The second loop

is drawn through. Increase the spring pressure on

the twine button. The lead end of the string which

protrudes from the twine button must not move

when the tying arm starts up.

Loop ends torn

Upper or lower finger of knotter or stripper has

sharp edges.

The perfect knot

A correct knot has two loops of equal length

and one short and one long end of string.

The knot is tight and hard.

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 18

Faults and their causes

Never rework the surface of the twine button housing! This

surface has an exactly specified contour. The notch is intentional

and has not been created by wear. Only ever make the necessary

settings by adjusting the string brake and twine button spring.

1. Threading: Make sure that threading has been performed properly. The

string taking the wrong course is the most common cause of string breaks

(see "Threading diagram" on pages 22-24).

2. String: The machine is set to a certain string thickness. Always use

the same quality and thickness of string in order

to achieve the best results..

a) String, which is too weak often breaks on the twine button

instead of being pulled out without hindrance

b) If the string is too thick, it will not be released by the knotter

c) String, which is too thin causes a loose knot

3. Twine button:

If you are using a good quality of string of the correct

thickness and it still breaks and leaves behind residual fibres in the twine

button, this is generally caused by excessive spring tension on the twine

button.

Reduce the spring tension. Make sure that the setting wheel re-engages

properly and the retainer screw is tightened.

4. String tension:

You achieve the best results with an even, smooth

string brake setting. Check the setting by pulling out a few metres of string

from the tying arm tube. You can change the string tension by turning the

knurled nut on the string brake

Every person on the user's premises given the task of setting

up, commissioning, operating, maintaining and repairing this

machine must have read and understood this operating

manual, and in particular the chapter "Safety".

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 19

Residual risks and incorrect operation

Residual risks and incorrect operation, which exist despite measures for

integrated safety and technical protective equipment, are described and

illustrated in the following. These risks are documented in a risk analysis and

filed by the manufacturer.

When the machine hood is open, the knotting aggregate can be driven using

jog button at reduced step by step (jog mode). The individual movement

sequences can thus be observed quite easily.

Jog mode:

Only authorised and trained staff are allowed to perform this

procedure!

In the entire area of the knotting aggregate, in particular on its

drive elements, chain wheel to roller chain, there is a

considerable risk of crushing.

Attention Risk of crushing!

Make sure you keep the opening in the middle of the table top

clear. When inserting the needle here, there is a considerable risk

of injury.

Thermal hazard!

The drive motors can reach temperatures of up to 80° C. If the

covers are removed, contact can cause injuries.

Siebeck GmbH Translation of the original operating manual jet_in_bed_0315

Seite 20

Risk of cuts.

When installing and removing the knife M.

When installing and removing the knife M, you must adhere to the following::

-Do not touch the knife blade S

Risk of injury!

-The cover plate A must be fitted as illustrated. If the cover

plate is missing, the knife M will wear quickly.

AM

S

S

Only authorised and trained staff are allowed to perform this

procedure!

Every person on the user's premises given the task of setting

up, commissioning, operating, maintaining and repairing this

machine must have read and understood this operating

manual, and in particular the chapter "Safety".

This manual suits for next models

1

Table of contents

Other Siebeck Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

AirSaver

AirSaver F2 Safety instructions, setup & installation manual

HUALIAN

HUALIAN M-PE Series Operation manual

Pro Pack Solutions

Pro Pack Solutions Eagle 710 Operation manual

Oliver

Oliver 1808-D User's operation

Kronos

Kronos H-46 Series Operation, safety and spare parts manual

Robopac

Robopac ROBOT S7 Use and maintenance manual