Strack SN1598 User manual

SAFETY RING BOLTS, ROTATABLE SN1598

OPERATING MANUAL

2STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

ILifting elements

Information about this operating manual

This manual addresses to the operating-

and maintenance staff.

It contains all the important information which is

necessary for the safe handling of this device.

The machine operator has to take care that this

operating manual is available for the operating- and

maintenance staff in an understandable language.

In addition to the operating manual also further

information for a safe handling with this device are

essential:

• Read the respective guidelines for your country.

STRACK NORMA recommends adding all relevant

guidelines and regulations for accident prevention to

this operating manual.

If, despite of this, concerning this device, problems

should occur or if questions arise, we are of course

always at your disposal.

About the document

The language of the original operating manual is

German. All other languages of this manual are a

translation of the original operating manual. It has

to be placed at every time in the near of the product.

The strict observance of this manual is a precondition

for the intended use and the correct operation of the

product.

The operating manual corresponds to the design of the

product and the state of the based technical safety

regulations and standards.

Definition qualified personnel

Qualified personnel are persons who, in view of

their expert training and experience, have sufficient

knowledge in the use of lifting means and is suffi-

ciently familiar with the relevant norms and national

regulations so that they can judge the safe-for-

working state of the product being used.

Operating manual -- Safety ring bolts, rotatable SN1598

Content Page

Informationen zu dieser Anleitung 2

Grade 10 3

Intended use 4

Information for use 4

Limits of use 4

Mounting instruction 5

Maintenance, Checks, Repairs 5

Serviceanweisung 6

Declaration of conformity 7

3

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

ILifting elements

Operating manual -- Safety ring bolts, rotatable SN1598

Grade 10

These lifting points are designed considering this

manual as well as the national regulations for

lifting and holding the load. Read the manual

carefully before using the lifting points. The user

must have access to the operating manual until

withdrawal of the connecting links from service.

The manual is updated continuously and valid only

in the latest version. The manual is available as a

download under the following link: www.strack.de

Method of lifting

No. of legs

Angle of inclination

1

0°

1

90°

2

0°

2

90°

2

0°-- 45°

2

45°-- 60°

3 + 4

0°-- 45°

3 + 4

45°-- 60°

2

asymm.

3 + 4

asymm.

Code Thread

[mm]

Tightening

torque [Nm]

Load capacity

[kg]

SN1598-M8 M8 800 300 1600 600 400 300 600 400 300 300

SN1598-M10 M10 1100 500 2200 1000 700 500 1000 700 500 500

SN1598-M12 M12 2000 700 4000 1400 1100 700 1400 1000 700 700

SN1598-M16 M16 4000 1500 8000 3000 2100 1500 3000 2200 1500 1500

SN1598-M20 M20 Can be tightened 5000 2300 10000 4600 3200 2300 4800 3400 2300 2300

SN1598-M24 M24 manually 6500 3200 13000 6400 4500 3200 6700 4800 3200 3200

SN1598-M30 M30 12000 4900 24000 9800 6900 4900 10300 7300 4900 4900

SN1598-M36 M36 15000 7000 30000 14000 9800 7000 14700 10500 7000 7000

SN1598-M42 M42 22000 9000 44000 18000 12600 9000 18900 13500 9000 9000

SN1598-M48 M48 30000 12000 60000 24000 16800 12000 25000 18000 12000 12000

Safety factor 4

Attention: Subject to technical changes!

4STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

ILifting elements

Operating manual -- Safety ring bolts, rotatable SN1598

Intended use

Load capacity: working load limit according to test

certificate or working load limit table in the given

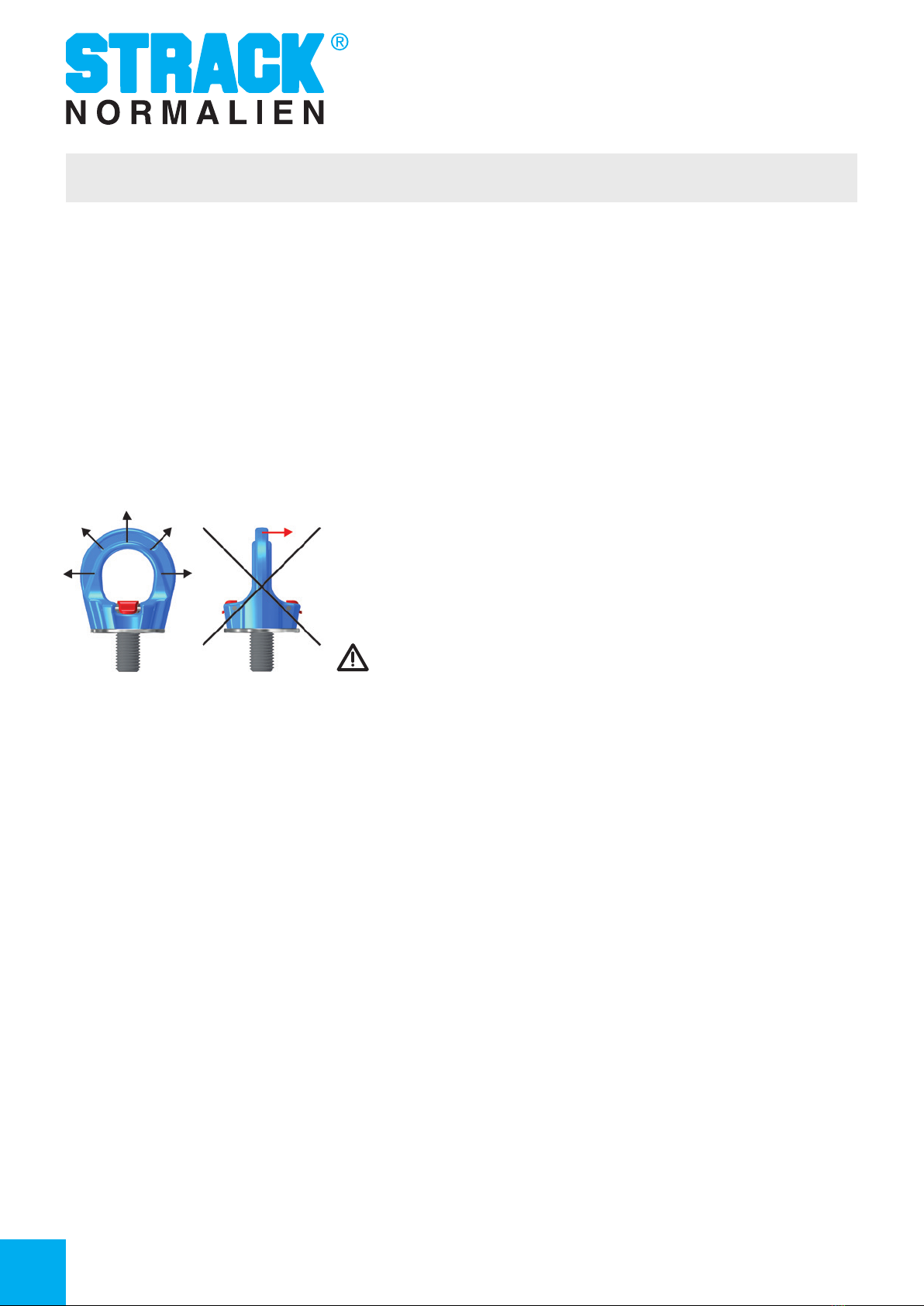

directions of tension – see picture 1.

Admissible operating temperature: -20° to 200°.

Impacts: impacts which occur because of e.g.

acceleration during lifting and lowering can be

unconsidered.

Other: Lifting points have to be mounted only with

the included screw. The body is rotatable 360° and

must be aligned in the permitted direction of tension

before use.

Picture 1: permitted Picture 2: not permitted

Information for use

• Lifting points should be used by a competent

authorised person.

• Visual inspection before first usage (see main-

tenance instruction)

• Before every usage check for damages on screw

and thread – lifting points must be rotatable.

• Load only in the specified direction (see picture 1)

with WLL acc. to table.

• Make sure before each use that the lifting point

is hand tight (by the lock system or an Allen key).

• Please note restriction in application for eventually

appearing difficulties in load.

• Connected lifting gear (e.g. hook) must be flexible

in the ring.

• Lifting points must be stored in a clean and dry

area.

• SN1598 lifting points are not designed to be

rotated under load.

• Do not overload lifting points. A falling down load

may lead to injuries or death!

• Do not use damaged lifting points (see maintenance

instruction) – they can fail in operating conditions –

load can fall down!

Limits of use

When lifting points are used under other conditions

than the one mentioned in Intended use (see above),

restrictions on used must be applied.

• Do not use lifting points in connection with acids,

bases or their steams.

For application in chemical environments, please

contact our technical service.

•Do not load lifting points when they come into

contact with corners or sharp edges!

• Do not lift people!

• If the load distribution is asymmetrical (sling legs

subtend different angles to the vertical), only load

the 2-leg sling with the WLL of a 1-leg sling.

In the case of a 3- or 4-leg lifting sling, it is only

allowed to load it with a maximum WLL of a 2-leg

lifting sling. In case of doubt, it must be supposed

that only one of the legs will carry the entire load.

5

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

ILifting elements

Mounting instruction

Mounting only by competent authorized person.

Tool-free assembly and disassembly

The cap in pos. 1 (assembly position) has contact with

the screw:

0°

The cap in pos. 2 (input position) does not have any

contact with the screw:

360°

• The equipment, where the lifting points are

mounted on, has to meet the requirements of the

Machinery Directive 2006/42/EC.

•Choose adjustment of lifting points so that you

have a symmetric load. Center of gravity must be

under the lifting point.

• The base material must be of sufficient strength

that the force induced can be absorbed without

deformation.

• Choose lifting points with adequate WLLs –

see table.

• The screwing area must be flat and be provided

with a diameter not smaller than the bottom part

of the lifting point. The threaded hole with

adequate depth must be in the middle and in a

square to ensure that the screw can be screwed

in correctly (blind hole).

Operating manual -- Safety ring bolts, rotatable SN1598

• Minimum screw penetration:

1 x M in steel (M = thread size e.g. M20 =

20 mm)

1.25 x M in cast steel

2 x M in aluminum

• Threaded hole must be cleaned before screwing.

• SN1598 lifting points can also be fixed with an

Allen key.

• If necessary (e.g. if vibrations occur), use liquid

thread adhesives (please note manufacturer’s

instructions).

• Make sure that the adjustment of the lifting point

will not lead to improper loading, e.g. if:

– There is no possibility to align in the direction

of tension

– The direction of tension is not in the foreseen

area acc. to picture 1

• Use only original parts – recognizable by the

marking (WLL, thread).

• It is not allowed to modify the lifting point, e.g.

welding, heat treatments and surface treatments

(galvanising) are prohibited. Also shortening of

screw is forbidden.

• Mount only lifting points free from defects.

• Check used lifting points acc. to maintenance

instruction before application.

• After assembling, lifting points must be able to

rotate properly.

•Do not use any extension when assembling.

Maintenance, Checks, Repairs

• An inspection in accordance with the national

standards must be carried out annually by a tech-

nical expert. If used frequently under a full load

these inspections can be implemented regularly.

We also recommend a crack test every two years.

The screw must be taken out from the body.

• The parts must be free from oil, dirt and rust for

inspection and crack test. Adequate cleaning pro-

cedures are the ones, which do not overheat, hide

failures on surface and cause hydrogen embrittle-

ment or stress crack corrosion.

• During inspection check all parts which can influence

safety and function, – e.g.:

– Cracks, notches, deformation, noticeable signs of

excessive heat

– Abrasion resp. corrosion of more than 10 % of the

cross section

In case of doubt, if the lifting points are damaged,

stop using them and have them examined by an

expert.

Repairs

• Maintenance of the lifting points should only be

carried out by technical experts.

• If small defects like notches or score marks are

visible, they can be carefully removed by using

grinders or files. The repaired area has to merge

smoothly without sudden changes of the cross-

section. When repairing, the cross section must not

decrease of thickness by more than 5 %.

• Welding procedures and heat treatments are pro-

hibited.

Exact dimensions can be found in the Operating

manual of this product on our website www.strack.de

6STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

ILifting elements

Operating manual -- Safety ring bolts, rotatable SN1598

4. Distortion of the ring caused by excessive lateral

stress

In case of any noticeable distortion, the lifting point

must be decommissioned.

5. Checking the flap function

Check the flaps for distortion, wear and fault-free func-

tioning. Both flaps must be fully functional – it must

be possible to tighten and disassemble the lifting point

by hand. When fully assembled, it must be possible to

turn the ring smoothly (towards the loading direction).

The flaps must be held in position by the spring and

the pins must not be bent.

In case of malfunctioning exchange the flap set.

6. Screw cracking test

Disassemble the lifting point in accordance with the

opera-ting instructions. The screw must be cleaned and

the thread must be checked for damage, distortion and

correct functio-ning (thread gauge). The marking must

be clearly legible and a magnetic surface crack test

must be performed. Smaller cracks on the screw head

may be repaired by filing, grinding etc. Care must be

taken not to reduce the cross-section by more than

10 %. If in doubt, the screw must be replaced.

7. Checking the sleeve

Check the sleeve for distortion and wear. If any doubts

remain regarding functionality or safety of the lifting

point, we suggest to exchange the sleeve or decommis-

sion the lifting point.

Check that all parts have been mounted correctly and

that the lifting point may once again be released for

safe operation.

Service instructions

General information

The lifting point SN1598 operator must perform a

risk assessment test and take measures to ensure the

safe use of the safety ring bolt, including the deter-

mination of the kind of test to be performed on the

safety ring bolt and its scope. STRACK NORMA recom-

mends that such a test is carried out annually by a

qualified person.

Depending on the conditions of use, tests may also

be performed more frequently. In case of frequent use,

we recommend to perform a cracking test every two

years.

To perform this test, the screw must be removed

from the main casting. For regular checks and for the

cracking test, all parts must be free from oil, dirt and

rust. Only choose a cleaning procedure that does not

overheat, cover up surface defects or cause hydrogen

embritt-lement or stress-corrosion cracking.

When performing a test, all parts must be checked

for damages that could impair safety or function;

e.g. breakages, notches, cracks, distortion, improper

heat impact, wear and tear and/or corrosion of more

than 10 % of the cross-section.

If any doubts remain with regard to functionality or

safety, the lifting point must be decommissioned.

Checking

Safety ringbolts SN1598 must be checked as follows:

1. Check that all parts are in their original condition

--- may be seen from the stamping (load capacity,

screw, thread).

Check that the condition of the product upon delivery

has remained unchanged; i.e. no soldering, heat

treatments or surface treatments have been carried

out. Check that the screw has not been shortened.

In all cases, changes must be agreed to determine

whether the lifting point remains suitable for use.

2. Mount the lifting point according to the operating

instructions

Check that the screw-on surface is in full contact with

the mounting surface. If in doubt, check the screw

and the sleeve for distortions or other signs of over-

stressing and exchange if necessary.

3. Distortion of the ring caused by excessive

vertical stress

If the ring exceeds the measure “e” (inside dimen-

sion of the screw head ring), the lifting point must

be decommissioned.

SN1598- e max.

M8 / M10 29.20 mm

M12 34.70 mm

M16 39.10 mm

M20 44.60 mm

M24 55.20 mm

M30 66.00 mm

M36 77.00 mm

M42 79.20 mm

M48 96.80 mm

7

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

ILifting elements

Operating manual -- Safety ring bolts, rotatable SN1598

Declaration of conformity

According to Annex II A of the Machinery Directive

2006/42/EG and Machinery Safety Regulation 2010

for lifting devices:

Description/ Denomination:

Ring bolt, rotatable

with the article designation SN1598

We declare in our sole responsibility that the product

mentioned in this certificate fulfills the relevant

conditions of the Machinery Directive 2006/42/EG

and that the mentionedstandards have been applied.

In case of any not by us approved changes of the

product this declaration gets invalid.

The following standards were applied:

EN 16777-1, DIN ISO 9001

It is a precondition to put the product into service that

the instruction for use has been read and understood.

This declaration is binding for the manufacturer

STRACK NORMA GmbH & Co. KG

Königsberger Str. 11

D-58511 Lüdenscheid - Germany

Date: 30.07.2018

Dag Friedrich, i.V. Ludger Müller,

Managing Director Technical Manager

STRACK NORMA GmbH & Co. KG

Königsberger Str. 11

D-58511 Lüdenscheid

Tel.: +49 2351 8701-0

Fax.: +49 2351 8701-100

www.strack.de

08.2018

STRACK NORMA

GmbH & Co. KG

Königsberger Str. 11

D-58511 Lüdenscheid

Postfach 16 29

D-58466 Lüdenscheid

Tel +49 2351 8701-0

Fax +49 2351 8701-100

Mail [email protected]

Web www.strack.de

This manual suits for next models

10

Table of contents