Straval PRH-04 FLG User manual

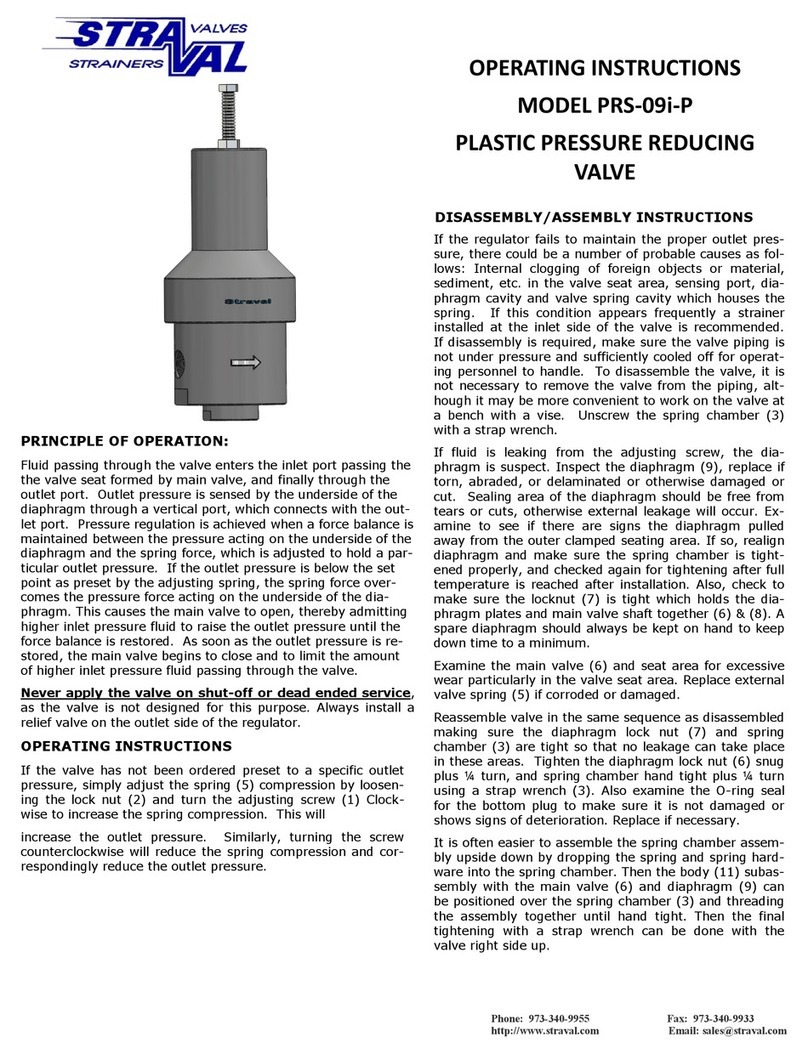

OPERATING INSTRUCTIONS

MODEL PRH-04 FLG

PRESSURE REDUCING VALVE

MAINTENANCE & REPAIR

To disassemble the valve, it is best to remove the valve

from the piping, since it is more convenient to work on

the valve on a bench with a vise. Unscrew the spring

chamber with a wrench in the area provided with wrench

flats. With the spring chamber off, the packing nut may

be removed and the Teflon v-packing rings extracted.

Make sure the valve is not under pressure if it is still in

the line. Be sure not to damage them as they perform a

critical sealing function. If they are damaged or worn

they need to be replaced. When reinstalling the v-

packing rings, make sure that they are properly installed

as shown in the illustration with the open part of the “v”

facing the pressure side.

APPLICATIONS:

Valve should only be used for non-corrosive fluids, or where

the materials selected are compatible with the fluid and will

not cause corrosive buildup, which could keep the main valve

from opening. When liquids contain debris or other solid mat-

ter, which might cause internal clogging or improper opera-

tion of the valve, a strainer with a fine wire mesh should be

installed before the inlet of the valve. In-line strainer fittings

or basket strainers can be purchased from STRAVAL to solve

this problem. Do not use this valve as a shutoff valve,

even though the valve, when new, is able to do so. In time as

wear sets in, seat leakage may increase and result in an ob-

jectionable pressure rise at zero flow. As long as the flow

through the valve is greater than the seat leakage, the valve

could still regulate.

PRINCIPLE OF OPERATION

Fluid passing through the valve enters through the inlet port

through the valve seat formed by the main valve and seat,

and finally through the outlet port. Outlet pressure is sensed

by the underside of the piston, which is able to move up and

down with changes in outlet pressure. Pressure regulation is

achieved when a force balance is maintained between the

pressure acting on the underside of the piston and the spring

force, which is adjusted to hold a particular outlet pressure.

If the outlet pressure is below the set point, which is preset

by the adjusting spring, the spring force overcomes the pres-

sure force acting on the underside of the piston. This causes

the main valve to open, thereby admitting higher inlet pres-

sure fluid to raise the outlet pressure until the force balance

is restored. As soon as the outlet pressure is restored, the

main valve begins to close to limit the amount of higher inlet

pressure fluid passing through the valve.

Phone: 973-340-9955 Fax: 973-340-9933

http://www.straval.com Email: sales@straval.com

When the valve is shipped from the factory it is usually

ready for operation. On larger valves, all that may be

required is to install the adjusting screw if it is strapped

to the spring chamber and make a final pressure adjust-

ment at the final operating conditions. This step is not

required if the valve is ordered preset for a specific pres-

sure setting and so marked. Check to make sure that the

discharge piping is not blocked off and that the valve

does not operate against a shut-off condition. Check to

make sure there is no visible leakage coming from the

spring chamber. This would occur if the packing nut is

set too loose or if the packing rings take a slight set. A

simple adjustment of the packing nut by 1/6 or 1/4 turn

is normally sufficient. This would have to be done with

the spring chamber removed If after extensive use the

valve begins to lose its ability to regulate, or if there is

excessive seat leakage due to wear, which would cause

an excessive pressure rise on the outlet side of the valve,

or if there is external seal leakage, the valve will require

parts to be replaced and the valve sent in for possible

repair. Before removing the valve from service Make

sure that the valve is isolated from the piping com-

pletely in order avoid any personal injury.

Usually, only the v-packing rings will require replace-

ment. However, if there is excessive seat leakage, then

the main valve may also require replacement or just a

minor re-cutting of the seating surfaces. With the valve

removed from service, a quick test for mechanical opera-

tion is to see if the main valve is free to move by

hand. This should be done with the spring chamber re-

moved. If the main valve is not free to move, the pack-

ing nut is either too tight or the main valve is frozen

in place or worn, and will therefore need to be disassem-

bled.

DISASSEMBLY / ASSEMBLY INSTRUCTIONS

OPERATING INSTRUCTIONS

MODEL PRH-04 FLG

PRESSURE REDUCING VALVE

Phone: 973-340-9955 Fax: 973-340-9933

http://www.straval.com Email: sales@straval.com

The packing rings expand under pressure and therefore should

not be over tightened. If the packing rings are over tightened,

the valve will not be very responsive to pressure changes or not

even regulate at all. It is usually sufficient to make the packing

nut hand tight and add 1/4 to 1/2 turn with a wrench. Finally

when the valve is installed in the line without the spring chamber

any additional tightening may be performed while under pres-

sure, if there still any leakage through the v-packing rings. After

this adjustment is performed, the spring chamber and spring

hardware may be installed. Next inspect the seat and main valve

in the area where sealing contact is made. It may be necessary

to just re-lap these parts with a fine grit lapping compound such

as A#600 grit. If there is more severe wear or damage that can’t

be corrected by lapping, then the parts need to be replaced or re-

machined making sure that the parts remain concentric. Also in-

spect the main valve in the area where the teflon-v-packing rings

perform their sealing function.

If the area is not too severely worn, the surface may be re-

polished and restored to a smooth low friction surface finish. If

this area is very rough or worn, the valve will not regulate

properly and will stick because of excessive friction and wear. If

in doubt, replace the entire main valve from the factory. It is

generally recommended that the valve be overhauled by replac-

ing the main valve, and v-packing rings, in order to restore the

valve in an as new condition. If the main valve is purchased from

the factory, it must be lapped into the body at final assembly for

optimum regulating performance, particularly if the valve is oper-

ating in a low flow mode where the valve travel is very small and

the clearance through the valve seat is very small.

After the valve is properly assembled, reset the adjusting screw

until the desired outlet pressure is achieved at the flow range the

valve will be operating, then tighten the adjusting screw lock nut.

Little or no adjustment is required to compensate for changes in

inlet pressure, as this valve is a balanced design.

Adjust the spring compression by loosening the lock nut and turn

the adjusting screw clockwise to increase the spring compression;

this will increase the outlet pressure. Similarly, turning the screw

counterclockwise will reduce the spring compression and corre-

spondingly reduce the outlet pressure. A slow pressure build up

will take place if the outlet is completely blocked off which may

take place over a period of time depending on how effective the

valve seat is performing and the volume of the discharge piping.

For this reason it is strongly recommended that a relief

valve be installed on the outlet side of the valve to protect

any equipment damage that may take place because of this

possible pressure build up in a shut off or blocked discharge con-

dition. If the regulator fails to maintain the proper outlet pres-

sure, there could be a number of probable causes as follows:

Packing nut may be over tightened, Internal clogging of foreign

objects or material, sediment, rust, etc. in the valve seat area. If

disassembly is required make sure the valve piping is not under

pressure and sufficiently cooled off for operating personnel to

handle.

OPERATING INSTRUCTIONS

SOCKET WELD APPLICATIONS

When a valve is ordered with socket weld connections,

the valve seat must be re-lapped by the customer after

the valve is welded to the piping. Every precaution

should be made to minimize distortion due to excessive

heat during welding. Depending on the degree of dis-

tortion caused by welding, it is recommended that lap-

ping be performed with several course grit grades first,

and finally finishing with a #600 or better yet a #800

grit to get the best seat finish.

Other Straval Control Unit manuals