OPERATING INSTRUCTIONS

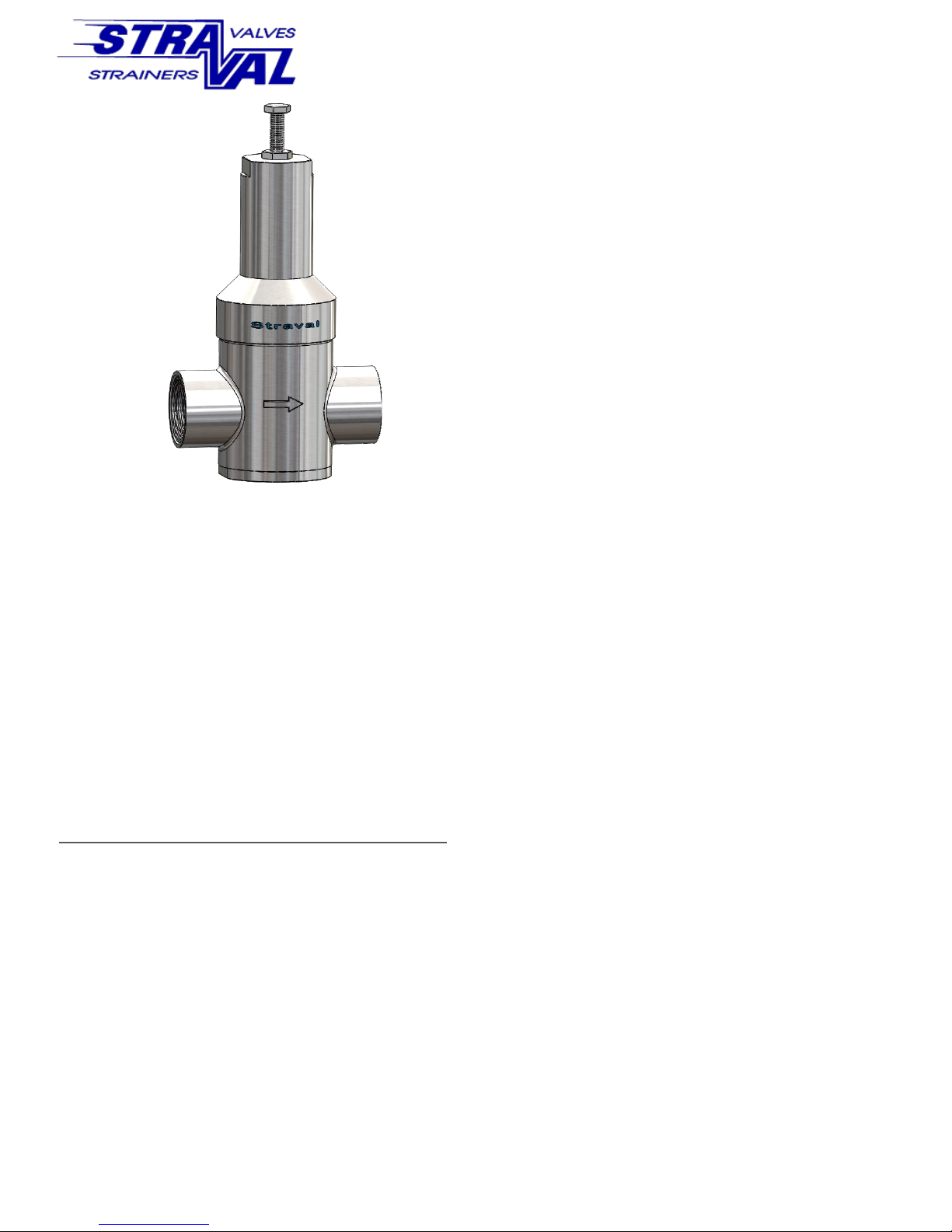

MODEL PRS-07i THD

PRESSURE REDUCING VALVE

DISASSEMBLY/ASSEMBLY INSTRUCTIONS

If the regulator fails to maintain the proper outlet pressure,

there could be a number of probable causes as follows: Internal

clogging of foreign objects or material, sediment, rust, etc. in

the valve seat area, sensing port, diaphragm cavity and valve

spring cavity which houses the spring. If this condion appears

frequently a strainer installed at the inlet side of the valve is

recommended. If disassembly is required, make sure the valve

piping is not under pressure and suciently cooled o for oper-

ang personnel to handle. To disassemble the valve, it is not

necessary to remove the valve from the piping, although it may

be more convenient to work on the valve at a bench with a vise.

Unscrew the spring chamber (3) with a wrench.

If uid is leaking from the adjusng screw, the diaphragm is sus-

pect. Inspect the diaphragm (9), replace if torn, abraded, or de-

laminated or otherwise damaged or cut. Sealing area of the

diaphragm should be free from tears or cuts, otherwise external

leakage will occur. Examine to see if there are signs the dia-

phragm pulled away from the outer clamped seang area. If so,

realign diaphragm and make sure the spring chamber is ght-

ened properly, and checked again for ghtening aer full tem-

perature is reached aer installaon. Also, check to make sure

the locknut (6) is ght which holds the diaphragm metal plates

together (8) & (10). A spare diaphragm should always be kept

on hand to keep down me to a minimum.

Examine the main valve (12) and seat area for excessive wear

parcularly in the valve seat area. If excessive, replace with

new parts. Otherwise, parts may be restored by remachining

and re-lapping with a ne lapping compound, such as 600 or

800 grit. Replace external valve spring (5) if corroded or dam-

aged.

Reassemble valve in the same sequence as disassembled mak-

ing sure the diaphragm lock nut (6) and spring chamber (3) are

ght so that no leakage can take place in these areas. Apply

approximately 45 -lbs of torque to ghten the diaphragm lock

nut (6) and approximately 500 -lbs to the spring chamber (3).

Also examine the O-ring seal for the boom plug to make sure it

is not damaged or shows signs of deterioraon. Replace if nec-

essary.

PRINCIPLE OF OPERATION

Steam or other uid passing through the valve enters through the

inlet port, through the valve seat formed by main valve and seat, and

nally through the outlet port. Outlet pressure is sensed by the un-

derside of the diaphragm through a vercal port, which connects

with the outlet port. Pressure regulaon is achieved when a force

balance is maintained between the pressure acng on the underside

of the diaphragm and the spring force, which is adjusted to hold a

parcular outlet pressure. If the outlet pressure is below the set

point as preset by the adjusng spring, the spring force overcomes

the pressure force acng on the underside of the diaphragm. This

causes the main valve to open, thereby adming higher inlet pres-

sure uid to raise the outlet pressure unl the force balance is re-

stored. As soon as the outlet pressure is restored, the main valve

begins to close and to limit the amount of higher inlet pressure uid

passing through the valve.

Never apply the valve on shut-o or dead ended service, as the

valve is not designed for this purpose. Always install a relief valve on

the outlet side of the valve.

OPERATING INSTRUCTIONS

If the valve has not been ordered preset to a specic outlet pressure,

simply adjust the spring (5) compression by loosening the lock nut (2)

and turn the adjusng screw (1)

Clockwise to increase the spring compression. This will increase the

outlet pressure. Similarly, turning the screw counterclockwise will

reduce the spring compression and correspondingly reduce the out-

let pressure.

Phone: 973-340-9955 Fax: 973-340-9933

http://www.straval.com Email: sales@straval.com