HB-THERM THERMO-5 HB-100Z1 User manual

Instruction Manual

HB-100/140/160Z1

Temperature Control Unit

2 O8285-EN 2017-12

HB-THERM AG

Spinnereistrasse 10 (WU 3)

Postfach

9006 St. Gallen

Switzerland

www.hb-therm.ch

Phone +41 71 243 6-530

Fax +41 71 243 6-418

Translation of original instruction

Contents

2017-12

O8285-EN

Instruction Manual

HB-100/140/160Z1

Temperature C ontrolU nit

(Typenschild)

HB-100/140/160Z1 Temperature Control Unit

Contents

O8285-EN 2017-12 3

Index................................................................................................7

1General....................................................................................9

1.1 Information about this manual.....................................9

1.2 Explanation of symbols .............................................10

1.3 Limitation of liability ...................................................11

1.4 Copyright...................................................................11

1.5 Warranty terms..........................................................12

1.6 Customer Service......................................................12

2Safety.....................................................................................13

2.1 Intended Use.............................................................13

2.2 Customer’s responsibility ..........................................14

2.3 Personnel requirements ............................................15

2.3.1 Qualifications..............................................15

2.3.2 Unauthorized persons................................16

2.4 Personal protective equipment..................................17

2.5 Specific dangers........................................................18

2.6 Safety devices...........................................................20

2.7 Stickers and decals ...................................................21

2.8 CE Declaration of Conformity for Machinery.............22

3Technical data ......................................................................23

3.1 General Information...................................................23

3.2 Emissions..................................................................24

3.3 Operating conditions .................................................24

3.4 Connection values.....................................................25

3.5 Operating fluids .........................................................26

3.6 Nameplate.................................................................27

4Structure and function.........................................................28

4.1 Overview....................................................................28

4.2 Brief description.........................................................28

4.3 Functional principle ...................................................29

4.4 Heat transfer medium................................................29

4.5 Connections...............................................................30

4.6 Additional equipment.................................................31

4.7 Operation modes.......................................................32

4.7.1 Main operating modes ...............................32

4.7.2 Auxiliary modes..........................................32

4.8 Work and danger zones ............................................33

5Transport, packing and storage .........................................34

5.1 Safety notes for transport..........................................34

5.2 Transport...................................................................34

5.3 Transport inspection..................................................36

5.4 Packing......................................................................36

5.5 Symbols on the packing ............................................37

HB-100/140/160Z1 Temperature Control Unit

Contents

4 O8285-EN 2017-12

5.6 Storage......................................................................38

6Installation and initial commissioning...............................39

6.1 Safety ........................................................................39

6.2 Requirements for the installation location .................40

6.3 Installation work.........................................................41

6.3.1 Lock castors...............................................41

6.3.2 Water treatment .........................................41

6.3.3 Set the separate connection for system

water..........................................................42

6.3.4 Setting up system connections..................43

6.3.5 Connect data interfaces.............................45

6.3.6 Connect external sensor............................47

7Control...................................................................................48

7.1 Keyboard...................................................................48

7.1.1 Key functions on an individual unit ............48

7.1.2 Key functions and operation on an

individual unit.............................................49

7.1.3 Key functions on unit operated as module.50

7.1.4 Basic display..............................................51

7.2 Operating structure....................................................53

7.3 Menu structure...........................................................54

8Operation ..............................................................................63

8.1 Mains ON...................................................................63

8.2 Registering new modular units..................................64

8.3 Special features for operation of modular units.........65

8.4 Operate singular unit as modular unit .......................66

8.5 Switching on..............................................................67

8.5.1 Normal operation .......................................67

8.5.2 Leak stopper ..............................................68

8.5.3 External sensor..........................................69

8.5.4 Mode 2nd nominal value............................71

8.5.5 Remote mode.............................................72

8.6 Switching off..............................................................75

8.6.1 Cooling down and switching off .................76

8.6.2 Mould evacuation.......................................77

8.6.3 Mould evacuation with compressed air......78

8.7 Emergency stop.........................................................79

8.8 Define access rights..................................................80

8.8.1 Set user profile...........................................80

8.8.2 Set operating release.................................80

8.8.3 Change access code .................................81

8.9 Settings......................................................................82

8.9.1 Setting time zone, date and time ...............82

8.9.2 Define internal measuring points ...............83

8.9.3 Set switch clock .........................................84

8.9.4 Set ramp programme.................................85

HB-100/140/160Z1 Temperature Control Unit

Contents

O8285-EN 2017-12 5

8.9.5 Cyclical change-out of the system water ...87

8.10 Process monitoring....................................................88

8.10.1 Limit value monitoring................................88

8.10.2 Monitor pump wear ....................................90

8.10.3 Optimise controller.....................................91

8.11 Explorer window........................................................92

8.12 Save/Load .................................................................93

8.12.1 Tool data....................................................95

8.12.2 Recording actual data................................97

9Maintenance..........................................................................99

9.1 Safety ........................................................................99

9.2 Open the unit...........................................................100

9.3 Maintenance schedule ............................................102

9.4 Maintenance tasks ..................................................104

9.4.1 Cleaning...................................................104

9.4.2 Pump........................................................105

9.4.3 Temperature measurement .....................106

9.4.4 Pressure measurement............................107

9.4.5 Safety valve..............................................108

9.4.6 Software update.......................................109

9.4.7 Gain access to components.....................111

10 Faults...................................................................................113

10.1 Safety ......................................................................113

10.2 Fault indications.......................................................115

10.2.1 Fault indication display.............................115

10.3 Determine the cause of a fault ................................116

10.4 Troubleshooting chart..............................................116

10.5 Startup after eliminating fault...................................118

11 Disposal ..............................................................................119

11.1 Safety ......................................................................119

11.2 Disposal of materials...............................................119

12 Spare parts..........................................................................120

12.1 Ordering spare parts ...............................................120

13 Technical information........................................................121

13.1 Electrical circuit diagram .........................................121

13.2 Hydraulic scheme....................................................123

13.3 Item location............................................................125

13.4 Legend.....................................................................128

14 Interface cables..................................................................130

14.1 External sensor........................................................130

14.2 External control........................................................131

14.3 Serial data interfaces...............................................131

14.4 CAN-Bus interfaces.................................................133

14.5 Interface HB.............................................................134

HB-100/140/160Z1 Temperature Control Unit

Contents

6 O8285-EN 2017-12

Appendix

A Special execution

B Spare parts list

HB-100/140/160Z1 Temperature Control Unit

Index

O8285-EN 2017-12 7

Index

A

Access code .......................................................81

Access rights ......................................................80

Additional equipment..........................................31

B

Basic display.......................................................51

C

CE Declaration of Conformity.............................22

Cleaning............................................................104

Code ...................................................................81

Connect external sensor.....................................47

Connect interfaces..............................................45

Connection

Cooling water,.................................................25

Electrical .........................................................30

Electrical .........................................................25

main and return line........................................25

separate system water....................................25

Connection values ..............................................25

Control ................................................................48

Controller optimisation........................................91

Cooling................................................................76

Customer Service ...............................................12

Cyclical change-out of the system water............87

D

Danger zones .....................................................33

dangers...............................................................18

Date, set .............................................................82

Disposal............................................................119

Disposal of materials ........................................119

Drain connection.................................................25

E

Electric current....................................................18

Electrical circuit diagram...................................121

Emissions ...........................................................24

F

Faults................................................................113

cause.............................................................116

indications.....................................................115

overview....................................................... 116

Functional principle............................................ 29

H

Heat transfer medium ........................................ 29

Hydraulic connections........................................ 30

Hydraulic scheme ............................................ 123

Hydraulic specialist............................................ 15

I

Installation.......................................................... 41

Installation location ............................................ 40

Intended Use...................................................... 13

Interface cables................................................ 130

Item location..................................................... 125

K

Keyboard............................................................ 48

L

Leak stopper...................................................... 68

Legend............................................................. 128

Liability............................................................... 11

Lock castors....................................................... 41

Logbook Alarms............................................... 116

M

Main switch ........................................................ 20

Maintenance ...................................................... 99

schedule....................................................... 102

tasks............................................................. 104

Maximum fusing............................................... 121

Measurement

flow rate.......................................................... 23

pressure ......................................................... 23

Temperature................................................... 23

Measuring points................................................ 83

Menu structure................................................... 54

Monitoring .......................................................... 88

level................................................................ 89

limit values ..................................................... 88

Pump wear..................................................... 90

Mould evacuation............................................... 77

compressed air............................................... 78

HB-100/140/160Z1 Temperature Control Unit

Index

8 O8285-EN 2017-12

N

Nameplate ..........................................................27

Nominal value 2..................................................71

Normal operation................................................67

O

Opening the unit ...............................................100

Operating conditions...........................................24

Operating fluids...................................................26

Operating release ...............................................80

Operating structure.............................................53

Operation............................................................63

Operation modes................................................32

Overview.............................................................28

P

Packing...............................................................36

Personnel..............................................15, 99, 113

Pressure measurement ....................................107

Professional electrician.......................................15

Protective equipment............................17, 99, 113

Pump.................................................................105

Q

Qualified personnel.............................................15

R

Ramp programme...............................................85

Recording actual data.........................................97

Remote mode .....................................................72

S

Safety..................................................................13

Safety devices ....................................................20

Safety valve ......................................................108

Save/Load...........................................................93

Settings...............................................................82

Software update................................................109

Sound pressure level......................................... 24

Spare parts ...................................................... 120

Special Design..................................................... 9

Status display..................................................... 52

Stickers .............................................................. 21

Storage .............................................................. 38

Structure ............................................................ 28

Surfaces, hot...................................................... 19

Switch clock ....................................................... 84

Switching off....................................................... 75

Switching on....................................................... 67

Symbol display................................................... 52

Symbols

in this manual................................................. 10

Packing .......................................................... 37

rear of unit...................................................... 30

T

Technical data.................................................... 23

Technical information....................................... 121

Temperature measurement ............................. 106

Time, set ............................................................ 82

Tool data............................................................ 95

Transport............................................................ 34

Troubleshooting

Chart ............................................................ 116

U

Used for ............................................................. 13

User profile......................................................... 80

W

Warranty ............................................................ 12

Water treatment................................................. 41

Weight................................................................ 23

Work zones........................................................ 33

Working materials.............................................. 18

HB-100/140/160Z1 Temperature Control Unit

General

O8285-EN 2017-12 9

1 General

1.1 Information about this manual

This manual enables the safe and efficient handling of the unit.

The manual is a component part of the unit and must always be

kept close to the unit readily accessible for personnel. Before

starting any work, the personnel must have carefully read through

and understood this manual. A basic requirement for safe work is

the observance of all safety and handling instructions in this

manual.

Furthermore, the local accident prevention regulations and general

safety regulations are valid for the application area of the unit.

Illustrations in this manual serve the basic understanding and can

deviate from the actual design of the unit.

For units with a special design (see the nameplate on the unit or on

page 2), the corresponding additional documents are included in

Appendix A.

We reserve the right to make technical modifications in order to

improve usability.

HB-100/140/160Z1 Temperature Control Unit

General

10 O8285-EN 2017-12

1.2 Explanation of symbols

Warnings

Warnings are identified by symbols. These warnings are

introduced by signal words, which express the severity of a danger.

Adhere to these warnings and act cautiously in order to avoid

accidents, personal injuries and damage to property.

DANGER!

… indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury.

WARNING!

… indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION!

… indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury.

ATTENTION!

… indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

Hints and recommendations

NOTE!

… emphasizes useful hints and recommendations

as well as information for efficient and trouble-free

operation.

Special safety notes

The following symbols are used in connection with the safety notes

to highlight particular dangers:

… highlights hazards caused by electric current.

There is a danger of serious injury or death if the

safety notes are not complied with.

HB-100/140/160Z1 Temperature Control Unit

General

O8285-EN 2017-12 11

1.3 Limitation of liability

All information and notes in this Manual were compiled under due

consideration of valid standards and regulations, the present status

of technology and our years of knowledge and experience.

The manufacturer can not be made liable for damage resulting

from:

disregarding this Manual

unintended use

employment of untrained personnel

unauthorized conversions

technical modifications

use of unapproved spare parts

In case of customised versions the actual scope of delivery can

vary from the explanations and representations in this Manual,

because of the utilization of additional options or due to latest

technical changes.

Apart from this, the obligations agreed upon in the delivery

contract, the general terms and conditions and the delivery

conditions of the manufacturer and the legal regulations valid at the

time of contract do apply.

1.4 Copyright

This Manual is protected by copyright law and exclusively to be

used for internal purposes.

Passing this Manual on to third parties, duplication of any kind –

even in form of excerpts –as well as the use and/or disclosure of

the contents without the written consent of the manufacturer is not

permitted, except for internal purposes.

Violations oblige to compensation. The right for further claims

remains reserved.

HB-100/140/160Z1 Temperature Control Unit

General

12 O8285-EN 2017-12

1.5 Warranty terms

The warranty terms are provided in the manufacturer's terms and

conditions.

1.6 Customer Service

For technical information, please contact the HB-Therm

representatives or our customer service department

www.hb-therm.ch.

Furthermore, our employees are always interested in new infor-

mation and experiences resulting from the application that could be

valuable for the improvement of our products.

HB-100/140/160Z1 Temperature Control Unit

Safety

O8285-EN 2017-12 13

2 Safety

This paragraph provides an overview of all important safety

aspects for optimal protection of personnel as well as safe and

trouble-free operation.

Disregarding this Manual and safety regulations specified therein

may result in considerable danger.

2.1 Intended Use

The unit is designed and constructed exclusively for the intended

use described here.

The temperature control unit serves exclusively to bring a

connected consumer (for example a tool) to a specified

temperature and to keep this constant by means of the heat

transfer medium water and by heating and cooling.

The temperature control unit must only be operated in

accordance with the values specified in the technical data.

Observance of all information in this manual also pertains to the

intended use.

Any use of the unit other than or going beyond the intended use is

deemed as misuse and can lead to dangerous situations.

WARNING!

Danger on misuse!

Misuse of the unit can lead to dangerous situations.

In particular, refrain from the following applications

of the unit:

–Use of a heat transfer medium other than water.

Claims of any nature regarding damage caused by improper use

are excluded.

HB-100/140/160Z1 Temperature Control Unit

Safety

14 O8285-EN 2017-12

2.2 Customer’s responsibility

The device is implemented commercially. Thus the owner of the

device is subject to legal industrial safety obligations.

In addition to the safety instructions in this Manual, the safety,

accident prevention guidelines and environmental protection

regulations, applicable at the site of implementation must be

complied with. In particular:

Owner must inform himself of applicable industrial safety

regulations and determine additional hazards that arise due to

the specific working conditions prevailing at the site where the

device is implemented, in a risk analysis. The risk assessment

must be implemented in the form of work instructions for device

operation.

Owner must check throughout the entire implementation period

of the device, whether the work instructions that owner has

created satisfy current legislation, and must adapt the

instructions if necessary.

Owner must clearly regulate and specify the responsibilities for

installation, operation, maintenance, and cleaning.

Owner must ensure that all employees who deal with the device

have read and understood this Manual.

In addition, owner must train personnel at regular intervals and

inform personnel of the hazards.

Owner must provide personnel with the required protective

equipment.

In addition, owner is responsible to ensure that the device is

always in a technically perfect condition, and therefore the

following applies:

Owner must ensure that the maintenance intervals described in

these operating instructions are complied with.

Owner must have all safety devices inspected regularly for

function and completeness.

HB-100/140/160Z1 Temperature Control Unit

Safety

O8285-EN 2017-12 15

2.3 Personnel requirements

2.3.1 Qualifications

WARNING!

Danger of injury if insufficiently qualified!

Improper operation can lead to serious personal

injuries or property damage.

Therefore:

–Have all activities performed only by qualified

personnel.

The following qualifications are specified for different areas of

activity listed in the Manual.

An instructed person

has been instructed by the customer in an orientation session

on the assigned tasks and possible dangers in case of improper

behavior.

Qualified personnel

based on their professional training, know-how and experience

as well as knowledge of the applicable standards and

regulations is able to perform assigned work activities and to

detect and avoid possible dangers on their own.

A professional electrician

based on his/her professional training, know-how and

experience as well as knowledge of the applicable standards

and regulations is able to perform work on electrical systems

and to detect and avoid possible dangers on his/her own.

The professional electrician has been trained for the special

location where he/she works and knows the relevant standards

and regulations.

Hydraulic specialist

based on his or her technical training, knowledge and

experience as well as knowledge of the relevant standards and

regulations, is able to carry out work on hydraulic systems and

to independently recognise and avoid possible dangers.

The hydraulic specialist is trained for the specific location at

which he or she is employed and is familiar with the relevant

standards.

HB-100/140/160Z1 Temperature Control Unit

Safety

16 O8285-EN 2017-12

2.3.2 Unauthorized persons

WARNING!

Danger for unauthorized persons!

Unauthorized persons not meeting the

requirements outlined here are not aware of the

dangers in the work area.

Therefore:

–Keep unauthorized persons away from the work

area.

–If in doubt, address the persons and direct them

to leave the work area.

–Interrupt work activities as long as unauthorized

persons are present in the work area.

HB-100/140/160Z1 Temperature Control Unit

Safety

O8285-EN 2017-12 17

2.4 Personal protective equipment

When working, it may be necessary to wear personal protective

equipment in order to minimise dangers to health.

During work, always wear the protective equipment necessary

for the particular work.

Follow the information placed in the working area with regard

personal safety equipment.

Personal protective equipment for

special tasks

When performing special tasks it is necessary to wear personal

protective equipment. This personal protective equipment will be

separately specified in the chapters of this Manual. This special

protective equipment is explained below.

Protective clothing

means close-fitting working clothes with long arms and long

trousers. It serves primarily as protection against hot surfaces.

Protective gloves

to protect the hands against abrasions, cuts or deeper wounds as

well as against contact with hot surfaces.

Safety goggles

to protect the eyes against parts flying around or squirts of fluids.

Safety boots

to protect against heavy parts falling down or slipping on slippery

ground.

HB-100/140/160Z1 Temperature Control Unit

Safety

18 O8285-EN 2017-12

2.5 Specific dangers

The following section lists the residual risks that have been

determined by the risk assessment.

Heed the safety instructions listed here, and the warnings in

subsequent chapters of this Manual, to reduce health

hazards and to avoid dangerous situations.

Electric current

DANGER!

Danger of death by electric current!

Live parts are dangerous. Contact with high

voltages causes injury or death. Damaged

insulation or components can cause injury or

death.

Therefore:

–In case of damage of the insulation of the

powersupply, switch off immediately and

arrange repair.

–Work on the electrical system must only be

carried out by certified electricians.

–For all work on the electrical system, for

maintenance, cleaning or repair work,

disconnect from the mains or disconnect all

phases of the external power supply and secure

them against being switched on again. Check

unit is isolated from power supply.

–Do not by-pass or disable fuses. Comply with

the correct ampere when changingfuses.

–Keep away humidity from live parts. This could

cause a short circuit.

Hot materials

WARNING!

Danger of burns due to hot working materials!

During operation, working materials can reach high

temperatures and pressures and can cause burns

on contact.

Therefore:

–Only allow work on the hydraulics to be carried

out by qualified personnel.

–Before beginning work on the hydraulics, check

whether working materials are hot and under

pressure. If necessary, cool the unit down,

depressurise and switch off.

Check that the unit is free of pressure.

HB-100/140/160Z1 Temperature Control Unit

Safety

O8285-EN 2017-12 19

Hot surfaces

CAUTION!

Danger of burning on hot surfaces!

Contact with hot components can cause severe

burns.

Therefore:

–Always wear protective clothes and protective

gloves when working on hot components.

–Before starting work make sure that all

components have cooled down to ambient

temperature.

Danger of crushing

WARNING!

Danger of crushing due to rolling away or

tipping

With an uneven floor or when the castors are not

locked, there is a danger that the unit tips over or

rolls away causing crushing.

Therefore:

–Only install the unit on an even floor.

–Ensure that the castors are locked.

HB-100/140/160Z1 Temperature Control Unit

Safety

20 O8285-EN 2017-12

2.6 Safety devices

WARNING!

Malfunctioning safety devices may pose a fatal

risk!

Safety devices must be intact in order to guarantee

safety.

Therefore:

–Never disable safety devices.

–Take care to ensure that safety devices such as

main switch are always accessible.

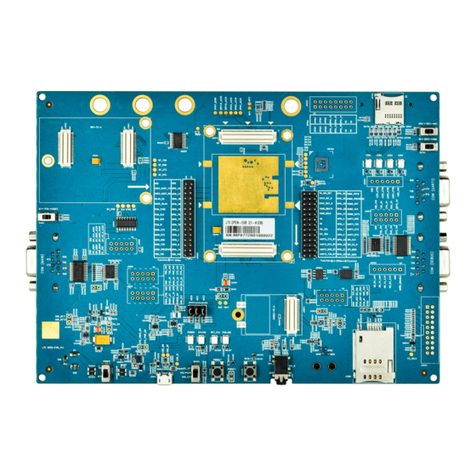

Main switch

Fig. 1: Main switch

The power supply to consumers is cut and an emergency stop is

triggered by turning the main switch to the "0" position.

WARNING!

Danger of fatal injury from live conductors!

After switching off the unit via the main switch,

there are still live conductors in the unit!

Therefore:

–For all work on the electrical system, for

maintenance, cleaning or repair work,

disconnect from the mains or disconnect all

phases of the external power supply and secure

them against being switched on again

–Check unit is isolated from power supply

WARNING!

Danger of fatal injury from uncontrolled

restarting!

Premature uncontrolled restarting can lead to

severe personal injury or to death!

Therefore:

–Before restarting, make sure that the cause for

the emergency stop is eliminated and all safety

devices are installed andoperational.

This manual suits for next models

2

Table of contents

Other HB-THERM Control Unit manuals