Stricker Lipo Lomo Series User manual

Instructions for use

Electric Power Assist Devices

R&E Stricker Reha-Entwicklungen GmbH

V-Nr.: EL EN EC 20210818 1119

Model series

Lipo Lomo

Pico

Crossbike

Manufacturer

R&E Stricker Reha-Entwicklungen GmbH

Klotzberg 64

D-77815 Bühl

Phone: +49 7223 / 72510

Fax: +49 7223 / 74947

E-Mail: [email protected]

Web: www.stricker-handbikes.de

Misprints, mistakes and price or product changes reserved. Product changes include changes resulting from the

further development of the mechanics or the legal requirements.

18.08.2021

© R&E Stricker Reha-Entwicklungen GmbH, Bühl

Reprint, even in part, only with the written permission of R&E Stricker Reha-Entwicklungen GmbH , Bühl.

Notice to reader

For reasons of readability, the masculine form has been chosen in these instructions for use, nonetheless

the information relates to members of all genders.

R&E Stricker Reha-Entwicklungen GmbH

1

Power Assist Devices

Table of Content

1 Declaration of Conformity ..................................................................................................................3

2 Introductory notes..............................................................................................................................3

3 Product Description & Intended Use ...................................................................................................4

4 Safety and driving instructions for accident prevention ......................................................................4

4.1 Safety instructions ......................................................................................................................................4

4.2 Safety checks ..............................................................................................................................................4

4.3 Driving instructions .....................................................................................................................................5

4.4 Safety instructions for battery and charger...............................................................................................6

5 Condition of the wheelchair................................................................................................................7

6 Commissioning ..................................................................................................................................8

7 Fitting the handbike to the wheelchair and the rider............................................................................8

7.1 Unpacking the handbike .............................................................................................................................8

7.2 Adjusting the inclination of the headstock tube........................................................................................9

7.3 Adjusting the length and width of the clamping device............................................................................9

......................................................................9

7.5 Adjusting the ground clearance .............................................................................................................. 11

8 Adjusting the traction device to the wheelchair and the driver (Pico frame) ......................................12

8.1 Assembly of the U-frame......................................................................................................................... 13

8.2 Adjusting the inclination of the coupling plate....................................................................................... 14

8.3 Adjusting the height of the coupling plate.............................................................................................. 15

8.4 Adjusting the handlebar height ............................................................................................................... 15

9 Coupling the handbike to the wheelchair ..........................................................................................15

9.1 Coupling standard frame......................................................................................................................... 15

9.2 Coupling the Pico frame .......................................................................................................................... 16

10 Uncoupling the handbike from the wheelchair ..................................................................................16

10.1 Unhitching Standard Frame..................................................................................................................... 16

10.2 Uncoupling the Pico frame ...................................................................................................................... 16

11 Operation .........................................................................................................................................16

11.1 Model range Lipo Lomo........................................................................................................................... 16

11.2 Crossbike range........................................................................................................................................ 20

12 Steer ................................................................................................................................................24

12.1 Function of the steering damper............................................................................................................. 24

13 Breaks..............................................................................................................................................24

14 Kickstand.........................................................................................................................................24

14.1 Standard equipment................................................................................................................................. 24

14.2 Special equipment quick adjustment ..................................................................................................... 25

15 Battery and charger..........................................................................................................................25

15.1 Charging the battery................................................................................................................................. 25

15.2 Model series Lipo Lomo .......................................................................................................................... 25

2

R&E Stricker Reha-Entwicklungen GmbHPower Assist Devices

16 Repair, cleaning and maintenance ....................................................................................................25

16.1 Cleaning and care..................................................................................................................................... 26

16.2 Air pressure of the drive wheel................................................................................................................ 26

16.3 Clamping device ...................................................................................................................................... 26

16.4 Automatic catch....................................................................................................................................... 26

16.5 V-Brake...................................................................................................................................................... 26

16.6 Disc brake ................................................................................................................................................. 28

17 Transport .........................................................................................................................................29

17.1 Transporting batteries ............................................................................................................................. 29

17.2 Transportation in vehicle ........................................................................................................................ 30

17.3 Airplane transportation............................................................................................................................ 30

18 Reuse...............................................................................................................................................30

19 Disposal and recycling .....................................................................................................................30

20 Materials used .................................................................................................................................30

21 Warranty and guarantee ...................................................................................................................30

22 Liability ............................................................................................................................................31

Attachment ............................................................................................................................................32

A Torque list................................................................................................................................................. 32

B Technical data Lipo Lomo ....................................................................................................................... 32

C Technical data Lipo Lomo Pico............................................................................................................... 32

D Technical data Crossbike ........................................................................................................................ 33

R&E Stricker Reha-Entwicklungen GmbH

3

Power Assist Devices

Declaration of Conformity

1 Declaration of Conformity

The device complies with the current standards and guidelines of the EU. We certify

this in the EC declaration of conformity. If required, we will be happy to send you the

corresponding declaration of conformity. Our power assist devices have been tested by

means of an electromagnetic compatibility test (EMC).

In the event of a change not agreed with R&E Stricker GmbH, this declaration loses its validity.

devices - Stricker Handbikes) comply with the essential requirements according to the new regulation

(EU) 2017/745 (MDR) or the Medical Devices Act. The documentation of the production is available at

the company R&E Stricker Reha-Entwicklungen GmbH. R&E Stricker Reha-Entwicklungen GmbH holds full

responsibility for the issuance of the declaration of conformity.

DECLARATION OF CONFORMITY (CE, MDR)

https://www.stricker-handbikes.de/en/about-us

2 Introductory notes

WARNING

Before operating the handcycle or power assist device, please read these operating instructions and all

other supplied operating instructions carefully and observe them.

WARNING

Visually impaired persons or persons with cognitive impairments must have the information material and

operating instructions read aloud by assistants. Corresponding documents are available on our website

www.stricker-handbikes.de on the Internet. Videos and photos are also available there.

DEALER NOTICE

It is imperative that you hand over these operating instructions to each customer when handing over the

handbike and expressly draw the customer’s attention to the safety and danger instructions.

Never deliver a handbike without operating instructions!

4

R&E Stricker Reha-Entwicklungen GmbHPower Assist Devices

Product Description & Intended Use

3 Product Description &

Intended Use

The handbike is coupled to a manual wheelchair as

a manual traction aid. This allows the driver to be

supported in his mobility. The aim is to extend the

range of action by making it easier to cover longer

distances independently. Coupling the handbike

creates a three-wheeled vehicle with three relatively

large wheels. The handbike therefore improves

driving characteristics on uneven surfaces.

Obstacles can also be overcome more easily.

Driving downhill and on slopes becomes safer due

to the additional braking systems. The handbike

can be independently coupled to and released

from the wheelchair by the rider. The wheelchair as

such is not changed and its properties remain fully

intact.

4 Safety and driving

instructions for accident

prevention

WARNING

These instructions are for your own safety.

Please read them carefully before operating the

hand bike and observe the instructions! Failure

to observe the operating instructions could result

in damage to the product as well as serious

personal injury. We accept no liability for damage

resulting from failure to observe the operating

instructions.

NOTE

Observe all safety and hazard information and

instructions, both in this and in all other operating

instructions supplied.

4.1 Safety instructions

For your own safety, do not go without a bicycle

helmet when riding a handcycle or power assist

device.

4.1.1 Permitted speed

Richten Sie sich unbedingt nach den gesetzlichen

Bestimmungen des Landes, in dem Sie das

Zuggerät betreiben. Das Zuggerät ist für eine

Höchstgeschwindigkeit von 15 km/h zugelassen.

In Deutschland brauchen Sie eine Betriebserlaubnis

und ein Versicherungskennzeichen, wenn

Ohne Betriebserlaubnis gilt 6 km/h als

Höchstgeschwindigkeit. Bei starkem Gefälle darf

nur mit einer deutlich niedrigeren Geschwindigkeit

gefahren werden, um jederzeit sicher Bremsen zu

können.

4.1.2 Permitted payload

The maximum load of the handbike is 120 kg. The

manufacturer may limit this. Use the lower value as

a guide.

4.1.3 Users with small children

In the interest of the child, please refrain from

driving a traction device with a child on your lap.

There is a high risk of injury.

4.2 Safety checks

WARNING

Carry out the following safety checks before every

journey. These are primarily for your safety and

the safety of all other road users.

4.2.1 Air pressure of the drive wheel

Check the air pressure of the handbike and

wheelchair tires. The air pressure of the handbike

tire should be about 3-4 bar, the air pressure of

the wheelchair drive wheels about 5-7 bar. For the

exact maximum values, please refer to the imprint

on the respective tire. Too low an air pressure of

the wheelchair wheels increases the risk of tipping

over, especially in curves!

4.2.2 Secure t of all components

Check all components, especially all screws, for

be checked particularly carefully and tightened if

necessary to exclude twisting. For the exact torque

values, please refer to „Attachment - A Torque list“.

Achten Sie auf einen festen Sitz der Batterien

in den dafür vorgesehenen Halterungen und

schließen Sie die Batterien ab. Dies gilt besonders,

wenn Sie die Batterien zuvor zum Ladevorgang

vom Zuggerät abgenommen haben.

4.2.3 Straight run

Determine whether the drive wheel is aligned

centrally to the wheelchair. The wheel must be in

the center of the wheelchair track. Deviations of no

R&E Stricker Reha-Entwicklungen GmbH

5

Power Assist Devices

Safety and driving instructions for accident prevention

more than 1 cm from the center are permissible. If

necessary, use the instructions from „7.4 Coupling

the handbike to the wheelchair for the rst time“.

The double-acting steering return supports

straight-ahead running. Detailed information or

setting instructions can be found in „12.1 Function

of the steering damper“.

WARNING

An incorrectly aligned drive wheel can lead to

accidents due to poor straight-ahead running and

vibrations.

4.2.4 Braking

Check whether the braking power of your handbike

settings of the brakes

(„16.5 V-Brake“ & „16.6 Disc brake“)

Note that weather conditions, the road surface

and the weight of the handbike and rider have a

Make sure that the parking brakes of your

wheelchair are correctly adjusted. Always secure

your vehicle with the parking brakes against

unintentional rolling away, especially when parking

on sloping surfaces. Avoid parking on sloping

surfaces if possible.

4.3 Driving instructions

4.3.1 Getting used to the handbike

WARNING

Always adjust your driving to the degree of your

disability.

WARNING

Always drive only fast enough to be able to

brake safely at any time, even in unforeseeable

situations! This applies especially to downhill

driving.

WARNING

Always hold the cranks with both hands when

riding and braking to reduce the risk of accidents.

Safe control of the combination of wheelchair and

handbike requires some practice. Cautious and

slow riding is particularly useful for beginners.

Avoid mountainous terrain and bad roads at the

beginning until you have familiarized yourself with

the driving characteristics of the handbike.

By attaching the handbike or power assist device

to your wheelchair, the four-wheeled wheelchair

becomes a tricycle with various advantages

and disadvantages. In curves, a tricycle is

more unstable than a normal wheelchair! In the

beginning, familiarize yourself with the new driving

and tilting behavior by driving carefully. Avoid jerky

steering movements at all costs!

Also slowly get used to the higher speeds that can

be reached with the handbike. Adjust your speed to

4.3.2 Driving at dusk and darkness

Always switch on the built-in lighting for rides at

dusk and in the dark. Attach the supplied rear light

to the back of your wheelchair. Always check the

batteries for the rear light before driving off and

have new ones ready.

4.3.3 Risk of falling

Avoid jerky steering movements at all costs!

Drive at a slow speed, especially in curves and in

unclear situations. Tilt your upper body towards the

inside of the curve (like a cyclist) to avoid tipping

over the wheelchair.

With narrow wheelchairs and little camber of the

wheelchair’s drive wheels, the lateral tipping hazard

is particularly high. To reduce the risk of tipping, we

recommend our track widening Kippex.

To avoid the risk of falling, do not perform the

following maneuvers with the handcycle or power

assist device:

• Driving over several steps or landings

• Driving over a curb at an angle

• Turning on sloping roads

• Quick steering movements

• Abrupt braking in curves

• Braking too hard on wet roads

Reduce your speed when transitioning between

slopes and level terrain.

negative camber of the wheelchair’s rear wheels.

6

R&E Stricker Reha-Entwicklungen GmbHPower Assist Devices

Safety and driving instructions for accident prevention

4.3.4 Mountain rides

If the incline is too steep, the drive wheel can lose

grip and spin. To improve the climbing ability,

you can equip your handbike with a wheelbase

extension and additional weights. These also have

a positive effect on traction on unpaved paths and

braking behavior. Avoid attaching weight (e.g. a

backpack) to the back of the wheelchair. It is better

to use a luggage carrier at the front.

Observe the battery temperature on the display

when driving uphill in extreme conditions. The

temperature must not exceed 45°C. To prevent

overheating, take an operating break to relieve the

batteries.

WARNING

If the drive wheel slips when driving downhill, it

may be necessary to additionally apply the brakes

of the wheelchair.

4.4 Safety instructions for battery

and charger

WARNING

Before carrying out any repair, cleaning or

maintenance tasks on the power assist device,

switch off the electrical components and remove

the batteries from the traction unit.

The batteries supplied are only used to power

the power assist device‘s drive systems. Do not

connect any other systems to the battery. Any use

beyond this requires the written permission of the

at the time of printing. A case of misuse includes,

but is not limited to:

• Use of the battery contrary to the description

and instructions in the user manual.

• Use of the battery in excess of the technical

performance limits

•

•

• Use of the battery to supply other systems

We accept no liability for damage in the event of

misuse.

HEALTH INFORMATION

In case of contact with escaping gases, supply

fresh air. In case of body contact with battery

plenty of water. In case of contact with mucous

membranes or discomfort, consult a doctor.

4.4.1 Operation

Operate the battery only in ambient temperatures

between -20°C and 50°C. Operating outside the

temperature range will shorten the life of the

battery and may cause ignition.

Do not subject the battery to shocks. If the battery

has been dropped or has taken a knock, the battery

must be checked by the manufacturer. Contact

your dealer or the manufacturer for return and

repair/disposal procedures. This also applies to

otherwise damaged or defective batteries. Never

continue to use a damaged or defective battery. Do

not open the battery yourself.

Keep the battery dry and clean. Protect the battery

against the ingress of moisture or foreign particles.

Do not connect the battery‘s contacts to metallic

or other conductive objects. Keep the battery away

from small metallic objects such as screws, coins,

paper clips, keys or similar to avoid a short circuit.

Clean dirty contacts only with a dry, clean cloth. Do

not immerse the battery in water.

If you notice that the battery is overheating, leaking,

smoking, emitting an unusual odour or deforming,

stop using the battery immediately and switch it

off.

(radiators, microwaves, ovens, strong sunlight).

Exposure to heat can cause ignition and explosion.

Do not open the battery casing. Do not

disassemble the battery. Damage to the battery

explosion. Opening the battery will void the

warranty.

FIRE FIGHTING

Do not attempt to extinguish lithium-ion

batteries with water or other liquids in the event

manufacturers as the only extinguishing agent.

R&E Stricker Reha-Entwicklungen GmbH

7

Power Assist Devices

Condition of the wheelchair

Extinguish lead-gel batteries with water, foam or

CO2

involving lead-gel batteries. Do not breathe in the

gases under any circumstances.

4.4.2 Charging process

WARNING

Do not leave the battery unattended during the

charging process.

Charge the battery only at temperatures between

0 and 40°C. Charging outside the temperature

range will be automatically aborted by the battery.

To optimise battery life, charge the battery at

temperatures between 10-30°C.

circulation during the charging process.

substances (solids, liquids, gases).

Protect the battery from moisture during the

charging process. Do not charge the battery in

rooms where water could condense on the battery

or the charger. Only use the charger when it is

completely dry. If condensation has formed, allow

the charger to dry completely before charging.

Only use the charger supplied to charge the

battery. Using any other charger may cause

malfunction, damage, defect, ignition or explosion.

Do not charge the battery with a defective charger.

Replace a defective charger immediately.

Do not use a charger that has been knocked

or dropped. Do not open or repair the charger

yourself.

Do not charge damaged batteries.

Avoid unnecessary charging and do not charge the

battery for a long time when not in use.

The battery charging process is automatically

terminated as soon as the battery is fully charged.

charger from the mains socket and then from the

battery.

Do not carry the charger by the mains cable or the

charging cable. Do not pull on the mains cable to

disconnect the charger from the mains socket. Do

not subject the cables and plugs to pressure or

pinch the parts. There is a risk of electric shock or

ignition.

Position the charger so that no one can step on

or trip over the cable or charger. Also protect the

charger and all related components from other

4.4.3 Storage

Do not store the batteries in places that are

exposed to heat for long periods of time (sunlit

car boot, garden shed, etc.). The service life of

the battery depends, among other things, on the

storage conditions.

Only use your car for transport, not for storing or

keeping the battery.

For optimum service life, store the battery at

18-23 °C and a maximum humidity of 80%. Do not

expose the battery to moisture (rain, snow, etc.)

during storage.

Charge the battery before storage according to

the charge level at least every three months and

recharge the battery if necessary.

Ensure that the battery is stored away from

damage and unauthorised access.

Store the battery out of the reach of children.

5 Condition of the wheelchair

Your handbike can be mounted to different

wheelchairs. For this purpose, your wheelchair

should be in a technically perfect condition. Do not

use a wheelchair that has already undergone major

repairs to the frame. We recommend wheelchairs

with rigid frames, as these offer greater stability

for use with a handbike than folding wheelchairs.

Nevertheless, most folding wheelchairs are

suitable for combination with our handbikes. If you

have any questions about your wheelchair model or

a planned new purchase, please contact us.

Make sure that the brakes of the wheelchair are in

perfect condition.

Despite the attached handbike, you can move the

wheelchair normally by driving the rear wheels.

This means that driving forwards and backwards

is possible without restriction. Steering by moving

the wheelchair wheels is only possible to a limited

extent due to the automatic steering reset.

8

R&E Stricker Reha-Entwicklungen GmbHPower Assist Devices

Commissioning

6 Commissioning

Instruction is provided by a dealer, a medical

or a Stricker employee at R&E Stricker GmbH on

site. We recommend involving an assistant for

instruction and commissioning who can later

provide handling support if necessary.

When using the handcycle or power assist device

yourself with the handcycle. Always adapt the

speed and driving maneuvers to your own ability,

the legal regulations. After a short time you will

get a feeling for the handbike. Before you ride the

handbike on slopes, inclines or uneven terrain,

ground.

7 Fitting the handbike to the

wheelchair and the rider

NOTE

Unpacking and installation video can be found on

www.stricker-handbikes.de/installationsupport

WARNING

Ensure that all screws are tightened to the

appropriate torques after adjustment is complete.

The corresponding torques can be found in

the following instructions and in „Attachment

- A Torque list“. Screws that are not tightened

lead to serious injuries.

Fig. 1: Lipo Lomo

Fig. 2: Standard frame

7.1 Unpacking the handbike

The handbike is tied up in the box for transport. Cut

the cord before removing the handbike.

Zum Transport werden beide Längsrohre nach

oben verdreht. Die Einstellungen der Teile wird im

Folgenden erklärt.

R&E Stricker Reha-Entwicklungen GmbH

9

Power Assist Devices

Fitting the handbike to the wheelchair and the rider

NOTE

To perform all adjustments, place the handcycle

and your wheelchair securely on level, solid

ground. Make sure there is enough space and

light to carefully implement the adjustments.

7.2 Adjusting the inclination of

the headstock tube

WARNING

Make sure that the corner brackets secured by the

S1L and S1R screws do not slip out of the cross

tubes. Do not use the insertion depth of the corner

brackets to adjust the width of the clamping

device.

Loosen the S1L and S1R screws using the Allen

key (SW 6) provided. Turn the longitudinal tubes

to the desired angle to the control bearing tube.

of the crank position, you may have to adjust the

angle again. Lightly tighten the S1L and S1R bolts

(Fig. 2).

After completing all adjustments, tighten the S1L

and S1R screws to a torque of 30 Nm.

NOTE

If you make adjustments to the inclination of the

headset tube while the handbike is coupled to the

wheelchair, also loosen the S3L and S3R screws

to prevent tension in the frame. Tighten them

again afterwards with a torque of 30 Nm.

7.3 Adjusting the length and

width of the clamping device

To adjust the length of the longitudinal tubes and

the angle of the clamps, loosen screws S3L and

S3R. Make sure that the length of the longitudinal

tubes is always set identically on both sides (Fig.

3).

Adjust the angle of the clamps according to the

wheelchair frame at the clamping position. This is

especially important for wheelchairs with V-shaped

frames. Lightly tighten the S3L and S3R screws.

After completing all adjustments, tighten the S3L

and S3R screws to a torque of 30 Nm.

NOTE

If you make adjustments to the length of the

longitudinal tubes while the handbike is coupled

to the wheelchair, also loosen the S2L and S2R

bolts to avoid tension in the frame.

To adjust the width of the clamping device, loosen

the S2L and S2R screws. Adjust the clamping

device to the width of the wheelchair frame. Make

sure to set the same angle to the cross tube on

both sides. Lightly tighten the S2L and S2R screws.

After completing all adjustments, tighten the S2L

and S2R screws to a torque of 30 Nm.

Fig. 3: Setting the default frame

7.4 Coupling the handbike to the

wheelchair for the rst time

Fig. 4: Clamp xed to the wheelchair frame

Fig. 4

to the wheelchair. The position clamps mounted

under the clamps ensure that the clamp always

10

R&E Stricker Reha-Entwicklungen GmbHPower Assist Devices

Fitting the handbike to the wheelchair and the rider

sits at the set height. The position clamps are

included in the delivery and should be attached to

the wheelchair.

If your wheelchair has removable footrests, an

adaptation is necessary, as otherwise no stable

connection can be made between the handbike or

traction device and the wheelchair.

7.4.1 Fitting the stem x (optional)

swivelled to the side and ensures that the clamps

of the handbike or traction device can correctly

transfer the power transmission to the wheelchair

determined with the holes. See Fig. 5.

Fig. 5: The pre-mounting x stabilises the swing-away

footrests and enables a stable clamp connection.

7.4.2 Fitting the general adapter

(optional)

the general adapter can be used. The clamps are

mounted on the rigid part of the wheelchair. The

clamping surface then runs forward and provides

a stable and straight support surface for the

clamp. With the different holes, the adapter can be

adapted to the wheelchair.

Fig. 6: Mounted general adapter if a stable clamp connection

is not possible due to removable footrests.

7.4.3 Wheel alignment

Make sure that the screws S1L and S1R as well as

S3L and S3R are only slightly tightened. A slight

adjustment according to the wheelchair should still

be possible. Make sure that the handbike stands

straight.

Align the wheel of the handbike exactly in the

center of the wheelchair track. A maximum

deviation of 1 cm from the center is permissible.

Use the footrest to check the alignment.

WARNING

An incorrectly aligned drive wheel can lead to

accidents due to poor straight-ahead running and

swinging tendencies.

To simplify the adjustment, you can make a

template. Then drive the wheelchair up to the

template so that the wheels are the same distance

from the line of symmetry. Place the drive wheel of

the handbike exactly on the line of symmetry (Fig.

7).

R&E Stricker Reha-Entwicklungen GmbH

11

Power Assist Devices

Fitting the handbike to the wheelchair and the rider

Fig. 7: Template

A Front wheel

B Symmetry line

C Markings for the wheelchair front wheels

D Wheelchair front wheels

Couple the handbike to the wheelchair. Then follow

the further adjustment instructions to adapt the

handbike exactly to you and your wheelchair.

7.5 Adjusting the ground

clearance

Clamp the handbike to the wheelchair.

WARNING

Leave the front wheels of the wheelchair on the

ground. Make all adjustments only when the

wheelchair is parked. There is a considerable risk

of injury when making adjustments in the driving

position.

Fig. 8: Automatic catch open

Fig. 9: Automatic catch closed

1 Locking slot

2 Flap / Cover

3 Bolt

4 Nut

between the front wheels of the wheelchair and

the ground. The setting is made using the SL Allen

screw in the slotted hole adjustment. Set both

automatic notches in the same way. Open the grid

slot in the automatic latch. Move the Automatic

catch mechanism according to your wishes and

tighten the Allen screw SL with a torque of 30 Nm.

If the adjustment of the elongated holes is not

lock nut. Loosen the lock nut. Turn the adjusting

nut according to your requirements. Retighten the

lock nut after completing the settings.

12

R&E Stricker Reha-Entwicklungen GmbHPower Assist Devices

Adjusting the traction device to the wheelchair and the driver (Pico frame)

frame and a cross bike, you may have to mount

loosen the screw SL with which the automatic latch

is attached in the elongated hole and unscrew

the screw completely. Remove the sleeve and all

washers. Make sure you slide the sleeve and all

washers back onto the appropriate screw in the

correct order. Fig. 9.

Now loosen the lock nut on both Automatic catch

and completely unscrew the eyebolt. Also take the

adjusting nut out of the Automatic catch housing.

Install the sleeve from the eyebolt into the slot in

the housing of the automatic catch. Now mount

the screw SL again with all washers through the

Automatic catch-in housing in the elongated hole.

NOTE

Pay particular attention that the smaller washer

(shim washer) is in direct contact with the sleeve.

Otherwise there is a risk of damage to the parts.

with the screw SL. Therefore you have to bend the

screw SL with a torque of 30 Nm. (Fig. 10).

Fig. 10: Converted Automatic catch

WARNING

When lifting the front wheels into the driving

position, both locking pins must engage

simultaneously. This is absolutely necessary for

proper function.

The length of the latching slot provides a reference

point for the setting. When the handbike is parked,

about 1 cm of this should be visible. The longer the

visible part is in the parked position, the greater the

ground clearance in the driving position.

After adjustments have been completed, check the

ground clearance by lifting the front wheels of the

wheelchair into driving position. We recommend a

ground clearance of approx. 3-4 cm. Carry out the

previously described steps until the adjustment

meets your requirements. The adjustment of the

ground clearance may have an effect on the crank

position. Adjust this again if necessary.

8 Adjusting the traction

device to the wheelchair

and the driver (Pico frame)

Fig. 11: Lipo Lomo Pico

WARNING

Ensure that all bolts are tightened to the

appropriate torques after adjustment is complete.

safety risk and can cause serious injury.

R&E Stricker Reha-Entwicklungen GmbH

13

Power Assist Devices

Adjusting the traction device to the wheelchair and the driver (Pico frame)

Fig. 12: Pico frame

8.1 Assembly of the U-frame

The aim of the assembly steps is to position the

top edge of the coupling plate approx. 42 cm

Fig. 13). Once the U-frame with the

coupling plate is correctly positioned and securely

fastened, the traction device can be coupled

to the wheelchair and also uncoupled from the

wheelchair at any time without any problems and

without tools by the driver.

Fig. 13: Adjusting the Lipo Lomo Pico

To do this, open the clamps on both sides just

enough to slide them over the front frame tubes

of the wheelchair. Only open the clamps as far

as necessary, as if they are opened too far the

clamping nuts could fall out (after approx. 20

turns).

Loosen the screws S2L and S2R so that the width

of the U-frame can be adjusted.

Fig. 14: Loosening S2R and S2L

Adjust the angle of the clamps according to the

wheelchair frame at the clamping position. To

do this, loosen the screws S5L and S5R. This is

especially important for wheelchairs with V-shaped

frames.

WARNING

When loosening and tightening the screws S5L

and S5R, be sure to counteract from the inside

with a 4 mm Allen key and tighten the nut with a

5 mm Allen key. Be careful not to overtighten the

screws (10 Nm).

Fig. 15: Loosening S5R and S5L

Now attach the clamping device to the frame of the

wheelchair using the levers H1L and H1R on the

left and right. Make sure that the clamps are at the

that small adjustments can still be made.

14

R&E Stricker Reha-Entwicklungen GmbHPower Assist Devices

Adjusting the traction device to the wheelchair and the driver (Pico frame)

Now carefully align the U-frame so that it is

symmetrical and centred in front of the wheelchair.

Fig. 16: Correctly adjusted frame

To adjust the distance of the cross tube, you can

move the slide tubes in the clamp. This allows you

to shorten or lengthen the frame by a maximum of

3 cm. To do this, loosen the screws S5L and S5R.

Make sure that the slide tubes are in the same

position on both sides to prevent the cross tube

from slipping. Under no circumstances pull the

slide pipes too far out of the clamp. The end caps

must remain completely in front of the clamp.

NOTE

If you need a greater distance from the traction

device to the wheelchair, frames with longer push

tubes are available.

Fig. 17: Adjusting the Pico frame

Check the U-frame carefully for an exact,

symmetrical and centred position in front of the

frame of the wheelchair. Then all screws and

levers loosened so far can be tightened securely to

ensure absolute form stability. Tighten all screws

accordingly: „Attachment - A Torque list“.

If you have carried out all steps one after the

other according to the instructions, the U-frame

is basically ready for use. If necessary, however,

adjustments of the coupling plate must be carried

out before the traction unit can be coupled. To do

this, please carry out the necessary steps below.

8.2 Adjusting the inclination of

the coupling plate

You can adjust the ground clearance of the

front wheels of the wheelchair by adjusting the

inclination of the coupling plate. Loosen the screws

S1L and S1R. Now you can change the inclination

of the coupling plate by turning the cross tube.

After you have adjusted the inclination according to

your wishes, carefully tighten all screws according

to the torque list: „Attachment - A Torque list“.

Fig. 18: Coupling plate tilted too much

Fig. 19: Correctly inclined coupling plate

R&E Stricker Reha-Entwicklungen GmbH

15

Power Assist Devices

Coupling the handbike to the wheelchair

8.3 Adjusting the height of the

coupling plate

(Abb. 17) Loosen the screws S4L and S4R. Now

you can adjust the height of the coupling plate

by tilting the U-frame up or down. After you have

adjusted the height according to your wishes,

tighten all screws carefully according to the torque

list: „Attachment - A Torque list“.

Fig. 20: Loosening S4R and S4L

8.4 Adjusting the handlebar

height

Loosen the lever HS and adjust the height of the

handlebars according to your wishes. For transport,

it is a good idea to push the handlebars together

completely. (Fig. 24).

9 Coupling the handbike to

the wheelchair

9.1 Coupling standard frame

Once you have carefully adjusted the handbike to

your wheelchair, you can easily and quickly connect

and disconnect it from your wheelchair at any time.

If locked, unlock the Automatic catch. To do this,

(Fig. 8 und Fig. 9

spring open and release the locking pin. Now you

can adjust the clamping device and thus relax

the automatic detents to maximum length. We

recommend that you close the detents again

immediately to avoid injury when operating the

clamping levers.

Open the clamping device on both sides just

enough so that they can be slid over the front

frame tubes of the wheelchair. Open the clamps

only as far as necessary, as opening them too far

could cause the clamping nuts to fall out (after

approx. 20 turns).

WARNING

Tighten the ball handle nut or the tetrastar nut

with a maximum torque of 6-8 Nm!

Grasp the handbike by the handlebar and attach

it to the front frame of the wheelchair using the

clamping device. Now tighten the clamps on both

sides.

For your own safety, we recommend locking the

brakes on the wheelchair and handbike for the

coupling process. This will prevent the handbike

or wheelchair from moving and you will have both

hands free to close the clamps..

To further simplify the coupling process, you

will receive positioning clamps together with the

handbike, which you can permanently mount on the

wheelchair. You can easily and safely position the

handbike’s clamping device on these and only have

to close the clamps.

NOTE

When closing the clamps, always make sure that

the clamps are aligned parallel to the tubes of

the front frame of the wheelchair. If this is not the

case, there is a risk of damage to the PVC caps.

Before coupling, make sure that the PVC caps

are undamaged. Damaged PVC caps can cause

damage to the wheelchair.

WARRANTY & LIABILITY NOTICE

The PVC caps are wearing parts, therefore no

warranty applies to them. We accept no liability

for damage caused by damaged PVC caps.

Now release the brakes of the handbike. Push the

handbike forward by the handlebar so that the front

wheels of the wheelchair lift off the ground. Push

the handbike forward until the automatic locks

engage on both sides. You should hear a distinct

click. Check whether both locking pins are visibly

engaged.

16

R&E Stricker Reha-Entwicklungen GmbHPower Assist Devices

Uncoupling the handbike from the wheelchair

9.2 Coupling the Pico frame

As soon as the U-frame and the coupling plate

have been brought into the optimal position, you

can couple the traction device to the wheelchair.

Check the position of the rotary switch D1. This

must point downwards before the docking process

so that the pin controlled by it protrudes. (Fig. 12).

Position the towing device centrally in front of the

coupling plate and lift the lateral pins of the towing

device into the slots provided in the coupling plate.

in and must then automatically pop out again as

soon as the towing device is in the correct position.

Now push the handlebar of the towing device away

from you and thereby carefully lift the front wheels

of the wheelchair until the lower pins of the towing

device engage in the coupling plate. Make sure that

the pins are engaged on both sides. The towing

device is now ready to drive.

10 Uncoupling the handbike

from the wheelchair

10.1Unhitching Standard Frame

If locked, unlock the Automatic catch. To do this,

(Fig. 8 und Fig. 9

on the locking bolt. The release only works as

long as the indexing bolt is unloaded. To release

the indexing plunger, grasp the handbike by the

handlebar and push it forward away from your

bolt back and unlock the automatic locking

mechanism. Now carefully set down the front

wheels of the wheelchair. We recommend closing

when operating the clamping levers.

WARNING

As soon as you press the handbike forward by the

handlebar with the louvers open, the automatic

louvers unlock. You now hold the full weight.

force the detent bolts back. This could bend the

the function of the automatic detent.

Once you have parked the handcycle or power

assist, you can open the clamps and release

the handcycle from the wheelchair. Only open

the clamps as far as necessary, since if they are

opened too far, the clamping nuts could fall out

(after approx. 20 turns).

10.2Uncoupling the Pico frame

To uncouple the towing device from the wheelchair,

push lever H2 all the way forward. This unlocks

the pins at the bottom of the coupling plate and

the traction unit detaches from the coupling

plate, thereby lowering the raised wheels of the

wheelchair to the ground.

Now turn the rotary switch D1 upwards so that the

pin controlled by it is lowered. The traction device

is now completely detached from the U-frame. Lift

the traction device slightly out of the coupling plate

and place it on the stand.

NOTE

Turn the rotary switch back down immediately

after uncoupling so that you do not forget to do

so the next time you couple it.

11 Operation

11.1Model range Lipo Lomo

1 Key switch

2 Three-position switch

3 Light

4 Capacity indicator

5 Rotary throttle

6 Brake lever with break contact

7 Bell

8 Reverse gear (extra equipment)

9 Cruise control (extra equipment)

10 Speedometer

11 USB socket (extra equipment)

HS Handlebar height adjustment

HL Handlebar screw

H2 Coupling plate release

R&E Stricker Reha-Entwicklungen GmbH

17

Power Assist Devices

Operation

Fig. 21: Lipo Lomo control unit

Fig. 22: Lipo Lomo Pico control unit

Fig. 23: Lipo Lomo handlebar

Fig. 24: Lipo Lomo Pico handlebar

11.1.1 Start driving

WARNING

When parking the traction unit, always remove the

key for the key switch to prevent unauthorised use

of the unit.

Fig. 25: Battery

18

R&E Stricker Reha-Entwicklungen GmbHPower Assist Devices

Operation

Switch on the battery with the main switch on the

battery. You will know that the battery is switched

on when the lamp on the battery lights up (Fig. 25).

Turn the key switch with the key to the „ON“

position (Fig. 21 bzw. Fig. 22). Remove the key and

stow it safely so as not to lose it while driving.

Turn the right handle to accelerate.

The brake lever on the right side of the handlebar

automatically interrupts the drive electronics when

actuated. You therefore cannot operate the right

brake lever and accelerate at the same time.

The brake lever on the left side of the handlebar

has no breaker contact. You can use the left brake

lever for starting uphill.

11.1.2 Starting uphill

If you have stopped on an incline and want to start

again, you may roll backwards and not be able to

start. In order to be able to start despite the slope,

lean forward to put more weight on the front wheel.

Press and hold the left brake lever. At the same

time, carefully apply the accelerator. Reduce the

pressure on the brake while slowly increasing the

throttle. As soon as you feel that you are moving

in the direction of travel, you can release the brake

completely.

11.1.3 End of ride

Switch off the battery using the main switch on the

battery. You will know that the battery is off when

the light on the battery is not lit. (Fig. 25).

Turn the key switch on the control unit with the

key to the „OFF“ position. (Fig. 21 bzw. Fig. 22).

Remove the key and store it in a safe place. Make

sure it is not within reach of unauthorised persons

or children.

11.1.4 Optional extras: lights/horn and

cruise control/reverse gear.

Fig. 26: Left: Light (red) and horn (green); Right: reverse gear

(red) and cruise control (green).

To switch on the light on the traction unit, press the

red button with the light symbol on the left handle.

Press the button again to switch the light off. Press

the green button with the horn symbol to activate

the horn.

To activate reverse gear, press the red button

on the right handle. Press the button again to

disengage reverse gear. Press the green button

to activate the cruise control. When the cruise

control is activated, it saves and maintains your

current driving speed. Press the button again to

deactivate cruise control. Pressing the brake with

breaker contact (brake on the right handle) also

deactivates the cruise control. Should you use the

throttle handle while the cruise control is active,

the traction unit will not accelerate. If the throttle

grip is turned back to the zero position after

accelerating, this will deactivate the cruise control.

WARNING

permits. Be ready to deactivate cruise control at

any time with the brake with breaker contact.

11.1.5 Optional equipment: 2 Lipo

batteries with 2 change-over

switches

With this optional equipment for the Lipo Lomo you

get a towing device with two batteries on the fork

and a control box with two toggle switches. The

standard battery holder on top is omitted with this

equipment.

This manual suits for next models

2

Table of contents

Popular Wheelchair manuals by other brands

Vicair

Vicair VECTOR O2 Important notice

Drive Medical

Drive Medical Travelite Chair In A Bag Owner's handbook

Pressalit

Pressalit PLUS shower seat 450 Operation and maintenance manual

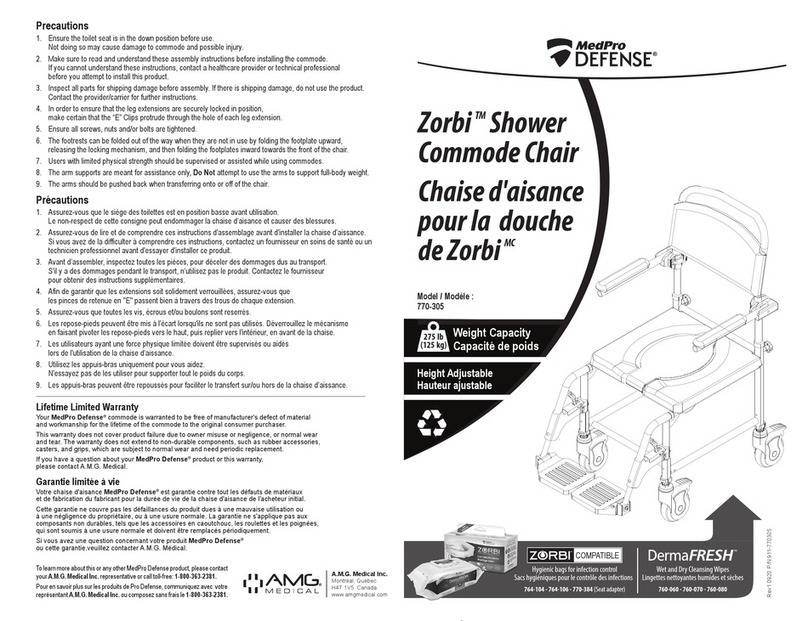

AMG Medical

AMG Medical MedPro DEFENSE Zorbi 770-305 Assembly instructions

Vermeiren

Vermeiren Forest 3 installation manual

DiscountRamps

DiscountRamps Silver Spring ESC400 instructions