Strongarm 727 User manual

M17-SA030470

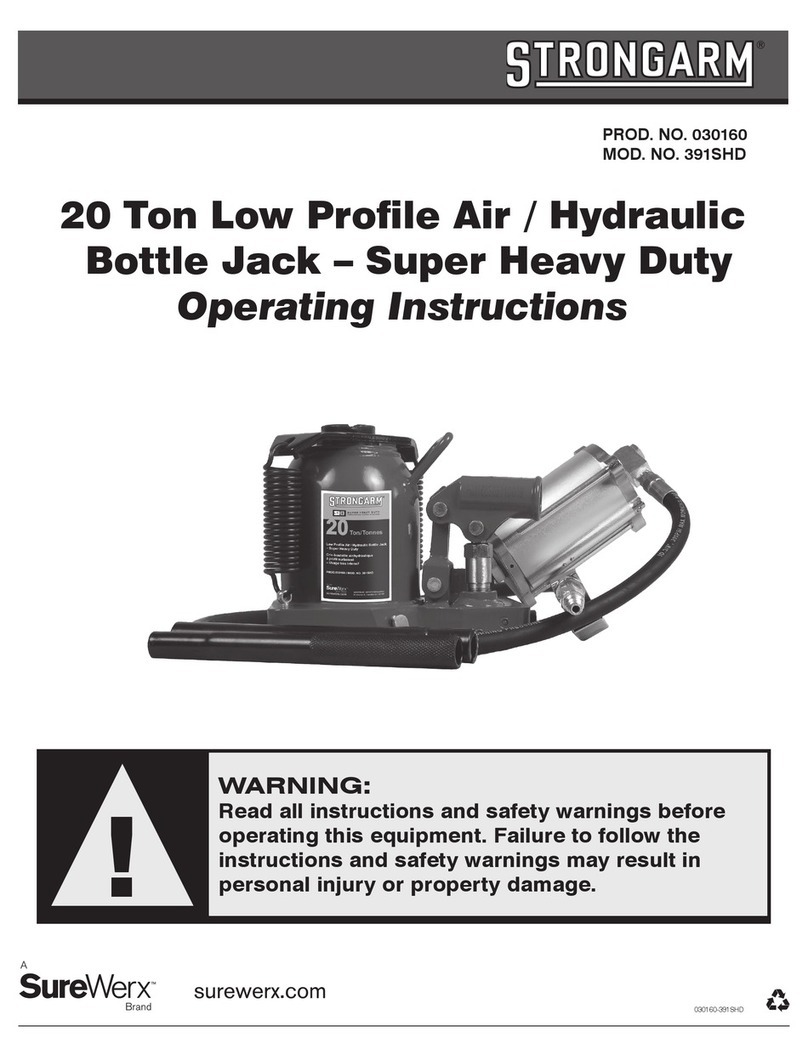

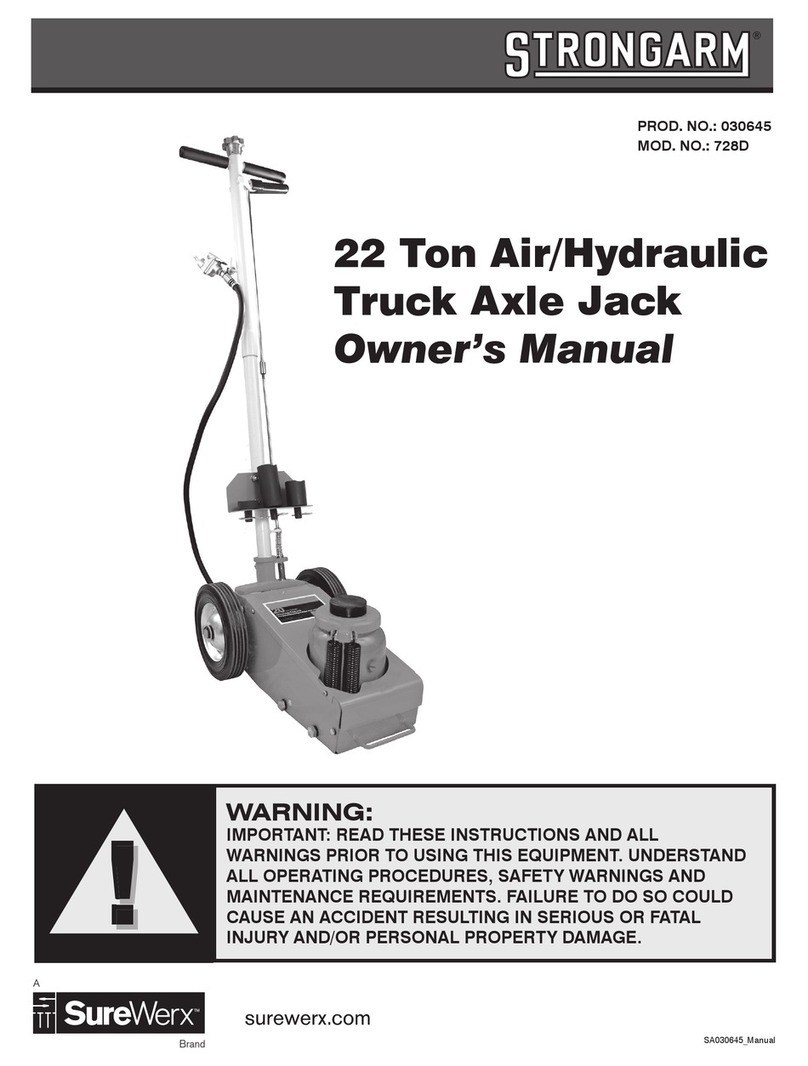

22 Ton Air/Hydraulic

Truck Axle Jack

Owner’s Manual

PROD. NO.: 030470

MOD. NO.: 727

WARNING:

IMPORTANT: READ THESE INSTRUCTIONS AND ALL

WARNINGS PRIOR TO USING THIS EQUIPMENT. UNDERSTAND

ALL OPERATING PROCEDURES, SAFETY WARNINGS AND

MAINTENANCE REQUIREMENTS. FAILURE TO DO SO COULD

CAUSE AN ACCIDENT RESULTING IN SERIOUS OR FATAL

INJURY AND/OR PERSONAL PROPERTY DAMAGE.

!

!

A / Une / Una

Brand / Marque / Marca

surewerx.com

Una

Marca

surewerx.com

Un partenaire

A

Partner

surewerx.com

2

!WARNING!

The use of portable automotive lifting devices is subject to certain hazards that cannot be

prevented by mechanical means, but only by exercise of intelligence, care, and common sense.

It is therefore essential to have personnel involved in the use and operation of equipment who are

careful, competent, trained, and qualified in the safe operation of this equipment and its proper use

when servicing motor vehicles and their components. Examples of hazards are dropping, tipping,

or slipping of motor vehicles or their components caused primarily by improperly securing loads,

overloading, off-centered loads, use on other than hard level surfaces, and using equipment for a

purpose for which it was not designed.

The owner and / or operator shall study and understand the product and safety instructions

before operating this equipment. Safety information shall be emphasized and understood.

If the operator is not fluent in English, the product and safety instructions shall be read to and

discussed with the operator in the operator’s native language by the purchaser / owner or his

designee, making sure that the operator comprehends their contents. A copy of these instructions /

warnings shall be retained for future reference.

!INSPECTION

Visual inspection shall be made before each use of this equipment, checking for abnormal

conditions, such as cracked welds, leaks, damaged, loose or missing parts. This equipment shall

be removed immediately from service if it is believed to have been subjected to an abnormal

or shock load, the equipment shall be inspected by a qualified repair facility. Owners and / or

operators should be aware that repair of this equipment may require specialized knowledge and

facilities. It is recommended that this equipment be inspected annually by a qualified repair facility.

Defective parts, decals, safety labels or signs should be replaced with Strongarm specified parts.

!WARNING!

• Prior to lifting a vehicle, refer to vehicle manufacturer’s recommended lifting points.

• Inspect the jack prior to each use, remove from service if it is leaking, damaged,

excessively worn, or has been altered in any way.

• This jack was designed for lifting purposes only. Do not attempt to work on the

vehicle until appropriately rated jacks stands are supporting the load.

• Do not exceed rated capacity.

• Do not move or dolly the vehicle while on jack.

• Chock vehicle to prevent movement.

• Center load on saddle, off center loads may cause jack failure and / or loss of load.

• Use jack on a hard level surface.

• Only attachments and / or adapters supplied by the manufacturer shall be used.

• No alterations shall be made to this product.

• Failure to heed these markings may result in severe or fatal personal injury and /

or property damage.

surewerx.com 3

!SET UP

ASSEMBLY

1. Connect two piece handle assembly, ensure that internal and external rods mate properly.

Use screw provided to secure outer handle tube and cotter pin to secure external handle locator rod.

2. Loosen handle retaining bolt from yoke assembly, insert handle assembly and handle locator rod into

yoke assembly. NOTE: Rotate release knob at top of handle to ensure that the internal handle rod is

engaged within the yoke assembly fully. Tighten handle retaining bolt on yoke assembly.

3. Extract air hose assembly from initial storage position and attach to top of handle.

4. Add a few drops of air tool lubricant into air valve assembly.

AIR PURGE

1. Open release valve by rotating release knob at top of handle counterclockwise two turns.

2. Remove oil filler plug on side of hydraulic unit, ensure oil level is just below filler plug hole,

reinstall plug.

3. Depress the air valve for 30 seconds.

4. Close release valve by rotating release knob at top of handle clockwise until firm.

Do Not Overtighten.

5. Depress air valve until ram is fully extended.

6. Repeat if necessary.

LIFTING

1. Secure the vehicle by chocking wheels and apply parking brake.

2. Refer to vehicle manufacturer’s recommended lifting points and position jack accordingly,

ensure that load is centered on saddle.

3. Rotate release valve clockwise until tight.

4. Lock handle position using one of the three position of the handle locator.

5. Attach air valve to suitable air source (90-175 psi). Depress air valve until saddle makes

contact with recommended lifting point, (ensure lifting point is aligned properly and safely).

Raise load to desired height.

6. WARNING: During lifting ensure load and jack are stable, if either appear to be unstable,

stop lifting, lower load and reposition jack.

7. IMMEDIATELY after reaching desired height, secure load with appropriately rated safety stands.

(refer to vehicle manufacturer’s recommended positioning)

LOWERING

1. Raise load high enough to remove safety stands.

2. WARNING: Ensure load does not shift or become unstable when lifting. If load is unstable,

slowly lower load back on to the safety stands. Correct instability and try again.

3. Carefully remove safety stands.

4. Lower load slowly.

!MAINTENANCE

1. Depending upon usage, periodically add a few drops of air tool oil to air inlet.

2. Store unit in fully retracted position to avoid rusting of lift piston.

3. Grease the extension screw threads with a general purpose grease

4. Keep saddle area clean and free of grease or dirt.

surewerx.com

4

727 - 22 Ton Air/Hydraulic Truck Axle Jack

PROD. NO.: 030470 • MOD. NO.: 727

surewerx.com 5

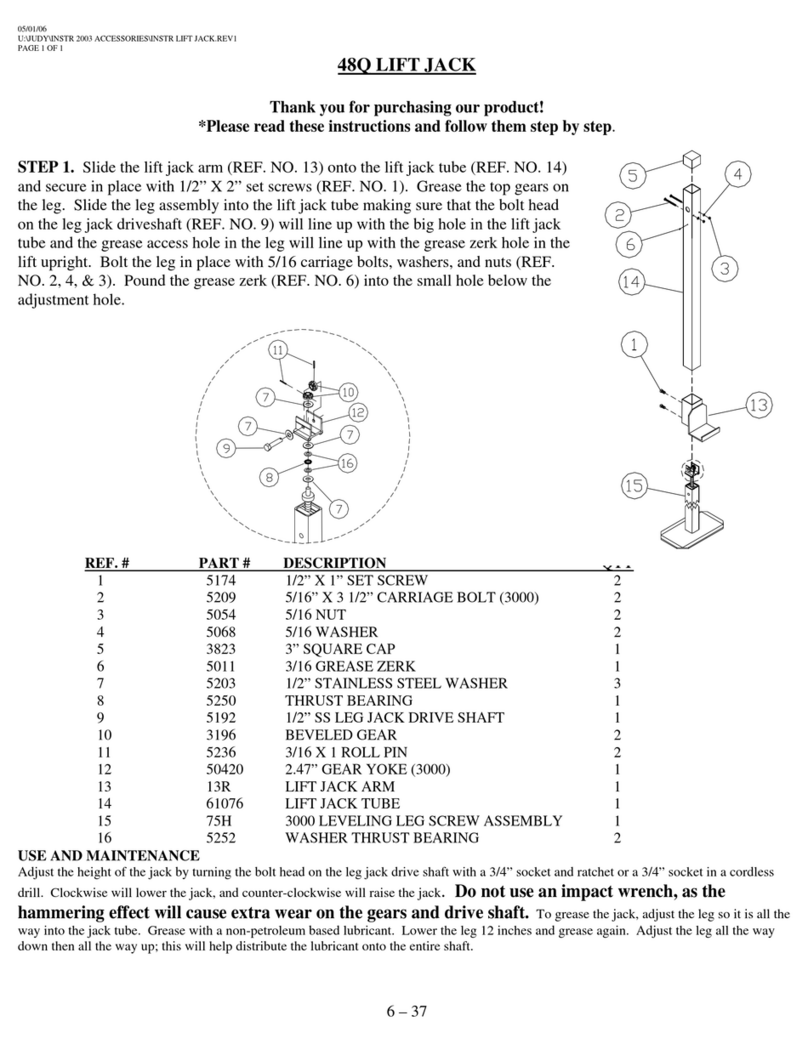

PARTS LIST

1PFH-727CP01 KNOB 1

2PFH-727CP02 SPRING PIN 1

3PFH-727CP03 HANDLE UPPER 1

4PFH-727CP04 SPRING PIN 1

5PFH-727CP05 HANDLE CAP 2

6PFH-727CP06 SCREW 2

7PFH-727CP07 LOCK LEVER 1

8PFH-727CP08 HANDLE CAP 1

9PFH-727CP09 STOPPER UPPER 1

10 PFH-727CP10 ROD UPPER 1

11 PFH-727CP11 HANDLE LOWER 1

12 PFH-727CP12 STOPPER LOWER 1

13 PFH-727CP13 SPLIT PIN 1

14 PFH-727CP14 WASHER 1

15 PFH-727CP15 SPRING 1

16 PFH-727CP16 SPRING WASHER 6 5

17 PFH-727CP17 RETANING RING 18 1

18 PFH-727CP18 BOLT M6X10 1

19 PFH-727CP19 ROD LOWER 1

20 PFH-727CP20 ADAPTOR D 1

21 PFH-727CP21 ADAPTOR C 1

22 PFH-727CP22 ADAPTOR B 1

23 PFH-727CP23 AIR VALVE ASSEMBLY 1

24 PFH-727CP24 SPRING 1

25 PFH-727CP25 AIR HOSE 1

26 PFH-727CP26 SPRING WASHER 8 4

27 PFH-727CP27 NUT M8 4

28 PFH-727CP28 U-BOLT 2

29 PFH-727CP29 R-PIN 3

30 PFH-727CP30 BOLT 1

31 PFH-727CP31 SPRING WASHER 10 5

32 PFH-727CP32 HANDLE FORK 1

33 PFH-727CP33 HANDLE FORK BRK 1

34 PFH-727CP34 FRAME 2

35 PFH-727CP35 BOLT M10X20 4

36 PFH-727CP36 WHEEL 2

37 PFH-727CP37 WASHER 2

38 PFH-727CP38 SNAP RING 2

39 PFH-727CP39 HOSE BAND 1

40 PFH-727CP40 SCREW 4

41 PFH-727CP41 SPRING WASHER 5 4

42 PFH-727CP42 BOLT M6X12 4

43 PFH-727CP43 BOLT M12X20 4

44 PFH-727CP44 SPRING WASHER 12 4

45 PFH-727CP45 LOWER COVER 1

46 PFH-727CP46 POWER UNIT 1

47 PFH-727CP47 AIR PUMPER ASSEMBLY 1

48 PFH-727CP48 O-RING 1

49 PFH-727CP49 GUIDE 1

50 PFH-727CP50 O-RING 1

51 PFH-727CP51 VALVE 1

52 PFH-727CP52 WASHER 1

53 PFH-727CP53 RETANING RING 1

54 PFH-727CP54 CONNECTING ASSEMBLY 1

55 PFH-727CP55 SPRING PIN 2

56 PFH-727CP56 SPLIT PIN 1

57 PFH-727CP57 WASHER 1

58 PFH-727CP58 CONNECTING ROD 1

59 PFH-727CP59 UPPER COVER 1

REF PART NUMBER DESCRIPTION REQ REF PART NUMBER DESCRIPTION REQ

surewerx.com

6

1PFH-727AM01 PLUNGER COVER 1

2PFH-727AM02 NUT 1

3PFH-727AM03 AIR PUMP BODY 1

4PFH-727AM04 BALL 3

5PFH-727AM05 SPRING 1

6PFH-727AM06 NUT 1

7PFH-727AM07 O-RING 1

8PFH-727AM08 NL RETAINER 1

9PFH-727AM09 PACKING GUIDE 1

10 PFH-727AM10 PLUNGER 1

11 PFH-727AM11 O-RING 2

12 PFH-727AM12 PISTON 1

13 PFH-727AM13 WASHER 1

14 PFH-727AM14 O-RING 2

15 PFH-727AM15 RETAINER 1

16 PFH-727AM16 PACKING WASHER 1

17 PFH-727AM17 MUFFLER COVER 1

18 PFH-727AM18 PIPE JOINT 1

19 PFH-727AM19 VALVE ROD 1

20 PFH-727AM20 PACKING WASHER 1

21 PFH-727AM21 RUBBER PAD 1

22 PFH-727AM22 COVER 1

23 PFH-727AM23 FILTER ELEMENT 1

24 PFH-727AM24 FILTER COVER 1

25 PFH-727AM25 SPRING WASHER 4

26 PFH-727AM26 HEX-SOCKET SCREW 4

REF PART NUMBER DESCRIPTION REQ REF PART NUMBER DESCRIPTION REQ

727 - 22 Ton Air/Hydraulic Truck Axle Jack

PROD. NO.: 030470 • MOD. NO.: 727

PFH-727 AMRPK Air Motor Kit

1 EACH NUMBER 7, 8, 9, 13, 15, 16, 20, 21, 23

2 EACH NUMBER 11 and 14

surewerx.com 7

1PFH-727PU01 ADAPTOR 1

2PFH-727PU02 SPRING HANGER 1

3PFH-727PU03 SPRING 4

4PFH-727PU04 SCREW ROD 1

5PFH-727PU05 BUSH 1

6PFH-727PU06 PISTON ROD 1

7PFH-727PU07 BACK-RING 1

8PFH-727PU08 U-SEAL 1

9PFH-727PU09 PISTON 1

10 PFH-727PU10 SNAP RING 1

11 PFH-727PU11 DUST SEAL 1

12 PFH-727PU12 TANK NUT 1

13 PFH-727PU13 O-RING 1

14 PFH-727PU14 OIL TANK 1

15 PFH-727PU15 BREATHING SCREW 1

16 PFH-727PU16 PACKING 2

17 PFH-727PU17 O-RING 1

18 PFH-727PU18 SCREW 4

19 PFH-727PU19 NUT 4

20 PFH-727PU20 CYLINDER 1

21 PFH-727PU21 SCREW 3

22 PFH-727PU22 SPRING WASHER 3

23 PFH-727PU23 OIL STRAINER 1

24 PFH-727PU24 O-RING 3

25 PFH-727PU25 BACK-UP RING 1

26 PFH-727PU26 OIL BOX 1

27 PFH-727PU27 WASHER 1

28 PFH-727PU28 WASHER 1

29 PFH-727PU29 SAFETY VALVE 1

30 PFH-727PU30 SPRING 1

31 PFH-727PU31 SCREW 1

32 PFH-727PU32 SCREW 1

33 PFH-727PU33 STEEL BALL 1

34 PFH-727PU34 SEPARATOR 1

35 PFH-727PU35 STEEL BALL 1

36 PFH-727PU36 SPRING 1

37 PFH-727PU37 COPPER PACKING 1

38 PFH-727PU38 BOLT 1

727 - 22 Ton Air/Hydraulic Truck Axle Jack

PROD. NO.: 030470 • MOD. NO.: 727

REF PART NUMBER DESCRIPTION REQ REF PART NUMBER DESCRIPTION REQ

PFH-727PUHRK HYD REPAIR KIT

1 EACH NUMBER 7, 8, 10, 11, 13, 15, 17,

25, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36,

37, 38

2 EACH NUMBER 16

3 EACH NUMBER 24

Table of contents

Other Strongarm Jack manuals