2 A6V10323930_c_en_--

DETECTOR PROGRAMMING

Each detector must be programmed to respond to a

address between 001 - 252.

To program the detector address, use the Model DPU

Device Programming Unit. Refer to the DPU Manual, P/N

315-033260.

Record the loop and device number (system

the detector on the detector label and on the base to

prevent installing the detector in the wrong base. The

optional DPU label printer can be used for this purpose.

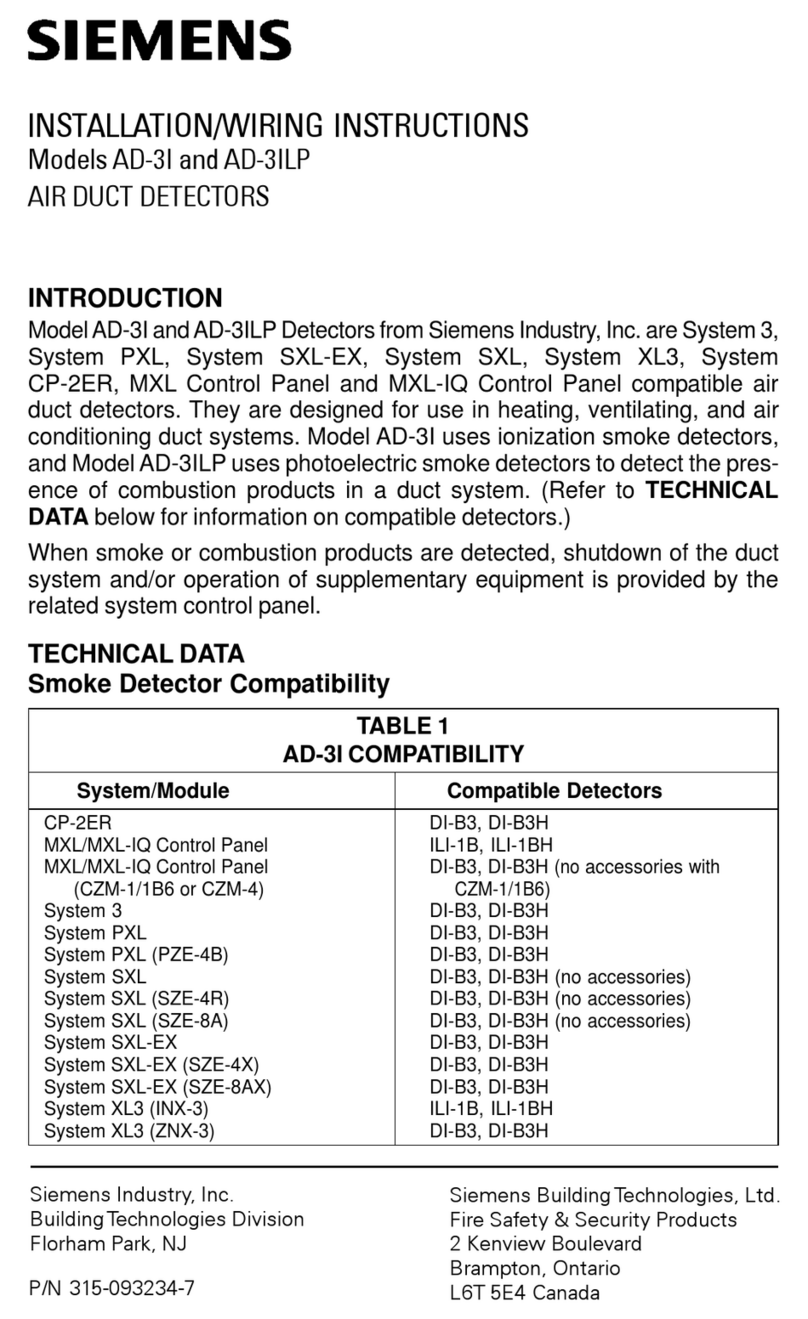

Each detector provides pre-

programmed parameter sets

corresponding description of the panel used.

Fixed temperature 135 °F (57 °C)

Fixed temperature 145 °F (63 °C)

Fixed temperature 155 °F (68 °C)

Fixed temperature 165 °F (74 °C)

Fixed temperature 174 °F (79 °C)

Rate-of-rise detection:

·15 °F/min (8.3 °C) at fixed 135 °F (57 °C)

·15 °F/min (8.3 °C) at fixed 174 °F (79 °C)

Additionally, the detector can be configured by some

panels to have a low temperature warning at 40

(4.4 °C).

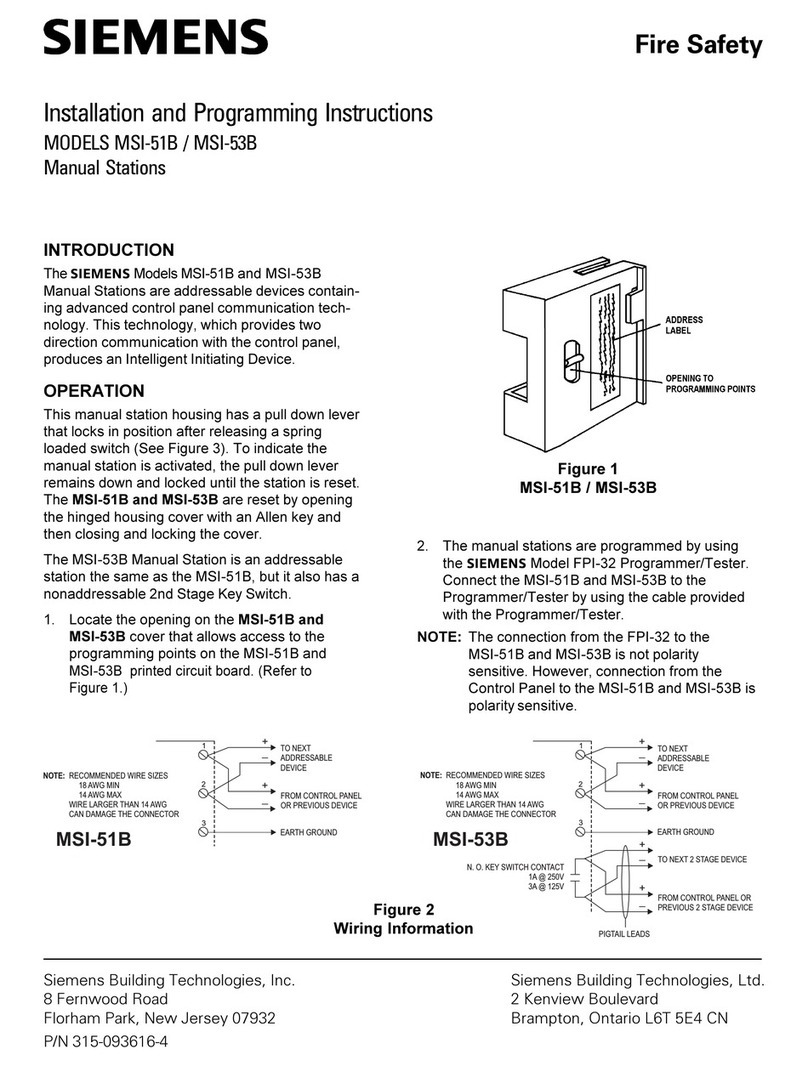

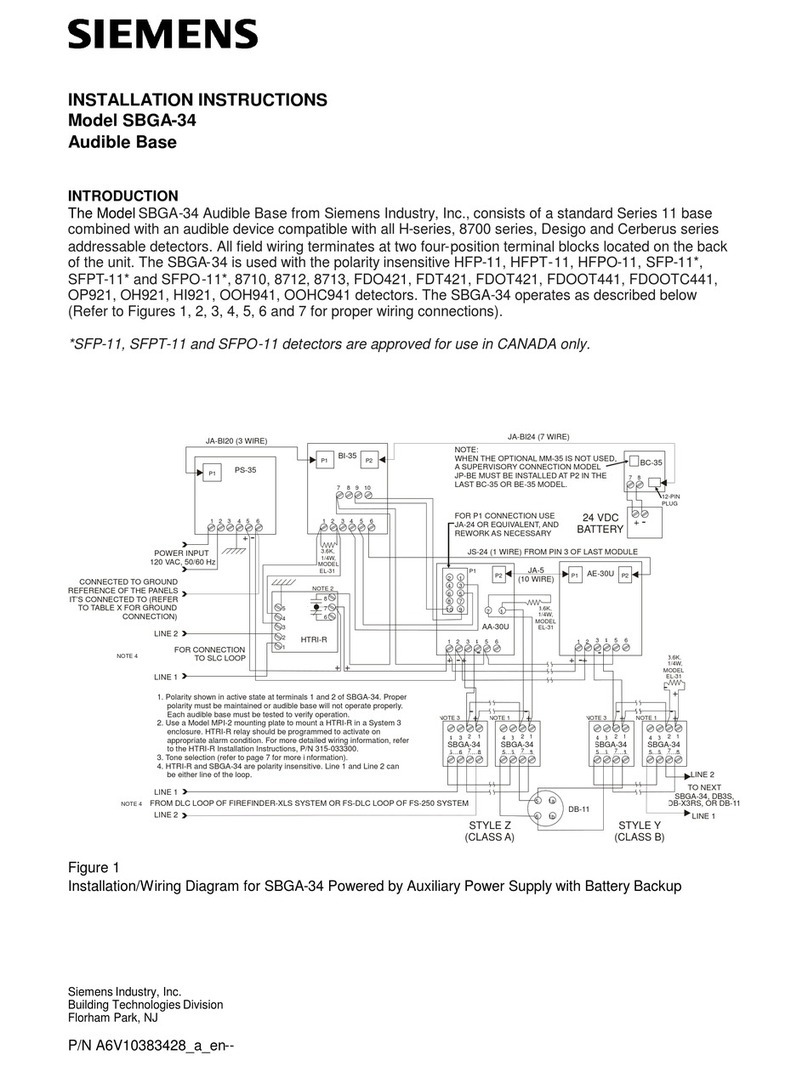

WIRING

The FDT421

supports two operation modes: polarity

insensitive mode and isolator mode. The Detector can be

wired for either mode (refer to Figure 2 and 3). During

the isolator mode, the built-

in dual isolators will work at

both sides of the Detector to isolate the li

or behind the device.

When the FDT421

is wired in polarity insensitive mode,

Line -6 and -5 can be either line of the loop.

When the FDT421 is wired for I

solator mode, the positive

line needs to be connected to 1b and the negative line to

6. The next device needs to be connected to 1b and 5.

The Line Isolator is located between connector 6 and 5.

NOTICE

Ensure that the panel supports Isolator mode

the FDT421 product version 17.

Isolator mode must not be used with a FDT421

product version <17. You will find the product

version number on the detector label.

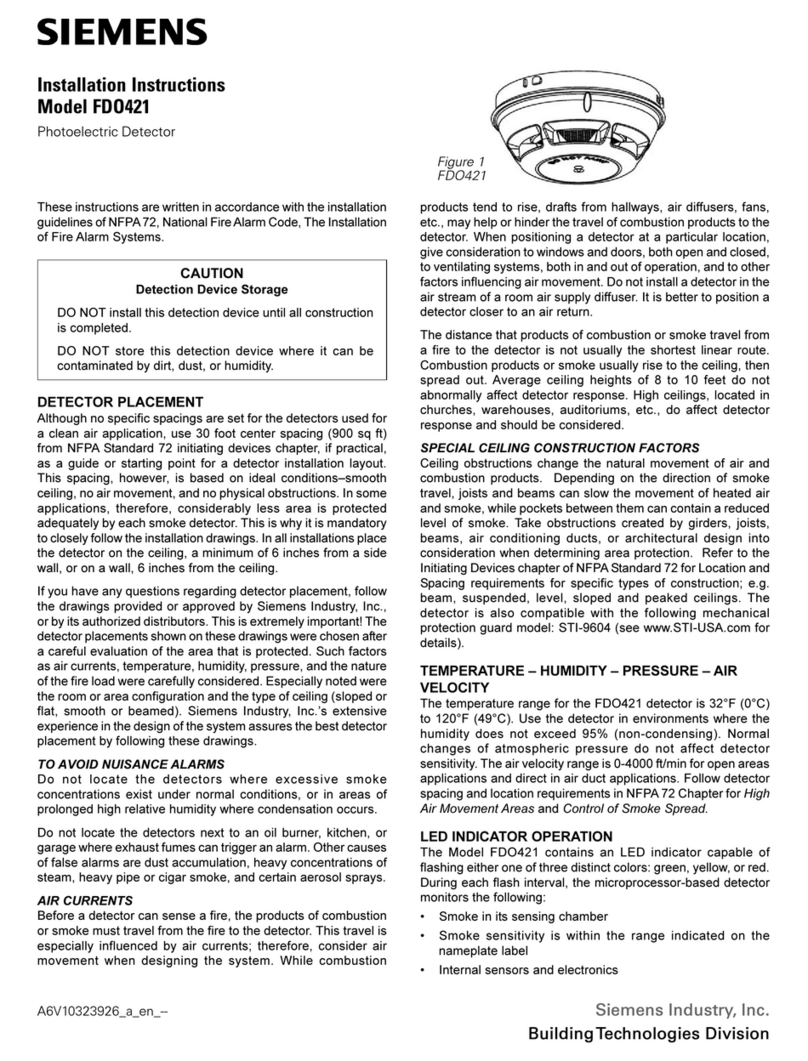

DETECTOR MOUNTING

To ensure proper installation of the detector head into the

base, be sure the wires are properly dressed at

installation:

·Position all wires flat against the base.

·Take up all slack in the outlet box

·Route wires away from connector terminals.

TO INSTALL DETECTOR HEAD

·

Rotate detector counterclockwise while gently

pressing on it until the detector seats fully into base.

·

Then rotate the detector clockwise until it stops and

locks in place. Insert optional locking screw (Order

Model LK-11).

TO REMOVE DETECTOR HEAD:

·

Loosen locking screw, if installed. Then rotate the

detector counterclockwise until stop is reached.

·Pull detector out of base.

DETECTOR TESTING

Only qualified service personnel should test. To assure

proper operation of the detector, the Functional Test

should be conducted. The minimum test schedule may

be found in the current edition of NFPA 72

installations in the U.S.

The detectors can be tested individually using the DPU.

Refer to the DPU Manual, P/N 315-033260

MAINTENANCE

No special maintenance procedures are required for the

FDT421.

The control unit automatically indicates the

trouble

message for any detector. The detector may

require replacement.

CAUTION

Under no circumstances is the detector head to be

disassembled.

No repairs should be attempted.

DO NOT PAINT

The detector is marked DO NOT PAINT. This is intended

to prohibit painting

during routine maintenance of the

occupancy which can affect proper operation of the

detector.

FDT421

S54320-F5-A1