Struck MAGNATRAC MH8000 User manual

MH8000

COMPACT

CRAWLER

&

Version 8.12

$#% !#" #%#

Copyright 2012 C. F. truck Corp. All rights reserved.

"#$!# %

i

********* SER ICE BULLETIN *********

C. F. STRUCK CORPORATION

Cedarburg, Wisconsin 53012

Dear agnatrac Owner:

Working with thousands of customers over the last 45 years, I’ve gained some tips that I would

like to share with you to make your agnatrac experience as safe and rewarding as possible.

When a customer first receives his new agnatrac he grabs the keys, fires-up the engine

and dives into his first big job. This is human nature and quite understandable, but experi-

ence has shown that such action is DANGEROUS to the operator and can lead to unnecessary

and costly damage to the agnatrac.

As a agnatrac Operator/ echanic, you are expected to understand your crawler’s opera-

tion & safety, basic mechanical construction, and proper maintenance. All the information you

need is in the following Operator anual! Take time NOW, before you start to operate your

agnatrac, to go over the complete anual. Read in detail the operating, and safety instruc-

tions. Read for “background” other sections such as lubrication, service, etc...you can go back

later for more detailed reading when you actually have to perform those operations.

In conclusion, I want to bring two critical topics to your attention: Periodic aintenance &

Tractor Operation. Experience shows that many operators let these areas go, creating either

dangerous situations for themselves or needless damage and subsequently expensive repairs.

By taking the following three points seriously, you can make your agnatrac experience

satisfying, profitable, but above all...SAFE!

Sincerely yours,

ii

#1 - PERIODIC MAINTENANCE:

Though periodic maintenance is well covered in the Operator’s anual, it seems that some opera-

tors have let some points “slide” and have suffered expensive repairs. In the hopes of saving you

from premature failure in the future, due to forgotten maintenance, the following points are brought

to your attention!

1) The #4004 Bushings (steel) which restrain the #4003 Torque Arms mounted to the #524 Track

Drive otors must be replaced before they wear through and damage their mating otor Box

Pins. [Check Drawings & Photos H-B, H-C & H-9].

2) The #4007 Chains should be checked for proper tensioning. See “DRIVE CHAIN TENSIONING”

in Service section of your Operator anual for complete instructions.

Failure to inspect and properly tension the chains can result in stripped sprocket teeth and exten-

sive repair work.

3) #1210R & #1210L Right & Left Guards, must be periodically removed and cleaned. Located under

the crawler, these guards protect the#1090 Chain from being damaged (seee Photo H-14).

Due to the varied materials your tractor operates in, there is no specific maintenance schedule for

these #1210 Guards. Rather it is up to the operator to gain experience with the use of the Guards

and create his own maintenance schedule...the Guards may require daily removal and cleaning if

the tracks are run all day submerged in mud, or it may be monthly or quarterly maintenance

because your tractor is working in a relatively clean environment like grass.

4) Grease is good. Consistent lubrication of all moving joints, like all pins and cylinders, will greatly

extend the life of your equipment, with one exception. The #4007 & #1090 Drive Chains should

not be lubricated with a thick or sticky lubricant (like grease) as this will promote the adhesion of

abrasive material. However, keeping your drive chains lubricated with chain oil will stop the

chains from binding and causing repairs to the sprockets. Working in water and mud will dry

them out. After 200 hours these chains shuld be adjusted and lubricated.

5) Adjust the #1361 Front Pump Belt after 25 hours.

#2 - CRAWLER OPERATION...Uphill and Downhill:

It can not be repeated too often that you must operate your Track Control handles slowly and

smoothly...they control a hydraulic drive system that can produce literally “tons of physical force”.

But in addition, the Track Controls can also produce an opposite force or “resistance to move-

ment” when going up and down hills with heavy loads...in other words, they can provide a dynamic

braking action!

EXAMPLE

Potentially, if you are going downhill with a load that exceeds factory recommendations, you may

find that your “overload” is actually pushing you downhill faster than the crawler’s drive system is

propelling you down the hill. Under these circumstances you have basically two steps for safe control

of your crawler:

iii

First, slowly release the Track Controls so that they may go to neutral and provide a dynamic

braking action. Again, it must be emphasized that you must operate your Track Controls

slowly. Remember, you are controlling tons of force, and though significant overload strength

has been built into the Controls, you still can do serious damage to your tractor’s hydraulic

drive by “snapping” the Controls into the neutral position. The act of snapping the Controls to

neutral is equivalent to driving your car down the highway at 65 miles per hour and then

instantly shifting into reverse!

The second step in controlling your crawler is to apply your Parking/Emergency Brake. This is an

over-ride braking action used to augment the hydraulic system’s dynamic braking effect. Again, to

protect your drive system from harmful shock loads, the brakes, like the Track Controls, must be

applied with controlled force...never in a snapping action.

SUMMARY

Your crawler should always be operated with forethought, rather than in a series of sudden, and

potentially damaging, starts and stops. Always plan your crawler movements so as to eliminate the

need for any potentially damaging sudden Track Control or Brake operation. * NE ER carry or move

loads in excess of factory recommendations! *

******* As always, you are encouraged to contact the factory if you have any questions regarding the

above instructions, or for more information regarding other maintenance and operational procedures!

*******

iv

LIMITED WARRANTY FOR NEW STRUCK

CRAWLERS and/or ATTACHMENTS

(Effective with shipments made after August 1 , 2012)

A. GENERAL PROVISIONS

C.F. Struck Corp. will repair or replace, at its option, for the original purchaser of a new Struck Crawler and/or

Attachment, any covered part or parts found upon examination at our factory in Cedarburg, Wisconsin, to be

defective in material or workmanship or both; this is the exclusive remedy. Warranty service must be performed

by the C. F. Struck Corp. at their factory in Cedarburg, Wisconsin 53012. Warranty service will be performed

without charge for parts or labor. The purchaser will be responsible, however, for transportation charges to and

from the factory.

B. WHAT IS WARRANTED

All parts of any new Struck Crawler and/or Attachment are warranted for one (1) year, with the following excep-

tions: Belts, which are warranted for 90 days (excludes normal wear and tear); Engines, which are warranted by

their manufacturer; and Batteries, which are provided on a complimentary basis and carry no warranty whatso-

ever. C. F. Struck Corp. reserves the right to make product design and specification changes without notice and

without obligation on their part to present product owners. The Warranty term begins on the date the product

is delivered to the purchaser.

C. WHAT IS NOT WARRANTED

(1) Used Products; (2) Any product that has been altered or modified in ways not approved by C. F. Struck Corp.;

(3) Depreciation or damage caused by normal wear, lack of reasonable and proper maintenance, failure to follow

the product’s Operator’s/Technical Manual instructions, failure to upgrade crawler with parts furnished at no

charge, misuse, lack of proper protection during storage, or accident (4) Normal maintenance parts and service;

(5) Use of Struck Crawler and/or Attachments in certain industrial-type applications may affect Warranty cover-

age.

D. RETURNS AND REFUNDS

In the event of defective materials or workmanship the purchaser agrees to allow C.F. Struck Corp the opportu-

nity to correct the defect in a timely manner at the expense of C.F. Struck Corp. It is at the discretion of C.F.

Struck Corp to either correct the defect or refund the purchaser.

To return a Struck Crawler and/or attachment for reasons other than defect the purchaser will be financially

responsible for an 8% restocking fee, and for shipping the Struck Crawler and/or Attachment to the C.F Struck

Corp. factory in Cedarburg, Wisconsin 53012. No Returns after 90 days.

E. SECURING WARRANTY SERVICE

To secure Warranty service, the purchaser must:

(1) Report the product defect to the factory in Cedarburg, Wisconsin (262) 377-3300.

(2) Make the part available to the factory in a reasonable period of time.

F. LIMITATION OF IMPLIED WARRANTIES AND OTHER REMEDIES

To the extent permitted by law, neither C. F. Struck Corp. nor any company affiliated with it makes any

Warranties, representations or promises as to the quality, performance or freedom from defect of the products

covered by this Warranty. IMP IED WARRANTIES OF MERCHANTABI ITY AND FITNESS FOR A PAR-

TICU AR PURPOSE, TO THE EXTENT APP ICAB E, SHA BE IMITED IN DURATION TO THE

APP ICAB E PERIOD OF WARRANTY SET FORTH ON THIS PAGE. THE PURCHASER’S ON Y

REMEDIES IN CONNECTION WITH BREACH OR PERFORMANCE OF ANY WARRANTY ON C. F.

STRUCK CORP. PRODUCTS ARE THOSE SET FORTH ON THIS PAGE. IN NO EVENT WI C. F.

STRUCK CORP. OR ANY COMPANY AFFI IATED WITH IT BE IAB E FOR INCIDENTA OR

CONSEQUENTIA DAMAGES.

(Note: Some states do not allow limitations on how long an implied Warranty lasts or the exclusion or limitation

of incidental or consequential damages so the above limitations and exclusions may not apply to you.) This

Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

v

TABLE OF CONTENT

1- TO THE OPERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Recognize Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Understand Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Follow Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Service Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2- AFETY RULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety Before Starting or Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Service Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Fire Prevention Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Protection From oise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Avoid High-Pressure Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Install & Maintain ROPS Properly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Start Engine From Operator Seat Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3- CONTROL AND IN TRUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4- OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Pre-Starting Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Prepare For Engine Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Warm-up Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Use Seat Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Traveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Parking Crawler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5- FUEL AND LUBRICANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6- LUBRICATION AND PERIODIC ERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Hour Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Lubrication and Service Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Periodic Service Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

7- ERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

#000441 Interlock Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Safety Circuit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Seat Weight Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Drive Chain Tensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Parking/Emergency Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Track Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Sprocket & Idler Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Track Idler Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

TrackShoes ...............................................................26

Belt Tensioning & Replacement

(MH7000 only)

......................................26

8- TROUBLE HOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

9- OPERATING TIP & PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

10- PART IDENTIFICATION PHOTO & DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Drawing / Photo listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Index of Parts in Photos/Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Photos & Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

IMPORTANT: Though the MAG ATRAC is offered completely assembled, it’s still the customer’s responsibility to

provide competent service ability! The servicing can be provided either by the mechanically-inclined customer, or by

a local mechanic. We provide manuals & drawings for complete service and repair so that anyone with reasonable

mechanical skill can perform all required service work.

PAGE !

1- TO THE OPERATOR

RECOGNIZE SAFETY

INFORMATION

This is the safety-alert symbol. When you

see this symbol on your Crawler or in this

manual, be alert to the potential for

personal injury.

UNDERSTAND SIGNAL WORDS

A signal word—DANGER,WARNING, or

CAUTION—is used with the safety-alert symbol.

DANGER identifies the most serious hazards.

Safety signs with the signal word DANGER or

WARNING are typically near specific hazards.

General precautions are listed on CAUTION

safety signs. CAUTION also calls attention to

safety messages in this manual.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this

manual and on your Crawler and Attachment

safety signs. Follow recommended precautions

and safe operating practices.

Keep safety signs in good condition. Replace

missing or damaged safety signs.

To keep your Crawler running efficiently, read

the instructions in this Operator’s anual.

Left side, right side, front, and rear are viewed

by facing in the direction of the Crawler’s forward

travel.

Record your Crawler serial & model numbers

in the spaces below. You need this information

when you order parts or require technical support.

Crawler Records

odel: __________________________________________

Crawler Serial #________________________________

Engine Brand __________________________________

Engine Serial # ________________________________

Backhoe Serial # ______________________________

Ship Date_______________________________________

Should questions or concerns arise regarding

maintenance, service, or operation of your

crawler that are not addressed in this manual

please contact the factory by any of the following

means.

Mail: C. F. STRUCK CORPORATION

W51 N545 STRUCK LANE

CEDARBURG, WI 53012

Phone*: (262) 377 - 3300

(877) 828 - 8323

Fax: (262) 377 - 9247

email: [email protected]

We : www.struckcorp.com

*For immediate service always call the factory.

Maintenance & Service Records

Proper service and maintenance work is critical

to trouble free operation of your equipment. It is

also critical to diagnosing problems should they

arise. Use the space provided on the following

page to record maintenance and service work

performed.

1

Version 8.24.12

SERVICE & MAINTENANCE RECORDS

Date Service Work

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

Date Service Work

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

________ _____________________________________________

2

2- SAFET RULES

Reports on accidents show that careless use of

machinery causes a high percentage of accidents.

You can avoid many accidents by following the

safety rules on these pages. Study these rules

carefully and enforce them on the job.

SAFET BEFORE STARTING OR

OPERATING

•The Crawler should be operated only by

persons approved to do so.

•Clothing worn by the operator should be fairly

tight and belted.

•Fasten a first aid kit to the Crawler.

•Fasten a fire extinguisher to the Crawler.

Keep the extinguisher fully charged. Learn to

use it correctly.

•If the Crawler has an unsafe condition, do not

operate. ut a tag on the Track Drive

Controls.

•Do not start or operate the Crawler unless you

are in the operator’s seat.

•Before you start the Engine, be sure there is

plenty of ventilation.

•Keep hands, feet, and clothing away from

power-driven parts.

•Fasten a slow-moving vehicle sign to the rear

of the Crawler.

•Do not change Backhoe or Loader relief valve

setting without consulting factory.

•Before you operate Backhoe, be sure

stabilizers are in correct position.

•Before you start or operate the Crawler, clear

the area of all persons and obstacles.

•Guards, shields, and other protective devices

must be in place and in good condition.

OPERATION SAFET

•When you operate the Crawler, do not allow

anyone to ride on the Crawler or its

equipment.

•Drive at safe speeds at all times, especially on

rough ground and hillsides.

•Carry the Bucket or Blade as low as possible

at all times, especially when you work on a

hillside or back up a steep hill.

•Do not lower a loaded Bucket or Fork with the

control lever in float position.

•Do not drive too close to the edge of a ditch or

excavation.

•Watch for overhead wires. Do not touch wires

with any part of the Crawler or its Attachments.

•Do not leave your Crawler unattended with the

Engine running.

•Keep work areas as level as possible.

•Do not operate the Crawler Loader without the

minimum recommended counterweight.

•Do not dig under stabilizers of Crawler with the

Backhoe.

•When loading logs with the Log Forks, make

sure the logs are balanced.

•Before you transport the Backhoe, attach the

safety chains provided.

•When you drive out of a ditch or excavation, or

up a steep hillside, or when Crawler is hitched

to a heavy load, engage Track Drive Controls

slowly. If the front of the Crawler comes off the

ground, release Track Controls immediately.

•When you operate the Backhoe on a hillside,

avoid swinging Bucket downhill. If possible,

dump Bucket on the uphill side.

•Before you lower any hydraulic equipment, be

sure all persons are away from the Crawler.

•Do not use the Crawler as a battering ram.

•Do not guide cable onto Winch Drum with your

hands.

•When you drive the Crawler on a road, use the

correct lights to warn operators of other

vehicles.

•Before you move any equipment, be sure all

persons are away from the Crawler.

3Version 8.24.12

•When the Crawler is operating, only the

operator should be on it.

•If it is necessary to make checks with the

Engine running, always use two people...the

operator at the controls, should be able to see

the person doing the checking.

KEEP HANDS AWA FROM MOVING PARTS.

DANGER: Never use “quick-disconnect”

type couplings on this Crawler or any of its

mating Attachments unless specified; to do so

results in the potential of rupturing hydraulic

fittings or even “blowing-up” your hydraulic

pumps!

BEFORE OU DISMOUNT:

1) Move Track Drive Controls to neutral.

2) Push down Parking Brake and Lock.

3) Lower all equipment to the ground.

4) Stop Engine and remove the key.

SERVICE SAFET

•Be sure you understand a service procedure

before you work on the Crawler.

•Unauthorized modifications to the Crawler

may impair the function and/or safety and

affect Crawler

life.

•Do not work

under raised

e q u i p m e n t

unless it is

c o r r e c t l y

supported.

•Before you

work on the

Engine or

e l e c t r i c a l

s y s t e m ,

d i s c o n n e c t

the battery’s

“ground” ( - )

terminal first!

When work is

finished, connect battery’s “ground” terminal (

- ) last.

•When driving connecting pins, wear goggles

or safety glasses.

•Do not run Engine while working on the

Crawler.

•Be careful when handling any type of fuel. Do

not smoke while filling the fuel tank or working

on the fuel system.

•Check for faulty wiring or loose connections.

•Do not lubricate or work on the Crawler while

it is moving.

•Release hydraulic pressure before working on

hydraulic system. Move every hydraulic

control lever back & forth until equipment does

not move.

•Before using the hydraulic system, be sure

that all connections are tight and that lines are

in good condition.

•When you work near the Track Springs, use

extreme care. Do not disassemble parts

unless you know the correct procedure and

have correct tools.

FIRE PREVENTION MAINTENANCE

•Be prepared if an accident or fire should occur.

Know where the first aid kit and the fire

extinguishers are located—know how to use

them. Check fire extinguisher for correct

charge.

•Do not smoke while refueling or handling

highly flammable material.

•Shut off the Engine when refueling.

•Use care in refueling if the Engine is hot.

•Do not use open pans of gasoline or diesel

fuel for cleaning parts. Use good commercial,

nonflammable solvents.

•rovide adequate ventilation when charging

battery.

•Do not check battery charge by placing metal

objects across the posts.

•Do not allow sparks or an open flame near

battery. Do not smoke near battery.

•Never check fuel, battery electrolyte, or

coolant levels with an open flame.

4

•Never use an open flame to look for leaks

anywhere on the equipment.

•Never use an open flame as light anywhere on

or around the equipment.

•When preparing Engine for storage,

remember that inhibitor is volatile and

therefore dangerous. Seal and tape openings

after adding the inhibitor. Keep container

tightly closed when not in use.

•Inspect electrical wiring for worn or frayed

insulation. Install new wiring if wires are

damaged.

•Temperature in Engine and cooling

compartments may go up immediately after

you stop the Engine. Be on guard for fires.

•Before you clean trash from the Engine

compartment, wait until the Engine has

cooled. Open Side anels to cool the Engine

faster. While the Engine cools, clean trash

from other areas.

•Check for leaking fuel lines, hydraulic lines,

hoses, or fittings with a piece of cardboard or

wood. Do not use your hands. Tighten loose

fittings. If lines are bent or hoses kinked,

install new parts.

PROTECT AGAINST NOISE

rolonged exposure to loud noise can cause

impairment or loss of hearing. Wear a suitable

hearing protective device such as earmuffs or

earplugs to protect against objectionable or

uncomfortable loud noise.

AVOID HIGH-PRESSURE FLUIDS

Escaping fluid under pressure can penetrate

the skin causing serious injury. Relieve pressure

before disconnecting hydraulic or other lines.

Tighten all connections before applying pressure.

Keep hands and body away from pinholes and

nozzles which eject fluids under high pressure.

Use a piece of cardboard or paper to search for

leaks. Do not use your hand.

If ANY fluid is injected into the skin, it must be

surgically removed within a few hours by a doctor

familiar with this type of injury or gangrene may

result.

INSTALL AND MAINTAIN ROPS

PROPERL

If Roll-Over

r o t e c t i v e

Equipment is

loosened or

removed for any

reason, make

certain all parts

are reinstalled

correctly. Tighten

mounting bolts to

proper torque.

The protection

offered by RO S

will be impaired if

the RO S is

subject to

s t r u c t u r a l

damage, has been involved in an overturn

incident or is in anyway altered. Damaged RO S

should be replaced, not reused.

•DO use your Seat Belt if your Crawler has a

Roll-Over rotective Structure (RO S).

•DO NOT use a Seat Belt if your Crawler does

not have a RO S.

START ENGINE ONL FROM THE

OPERATOR’S SEAT!

•Avoid possible injury or death from Crawler

runaway.

•Do not start Engine by shorting across starter

solenoid terminals. Crawler may start and

move if normal circuitry is bypassed.

•Never start Engine while standing on ground.

Start Engine only from operator’s seat, with

arking Brake engaged.

•Inspect your Crawler carefully each day

before you start it. See “ re-Start Inspection”.

•Clean your Crawler regularly.

WARNING: The Seat Assembly is

equipped with an electrical safety switch to

prevent starting and operating the crawler while

not occupying the seat. Disabling this feature

creates the potential for severe injury or death.

See Chapter 7 -

Seat Weight Adjustment

for test

procedures to verify it is operating properly.

5

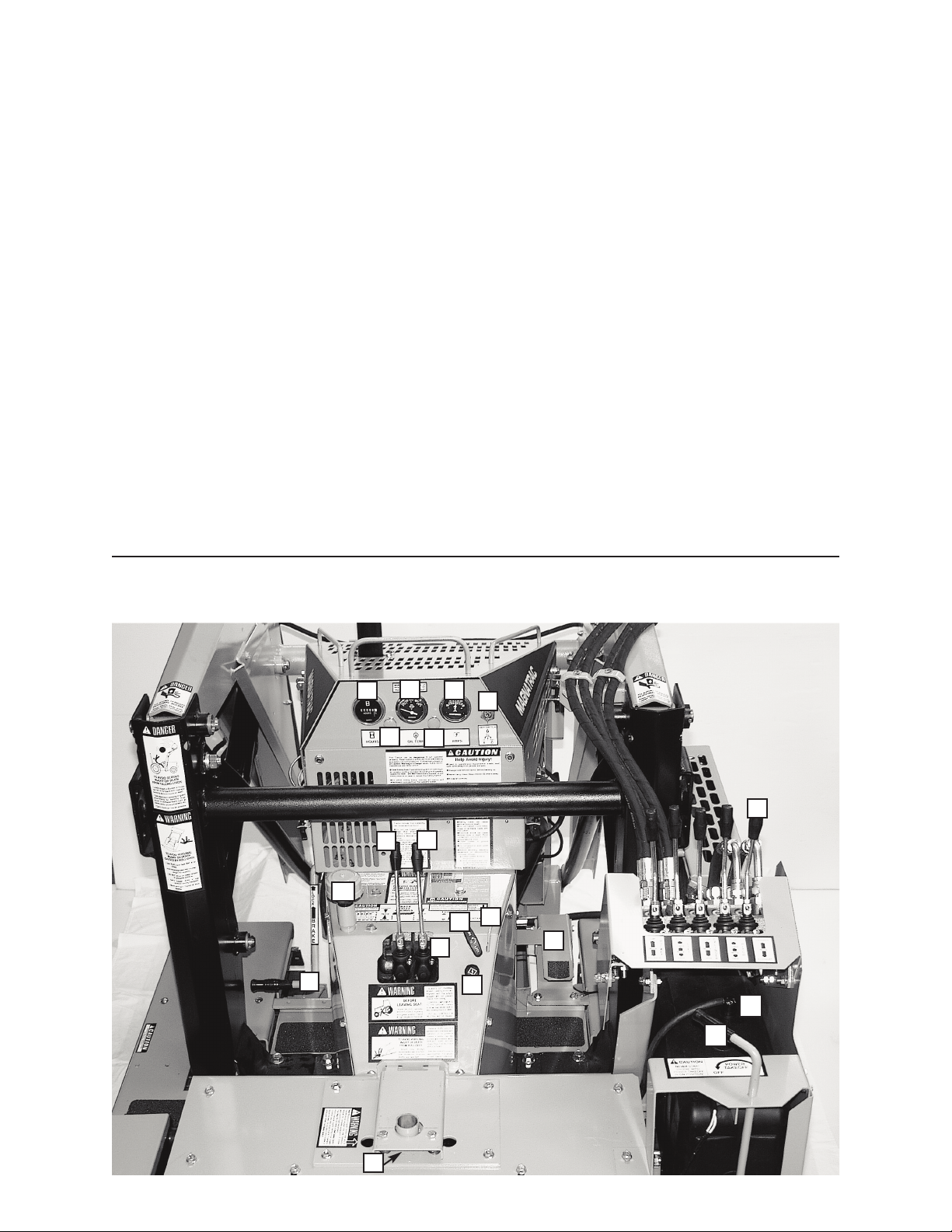

3- CONT OLS

AND

INST UMENTS

Learn the location and purpose of all

controls, instruments, and warning labels.

CONT OLS

(A) PA KING/EME GENCY B AKE

(B) LEFT T ACK CONT OL

(C) IGHT T ACK CONT OL

(D) B AKE LOCK/ ELEASE HANDLE

(E) CHOKE CONT OL

(F) HAND TH OTTLE CONT OL

(G) FOOT TH OTTLE CONT OL

( H ) LIGHT SWITCH

(I) SEAT SAFETY SWITCH

(J) IGNITION SWITCH

(K) OVE D IVE/ACCESSO Y

CONT OL

(L) FAN SWITCH

(M) HOU METE

(N) HYD AULIC OIL TEMPE ATU E

(O) AMMETE

(P) HYD AULIC CI CUIT CONT OL

(Q) HYD AULIC TANK

B EATHE /FILLE

( ) UNLEADED GASOLINE TANK

6

MH8000 Controls & Instruments

A

B

Q

C

D

K

E

F

J

M

P

NO

M

I

LH

G

Verson 8.24.12

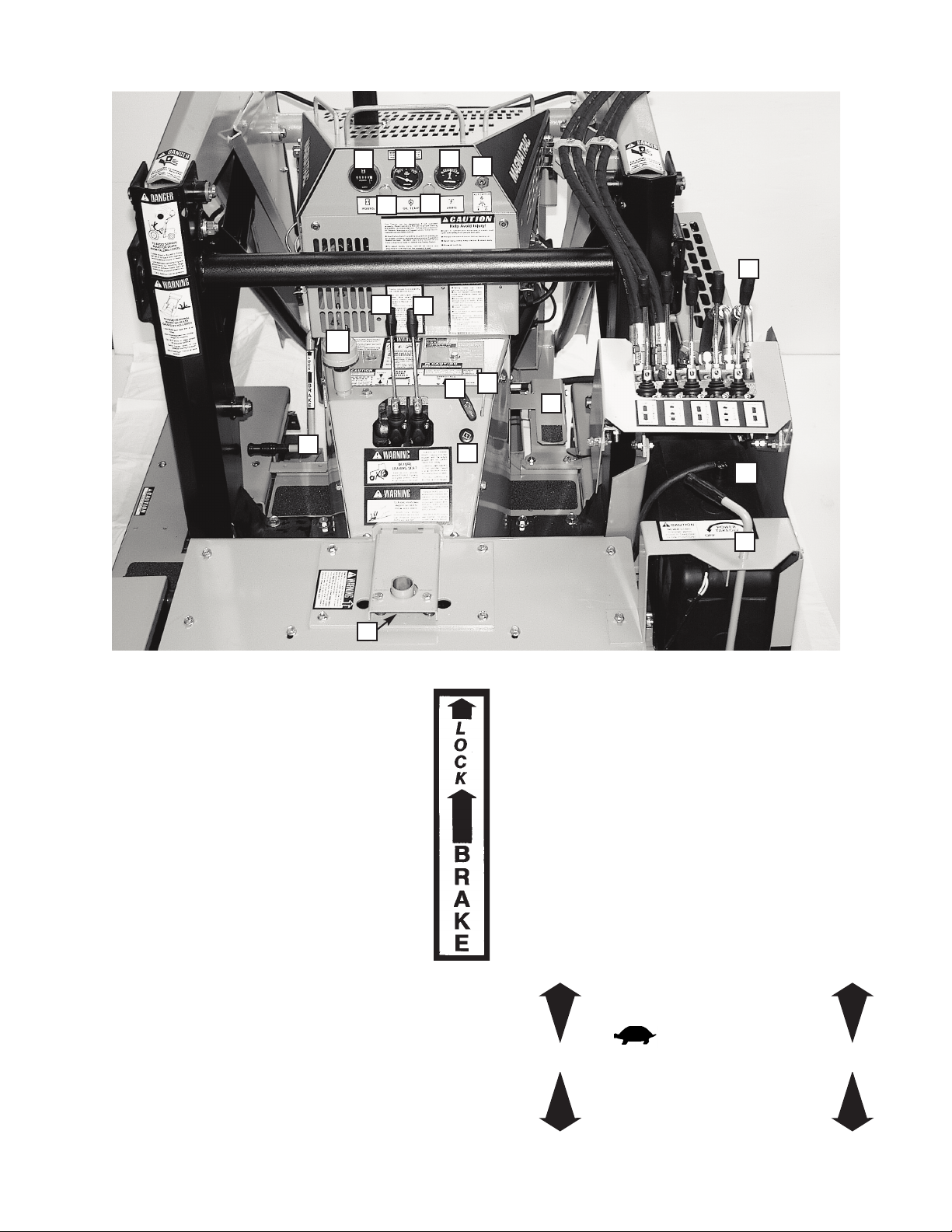

(A) PA KING/EME GENCY B AKE

Apply Brake by pushing forward on

its pedal with left foot.

To lock brake lift up on Brake

Lock/Release handle while Pedal (A) is

fully depressed.

To release Parking brake push forward

on Pedal (A) until Brake lock/Release

handle drops

(B) LEFT and (C) IGHT T ACK

CONT OLS

1) To move straight ahead, push both Left and

Right Track Controls forward.

2) To move straight rearward, pull both Left

and Right Track Controls rearward.

3) To turn right, push forward on Left Track

Control.

4) To turn left, push forward on Right Track

Control.

5) To counter-rotate Tracks (shortest turn

possible), push one Track Control forward

while simultaneously pulling rearward on

the other Track Control.

NOTE: When either Track Control lever is

released, it will automatically return to

neutral.

7

T R A C K

D R I V E

CONTROLS

Neutral

everse

Forward

Neutral

everse

Forward

L

L

E

E

F

F

T

T

R

R

I

I

G

G

H

H

T

T

MH8000 Controls & Instruments

A

BC

D

F

E

NOJ

K

L

Q

G

H

I

M

P

(D) B AKE LOCK HANDLE

To release Brake, apply foot pressure to Brake

Pedal (A) and lower Brake Lock Handle (D);

slowly release foot pressure and allow Brake

Pedal to come rearward to its natural unbraked

position.

(E) CHOKE CONT OL

Pull to open engine choke, push to close.

(F) HAND TH OTTLE CONT OL

Pull control handle toward operator to increase

Engine speed...turn handle 1/4 turn clockwise to

lock throttle setting (Do not over-tighten!)

(G) FOOT TH OTTLE CONT OL

The H8000 is also equipped with a foot throttle

control to facilitate changes in engine speed

during operation. Locking the hand throttle at a

desired engine RP will set the lowest operating

RP when foot pedal is released.

(H) LIGHT SWITCH

Pull control handle toward

operator to turn lights on. Push

fully back to turn lights off.

(I) SEAT SAFETY SWITCH

The seat safety switch prevents operation of the

crawler when the operator is not positioned in the

seat. The safety switch may need to be adjusted

to the operator’s weight in order to operate

correctly. See the Service section of this manual

for adjustment procedures.

(J) IGNITION SWITCH

Switch is activated by rotating key

clockwise. Turning it fully clockwise

will engage Engine starter ...

release key and it will return to the

un position. Turn fully counter-

clockwise to Off position to stop

Engine. Remove key.

AUXILIA Y HYD AULIC CONT OLS

An auxiliary bank of Control Valves is located

to the operator’s right. These valves are used to

control all attachments on your tractor. Your

H8000 crawler will contain from one to five of

these valves based on the attachments you have.

(K) OVE D IVE/ACCESSO Y CONT OL

This Overdrive/Accessory Control Valve has two

functions.

1) When pushed fully forward and “locked” into

the Overdrive position, this valve directs the oil

flow of the attachment pump into the track drive

system. When Track Drive Controls are activated,

this feature allows your tractor to gain extra speed

to get out of excavations or move quickly to dump

locations.

In addition, you can travel in “overdrive” for

lighter, higher speed operations. Your tractor will

automatically shift down to regular drive speed

whenever you change an attachment setting

(raise loader, tilt bucket, etc.) then shift back to

overdrive when you are through.

2) When pulled fully rearward and “locked” into

the Accessory position, it directs the oil flow to

optional attachments like our Backhoe, log splitter,

etc. Contact our Service Dept. for more

information on specific hydraulic flow rates,

pressures and various uses for this Accessory

setting.

CAUTION: With Control in “accessory position”

(and its mating Valve Port plugged), all power to

the tracks is lost! Do not leave control in

this position for any period of time!

8

TH OTTLE

pull out

1/4 turn

to lock

Pres s Brak e Ped a l and lower

B AKE LOCK HANDLE to “unlock”

Park i n g Br a k e. M a inta i n Br a k e

adjustment...see Operator ’s Manual.

B AKE

LOCK

HANDLE

LIGHTS

PULL OUT

(L) FAN SWITCH

Your agnatrac H 8000

comes equipped with an

automotive type fan attached to its

external oil cooler. Turn fan on by

pulling switch to help reduce

hydraulic oil temperature in hot

conditions. Turn off fan during extensive use of

headlights to prevent excessive battery drain.

(M) HOU METE

eter will begin recording time

the moment the Ignition Switch

(O) is switched to Run.

NOTE: The Engine does not

have to be running for the eter to record

time...the Ignition Switch just has to be in the un

position. Always turn Ignition Switch Off and

remove key when leaving Crawler. This will

assure you that your eter is recording only

actual running hours!

(N) TEMPE ATU E GAUGE

This gauge records the hydraulic oil

temperature just as it enters the Traction Drive

Pump. onitor this temperature so that it does

not exceed 180 degrees

Fahrenheit.

If the oil temperature

exceeds 180 degrees,

stop operating the

Crawler, but allow the

Engine to operate at

medium speed to circulate the oil through the oil

cooler and lower its temperature.

(O) AMMETE

easures electrical charge or

discharge to battery. If Ammeter

shows a discharge, shut down

electrical system by turning

Ignition Switch to Off and determine the problem.

(P) HYD AULIC CI CUIT CONT OL

The Hydraulic Circuit Control distributes flow

to the HC74 Hydraulic Circuit kit. This flow is

utilized for the PTO70 Power Takeoff option as

well as for other full flow and high pressure

accessories (snow blower, auger, stump grinder,

etc...). If the handle for the Hydraulic Circuit is

turned to the right, even just a little, the tractor will

not start, due to the #441 safety switch installed

on the unit. Never defeat this safety switch!

9

FAN

PULL OUT

HOU S

OIL TEMP.

KEEP BELOW 180°

AMPS

4- OPERATION

PRE-STARTING INSPECTION

Before you start your Crawler for the first

time each day, perform the following checks:

ENGINE COMPARTMENT

Check oil level.

Check air intake system.

Check fuel filter.

Remove trash and oil-dirt deposits.

GRILL AND SIDE PANELS

Remove trash.

Clean oil cooler fins.

TRACKS, ATTACHMENTS, SHEET METAL

Check for bent, broken, or missing parts.

Check Track springs and tension.

HARDWARE

Check for loose or missing parts.

ELECTRICAL SYSTEM

Check for worn or frayed wires or loose

connections.

LUBRICATION

Check lubrication points shown in

eriodic Service section of this manual.

GUARDS AND SHIELDS

Check for tightness and condition.

BATTERY COMPARTMENT

Remove trash.

Check cables for tightness and corrosion.

FUEL TANK

Check fuel level.

HYDRAULIC SYSTEM

Check for leaking lines and connections.

Check for bent or kinked lines.

Check for lines rubbing against each

other or against other parts.

Check oil level.

OPERATOR’S STATION

Check levers for free movement.

Check RO S and Seat Belt.

Clean floor and instrument panel.

Adjust Seat to comfortable height for

operator.

CAUTION - B for you start th ngin :

1) Check the condition of the Crawler. ( re-start

inspection).

2) Be sure there is enough ventilation.

3) Be sure to know the correct starting and

stopping procedure.

4) Sit in the operator’s seat.

5) Clear the work area of people and obstacles.

IMPORTANT: Do not tow or push your

Crawler to start it. You may damage the

hydraulic drive system.

10 Version 8.24.12

PREPARE FOR ENGINE STARTING

1) Fasten Seat Belt (only if you have RO S

installed).

2) Allow Left (B) and Right (C) Track Controls to

assume their natural spring loaded center

neutral positions.

3) ush forward on arking/Emergency Brake

(A) and lift up Lock/Release Handle (D) until

brake locks into position.

4) Check that Loader or front-mounted Bulldozer

Blade is in the fully lowered position, and that

the Backhoe is either in the chain d safe

traveling position, or resting on the ground.

5) Check that all other hydraulic controls are in

their centered neutral position.

NOTE: The hydraulic Accessory Control

(T) does not have a spring load d neutral

centering device; therefore, you must

move it back and forth to determine its

c nt r-n utral position.

6) Make sure you are properly seated so Seat

Safety Switch will engage.

STARTING THE ENGINE

1) lace the Throttle Control (F) midway between

the Slow and Fast positions.

2) Activate the Ignition Switch (J) by rotating it

clockwise until starter engages. Release the

switch as soon as the Engine starts...Switch

will return to the Run position.

CAUTION: Do not crank the Engine

continuously for more than 10 seconds at a

time. If the Engine does not start, allow a

60-second cool-down period between

starting attempts. Failure to follow these

guidelines can burn out the starter motor.

CAUTION: If the Engine develops sufficient

speed to disengage the starter but does not

keep running (a “false start”), the Engine

rotation must be allowed to come to a

complete stop before attempting to restart

the Engine.

If the starter is engaged while the flywheel is

rotating, the starter pinion and flywheel ring gear

may clash, resulting in damage to the starter.

If the starter does not turn the Engine over,

shut off starter immediately. Do not make further

attempts to start the Engine until the condition is

corrected.

If the battery charge is not sufficient to turn

over the engine, recharge the battery.

CAUTION: Do not attempt to jump start the

engine with another battery. Starting with

batteries larger than those recommended

can burn out the starter motor.

WARM-UP PERIOD

1. Run Engine at half speed for 5 minutes.

2. Do not run Engine at fast, or slow idle.

3. Operate Crawler at less-than-normal loads

and speeds for the first 15 minutes.

WARNING: L thal Exhaust Gas s

Engine exhaust gases contain poisonous

carbon monoxide. Avoid inhaling fumes, and

never run the Engine in a closed building or

confined area.

NOTE: Assembled Crawlers are “run in” under

no load at the factory for 20 - 30 minutes to

properly break-in their drive train and track drive

motors, and to test hydraulic systems.

USE SEAT BELT

CAUTION: Use a Seat Belt when you

operate with a Roll-Over rotective

Structure (RO S) to minimize chance of

injury from an accident such as an overturn.

Do not use a Seat Belt if operating without a

RO S.

TRAVELING

ush forward on arking Brake (A) and lower

Brake Lock (D); slowly release pressure on

arking Brake and allow it to come back to its

natural “rearward” position...remove foot from

Brake!

Raise all attachments to their recommended

traveling heights.

A) To mov straight ah ad, simultaneously

push Right Track Control (C) and Left

Track Control (B) forward.

11

B) To mov straight to th r ar, simultaneously

pull both Right and Left Track Controls

rearward.

C) To turn to th right, push Left Track Control

forward.

D) To turn to th l ft, push Right Track Control

forward.

E) To count r-rotat Tracks, (shortest turn

possible), push one Track Control forward

while simultaneously pulling rearward on

the other Track Control.

NOTE: The Right and Left Track Controls are

of the self-centering (neutral) “deadman” type.

This allows you to simply let go of both Track

Controls to disconnect active power to the Tracks.

F) Parking/Em rg ncy Brak (A) will stop or

hold Crawler in the neutral drive position.

PARKING THE CRAWLER

1) Lower all equipment to the ground.

2) Allow Right and Left Track Controls to go to

neutral.

3) ush forward on Brake and lift lock handle to

engage parking brake.

4) Run Engine at half speed 2 minutes without

load.

5) Move Throttle Control to slow idle.

6) Turn Ignition Switch to Off.

7) Release hydraulic pressure by “rocking” all

hydraulic controls back and forth.

IMPORTANT: If Engine stops under load,

remove load. Start Engine immediately. Run 30

seconds at half speed before adding load.

NOTE: If engine stops, you must turn key Off

before you can start the engine.

IMPORTANT: In freezing weather, park on a

hard surface to avoid freezing the Tracks to the

ground. If Tracks are frozen to the ground, be

careful to avoid damage to the Tracks and drive

train when you try to move the Crawler. When

storing your tractor for an extended period of time,

make sure to store it away from any moisture.

Moisture in contact with the steel tracks over an

extended period of time will rust. Lubricate the

track chains and the drive chains as specified in

this manual.

CAUTION: When you park your Crawler

on a slope, put blocks against tracks. Do

not park Crawler with tracks pointed

downhill.

12

5- FUELS and LUBRICANTS

FUELS

FUEL SPECIFICATIONS

Check enclosed Engine Owner’s Manual and

closely follow their recommendations.

FILLING FUEL TANK

The Fuel Tank is located to the right of

the operator’s seat. It is filled by removing

the 3” dia. Cap marked with the universal

Gasoline symbol (shown at left). Use fuel grade

per Engine Owner’s Manual shipped with your

MH8000... tighten Cap securely when finished

filling.

CAUTION:DO NOT confuse the Fuel

Tank with the Hydraulic Oil Tank which is

filled by removing the #616 (Q) Breather

Cap from the Coupling on top left of Magnatrac’s

dash.

Fill Fuel tank at end of each day’s operation.

Fuel tank capacity is approximately 5 U.S.

gallons.

CAUTION: Handle fuel carefully. Do not fill fuel

tank when the Engine is running. Do not smoke

while you fill fuel tank or work on fuel system.

STORING FUELS

eep fuel in a container in a protected area.

Water and sediment must be removed before fuel

gets to the Engine. Do not depend on fuel filters

to remove water.

If possible, install a water separator at the

storage tank outlet.

Store fuel drums on their sides with plugs up.

IMPORTANT: eep all dirt, scale, water, or

other foreign matter out of fuel.

LUBRICANTS

ENGINE OIL

Check enclosed Engine Owner’s Manual and

closely follow their recommendations.

HYDRAULIC OIL

Use a premium quality hydraulic oil with

maximum anti-wear properties, rust and oxidation

treatment. A high quality antiwear hydraulic fluid

designed for use in high pressure, high speed

hydraulic pumps in industrial hydraulic systems.

We use a Conoco (Phillips 66, 76), Megaflow AW

Hydraulic Oil 32. (ISO V632). 10 Weight.

Product Code: 1055927. An ISO of 32 is good for

“oil” temperature conditions of +5F to +170F

which are considered standard.

If the above specifications can not be found

consult with a local tractor/equipment dealership

or oil supplier for other brands of hydraulic oil

suitable for loaders, backhoe, and hydraulic drive

systems.

Fill Hydraulic Oil Tank through coupling on top

left of Dash, check level with #248 Dipstick

[Dipstick found below & inside #616 Breather Cap]

...remove Breather with a wrench before filling!

Approximately 12.5 gallons of hydraulic fluid fill

the hydraulic reservoir to the proper level.

GREASE

Use premium quality SAE Multi-Purpose

Grease.

STORE LUBRICANTS in clean containers in

area protected from dust, moisture, &

contamination.

13 Version 8.24.12

6- LUBRICATION and

PERIODIC SERVICE

HOUR METER

Use the Hour Meter (M) to determine when

periodic services are required. Should the hour

meter not be installed, keep a usage log for your

equipment to maintain service intervals.

LUBRICATION AND SERVICE

INTERVALS

IMPORTANT: Recommended service intervals

are for normal conditions. Service more often if

Crawler is operated under difficult conditions.

Such as extreme heat, dusty conditions, and daily

use for extended period of time.

IMPORTANT: Use only quality lubricants at

intervals specified in this manual.

PERIODIC SERVICE CHART

EVER TEN HOURS

EVER TEN HOURS

Air Cleaner(s) - Service per instructions in

Engine Owner’s Manual. The Engine has

an inner air cleaning element

(replacement part #1365) inside the

standard air cleaner body.

Engine Oil - Service per instructions in Engine

Owner’s Manual...replacement Engine Oil

Filter is #1367.

Hydraulic Oil - Check level; with equipment on

the ground (retract all possible cylinders),

level should be between marks on #248

Dipstick (Dipstick can be found when you

unscrew and remove #616 (Q) Breather

with a wrench. Don’t try to use a

screwdriver to unscrew the top cap. (See

page 17)...replacement Hydraulic Oil Filter

is #455B.

Grease Fittings - ubricate all grease fittings per

location instructions in manual of each

attachment you have mounted on your

Crawler. Recommended grease:

Multipurpose NLGI 2 Grade Lithium

Complex, ISO VG 220.

A small breakdown of how many grease

fittings are on each MH8000 tractor and

various Attachments is as follows.

MH8000: 14

For an MH8000, all grease fittings will be

on the outside of every Axle & Pin, except

for the Front Idler axle. On the Front Idler

axle, it is on the

inside end

of the welded

tube. Hint: You may have to rotate the

tracks to find these grease fittings. (See

Photo MH-12)

H 900, H 950, H 975: 12

D108: 21

D1065: 18

D1060: 14

For all others, please see each individual

attachment for the quantity of grease

fittings. As a standard guide, there will be

a zerk for each Axle & Pin that you see on

a particular attachment.

Oil Cooler - With

low pressure

air, blow clean the

“fins” of the oil cooler.

Track Tension - Maintain overall tightness of

each track. When your tractor leaves our

factory, the outside, black, #234 spring

measurement is 4 1/2 in. The inside,

yellow, #233 spring measurement WILL

NOT be the same! The most important

thing is for the front axle to be square. In

addition, check that the #235 washer

against the front face of each #215 Front

Axle is not loose enough to be rotated with

fingers. Check Service section of this

manual for complete explanation and

Track tensioning procedures. (See

Drawing MH-B and Photo MH-13.

Fittings & Hoses - Check hydraulic fittings and

hydraulic hoses for cracks, breaks, and

leaks.

General Once-Over - Check for loose nuts and

bolts and any signs of premature wear.

Correct any problems immediately.

NOTE: Check “NOTE” in Service Section

of this manual for information on Track

Idler wear!

14 Version 8.24.12

Table of contents

Other Struck Tractor manuals