2SECTION 10 -- ENGINE -- CHAPTER 1

6- 62730 -- 04 -- 2004

GENERAL SPECIFICATIONS

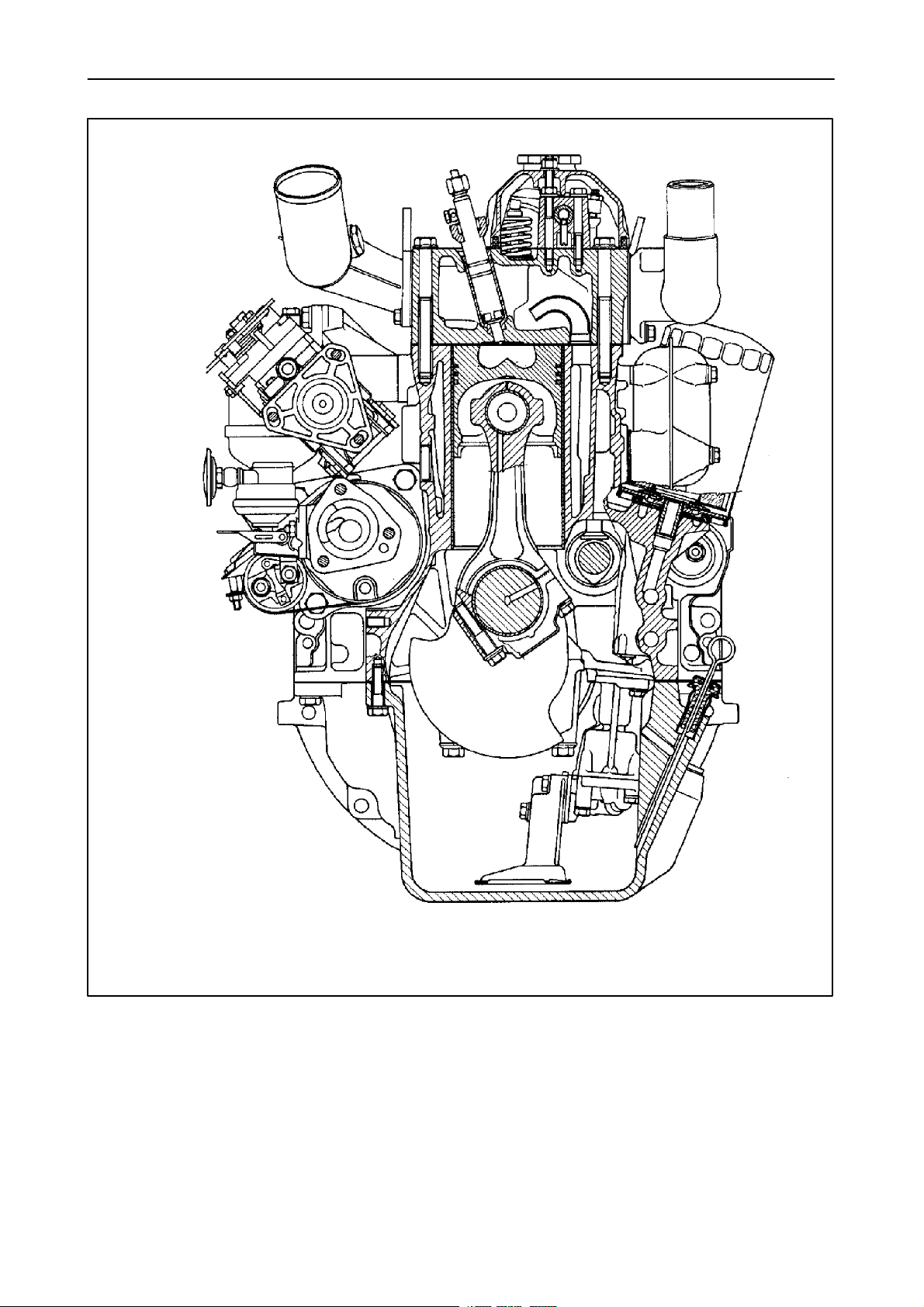

Engine, technical type:

-- Mod. JX1060V -- type 8035.05C.925/929 (BOSCH pump) .............. See data on page 6--7

-- Mod. JX1070V and JX1070N -- type 8035.25R.925/929 (BOSCH pump) . . See data on page 8--9

-- Mod. JX1075V and JX1075N -- type 8035.25.925/929 (BOSCH pump) . . . See data on page 10--11

Cycle ............................................................... diesel, 4--stroke

Fuelinjection ........................................................ direct

Number of cylinders in line ............................................. 3

Cylinder liners ....................................................... dry force--fitted in cylinder

block

Piston diameter

-- Mod. JX1060V .................................................... 4.0944 in. (104 mm)

-- Mod. JX1070V and JX1070N ...................................... 4.0944 in. (104 mm)

-- Mod. JX1075V and JX1075N ...................................... 4.0944 in. (104 mm)

Pistonstroke ........................................................ 4.5275 in. (115 mm)

Total displacement:

-- Mod. JX1060V .................................................... 178.84 in3(2931 cm3)

-- Mod. JX1070V and JX1070N ....................................... 178.84 in3(2931 cm3)

-- Mod. JX1075V and JX1075N ....................................... 178.84 in3(2931 cm3)

Compression ratio for Mod. JX1060V, JX1070V and JX1070N .............. 17:1 normally aspirated

Compression ratio for Mod. JX1075V and JX1075N ....................... 16.5:1 turbocharged

Maximum power:

-- Mod. JX1060V .................................................... 43.5 kW (59 Hp)

-- Mod. JX1070V and JX1070N ....................................... 53 kW (72 Hp)

-- Mod. JX1075V and JX1075N ....................................... 55.5 kW (76 Hp)

Maximum power speed ............................................... 2300 rpm

Maximum torque speed for Mod. JX1060V ............................... 1400 rev/min

Maximum torque speed for Mod. JX1070V and JX1070N .................. 1400 rev/min

Maximum torque speed for Mod. JX1075V and JX1075N .................. 1400 rev/min

Number of main bearings .............................................. 4

Sump ............................................................... structural, cast iron

(continued)