Studer OnAir 3000 Operating instructions

OnAir 3000

Digital Mixing System

1. Audio Block Diagram, System Wiring

2. Desk Modules

3. DSP Modules

For information on the D21m I/O system please refer to the separate documents BD10.275102

and BD10.275113

Service Instructions

Prepared and edited by Copyright by Studer Professional Audio GmbH

Studer Professional Audio GmbH

Technical Documentation Order no. BD10.275124-3 (0311)

Althardstrasse 30

CH-8105 Regensdorf – Switzerland

http://www.studer.ch Subject to change

Studer is a registered trade mark of Studer Professional Audio GmbH, Regensdorf

I

For Your Own Safety and to Avoid Invalidation of the Warranty

Please Read This Section Carefully

• Readtheseinstructions.

• Keeptheseinstructions.

• Heedallwarnings.

• Followallinstructions.

• Donotusethisapparatusnearwater.

• Cleanonlywithadrycloth.

• Donotblockanyventilationopenings.Installinaccordancewith the

manufacturer'sinstructions.

• Donotinstallnearanyheatsourcessuchasradiators,heatregisters,

stoves,orotherapparatus(includingampliers)thatproduceheat.

• Donotdefeatthesafetypurposeofapolarisedorgroundingtypeplug.A

polarisedplughastwobladeswithonewiderthantheother.Agrounding

typeplughastwobladesandathirdgroundingprong.Thewidebladeor

thethirdprongareprovidedforyoursafety.Iftheprovidedplugdoesnot

tintoyouroutlet,consultanelectricianforreplacementoftheobsolete

outlet

• Protectthepowercordfrombeingwalkedonorpinchedparticularly

atplugs,conveniencereceptaclesandthepointwheretheyexitfromthe

apparatus.

• Onlyuseattachments/accessoriesspeciedbythemanufacturer.

• Useonlywiththecart,stand,tripod,bracketortablespeciedbythe

manufacturer,orsoldwiththeapparatus.Whenacartisused,usecau-

tionwhenmovingthecart/apparatuscombinationtoavoidinjuryfrom

tip-over.

• Referallservicingtoqualiedservicepersonnel.Servicingisrequired

whentheapparatushasbeendamagedinanyway,suchaspower-supply

cordorplugisdamaged,liquidhasbeenspilledorobjectsfallenintothe

apparatus,theapparatushasbeenexposedtorainormoisture,doesnot

operatenormally,orhasbeendropped.

Note: It is recommendedthat all maintenance andserviceon the product

shouldbecarriedoutbyStuderoritsauthorisedagents.Studercannot

acceptanyliabilitywhatsoeverforanylossordamagecausedbyservice,

maintenanceorrepairbyunauthorisedpersonnel.

• WARNING:Toreducetheriskofreorelectricshock,donotexposethis

apparatustorainormoisture.Donotexposetheapparatustodripping

orsplashinganddonotplaceobjectslledwithliquids,suchasvases,

ontheapparatus.

• Nonakedamesources,suchaslightedcandles,shouldbeplacedonthe

apparatus.

• Ventilationshouldnotbeimpededbycoveringtheventilationopenings

withitemssuchasnewspapers,tablecloths,curtainsetc.

Warning: Donotusethisapparatusinverydustyatmospheres,orinatmospheres

containingammablegasesorchemicals.

• THISAPPARATUSMUSTBE EARTHED.Undernocircumstances

shouldthesafetyearthbedisconnectedfromthemainslead.

Safety Information

II

• Themainssupplydisconnectdeviceisthemainsplug.Itmustremain

accessiblesoastobereadilyoperablewhentheapparatusisinuse.

• Ifanypartofthemainscordsetisdamaged,thecompletecordsetshould

bereplaced.Thefollowinginformationisforreferenceonly.Thewires

inthemainsleadarecolouredinaccordancewiththefollowingcode:

• ProtectiveEarth (Ground):Green/Yellow(US:Greenor Green/

Yellow)

• Neutral:Blue(US:White)

• Live(Hot):Brown(US:Black)

Asthecoloursofthewiresinthemainsleadmaynotcorrespondwith

thecolouredmarkingsidentifyingtheterminalsinyourplug,proceed

asfollows:

• ThewirewhichiscolouredGreenandYellowmustbeconnectedto

theterminalintheplugwhichismarkedwiththeletterEorbythe

earthsymbol.

• ThewirewhichiscolouredBluemustbeconnectedtotheterminalin

theplugwhichismarkedwiththeletterN

• ThewirewhichiscolouredBrownmustbeconnectedtotheterminal

intheplugwhichismarkedwiththeletterL

Ensurethatthesecolourcodesarefollowedcarefullyintheeventofthe

plugbeingchanged

• Thisunit iscapableof operating overarange of mains voltages, as

markedontherearpanel.

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment gen-

erates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interfer-

ence to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

This Class A digital apparatus meets the requirements of the Canadian Inter-

ference-Causing Equipment Regulations.

Cet appareil numérique de la Classe A respecte toutes les exigences du Règle-

ment sur le matériel brouilleur du Canada.

WorkingSafelyWithSound Although your new console will not make any noise until you feed it signals,

it has the capability to produce sounds that, when monitored through a moni-

tor system or headphones, can damage hearing over time.The table below is

taken from the Occupational Safety & Health Administration directive on

occupational noise exposure (1926.52):

PermissibleNoiseExposure: Duration per day [h] Sound level [dBA, slow response]

8 90

6 92

4 95

3 97

2 100

1.5 102

1 105

0.5 110

<0.25 115

!

Safety Information

III

Conforming to this directive will minimise the risk of hearing damage caused

by long listening periods. A simple rule to follow is: The longer you listen, the

lower the average volume should be. Please take care when working with your

audio system – if you are manipulating controls which you don’t understand

(which we all do when we are learning), make sure your monitoring level is

turned down. Remember that your ears are the most important tool of your

trade. Look after them, and they will look after you. Most importantly: Don’t

be afraid to experiment to nd out how each parameter affects the sound;

this will extend your creativity and help you to get the best results.

A1 Safety Symbol Guide

For your own safety and to avoid invalidation of the warranty, all text marked

with these symbols should be read carefully.

To reduce the risk of electric shock, do not remove covers. No user-service-

able parts inside. Refer servicing to qualied service personnel (i.e., persons

having appropriate technical training and experience necessary to be aware

of hazards to which they are exposed in performing a repair action, and of

measures to minimize the danger of themselves).

The lightning ash with arrowhead symbol is intended to alert the user to the

presence of un-insulated “dangerous voltage” within the product’s enclosure

that may be of sufcient magnitude to constitute a risk of electric shock to

persons.

The exclamation point within an equilateral triangle is intended to alert the

user to the presence of important operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

Headphones safety warnings contain important information and useful tips

on headphone outputs and monitoring levels.

Assemblies or sub-assemblies of this product can contain opto-electronic

devices. As long as these devices comply with Class I of laser or LED prod-

ucts according to EN 60825-1:1994, they will not be expressly marked on

the product. If a special design should be covered by a higher class of this

standard, the device concerned will be marked directly on the assembly or

sub-assembly in accordance with the above standard.

A2 First Aid

InCaseofElectricShock: Separate the person as quickly as possible from the electric power source:

• By switching the equipment off,

• By unplugging or disconnecting the mains cable, or

• By pushing the person away from the power source, using dry insulating

material (such as wood or plastic).

• After having suffered an electric shock, always consult a doctor.

Warning! Do not touch the person or his clothing before the power is turned off,

otherwise you stand the risk of suffering an electric shock as well!

IfthePersonisUnconscious: • Lay the person down

• Turn him to one side

• Check the pulse

• Reanimate the person if respiration is poor

• Call for a doctor immed iately.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

ACHTUNG

GEFAHR: ELEKTRISCHER SCHLAG

NICHT ÖFFNEN

ATTENTION

RISQUE DE CHOC ELECTRIQUE

NE PAS OUVRIR

!

CLASS 1

LASER PRODUCT

CLASS 1

LED PRODUCT

!

Safety Information

IV

B General Installation Instructions

Please consider besides these general instructions also any product-specic

instructions in the “Installation” chapter of this manual.

B1 Unpacking

Check the equipment for any transport damage. If the unit is mechanically

damaged, if liquids have been spilled or if objects have fallen into the unit,

it must not be connected to the AC power outlet, or it must be immediately

disconnected by unplugging the power cable. Repair must only be performed

by trained personnel in accordance with the applicable regulations.

B2 Installation Site

Install the unit in a place where the following conditions are met:

• The temperature and the relative humidity of the environment must be

within the specied limits during operation of the unit. Relevant values

are the ones at the air inlets of the unit (refer to Appendix 1).

• Condensation must be avoided. If the unit is installed in a location with

large variation of ambient temperature (e.g. in an OB-van), appropriate

precautions must be taken before and after operation (refer to Appendix

1).

• Unobstructed air ow is essential for proper operation. Air vents of the

unit are a functional part of the design and must not be blocked in any

way during operation (e.g. by objects placed upon them, placement of the

unit on a soft surface, or installation of the unit within a rack or piece of

furniture).

• The unit must not be heated up by external sources of heat radiation (sun-

light, spotlights).

B3 Earthing and Power Supply

Earthing of units with mains supply (class I equipment) is performed via

the protective earth (PE) conductor integrated in the mains cable. Units with

battery operation (< 60 V, class III equipment) must be earthed separately.

Earthing the unit is one of the measures for protection against electrical shock

hazard (dangerous body currents). Hazardous voltage may not only be caused

by a defective power supply insulation, but may also be introduced by the

connected audio or control cables.

If the unit is installed with one or several external connections, its earthing

must be provided during operation as well as while the unit is not operated.

If the earthing connection can be interrupted, for example, by unplugging

the mains plug of an external power supply unit, an additional, permanent

earthing connection must be installed using the provided earth terminal.

Avoid ground loops (hum loops) by keeping the loop surface as small as

possible (by consequently guiding the earth conductors in a narrow, parallel

way), and reduce the noise current owing through the loop by inserting an

additional impedance (common-mode choke).

Installation

V

Installation / EMC

ClassIEquipment(MainsOperation)

Should the equipment be delivered without a matching mains cable, the

latter has to be prepared by a trained person using the attached female plug

(IEC 320 / C13 or IEC 320 / C19) with respect to the applicable regulations

in your country.

Before connecting the equipment to the AC power outlet, check that the local

line voltage matches the equipment rating (voltage, frequency) within the

admissible tolerance. The equipment fuses must be rated in accordance with

the specications on the equipment.

Equipment supplied with a 3-pole appliance inlet (protection conforming to

class I equipment) must be connected to a 3-pole AC power outlet in such a

way that the equipment cabinet is connected to the protective earth.

For information on mains cable strain relief, please refer to Appendix 2.

Female Plugs (IEC320), Front-Side View:

European Standard

(CENELEC)

North American Standard

(NAS)

Brown L (Live) Black

Blue N (Neutral) White

Green/Yellow PE (Protective Earth) Green (or Green/Yellow)

ClassIIIEquipment(BatteryOperationupto60VDC)

Equipment of this protection class must be earthed using the provided earth

terminal if one or more external signals are connected to the unit (see expla-

nation at the beginning of this paragraph).

B4 Electromagnetic Compatibility (EMC)

The unit conforms to the protection requirements relevant to electromagnetic

phenomena that are listed in guidelines 89/336/EC and FCC, part 15.

• The electromagnetic interference generated by the unit is limited in such

a way that other equipment and systems can be operated normally.

• The unit is adequately protected against electromagnetic interference so

that it can operate properly.

The unit has been tested and conforms to the EMC standards of the speci-

ed electromagnetic environment, as listed in the following declaration.

The limits of these standards ensure protection of the environment and cor-

responding noise immunity of the equipment with appropriate probability.

However, a professional installation and integration within the system are

imperative prerequisites for operation without EMC problems.

For this purpose, the following measures must be followed:

• Install the equipment in accordance with the operating instructions. Use

the supplied accessories.

• In the system and in the vicinity where the equipment is installed, use only

components (systems, equipment) that also fulll the EMC standards for

the given environment.

PE

LN

IEC 320 / C19IEC 320 / C13

PE

LN

VI

• Use a system grounding concept that satises the safety requirements

(class I equipment must be connected with a protective ground conduc-

tor) and that also takes into consideration the EMC requirements. When

deciding between radial, surface, or combined grounding, the advantages

and disadvantages should be carefully evaluated in each case.

• Use shielded cables where shielding is specied. The connection of the

shield to the corresponding connector terminal or housing should have a

large surface and be corrosion-proof. Please note that a cable shield con-

nected only single-ended can act as a transmitting or receiving antenna

within the corresponding frequency range.

• Avoid ground loops or reduce their adverse effects by keeping the loop sur-

face as small as possible, and reduce the noise current owing through the

loop by inserting an additional impedance (e.g. common-mode choke).

• Reduce electrostatic discharge (ESD) of persons by installing an appropri-

ate oor covering (e.g. a carpet with permanent electrostatic laments) and

by keeping the relative humidity above 30%. Further measures (e.g. con-

ducting oor) are usually unnecessary and only effective if used together

with corresponding personal equipment.

• When using equipment with touch-sensitive operator controls, please take

care that the surrounding building structure allows for sufcient capacitive

coupling of the operator. This coupling can be improved by an additional,

conducting surface in the operator’s area, connected to the equipment

housing (e.g. metal foil underneath the oor covering, carpet with conduc-

tive backing).

C Maintenance

All air vents and openings for operating elements (faders, rotary knobs) must

be checked on a regular basis, and cleaned in case of dust accumulation. For

cleaning, a soft paint-brush or a vacuum cleaner is recommended.

Cleaning the surfaces of the unit is performed with a soft, dry cloth or a soft

brush.

Persistent contamination can be treated with a cloth that is slightly humidied

with a mild cleaning solution, such as dishwashing detergent.

For cleaning display windows, commercially available computer/TV screen

cleaners are suited. Use only a slightly damp (never wet) cloth.

Never use any solvents for cleaning the exterior of the unit! Liquids must

never be sprayed or poured on directly!

For equipment-specic maintenance information please refer to the corre-

sponding chapter in the operating and service manuals.

D Electrostatic Discharge during Maintenance and Repair

Caution: Observe the precautions for handling devices sensitive to electrostatic dis-

charge!

Many semiconductor components are sensitive to electrostatic discharge

(ESD). The lifespan of assemblies containing such components can be dras-

tically reduced by improper handling during maintenance and repair. Please

observe the following rules when handling ESD sensitive components:

• ESD sensitive components should only be stored and transported in the

packing material specically provided for this purpose.

EMC / Maintenance / ESD

VII

ESD / Repair

• When performing a repair by replacing complete assemblies, the removed

assembly must be sent back to the supplier in the same packing material

in which the replacement assembly was shipped. If this should not be the

case, any claim for a possible refund will be null and void.

• Unpacked ESD sensitive components should only be handled in ESD

protected areas (EPA, e.g. area for eld service, repair or service bench)

and only be touched by persons wearing a wristlet connected to the ground

potential of the repair or service bench by a series resistor. The equipment

to be repaired or serviced as well as all tools and electrically semi-conduct-

ing work, storage, and oor mats should also be connected to this ground

potential.

• The terminals of ESD sensitive components must not come in uncontrolled

contact with electrostatically chargeable or metallic surfaces (voltage

puncture, discharge shock hazard).

• To prevent the components from undened transient stress and possible

damage due to inadmissible voltages or compensation currents, electrical

connections should only be established or separated when the equipment

is switched off and after any capacitor charges have decayed.

E Repair

By removing housing parts or shields, energized parts may be exposed. For

this reason the following precautions must be observed:

• Maintenance may only be performed by trained personnel in accordance

with the applicable regulations.

• The equipment must be switched off and disconnected from the AC power

outlet before any housing parts are removed.

• Even if the equipment is disconnected from the power outlet, parts with

hazardous charges (e.g. capacitors, picture tubes) must not be touched until

they have been properly discharged. Do not touch hot components (power

semiconductors, heat sinks, etc.) before they have cooled off.

• If maintenance is performed on a unit that is open ed while being switched

on, no un-insulated circuit components and metallic semiconductor hous-

ings must be touched, neither with bare hands nor with un-insulated

tools.

Certain components pose additional hazards:

• Explosion hazard from lithium batteries, electrolytic capacitors and power

semiconductors (Observe the component’s polarity. Do not short battery

terminals. Replace batteries only by the same type).

• Implosion hazard from evacuated display units.

• Radiation hazard from laser units (non-ionizing), picture tubes (ioniz-

ing).

• Caustic effect of display units (LCD) and components containing liquid

electrolyte.

Such components should only be handled by trained personnel who are prop-

erly protected (e.g. protection glasses, gloves).

VIII

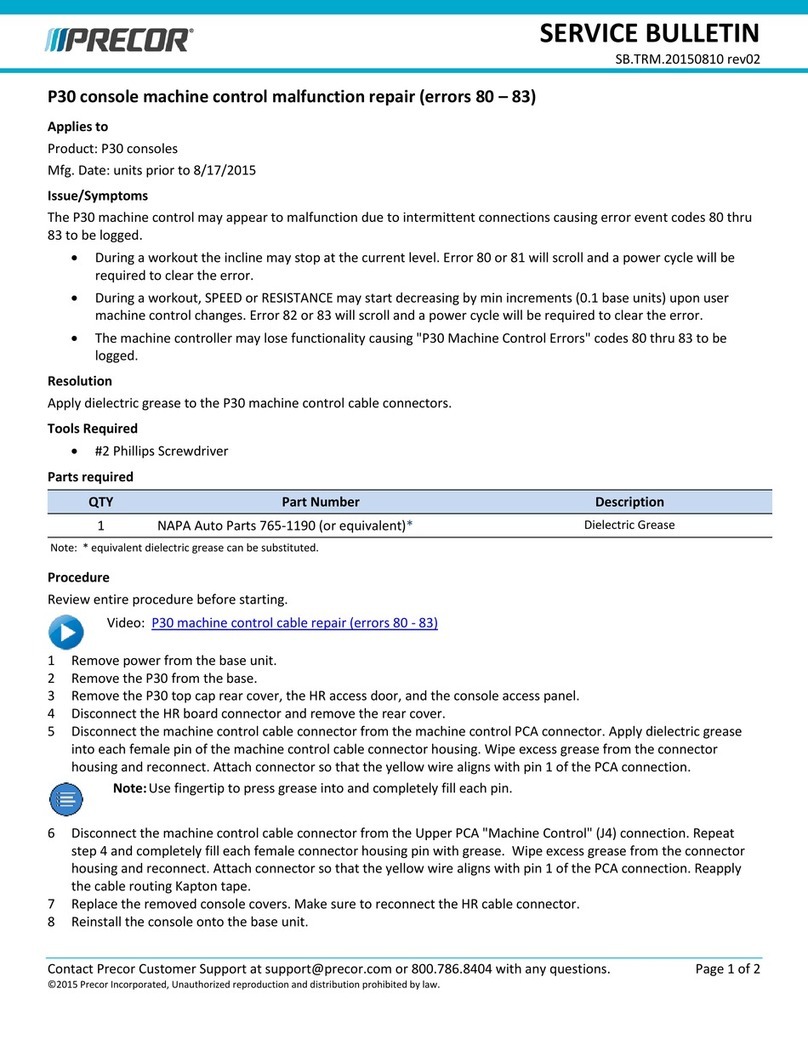

E1 SMD Components

Studer has no commercially available SMD components in stock for ser-

vice purposes. For repair, the corresponding devices have to be purchased

locally. The specications of special components can be found in the service

manual.

SMD components should only be replaced by skilled specialists using appro-

priate tools. No warranty claims will be accepted for circuit boards that have

been damaged. Proper and improper SMD soldering joints are illustrated

below.

F Disposal

PackingMaterials The packing materials have been selected with environmental and disposal

issues in mind. All packing material can be recycled. Recycling packing saves

raw materials and reduces the volume of waste.

If you need to dispose of the transport packing materials, please try to use

recyclable means.

UsedEquipment Used equipment contains valuable raw materials as well as materials that

must be disposed of professionally. Please return your used equipment via an

authorized specialist dealer or via the public waste disposal system, ensuring

any material that can be recycled is.

Please take care that your used equipment cannot be abused. To avoid abuse,

delete sensitive data from any data storage media. After having disconnected

your used equipment from the mains supply, make sure that the mains con-

nector and the mains cable are made useless.

Repair / Disposal

32

Dismounting

Mounting Examples

Solder

SMD

Component

Copper

Track

Adhesive

Soldering Iron

Desoldering

Iron

Desolder

Wick

Heat and Remove Cleaning

Solder

Ø 0.5...0.8 mm

Heating Time < 3 s per Side

Soldering

Iron Desolder

Wick

1

3

2

1

PCB

IX

G Declarations of Conformity

G1 Class A Equipment - FCC Notice

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide a reasonable protection against harmful interfer-

ence when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his own expense.

This Class A digital apparatus meets the requirements of the Canadian Inter-

ference-Causing Equipment Regulations.

Cet appareil numérique de la Classe A respecte toutes les exigences du Règle-

ment sur le matériel brouilleur du Canada.

Caution: Any changes or modications not expressly approved by the manufacturer

could void the user’s authority to operate the equipment. Also refer to relevant

information in this manual.

G2 CE Declaration of Conformity

We,

StuderProfessionalAudioGmbH,

CH-8105Regensdorf,

declare under our sole responsibility that the product

StuderOnAir3000,DigitalMixingSystem

(startingwithserialno.1001),

to which this declaration relates, according to following regulations of EU

directives and amendments

• Low Voltage (LVD):

73/23/EEC + 93/68/EEC

• Electro magnetic Compatibility (EMC):

89/336/EEC + 92/31/EEC + 93/68/EEC

is in conformity with the following standards or normative documents:

• Safety:

EN 60950:2001 (Class I equipment)

• Safety of laser products:

EN 60825-1:1994 + A11 + A2, EN 60825-2:2000

• EMC:

EN 55103-1/-2:1996, electromagnetic environments E2 and E4.

Regensdorf, April 14, 2005

B. Hochstrasser, President M. Lienert, Manager R&D

Conformity

X

Appendix 1: Air Temperature and Humidity

General

Normal operation of the unit or system is warranted under the ambient condi-

tions dened by EN 60721-3-3, set IE32, value 3K3.

This standard consists of an extensive catalogue of parameters, the most

important of which are: ambient temperature +5...+40 °C, relative humid-

ity 5...85% (i.e., no formation of condensation or ice); absolute humidity

1...25 g/m³; rate of temperature change < 0.5 °C/min. These parameters are

dealt with in the following paragraphs.

Under these conditions the unit or system starts and works without any prob-

lem. Beyond these specications, possible problems are described below.

Ambient Temperature

Units and systems by Studer are generally designed for an ambient tempera-

ture range (i.e. temperature of the incoming air) of +5 °C to +40 °C. When

rack mounting the units, the intended air ow and herewith adequate cooling

must be provided. The following facts must be considered:

• The admissible ambient temperature range for operation of the semicon-

ductor components is 0 °C to +70 °C (commercial temperature range for

operation).

• The air ow through the installation must provide that the outgoing air is

always cooler than 70 °C.

• Average heat increase of the cooling air shall be about 20 K, allowing for

an additional maximum 10 K increase at the hot components.

• In order to dissipate 1 kW with this admissible average heat increase, an

air ow of 2.65 m³/min is required.

Example: A rack dissipating P = 800 W requires an air ow of 0.8 * 2.65 m³/min which

corresponds to 2.12 m³/min.

• If the cooling function of the installation must be monitored (e.g. for fan

failure or illumination with spot lamps), the outgoing air temperature must

be measured directly above the modules at several places within the rack.

The trigger temperature of the sensors should be 65 °C to 70 °C.

Frost and Dew

The unsealed system parts (connector areas and semiconductor pins) allow

for a minute formation of ice or frost. However, formation of dew visible to

the naked eye will already lead to malfunctions. In practice, reliable opera-

tion can be expected in a temperature range above –15 °C, if the following

general rule is considered for putting the cold system into operation:

If the air within the system is cooled down, the relative humidity rises. If it

reaches 100%, condensation will arise, usually in the boundary layer between

the air and a cooler surface, together with formation of ice or dew at sensi-

tive areas of the system (contacts, IC pins, etc.). Once internal condensation

occurs, trouble-free operation cannot be guaranteed, independent of tempera-

ture.

Before putting into operation, the system must be checked for internal for-

mation of condensation or ice. Only with a minute formation of ice, direct

Appendix

XI

evaporation (sublimation) may be expected; otherwise the system must be

heated and dried while switched off.

A system without visible internal formation of ice or condensation should be

heated up with its own heat dissipation, as homogeneously (and subsequently

as slow) as possible; the ambient temperature should then always be lower

than the one of the outgoing air.

If it is absolutely necessary to operate the cold system immediately within

warm ambient air, this air must be dehydrated. In such a case, the absolute

humidity must be so low that the relative humidity, related to the coldest

system surface, always remains below 100%.

Ensure that the enclosed air is as dry as possible when powering off (i.e. before

switching off in winter, aerate the room with cold, dry air, and remove humid

objects such as clothes from the room).

These relationships are visible from the following climatogram. For a con-

trolled procedure, thermometer and hygrometer as well as a thermometer

within the system will be required.

Example1: An OB-van having an internal temperature of 20 °C and a relative humidity of

40% is switched off in the evening. If the temperature falls below +5 °C, the

relative humidity will rise to 100% (7 g/m³); dew or ice will be forming.

Example2: An OB-van is heated up in the morning with air of 20 °C and a relative

humidity of 40%. On all parts being cooler than +5 °C, dew or ice will be

forming.

Appendix

XII

Appendix 2: Mains Connector Strain Relief

For anchoring connectors without a mechanical lock (e.g. IEC mains connec-

tors), we recommend the following arrangement:

Procedure: The cable clamp shipped with your unit is auto-adhesive. For mounting please

follow the rules below:

• The surface to be adhered to must be clean, dry, and free from grease, oil,

or other contaminants. Recommended application temperature range is

+20 °C to +40 °C.

• Remove the plastic protective backing from the rear side of the clamp

and apply it rmly to the surface at the desired position. Allow as much

time as possible for curing. The bond continues to develop for as long as

24 hours.

• For improved stability, the clamp should be xed with a screw. For this

purpose, a self-tapping screw and an M4 bolt and nut are included.

• Place the cable into the clamp as shown in the illustration above and rmly

press down the internal top cover until the cable is xed.

Appendix

XIII

Appendix

Appendix 3: Software License

Use of the software is subject to the Studer Professional Audio Software

License Agreement set forth below. Using the software indicates your accep-

tance of this license agreement. If you do not accept these license terms, you

are not authorized to use this software.

Under the condition and within the scope of the following Terms and Con-

ditions, Studer Professional Audio GmbH (hereinafter “Studer”) grants the

right to use programs developed by Studer as well as those of third parties

which have been installed by Studer on or within its products. References

to the license programs shall be references to the newest release of a license

program installed at the Customer’s site.

Programs Covered by the Agreement

LicenseProgramsofStuder The following Terms and Conditions grant the right to use all programs of

Studer that are part of the System and/or its options at the time of its delivery

to the Customer, as well as the installation software on the original data disk

and the accompanying documentation (“License Material”). In this Agree-

ment the word “Programs” shall have the meaning of programs and data

written in machine code.

Using the software indicates your acceptance of this license agreement. If

you do not accept these license terms, you are not authorized to use this soft-

ware.

ProgramsofThirdParties Programs of third parties are all programs which constitute part of the System

and/or its options at the time of delivery to the Customer but have not been

developed by Studer. The following conditions are applicable to programs of

third parties:

• The right to use third parties’ programs is governed by the License Agree-

ment attached hereto (if applicable), which is an integral part of this Agree-

ment. The Customer shall sign any and all License Agreements for all

further programs of third parties installed on the system. The Customer

shall be deemed to have received all License Agreements upon delivery

of the system and/or its options.

• Studer shall accept no responsibility or liability for, and gives no warran-

ties (express or implied) as to the programs of third parties. The Customer

waives any and all claims versus Studer for any consequential damages,

which might occur due to defects of these programs.

Right of Use

Principle Studer grants the Customer the non-exclusive right to use the License Ma-

terial in one copy on the system and/or its options as laid down by the Sales

Agreement concluded between the parties and all Terms and Conditions

which shall be deemed to form and be read and construed as part of the

Sales Agreement. This right is assignable according to the “Assignability”

paragraph hereinafter.

CustomizedCongurations The Customer is not entitled to alter or develop further the License Material

except within the expressly permitted conguration possibilities given by the

software installed on the system or elsewhere. All altered programs, includ-

XIV

ing but not limited to the products altered within the permitted conguration

possibilities, are covered by this License Agreement.

ReverseEngineering Reverse engineering is only permitted with the express consent of Studer.

The consent of Studer can be obtained but is not limited to the case in which

the interface software can not be provided by Studer. In any case Studer has

to be informed immediately upon complete or partial reverse engineering.

CopyingtheLicenseMaterial The Customer is entitled to make one copy of all or parts of the License

Material as is necessary for the use according to this Agreement, namely for

backup purposes. The Customer shall apply the copyright of Studer found on

the License Material onto all copies made by him. Records shall be kept by

the Customer regarding the amount of copies made and their place of keeping.

The responsibility for the original program and all copies made lies with the

Customer. Studer is entitled to check these records on rst request. Copies

not needed anymore have to be destroyed immediately.

DisclosureofLicenseMaterial The License Material is a business secret of Studer. The Customer shall not

hand out or in any way give access to parts of or the complete License Material

to third parties nor to publish any part of the License Material without prior

written consent of Studer. The Customer shall protect the License Material

and any copies made according to the paragraph above by appropriate defense

measures against unauthorized access. This obligation of non-disclosure is a

perpetual obligation.

Third parties are entitled to have access to the License Material if they use the

License Material at the Customer’s site in compliance with this Agreement.

Under no circumstance are third parties entitled to have access to the instal-

lation software on the original data media. The Customer shall safeguard the

original data media accordingly.

Assignability The rights granted to the Customer according to this License Agreement shall

only be assignable to a third party together with the transfer of the system

and/or its options and after the prior written consent of Studer.

Rights to License Material

With the exception of the right of use granted by this License Agreement all

proprietary rights to the License Material, especially the ownership and the

intellectual property rights (such as but not limited to patents and copyright)

remain with Studer even if alterations, customized changes or amendments

have been made to the License Material.

Studer’s proprietary rights are acknowledged by the Customer. The Customer

shall undertake no infringements and make no claims of any patent, registered

design, copyright, trade mark or trade name, or other intellectual property

right.

Warranty, Disclaimer, and Liability

For all issues not covered herewithin, refer to the “General Terms and Condi-

tions of Sales and Delivery” being part of the sales contract.

Appendix

Date printed: 28.02.11

OnAir 3000 Digital Mixing Console

Important

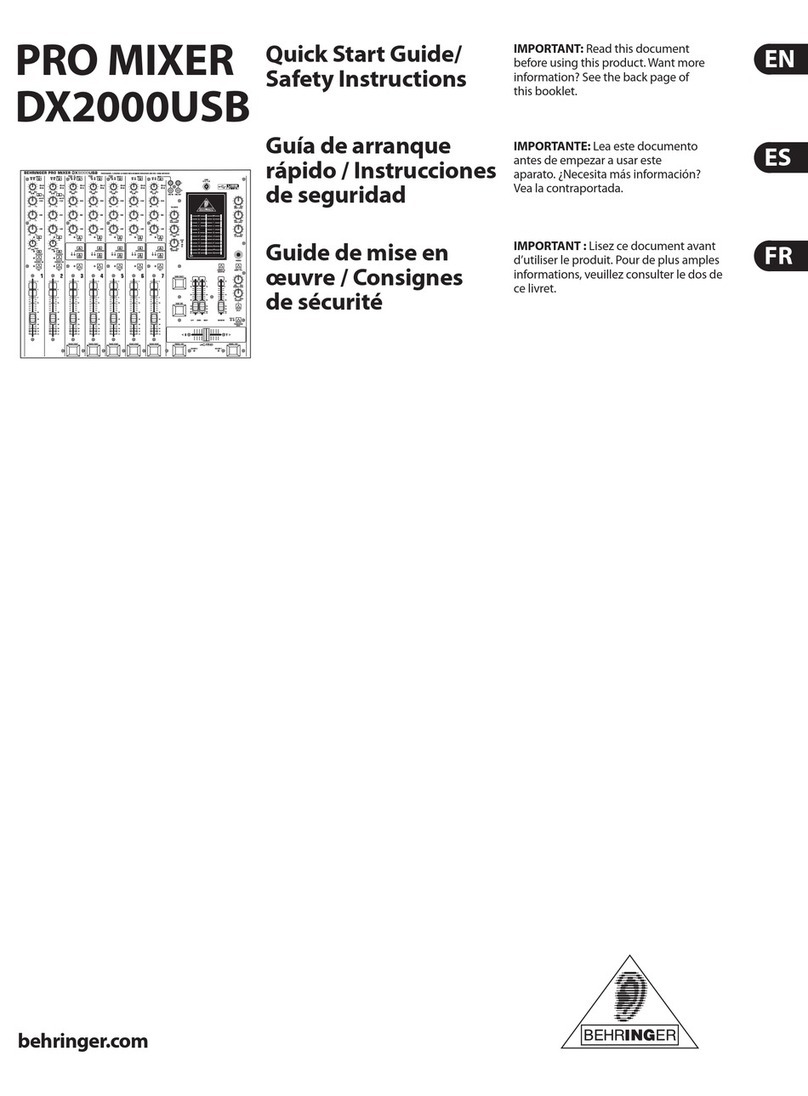

WIRING – IMPORTANT

The OnAir 3000 RS422 and Ethernet wiring must comply with

the following requirements:

Cable Type: Cat 5e, with shielded connectors on both ends

Cable Dimensions

Max. Length

for Screens

Max. Length

for Motor

Fader

Modules

Max. Length

for Other

Modules

Min.

AWG

Min.

Sectional

Area

20 m 30 m 100 m 24 0.21 mm2

13 m 18 m 60 m 26 0.13 mm2

Details Cat(egory) 5e Cable is an enhanced version of Cat 5 that adds specifications for far-end crosstalk.

It replaced the specification for Cat 5 with the 2001 introduction of the TIA/

EIA-568-B standard. Cat 5e cable performance characteristics and test meth-

ods are defined in TIA/EIA-568-B.2-2001.

RS422 Cables (Cat 5e) (both ends with shielded connectors) from the distribution box to all kinds

of desk and screen modules.

Distribution Box Wire Color Desk Module

Signal Pin Pin Signal

+24 V *1

2

wht/org

org

1

2+24 V *

RX+ 3 wht/grn 3 TX+

TX+ 4 blu 4 RX+

TX– 5 wht/blu 5 RX–

RX– 6 grn 6 TX–

Gnd *7

8

wht/brn

brn

7

8Gnd *

Ethernet Cables (Cat 5e) (both ends with shielded connectors) for use between the SCore host card

and the main screen module (via hub/switch), as well as for HD Link, D21m

control, and networking connections. Since modern hubs and switches have

auto polarity selection, straight-through cables may be used in any case.

Signal Pin Wire Color Pin Signal

TX+ 1 wht/org 1 TX+

TX– 2 org 2 TX–

RX+ 3 wht/grn 3 RX+

4 blu 4

5 wht/blu 5

RX– 6 grn 6 RX–

7 wht/brn 7

8 brn 8

* Caution Connectors are identical on the RS422 and the Ethernet cables.

Make sure not to mix them up since the RS422 sockets carry

DC supply voltage!

Top (tab

down):

18

18

Front:

Top (tab

down):

18

18

Front:

Order no. BD10.275230

Date printed: 28.02.11

OnAir 3000 Digital Mixing Console

Important

USB MEMORY DEVICE – IMPORTANT

A memory device connected to an USB socket must not be

unplugged while its indicator LED is illuminated or ashing.

1-1

Date printed: 28.02.11

AUX

MAIN

ΣMASTER / SEND / GROUP AND MONITORING

Master AUX Listen N-X GRPMPX

REC MASTER

PFL

AUX 1

AUX 4

PFL

PFL

PRG B MASTER

PRG A MASTER

PFL

PFL

ΣN-X 1

N-X

ΣN-X 16

N-X

PFL

CUE

CUE ST1

CUE

CUE ST1

MPX

MPX

MPX

MPX

FADER

FADER

PFL

ST1 TB RET

ST3 TB RET

ST2 TB RET

CR TB RET

SP SRC

CUT MONO

same as PFL CR

TB to Master/Send/Group

TB to Master/Send/Group

GRP 1

GRP 8

FADER

FADER

PFL

PFL

MPX

CUT

TB

DIM

TB

DIM

TB

DIM

TB

TB

TB

TALK

same as CONTROL ROOM

ST1 ADD SRC

TB to ST1

TB to ST1

TB to CR

TALK

ST2 SRC

TB to ST2

TB to ST3

TB to ST2 HP

TB to ST3 HP

ST3 SRC

ST1 SRC

same as STUDIO 2

SP SRC

SP SRC

/ MON

STUDIO 3

STUDIO 2

CONTROL ROOM

(Monitoring Mode I)

NONE

SPLIT

CR ADD MODE

MONO MONO

MONO

MONO

MONO

MIX

DJ HP MODE

STUDIO 1

with PFL SP

TALK

CR ADD SRC

CR SP SRC

MON to L

ST1 SP SRC

TALK

TB to CR

TB to CR HP

TB to ST1 HP

CR SRC

OUTPUTS

INS

L (M)

TB

DIM

SLATE

TB

DIM

TALK

TALK

TALK

D

DSFC

D

D

D

D

D

D

D

DSFC

D

D

D

D

D

D

AES MODULE (OUT)

d

d

d

d

d

d

d

d

TB

DIM

SLATE

TB

DIM

sync

sync

SLATE

LIM M/S R (M)

M

INS

L (M)

LIM M/S R (M)

M

INS

L (M)

LIM M/S R (M)

M

L (M)

M/S R (M)

M

L (M)

FADER

INS SEND

ONFADER

FADER

FADER

CHANNEL OUT

DIRECT OUT PP

DIRECT OUT AP

TB

DIM

TALK

LINE OUT MODULE

a

a

D

A

a

a

D

A

a

a

D

A

a

a

D

A

Audition

TB

DIM

TB

DIM

FADER ON

ON

ON

GUI Meter

ADAT / TDIF (OUT)

D

D

d

8/16

35

TB

DIM

TALK

TB

DIM

TB

DIM

TB

DIM

TALK

TALK

TALK

L (M)

M/S R (M)

M

L (M)

M/S R (M)

M

INS EQ 4B

COMP

DUCK

EQ 4B

COMP

DUCK

Side Chain

Side Chain

MPX

MPX Studio 1

M/S R (M)

M

L (M)

M/S R (M)

M

L (M)

M/S R (M)

M

PFL CR

PFL STUDIO 1

TB to EXT

TB to EXT1-4 [1-16]

CR SP

ST1 SP

#

ST2 MON LSP

ST3 GUEST HP

ST2 DJ HP

ST3 MON LSP

ST3 DJ HP

PFL ST1

D

D

MADI (OUT)

D

D

Control

DIMCUT

DIM

CUT DIM

PFL CR

SDI SD / HD / 3G (OUT)

D

D

D

D

HD LINK (OUT)

INS

ST2 GUEST HP

ST1 MON LSP

ST1 DJ HP

ST1 GUEST HP

CR MON LSP

CR DJ HP

CR GUEST HP

ADAT

D

D

D

D

D

D

D

D

018.02.02 HB 0.5 07.02.03 HB

0.7 12.02.05 HB

0.8

Regensdorf

Switzerland

BLOCK DIAGRAM

AUDIO

Software V3.2

19.04.02 HB

0.81 16.08.05 HB

0.82 21.07.06 SoG

OnAir 3000

0.83 4.12.06 SoG

0.9 16.07.07 SoG

1.0 27.06.08 SoG

1.1 15.03.10 SoG

Configurations C3...C6

64 d

d

64

ETHERSOUND (OUT)

D

D

64 d

d

8

d

8

CR/ST1 MONITOR

D

ADJ HP

D

A

D

A

DA

GUEST HP

MON LSP

DA

8

8

TB MIC

SP

d

8

d

8

d

8/16

d

96

MON

ST1 SP SRC

CR SP SRC

PRG A

PRG B

REC

AUX 1

AUX 4

PFL

PFL ST1

AUDITION

N-X 1

N-X 16

MPX 1

MPX 16

MPX Listen

MPX Listen

ST1

GRP 1

GRP 8

4 [16]

GPOUT

8

INPUTS

D

D

SFC

AES MODULE (IN)

D

D

SFC

D

D

SFC

D

D

SFC

D

D

SFC

D

D

SFC

D

D

SFC

D

D

SFC

d

d

d

d

d

d

d

d

GPIN

GPIO

16

A

D

MIC MODULE

A

D

A

D

A

D

a

a

a

a

A

D

LINE IN MODULE

A

D

A

D

A

D

a

a

a

a

a

a

a

a

#

ADAT / TDIF (IN)

D

D

8/16

d

D

D

8/16

d

GPOUT

16

GPIN

8

MADI (IN)

D

D

64

d

64

d

Control

AUX

SDI SD / HD / 3G (IN)

D

D

8

d

D

D

8

d

Dolby E (IN)

D

D

8/16

d

D

D

d8/16

ETHERSOUND (IN)

D

D

64

d

MAIN

d96 HD LINK (IN)

STEREO INPUT

CHANNEL 1...n

EXT PFL 1

n = max. 24 (for Configurations C3 and C5)

n = max. 48 (for Configurations C4 and C6)

EXT PFL 2

CUE

CUE ST1

INPUT CHANNELS

PHASE

STEREO

CAL

DE-ESSER EQ

4-band

INS RET

CH INP

N-X

GR METER

DYNDe-S

AP

PP

OVL

DYNAMICS INS

AP

PROCESSING

FADER BALANCE CHANNEL

ON/OFF

PRG A

PRG B

AUDITION

AUX 1

AUX 4

PFL

CH

active

AF

PF

PF

AF

AF

PF

CH METER

CUE

PFL

REC

REC PF

N-X 1

N-X 16

AF

PF

PF

AF

PP

AP

TB

35

STUDIO 1 SOURCE

CR SOURCE

STUDIO 3 SOURCE

STUDIO 2 SOURCE

TB from CR

TB from STUDIO 1

TB from STUDIO 2

TB from EXT

TB from EXT1-4 [1-16]

TB from STUDIO 3

4

4 [16] 4 [16]

4 [16]

4

4

TEST GEN.

SINE WAVE

WHITE NOISE

PINK NOISE

CR ADD SOURCE

STUDIO 1 ADD SOURCE

CR SP SOURCE

STUDIO 1 SP SOURCE

4

4

4

TB to CR

TB to CR HP

TB to ST1

TB to ST1 HP

TB to ST2

TB to ST2 HP

TB to ST3

TB to ST3 HP

TB to EXT

TB to EXT1

TB to EXT16

TB to INT1

TB to INT31

INS

PP

MPX 1

MPX 16

MPX Listen

PRG A

GRP 8

GRP 1

PRG B

REC

N-X 1

N-X 16

GRP 1..8 (for Configurations C5 and C6)

GRP

HP

LP

CUT

TB

CUT

TB

CUT

TB

DIM

TB

DIM

TB

CUT

Numbers in square brackets are valid for

Configurations C5 and C6 only

[xx]

MPX Option (Configurations C5 and C6 only)

Group and High-Pass/Low-Pass Filter Option

(Configurations C5 and C6 only)

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

1-2 Date printed: 28.02.11

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

MPX Option

Group and High-/Low-Pass

Filter Option

Numbers in square brackets are

valid for Config C109 only

[xx]

For CR and Studio1 Monitoring

without 5.1 option refer to the

C3...C6 block diagram

*

*

*

Σ

MASTER/SEND/GROUP AND MONITORING

Master AUX Listen N-X GRPMPX

ST1 TB RET

SP SRC

CUT

MPX VOL

MONO

same as PFL CR

TB to Master/Send/Group

MPX

CUT

TB

DIM

CR TB RET

ST2 TB RET

ST3 TB RET

TALK

TALK

ST2 SRC

TB to ST2

TB to ST3

TB to ST3 HP

ST3 SRC same as STUDIO 2

STUDIO 3

OUTPUTS

D

DSFC

D

D

D

D

D

D

D

DSFC

D

D

D

D

D

D

AES MODULE (OUT)

d

d

d

d

d

d

d

d

sync

sync

INS SEND

CHANNEL OUT

DIRECT OUT PP

DIRECT OUT AP

LINE OUT MODULE

a

a

D

A

a

a

D

A

a

a

D

A

a

a

D

A

GUI Meter

ADAT / TDIF (OUT)

D

D

d

8/16

PFL CR

PFL STUDIO 1

TB to EXT

TB to EXT1-16 [48]

CR SP

ST1 SP

#

ST2 LSP

ST3 GUEST HP

ST3 LSP

ST3 DJ HP

D

D

CUT DIM

ST2 GUEST HP

ADAT

D

D

D

D

D

D

D

D

018.02.02 HB 0.5 07.02.03HB

0.7 12.02.05 HB

0.8

Regensdorf

Switzerland BLOCK DIAGRAM

AUDIO

Software V3.2

19.04.02 HB

0.81 16.08.05 HB

0.82 21.07.06 SoG

OnAir 3000

0.83 4.12.06 SoG

0.9 16.07.07 SoG

1.0 27.6.08 SoG

1.1 15.3.10 SoG

Configurations C7 / C8 / C108 / C109

d

8

d

8

CR / ST1 MONITOR

D

ADJ HP

D

A

D

A

DA

GUEST HP

MON LSP

(or NF LSP)

DA

8

8

TB MIC

SP

ADAT

D

D

D

D

D

D

D

D

d

8

d

8

ST2 / ST3 MONITOR

D

ADJ HP

D

A

D

A

GUEST HP

MON LSP

DA

8

8

TB MIC

d

8/16

PRG A

PRG B

REC

AUX 1

AUX 4

PFL

PFL ST1

AUDITION

N-X 1

N-X 16 [48]

MPX 1

MPX 16

MPX Listen

MPX Listen

ST1

GRP 1

GRP 8

TB

DIM

TB

DIM

TB to ST1

TB to ST2 HP

STUDIO 2

TALK

TALK

TB to CR

TB to CR HP

TB to ST1 HP

ST2 DJ HP

DIM

ST1 DJ HP

ST1 GUEST HP

CR NF LSP

ST1 NF LSP

CR DJ HP

CR ENC RET

ST1 ENC RET

CR GUEST HP

ST1 SP SRC

CR SP SRC

AUX 1

AUX 4

PFL

PFL

N-X

N-X

PFL

CUE

CUE ST1

CUE

CUE ST1

FADER

FADER

PFL

TB to Master/Send/Group

TB

DIM

TALK

L (M)

M/S R (M)

M

L (M)

ONFADER

TB

DIM

TALK

TALK

Audition

TB

DIM

TB

DIM

TALK

FADER ON

ON

ON

35 [67]

M/S R (M)

M

L (M)

M/S R (M)

M

L (M)

M/S R (M)

M

PFL ST1

PFL CR

REC MASTER

PFL

PFL

PFL

PRG B MASTER

INS

L (M)

TB

DIM

TB

DIM

LIM DLY

DLY

DLY

DLY

DLY

DLY

DLY

DLY

DLY

DLY

DLY

M/S R (M)

M

INS

L (M)

LIM M/S R (M)

M

INS

L (M)

LIM M/S R (M)

M

FADER

FADER

FADER TB

DIM

PFL

PFL

L

SLATE

R

M

L

R

M

LIM

LIM

LIM

LIM

Side Chain

MPX

MPX

GRP 1

GRP 8

FADER

FADER

PFL

PFL

TB

DIM

TALK

TB

DIM

TALK

TB

DIM

TALK

TB

DIM

TALK

L (M)

M/S R (M)

M

L (M)

M/S R (M)

M

INS EQ 4B

COMP

DUCK

EQ 4B

COMP

DUCK

Side Chain

MPX

MPX Studio 1

INS

AUX

MAIN

MADI (OUT)

D

D

Control

SDI SD / HD / 3G (OUT)

D

D

D

D

HD LINK (OUT)

64 d

d

64

ETHERSOUND (OUT)

D

D

64 d

d

8

d

8

d

96

GPOUT

8

D

D

SFC

AES MODULE (IN)

D

D

SFC

D

D

SFC

D

D

SFC

D

D

SFC

D

D

SFC

D

D

SFC

D

D

SFC

d

d

d

d

d

d

d

d

GPIN

GPIO

16

A

D

MIC MODULE

A

D

A

D

A

D

a

a

a

a

A

D

LINE IN MODULE

A

D

A

D

A

D

a

a

a

a

a

a

a

a

#

ADAT / TDIF (IN)

D

D

8/16

d

D

D

8/16

d

GPOUT

16

STEREO INPUT

CHANNEL 1...n

EXT PFL 1

EXT PFL 2

CUE

CUE ST1

INPUT CHANNELS

PHASE

STEREO

CAL

DE-ESSER EQ

4-band

INS RET

CH INP

N-X

N-X

GR METER

DYN

De-S

INS

PP

AP

PP

OVL

DYNAMICS INS

AP

PROCESSING

FADER CHANNEL

ON/OFF

PAN /

BALANCE

PRG A

PRG B

AUDITION

AUX 1

AUX 4

PFL

CH

active

AF

PF

PF

AF

AF

PF

CH METER

CUE

PFL

REC

REC PF

N-X 1

N-X 16 [48]

AF

PF

PF

AF

PP

DIR OUT

AP

n + 4m = max. 24 for C7 only

n + 4m = max. 48 for C8, C108, C109

TB 35 [67]

16 [48]

STUDIO 3 SOURCE

STUDIO 2 SOURCE

TB from CR

TB from STUDIO 1

TB from STUDIO 2

TB from STUDIO 3

16 [48]

4

4

4

TEST GEN.

SINE WAVE

WHITE NOISE

PINK NOISE

4

16 [48]

4

4

TB to CR

TB to CR HP

TB to ST1

TB to ST1 HP

TB to ST2

TB to ST2 HP

TB to ST3

TB to ST3 HP

TB to EXT

TB to EXT1

TB to EXT16 [48]

TB to INT1

TB to INT33 [65]

INPUTS

CHANNEL

ON/OFF

5.1

PAN

5.1 A

5.1 B

6

6

DELAY

STUDIO 1 SOURCE

CR SOURCE 6

6

6

6

6

6

CR ADD SOURCE

STUDIO 1 ADD SOURCE

CR SP SOURCE

STUDIO 1 SP SOURCE

5.1 A

5.1 B

6

6

GPIN

8

MADI (IN)

D

D

64

d

64

d

Control

AUX

D

D

8

d

D

D

8

d

Dolby E (IN)

D

D

8/16

d

D

D

d8/16

ETHERSOUND (IN)

D

D

64

d

MAIN

d96 HD LINK (IN)

TB from EXT

TB from EXT1-16 [48]

ΣN-X 1

ΣN-X 16 [48]

GRP

GRP 1..8

HP

LP

PRG A

GRP 8

GRP 1

PRG B

REC

N-X 1

N-X 16 [48]

MPX 1

MPX 16

MPX Listen

SLATE

SLATE

SLATE

SLATE

PRG A MASTER

TB CUT

TB

DIM

CUT

TB

CUT

SDI SD / HD / 3G (IN)

+

+

+

+

+

5.1-Channel Option

5.1

6

6

6

6

6

6

6

5.1 CHANNEL OUT

5.1 DIRECT OUT PP

5.1 DIRECT OUT AP

5.1 A

5.1B

66

same as CONTROL ROOM

ST1 ADD SRC

ST1 SRC

CONTROL ROOM

NONE

SPLIT

CR ADD

MODE

5.1 /

STEREO

5.1 /

STEREO

5.1 /

STEREO

MIX

STUDIO 1

CR ADD SRC

CR SP SRC

ST1 SP SRC

CR SRC

CR MON LSP

CR ENC SEND

ST1 MON LSP

ST1 ENC SEND

5.1 /

STEREO

5.1 B

5.1 A

TB

DIM

LIM

M /

S /

5.1

LIMFADER

FADER

5.1 L

5.1 R

5.1 C

5.1 Lfe

5.1 Ls

5.1 Rs

M /

S /

5.1

5.1 L

5.1 R

5.1 C

5.1 Lfe

5.1 Ls

5.1 Rs

TB

DIM

5.1 /

STEREO

5.1 /

STEREO

MONO

MONO

SP SRC

CR MON/

LSP SRC

5.1 /

STEREO

STEREO

STEREO

ENC

ENC

DIR

MONO

5.1 /

STEREO

MONO

MONO

DJ HP MODE

MON LSP SEL with

PFL SP

MON to L

CR MON

NF LSP

SEL

MONO

6 x SP

ON

6 x SP

CAL

5.1 /

STEREO

MONO

PRG A

PRG B

AUDITION

AUX 1

AUX 4

PFL

CH

active

AF

PF

PF

AF

CUE

PFL

REC

REC PF

N-X 1

N-X 16 [48]

AF

PF

PF

AF

DIR OUT PP

5.1-CH INPUT

CHANNEL 1...m

n + 4m = max. 24 for C7 only

n + 4m = max. 48 for C8, C108, C109

6 x 6

INPUT

ROUTING

6 x 6

Individual

CAL

EQ

4-band 5.1 /

STEREO

5.1 /

STEREO

5.1 /

STEREO

5.1 INP 6

6

6

6

6

6

GR METER

OVL

(Max.

of 6)

DYNAMICSDELAY

PROCESSING

6 x FADER CHANNEL

ON/OFF

5.1 A

5.1 B

AF

PF

CH MTR (Max. of 6)

DIR OUT AP

CH OUT

HP

LP

GRP 8

GRP 1

MPX 1

MPX 16

MPX Listen

5.1

PAN

CUT

CUT

DIM

DIM

TB

DIM

TB

DIM

TB

CUT

MONO

MONO

Other manuals for OnAir 3000

2

Table of contents

Other Studer Music Mixer manuals

Studer

Studer OnAir 500 Modulo Quick guide

Studer

Studer 189 MK II Instruction sheet

Studer

Studer Compact InfinityCore 300 User manual

Studer

Studer OnAir 1500 User manual

Studer

Studer OnAir 1500 User manual

Studer

Studer Vista 5 M2 User manual

Studer

Studer OnAir 500 Modulo User manual

Studer

Studer D950 User manual

Studer

Studer OnAir 2500 User manual

Studer

Studer D19m Operating instructions