VIII

Appendix 1: Air Temperature and Humidity

General

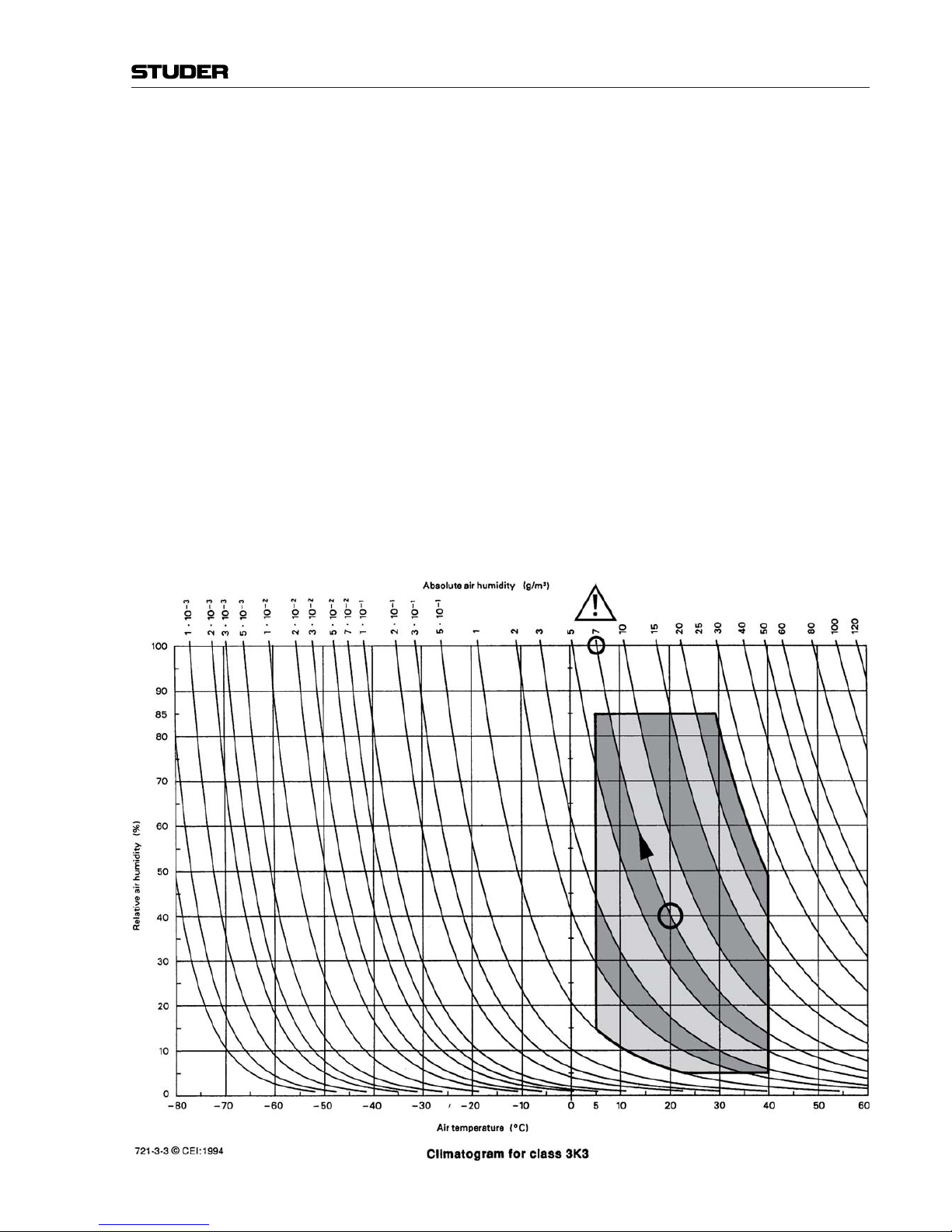

Normal operation of the unit or system is warranted under the ambient condi-

tions defined by EN 60721-3-3, set IE32, value 3K3.

This standard consists of an extensive catalogue of parameters, the most

important of which are: ambient temperature +5...+40 °C, relative humid-

ity 5...85% (i.e., no formation of condensation or ice); absolute humidity

1...25 g/m³; rate of temperature change < 0.5 °C/min. These parameters are

dealt with in the following paragraphs.

Under these conditions the unit or system starts and works without any prob-

lem. Beyond these specifications, possible problems are described below.

Ambient Temperature

Units and systems by Studer are generally designed for an ambient tempera-

ture range (i.e. temperature of the incoming air) of +5 °C to +40 °C. When

rack mounting the units, the intended air flow and herewith adequate cooling

must be provided. The following facts must be considered:

• The admissible ambient temperature range for operation of the semicon-

ductor components is 0 °C to +70 °C (commercial temperature range for

operation).

• The air flow through the installation must provide that the outgoing air is

always cooler than 70 °C.

• Average heat increase of the cooling air shall be about 20 K, allowing for

an additional maximum 10 K increase at the hot components.

• In order to dissipate 1 kW with this admissible average heat increase, an

air flow of 2.65 m³/min is required.

Example: Arack dissipating P = 800 W requires an air flow of 0.8 * 2.65 m³/minwhich

corresponds to 2.12 m³/min.

• If the cooling function of the installation must be monitored (e.g. for fan

failureor illumination withspot lamps), theoutgoing air temperaturemust

be measured directly above the modules at several places within the rack.

The trigger temperature of the sensors should be 65 °C to 70 °C.

Frost and Dew

The unsealed system parts (connector areas and semiconductor pins) allow

for a minute formation of ice or frost. However, formation of dew visible to

the naked eye will already lead to malfunctions. In practice, reliable opera-

tion can be expected in a temperature range above –15 °C, if the following

general rule is considered for putting the cold system into operation:

If the air within the system is cooled down, the relative humidity rises. If it

reaches100%, condensationwill arise,usually inthe boundarylayer between

the air and a cooler surface, together with formation of ice or dew at sensi-

tive areas of the system (contacts, IC pins, etc.). Once internal condensation

occurs,trouble-free operationcannot beguaranteed, independentof tempera-

ture.

Before putting into operation, the system must be checked for internal for-

mation of condensation or ice. Only with a minute formation of ice, direct

Appendix