DEZ SERIES 1000 INSTALLATION,OPERATION AND MAINTENANCE MANUAL

4

Whenever the nature of the

operation permits, keep one hand away from

the equipment to reduce the hazard of current

flowing through vital organs of the body.

Never work on electrical

equipment unless there is someone nearby

who is both familiar with the operation and

hazards of the equipment and competent to

administer first aid. When operators aid the

technician, the technician must warn them

about dangerous areas.

Do not be misled by the term

"low voltage" which may appear in this manual

or on drawings or documents in the Technical

Data Package. Electrical voltages as low as 50

volts can cause death under certain conditions.

Multiple power sources may be

used in the unit. Ensure power is disconnected

from all sources before servicing powered

components.

Do not touch hot system

components. The design reactivation

temperature range is 250–300 °F. The

components of the reactivation system may be

extremely hot during operation. Be absolutely

certain that the unit and/or reactivation

components are cool before attempting to work

on or near them.

Unless otherwise specifically

instructed, do not operate the equipment

without all grilles, guards, louvers and covers

in place and tightly secured. When instructed

to operate without a grille, guard, louver or

cover in place, do so with care.

Blower motors may start

unexpectedly when the unit is running due to

an automatic resetting of the internal overload

device.

Do not allow anyone under the

equipment while it’s suspended from a lifting

device.

Do not allow the unit to swing

while suspended from a lifting device. Failure

to observe this warning may result in injury to

personnel and damage to the equipment.

!

CAUTION

Ensure that the dehumidifier is

properly phased. Improper phasing can cause severe

damage to the equipment.

!

CAUTION

Air intake and discharge openings

must be completely free of obstructions. Ensure

panels are on and properly secured into position.

!

CAUTION

Do not operate the unit without

filters. It is better to operate the unit with dirty filters

than no filters. Operating the unit without filters may

void the warranty.

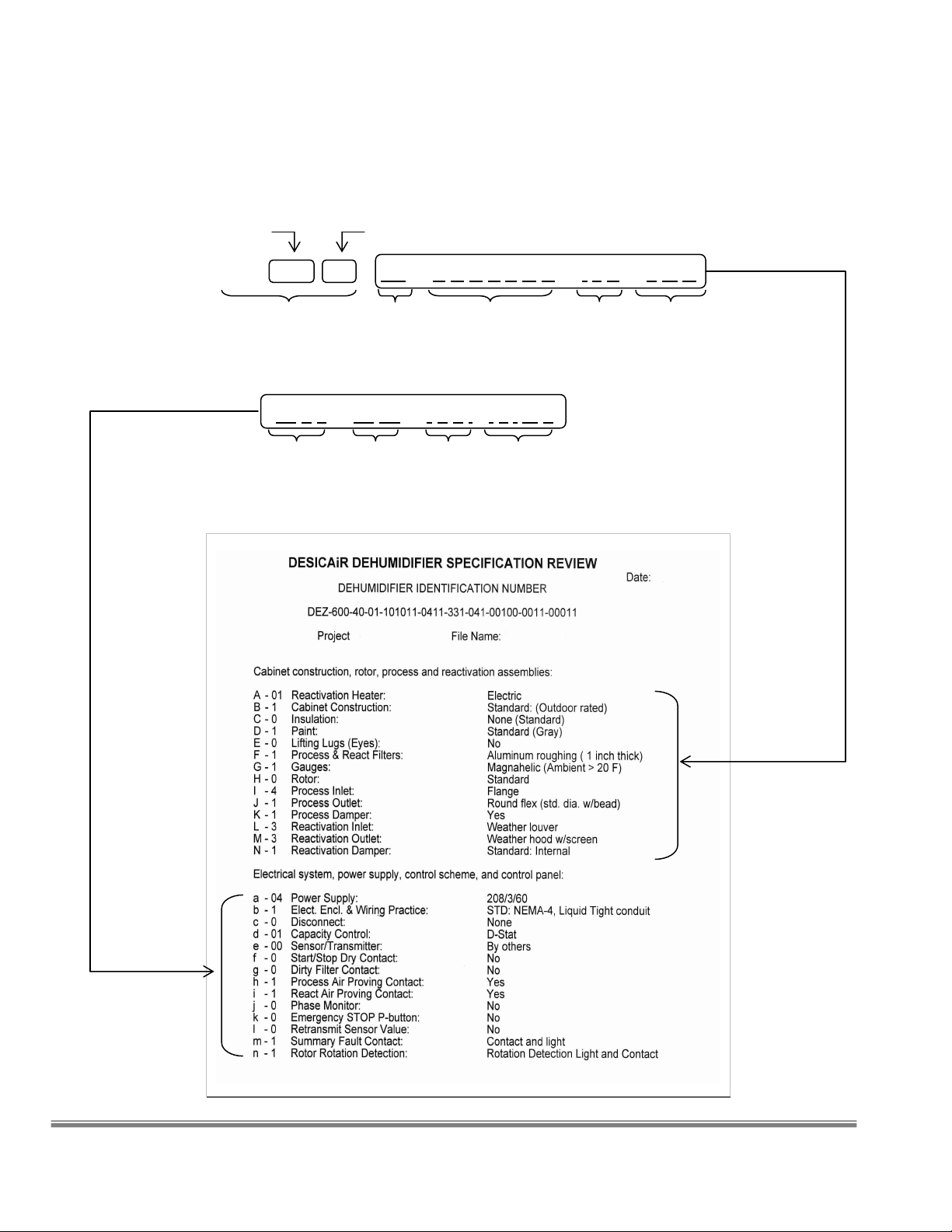

1.4 Theory of Operation

The DEZ Series 1000 dehumidification system is

designed to dehumidify a space to a level below that

attainable with a refrigeration-based dehumidification

system. Moisture is removed from the air by being

passed through a desiccant wheel (called the “rotor”)

that is impregnated with a dry desiccant. Process air

(the air being dehumidified) is filtered, dehumidified

and supplied to a conditioned space at a lower relative

humidity and a slightly higher dry bulb temperature

than its inlet condition.

Simultaneously, a second airstream (reactivation air)

is filtered and heated by a reactivation heater system,

then passed through a separate segment of the rotor.

This heated reactivation air removes the previously

adsorbed moisture from the desiccant rotor and

exhausts it to an area other than that being

conditioned. During operation, the desiccant rotor

rotates through the process and reactivation

airstreams of the dehumidifier at a constant speed.

The two airstreams are separated by face and

peripheral seals and by internal fluting in the desiccant

rotor. Process and reactivation airstreams are

counter-flow to maximize the efficiency of the

adsorption process and to help prevent the rotor's

flutes from fouling.

The reactivation heater is sized to raise the

temperature of the reactivation air entering the

desiccant rotor approximately 180 ºF above ambient

(depending upon moisture adsorbed from the process

air and reactivation airflows). The energy from the

heated reactivation air is used to desorb the moisture.

Reactivation discharge air temperature will vary and

can be as high as 150 ºF and moist. Controls are

included in the unit to vary reactivation heat based

upon the amount of moisture adsorbed from the

process airstream.