DRY Series 500 Installation, Operation and Maintenance Manual

6 (April 2017)

2.0 INSTALLATION

2.1 Receipt of the Unit

Upon receiving the DESICAiR desiccant

dehumidification unit, immediately inspect the

unit for damage which may have occurred

during shipment. Carefully remove the shipping

cover and protective packaging. Remove the top

access panel. If any damage is found, report it to

the carrier immediately. Any obvious damage

incurred during shipping must be noted on

the freight carrier’s delivery forms BEFORE

signing for the equipment. Freight claims

must be done through the freight carrier.

Generally, all equipment ships “F.O.B. Factory”.

STULZ can assist in the claim filing process with

the freight company.

Remove any loose parts, and check the

equipment against the packing list to see if the

shipment is complete. Report all discrepancies

to the appropriate authority.

2.2 System Location and Clearance

The dehumidifier is designed to be operated in a

level position. Choose a location convenient to

the area to be dehumidified. Allow enough room

around the dehumidification system to access

controls, gauges, dampers, stowage area, etc.

Recommended minimum clearances on all sides

of the unit are 1x the full width of the cabinet.

The reactivation discharge air

can be very warm and humid. Keep items that

may be damaged by excessive heat and

humidity away from the reactivation air outlet.

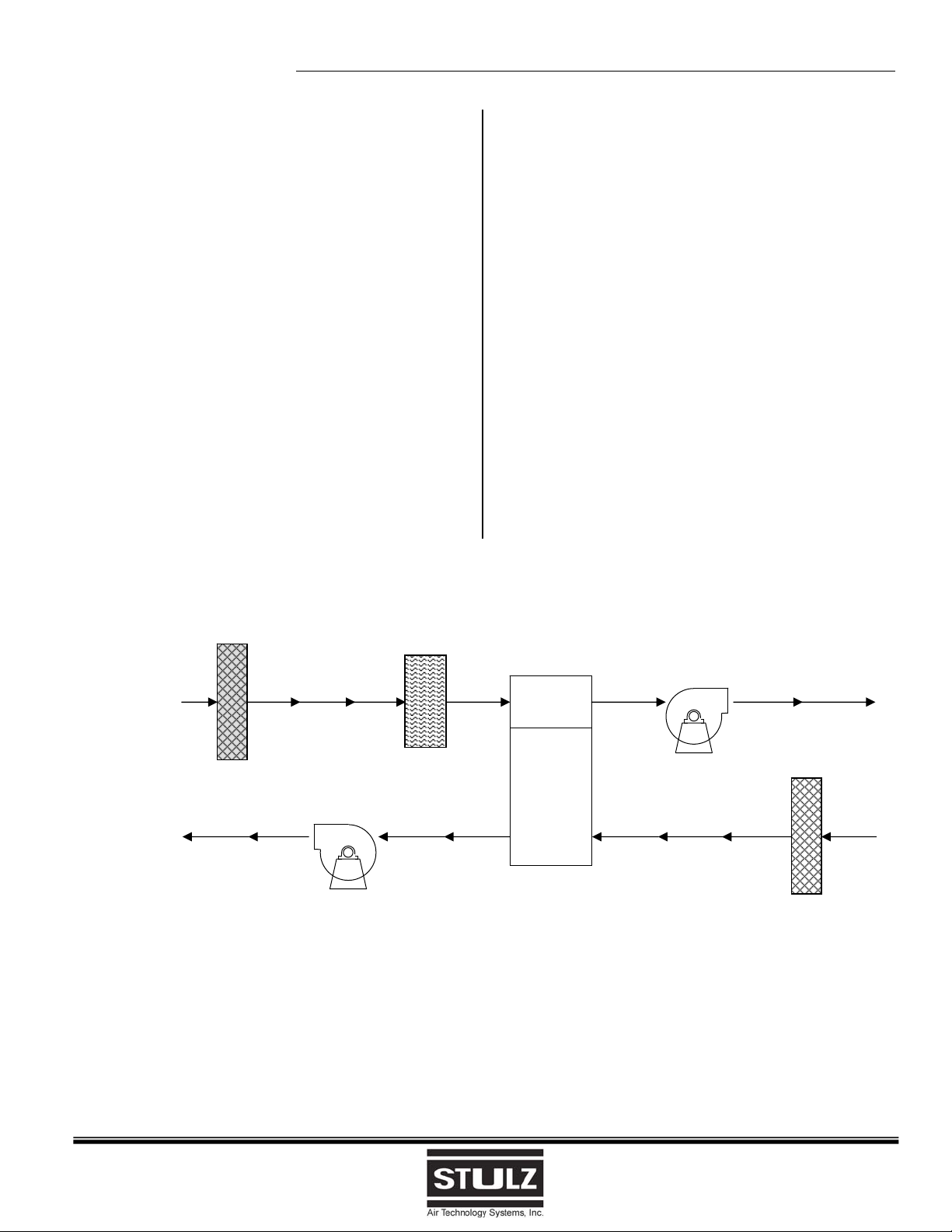

The “process” and “reactivation” inlet and outlet

openings are located on the ends of the unit as

shown on the Installation drawing.

To judge the clearance requirements, consider

that all the components are housed inside the

DESICAiR dehumidifier cabinet. The rotor is

typically the largest of the components that may

need removal. Blower assemblies, while

somewhat smaller, also require sufficient

clearance for removal.

Position the unit in the desired location. Make

sure the mounting surface is able to support the

weight of the equipment and keep it level. The

following general requirements should also be

considered:

1) The power source should be located as near

as possible to the installed location of the

equipment.

2) The power source wiring should include a

main power disconnect switch. If the unit is

purchased from STULZ without an optional

power disconnect switch, one should be

provided by the installer. Provisions should

be made to ensure power is not accidentally

disconnected during normal operation and

the main disconnect switch is not used

instead of the mode selector switch to turn

the system off for normal shut-down.

3) If possible, avoid locations where the air

intakes will be laden with dust, dirt, soot,

smoke, or other debris.

4) DO NOT operate the unit in or near

flammable or corrosive environments or

allow flammable or corrosive air into the unit.

5) Refer to the wiring diagram provided with

your unit for the proper electrical

connections.

2.3 Connecting Ductwork

Ducting should be sized for the appropriate air

quantity and pressure drop. The clearance

required for the duct connections depends on

whether the unit is to be ducted for process air,

reactivation air, or both.

When installing a unit outside the conditioned

space, the process inlet and outlet must be

ducted to and from the conditioned space to

prevent humid air from entering the process air

stream.

The reactivation air temperature at the outlet will

be warm (approximately 130º F) and humid.

When installing a unit in the conditioned space,

the reactivation inlet and outlet must be ducted

to and from another area to prevent the warm,

moist air from being returned to the conditioned

space. If duct work is connected to the

reactivation outlet, it should be insulated and

sloped down and away from the unit. This will

prevent condensed moisture from accumulating

at the reactivation outlet.

Refer to the Installation drawing provided with

your unit for the duct connection sizes and

locations.