TCV e2 User Manual 2 of 36 P/N 857414 Rev A

07/01/2020

Table of Contents

Quick Start Guide..........................................................................................................................................4

Overview.......................................................................................................................................................5

Warnings...................................................................................................................................................5

Cautions ....................................................................................................................................................5

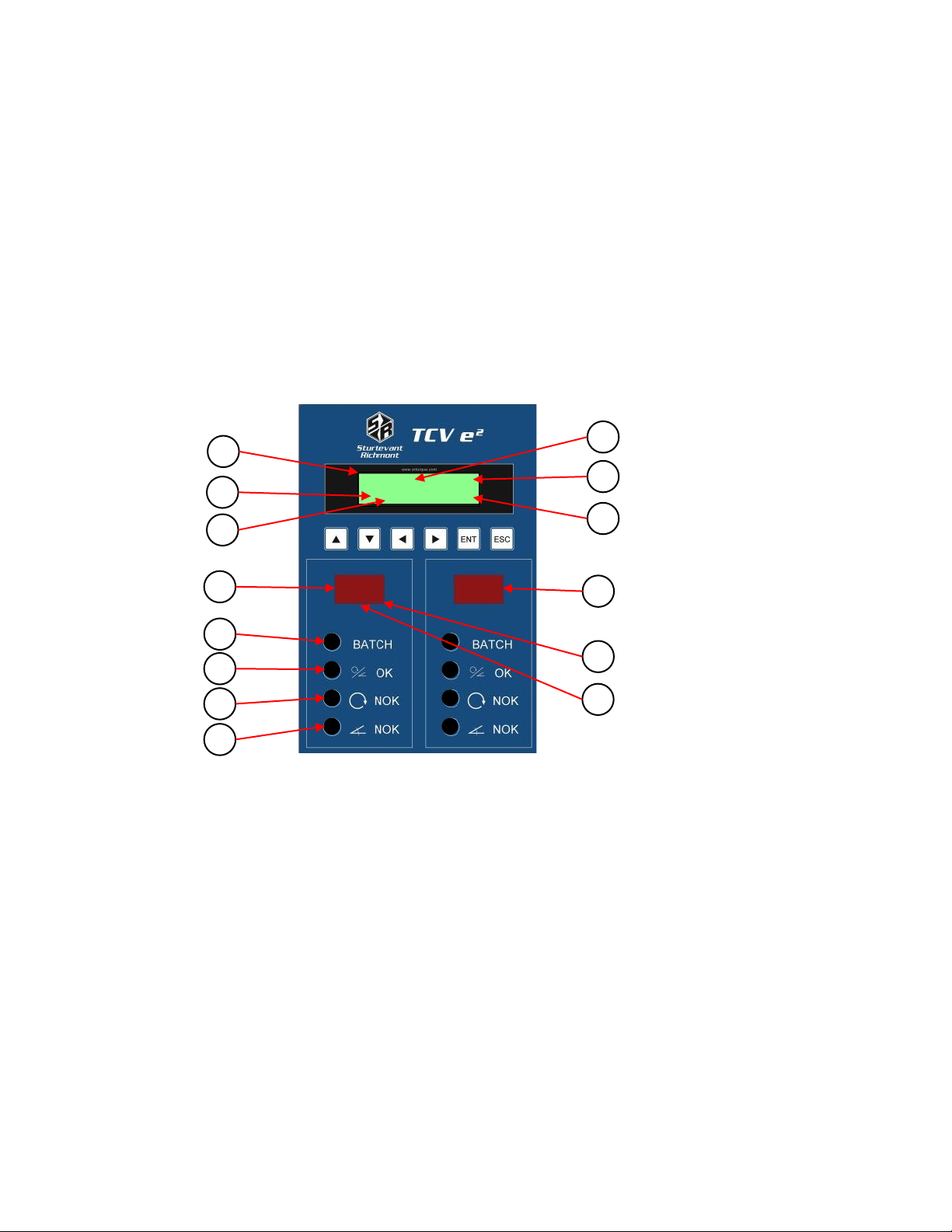

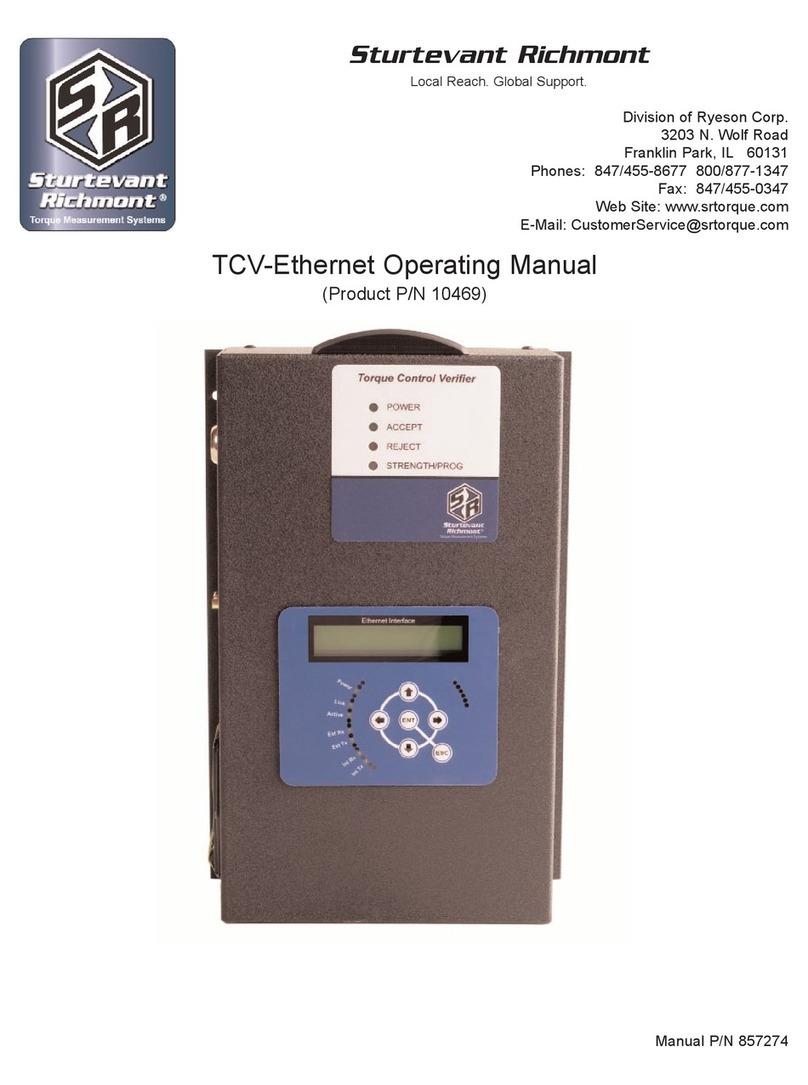

Unit Overview ...........................................................................................................................................5

Compatible Tools ......................................................................................................................................5

Using The Unit...............................................................................................................................................6

Concepts ...................................................................................................................................................6

Run Screen ................................................................................................................................................6

Configuring The Unit.....................................................................................................................................8

Tool Info Group.........................................................................................................................................8

Common Fields .....................................................................................................................................8

TAC Fields..............................................................................................................................................9

Click Tool Fields...................................................................................................................................10

Status Info Group....................................................................................................................................12

Network Connection Info Group.............................................................................................................12

IP Info Group...........................................................................................................................................12

Open Protocol.............................................................................................................................................14

ToolsNet......................................................................................................................................................16

PFCS Setup ..................................................................................................................................................18

EtherNet/IP™ ..............................................................................................................................................20

Studio 5000 Add-On Instructions............................................................................................................20

Connection Points...................................................................................................................................20

Output (O->T) Connection Points .......................................................................................................20

Input (T->O) Connection Points ..............................................................................................................21

Input Connection Points for Last Tightening Data..............................................................................21

Input Connection Points for Current Operation Status ......................................................................23

TCVe2 Setup in Studio 5000....................................................................................................................24

Importing the EDS file.........................................................................................................................24

Project Setup.......................................................................................................................................27

Discrete I/O.................................................................................................................................................30