Simco-Ion IQ Power User manual

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

IQ PowerTM

Control Station

with Sensor Technology

INSTALLATION AND OPERATING INSTRUCTIONS

i

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

TABLE OF CONTENTS

1. SAFETY WARNINGS .......................................................................... 1

2. DESCRIPTION .................................................................................. 3

3. SPECIFICATIONS ............................................................................... 4

4. INSTALLATION ................................................................................. 5

Mounting...............................................................................................................................5

Display Configuration ..........................................................................................................6

System Configuration...........................................................................................................6

Electrical Connections........................................................................................................17

Address / Device Number ..................................................................................................24

Set Up .................................................................................................................................27

5. OPERATION ....................................................................................28

6. MAINTENANCE ...............................................................................33

Cleaning the Control Station ..............................................................................................33

7. TROUBLESHOOTING..........................................................................34

8. PARTS AND ACCESSORIES.................................................................. 35

9. WARRANTY AND SERVICE ..................................................................37

1

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

1. SAFETY WARNINGS

PLEASE READ INSTRUCTIONS COMPLETELY BEFORE STARTING

INSTALLATION

ALL INSTALLATION AND TROUBLESHOOTING OPERATIONS MUST

BE PERFORMED BY QUALIFIED TECHNICAL PERSONNEL

This instruction manual uses symbols to identify dangerous situations as follows:

NOTE – Statements identified with NOTE indicate precautions necessary

to avoid potential equipment failure.

CAUTION – Statements identified with CAUTION indicate potential

safety hazards.

ATTENTION – Les déclarations identifiées avec ATTENTION indiquent

des dangers potentiels pour la sécurité.

WARNING – Statements identified with WARNING indicate potential

serious injury hazards.

AVERTISSEMENT – Les déclarations identifiées avec AVERTISSEMENT

indiquent un risque de blessures graves.

NOTE – This equipment must be correctly installed and properly

maintained. Adhere to the following notes for safe installation and operation:

1. Read instruction manual before installing or operating equipment.

2. Only qualified service personnel are to perform installation and repairs.

3. All equipment must be properly grounded, including the machine frame to

which the equipment is mounted.

4. Turn off input power to unit before connecting or disconnecting other

equipment.

5. Do not operate system in close proximity to flammable liquids.

6. Do not use standard Ethernet cables with IQ Power Systems.

2

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

CAUTION – Electrical Shock Hazard

Disconnect input power to high voltage power supply before connecting

or disconnecting static neutralizing bar or performing any maintenance to

the system. Avoid touching static neutralizing bar when power supply is

energized.

ATTENTION – Risque De Choc Électrique

Couper l’alimentation à l’alimentation électrique de haute tension avant de

brancher ou de débrancher la barre de neutralisation statique ou d’effectuer

un entretien au système. Évitez de toucher la barre de neutralisation statique

lorsque l’alimentation électrique est sous tension.

WARNING – Fire Hazard

Risk of explosion if battery is replaced by an incorrect type. Dispose of used

batteries according to instructions.

AVERTISSEMENT – Risque d’incendie

Risque d’explosion si la batterie est remplacée par un type incorrect. Jetez les

piles usagées conformément aux instructions.

3

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

2. DESCRIPTION

Simco-Ion’s IQ Power Control Station provides a power and communication hub

for IQ Power and IQ Easy devices.

The Control Station features a universal line voltage input and will operate on 100

to 240 VAC, 50/60 Hz. It can provide power & communication for up to ten

IQ Power or IQ Easy static neutralizing devices. The Control Station also allows

Warning / Fault relay output connections, a Standby (STBY) input connector,

Ethernet and a USB connector.

The display on the Control Station is a full color, backlit LCD with integrated touch

screen. This interface allows monitoring and control of the IQ Power / IQ Easy

static eliminating system. The control features four different operating modes for

static eliminators; fixed, manual, Auto-Tune and CLFB (Closed Loop Feed Back).

Along with providing a convenient user interface, the Control Station allows for data

logging of the system.

The Control Station also features a Fieldbus Interface that provides for a

factory installed module that provides network connectivity. A variety of fieldbus

communication protocols are available, such as EtherNet/IP, PROFIBUS DP-V1,

PROFINET IO, Modbus RTU, Modbus TCP, DeviceNet and ControlNet by use

of an HMS Industrial Network Anybus Module.

IQ Power system components, such as the BPS, HL, and HLC use 8-conductor

modular cable and RJ-45 connectors for connection. IQ Power devices are typically

supplied with a 7 foot modular cable assembly. Components, such as the IQ Easy

Static Bar, IQ Easy Sensor Bar, and IQ Power MPS use 5-conductor cable with

M12 connectors for connection. Cables are available by calling Simco-Ion customer

service (800) 203-3419 (refer to Section 8, Parts and Accessories).

4

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

3. SPECIFICATIONS

Input Power 100-240V~ 50/60 Hz, 4A max (IEC 320 inlet)

Output Voltage 24 VDC (all IQ Power and IQ Easy connectors)

Device Port USB-A

Network Port Ethernet

Interface 10.2”ColorTFT LCD (backlit) with resistive touch screen

Operating Temp 39°C [102°F] max

Mounting Slots M6 or M5 [1/4”or #10] hardware (not included)

Enclosure Steel, blue epoxy powder coated

Dimensions 197L x 314W x 118H mm [7.75”L x 12.38”W x 4.65”H]

Weight 5.2 kg [11.4 lb]

5

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

4. INSTALLATION

NOTE – DO NOT USE standard Ethernet cables with IQ Power systems.

Avoid permanent equipment damage by using only Simco-Ion modular

cables. (Refer to Section 8, Parts and Accessories).

Figure 1. IQ Power Crossover Modular Cable (black)

Mounting

Install the Control Station at a convenient place that keeps total overall cable length

to a minimum.

The black modular cable supplied with unit to connect the Control Station to an IQ

Power device is 2.13 meter [7 foot] long, however longer cables (not supplied) are

available. Cables must be 8-conductor modular cables with RJ-45 connectors wired

“crossover” (reference color: black, Figure 1).

Cables used to connect IQ Easy Static Bar, Sensor Bar or IQ Power MPS are

available in a variety of standard lengths with straight M12 connectors at the Control

Station end and with a straight or right angle M12 connector at the device end.

Secure Control Station to the mounting surface using M6 or M5 [1/4” or #10]

hardware (not included).

A small stylus and self-adhesive mounting clip are included with the unit. Remove

the protective backing from the mounting clip and place it adjacent to, or on the

side of, the Control Station.

6

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

Display Configuration

CAUTION – Electrical Shock Hazard

Disconnect input power before opening unit. Do not connect input power

with unit open.

ATTENTION – Risque De Choc Électrique

Mettre hors tension avant l’ouverture de l’unité. Ne rebranchez pas avec

l’unité ouverte.

The Control Station may be reconfigured, placing the connector panel at the “top”

of the unit, if desired (factory configuration is with the connector panel at the

“bottom” of the unit). To reconfigure the unit, remove line cord from power inlet

connector. Remove screws from sides of unit. Lift cover off of unit. The interface

display rests on brackets built into the case. Carefully lift the interface display just

off unit and rotate 180˚, use care not to stress the electrical cables. Place interface

display back onto brackets built into case. Check that no cables are pinched by

looking through gaps at top and bottom of unit. Move cables if necessary. Replace

cover and secure with screws on sides.

System Configuration

The Control Station and related IQ Power / IQ Easy devices can be configured in

a variety of ways. The range of static neutralizing and sensing equipment available

allow for flexibility in meeting application requirements. When a static neutralizing

device is paired with a static sensing device, the pair is considered a single device.

The following figures each illustrate a fundamental configuration with specific

equipment. Fundamental configurations may be combined on a system to meet the

particular needs of the application.

7

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

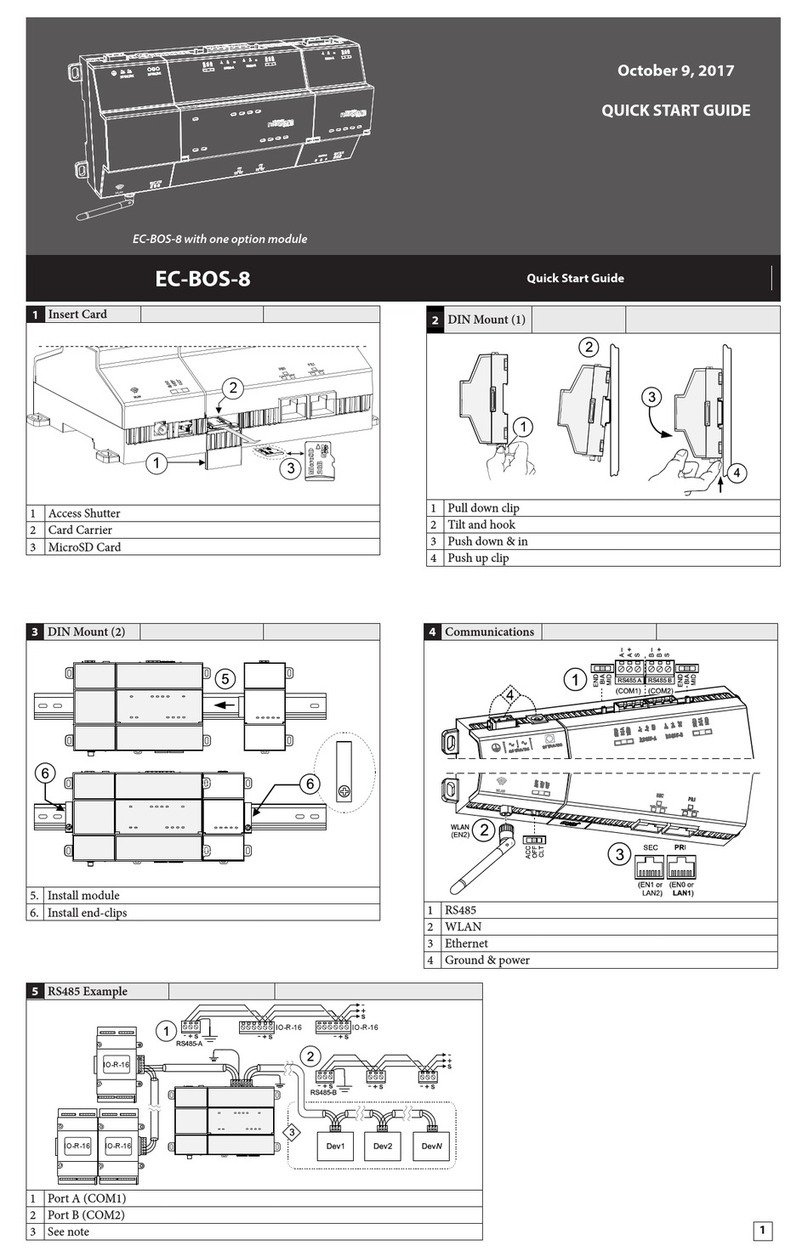

Figure 2. IQ Power Connections (Control Station 1 thru 10 to BPS Power Supply and Bar)

8

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

Figure 3. IQ Power Connections (Control Station to MPS Power Supply)

9

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

Figure 4. IQ Power Connections (Control Station to BPS Power Supply with Options)

10

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

Figure 5. IQ Power Connections (Control Station to IQ Easy Sensor and Neutralizing Bar)

11

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

Figure 6. IQ Power Connections (Control Station to HL Sensor Interface)

12

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

to PS COMM 2

Connection

to PS COMM 1

Connection

Comm / Data Cable Construction

1Crossover Wired Reference color black

Ground

Lead

Comm / Power (black)

1

IQ Power

HL Power Supply

NOTE:

HL Power Supply

and HL Sensor Interface

both report to CS under

HL Power Supply address.

Intrinsic Safety Barriers

see Control Drawing

5150010

IQ Power HL

Sensor Interface

to SI COMM 1

Connection

IQ Power HL Power Supply

with IQ Power HL Sensor

typically used for

CLFB mode

Comm / Power (black)

1

to Sensor Port

Connection

to

HV1 or HV2

IQ Power HL Sensor Cable

(part of Sensor)

IQ Power

HL Sensor

Ground Jumper

Machine Frame Ground

To Clean, Dry

Compressed Air Source

if Purge Required

Conduit and

Conduit Seals

see Control Drawing

5150003

Ground Jumper

Machine Frame Ground

Grounding Clamp

IQ Power HL Static Bar

Web Direction of Travel

Minimum 12" Downstream

IQ Power Control Station

to IQ Power device

to IQ Easy device

to CS 1 thru 10

POWER & COMM

DO NOT USE standard Ethernet cables.

See Section 8 Parts and Accessories for available cable lengths and part numbers.

Figure 7. IQ Power Connections (Control Station to HL Power Supply with Sensor Interface)

13

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

WARNING:

Substitution of components may

impair intrinsic safety.

AVERTISSEMENT:

La substitution de composants peut

compremettre la securite intrinseque.

Referto

Manual

IQ Power HL Static Bar

IQ Power

HLC Power Supply

Comm / Data Cable Construction

1Crossover Wired Reference color black

DO NOT USE standard Ethernet cables

to POWER & COMM

Connection

Comm / Power (black)

1

Conduit and

Conduit Seals

see Control Drawing

5150004 or 5150005

to

HV1 or HV2

to PS COMM 1

Connection

Grounding

Clamp Ground

Jumper

Machine

Frame

Ground

HV1 HV2

IQ Power

HLC Power Supply

(Interior View)

PS COMM 1

(2 Places)

to RDM COMM 2

Connection

to RDM COMM 1

Connection

Ground

Lead

with

IQ Power

RDM

Comm / Power (black)

1

IQ Power Control Station

to IQ Power device

to IQ Easy device

Figure 8. IQ Power Connections (Control Station to HLC Power Supply)

14

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

WARNING:

Substitution of components may

impair intrinsic safety.

AVERTISSEMENT:

La substitution de composants peut

compremettre la securite intrinseque.

Referto

Manual

IQ Power HL Static Bar

Web Direction of Travel

Minimum 12" Downstream

IQ Power

HLC Power Supply

Comm / Data Cable Construction

1Crossover Wired Reference color black

DO NOT USE standard Ethernet cables

to POWER & COMM

Connection

Comm / Power (black)

1

Intrinsic Safety Barriers

see Control Drawing

5150010

IQ Power HL

Sensor Interface

to SI COMM 1

Connections

IQ Power HLC Power Supply

& RDM with

IQ Power HL Sensor

typically used for

CLFB mode

Conduit and

Conduit Seals

see Control Drawing

5150004 or 5150005

to Sensor Port

Connection

IQ Power

HL Sensor

Ground Jumper

Machine Frame Ground

To Clean, Dry

Compressed Air Source

if Purge Required

Machine Frame Ground

to

HV1

or

HV2

to PS COMM 1

Connection

Comm / Power (black)

IQ Power HL Sensor Cable

(part of Sensor)

1

NOTE:

HLC Power Supply

and HL Sensor Interface

both report to CS under

HLC & RDM address.

Grounding

Clamp

Ground

Jumper

Machine

Frame

Ground

to RDM COMM 2

Connection

to RDM COMM 1

Connection

Ground

Lead

with

IQ Power

RDM

Comm / Power (black)

1

IQ Power Control Station

to IQ Power device

to IQ Easy device

Figure 9. IQ Power Connections (Control Station to HLC Power Supply with Sensor Interface)

15

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

Figure 10. IQ Power Connections (Control Station to Fantom Wide Blower)

16

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

Figure 11. IQ Power Connections (Control Station to Fantom with Options)

17

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

Electrical Connections

NOTE – If multiple IQ Power/IQ Easy devices are connected to the Control

Station, each static neutralizer must have a unique address / device number.

Addressing of devices takes place as the first step of the Set Up procedure.

NOTE – The maximum total number of devices plugged into “POWER &

COMM” 1 thru 10 and DEV1 thru DEV6 is 10 devices. A static neutralizer

is always considered one (1) device. When a Sensor Bar or HL Sensor

Interface is paired with a neutralizer, the pair is considered one (1) device. A

Sensor Bar or HL Sensor Interface that is not paired with a static neutralizer

is considered one (1) device. Exceeding 10 devices will cause communication

errors and system failure.

Figure 12. IQ Power Control Station Connectors

A. Connect the IQ Power BPS / HL Power Supplies

The Control Station can supply 24 VDC power for up to ten IQ Power BPS or HL

power supplies. Use the 2.13 meter [7 foot] black modular cable supplied with unit

or a longer cable (not supplied) is available. Cables for the Control Station must

be 8-conductor modular cables with RJ-45 connectors wired “crossover” (reference

color: black, Figure 1.).

When powered from the Control Station, the “Power” switch on the BPS / HL

power supply is not in-circuit, the BPS / HL will energize when the Control Station

power is switched on.

The modular cable plugs into either “PS COMM 1” connector on the BPS or HL

power supply.

18

IQ POWER CONTROL STATION

WITH SENSOR TECHNOLOGY

5201263 Rev D

The other end of the cable plugs into one of the ten connectors numbered 1 thru

10, labeled “POWER & COMM”.

CAUTION – Electrical Shock Hazard

Each power supply requires its own ground lead connection to machine

frame ground.

ATTENTION – Risque De Choc Électrique

Chaque bloc d’alimentation nécessite sa propre connexion de mise à la terre

au châssis de la machine.

If an IQ Easy Sensor Bar is to be used with the BPS (typically in CLFB - Closed

Loop Feed Back) it is required the sensor bar be plugged into connector “PS

COMM 2” of that BPS power supply. This will automatically associate (pair) the

sensor bar with the BPS for CLFB mode.

If an IQ Power HL Sensor is to be used with the HL power supply (typically in

CLFB – Closed Loop Feed Back) it is required the sensor interface (from either

“SI COMM 1” connector) be plugged into connector “PS COMM 2” of that HL

power supply. This will automatically associate (pair) the sensors connected to the

HL power supply for CLFB mode.

See diagram for Control Station to Power Supply with Options Connections.

Modular cables should not be run parallel with the static bar high voltage cable.

Route modular cables clear of moving machine parts and protect them from

abrasion. Secure using nylon wire ties (not included). Do not over-tighten wire tie.

If there is an excess of modular cable, do not coil it in the vicinity of the static bar

high voltage cable. If possible, cut modular cable to length and re-terminate using

an RJ-45 connector installed with the same polarization as connector removed (note

orientation of rib / wire color sequence to modular connector).

B. Connect the IQ Power HLC Power Supplies

Cables for connection must be 8-conductor modular cable with RJ-45 connectors

wired “crossover” (reference color: black, Figure 1).

Plug one end of modular cable into one of the HLC Power Supply “PS COMM

1” jacks. Run cable through rigid metal conduit to either Control Station or Sensor

Interface (if used).

If the system is without Sensor Interface, plug other end of modular cable (from

HLC Power Supply) into one of the “POWER & COMM” jacks on the Control

Station.

If the system is with Sensor Interface, plug other end of modular cable (from

HLC power supply) into one of the connections labeled “SI COMM 1” on Sensor

Interface. The second modular cable plugs in to the other connector labeled “SI

COMM 1” on Sensor Interface and into one of the connectors labeled “POWER &

COMM” on the Control Station.

Other manuals for IQ Power

1

Table of contents

Popular Control System manuals by other brands

Kemper

Kemper KHS Logic Control System Installation and operating instructions

Roger

Roger MCT88M-IO installation manual

Laguna Tools

Laguna Tools CNC Swift Series manual

ETC

ETC Expression Show Control System manual

Midea

Midea V4 Plus S Series instruction manual

Autotrol

Autotrol 460i Operation and maintenance manual