Table of Contents

WINDINGFEEDER - i -

TABLE OF CONTENTS

INTRODUCTION

The ideal solution for yarn preparation machines...................................................................................................I.1

How to use this manual ..............................................................................................................................................I.2

Symbols used ...............................................................................................................................................................I.2

Reference Documentation ..........................................................................................................................................I.2

Chapter 1 - OVERVIEW’

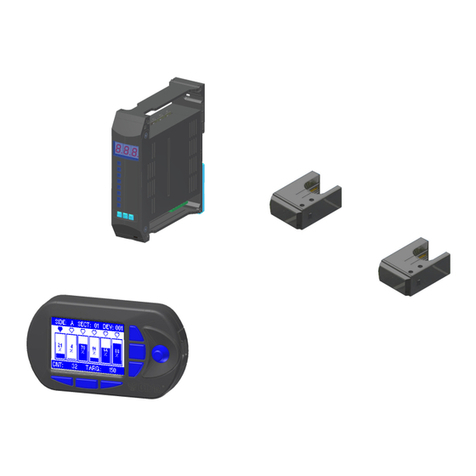

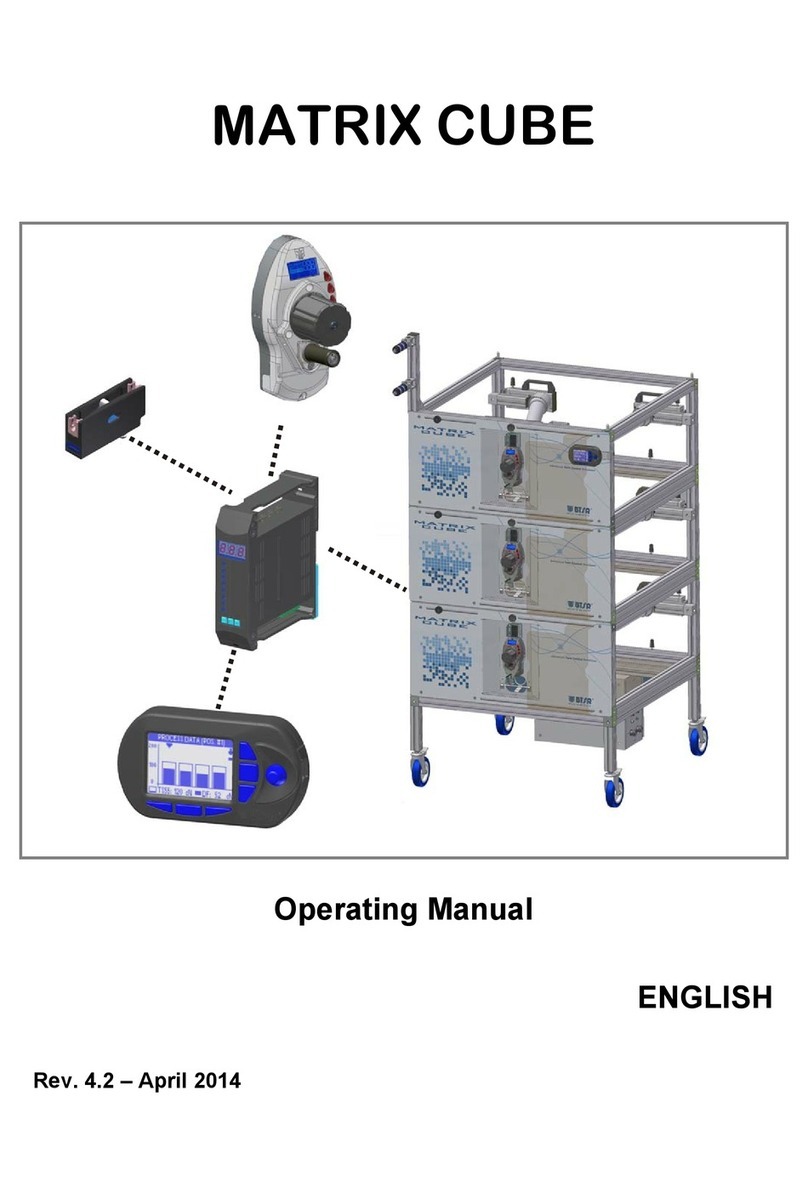

System Components................................................................................................................................................... 1.1

Main Characteristics of WINDINGFEEDER Devices ........................................................................................... 1.1

Advantages obtained by using the WINDINGFEEDER devices........................................................................... 1.3

Advantages obtained by using the SMART MATRIX FEEDER Terminal combined with

WINDINGFEEDER Devices .................................................................................................................................... 1.4

Further Advantages obtained by using a PC or Notebook connected to WINDINGFEEDER devices

via serial line............................................................................................................................................................... 1.5

Chapter 2 – TECHNICAL DATA AND INSTALLATION

Technical Features .................................................................................................................................................. 2.1

Electrical Interface of WINDINGFEEDER Devices............................................................................................... 2.2

SMART MATRIX FEEDER – WINDINGFEEDER Connection......................................................................... 2.3

Input/otput signals function...................................................................................................................................... 2.3

PC – WINDINGFEEDER Connection..................................................................................................................... 2.4

D WINDINGFEEDER overall dimensions (in mm) ............................................................................................... 2.5

Instructions for Correct Yarn Threading................................................................................................................ 2.7

Chapter 3 – OPERATION

Operating Characteristics of WINDINGFEEDER Devices ................................................................................... 3.1

Symbols shown on LCD ............................................................................................................................................ 3.2

Functions Directly Available to the Textile Machine Operator............................................................................. 3.3

1) Alarm Reset......................................................................................................................................................... 3.3

2) Current Yarn Type and Application Reading...................................................................................................... 3.3

3) Exclusion and Re-inclusion of a WINDINGFEEDER Device............................................................................ 3.4

4) Control of Temperature and Current Absorbed by WINDINGFEEDER ............................................................ 3.4

Programming the WINDINGFEEDER Devices ..................................................................................................... 3.5

General Diagram of Simple Programming Environment......................................................................................... 3.5

Advanced Programming of WINDINGFEEDER Devices ..................................................................................... 3.6

General Diagram of P1÷P4 Advanced Programming Levels and Default Settings ................................................ 3.8

P1 Programming Level.............................................................................................................................................. 3.9

P2 Programming Level............................................................................................................................................ 3.12

P3 Programming Level............................................................................................................................................ 3.15

P4 Programming Level............................................................................................................................................ 3.17

Chapter 4 – WINDINGFEEDER TROUBLESHOOTING AND MAINTENANCE

Indications Provided by the Red LEDs on WINDINGFEEDER Device .............................................................. 4.1

Troubleshooting Table .............................................................................................................................................. 4.2

Ordinary Maintenance.............................................................................................................................................. 4.4

Repairs........................................................................................................................................................................ 4.4