Contents and general instructions

IV Festo P.BE-CB-COMP-EN en 1102d

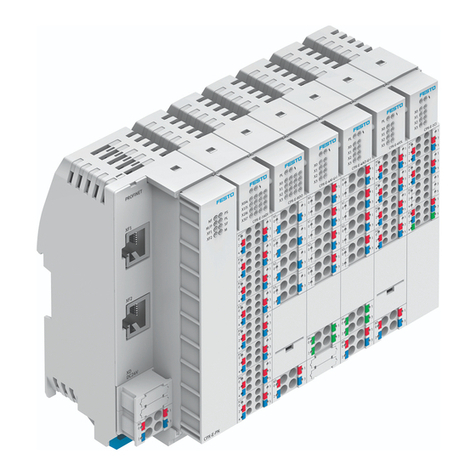

3. The I/O module 3-1................................................

3.1 Interfaces 3-3.....................................................

3.2 ACTUATORS 3-5...................................................

3.3 BUFFER/FEEDER 3-7...............................................

3.4 DIAG 3-10.........................................................

3.5 ENCODER 3-12.....................................................

3.6 PLC 3-14...........................................................

3.6.1 Start/Stop mode 3-17........................................

3.6.2 Controlling the teach procedure 3-19............................

3.6.3 Selecting the parts type 3-19..................................

3.6.4 Counting function 3-23.......................................

3.6.5 Actuators 3-26..............................................

3.6.6 Buffer zone sensors/small parts conveyor 3-27...................

3.6.7 Fault messages 3-30.........................................

3.6.8 Locking the control panel 3-31.................................

4. Teaching parts 4-1.................................................

4.1 Preparing the Teach procedure 4-3....................................

4.2 The Teach procedure 4-5............................................

4.2.1 Positioning the sample parts 4-9..............................

4.2.2 Observing the scatter of characteristics 4-10.....................

5. Testing parts 5-1..................................................

5.1 The test procedure 5-3..............................................

5.2 Test mode 5-4.....................................................

5.3 Influence of tolerance 5-7...........................................

5.4 Evaluation of the test results 5-9......................................

5.4.1 Checking the features 5-9....................................

5.4.2 Checking the orientation 5-10..................................

6. Maintenance 6-1..................................................