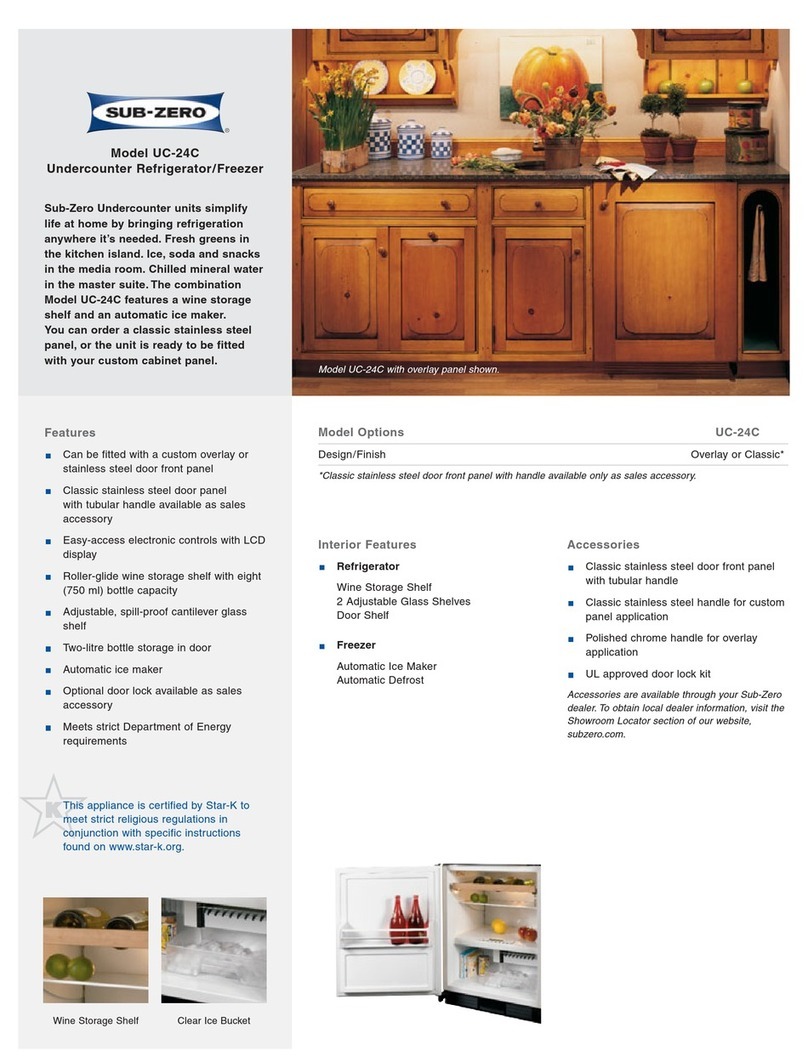

Sub-Zero Integrated Refrigeration

The importance of the installation of the Sub-Zero

integrated unit cannot be overemphasized. Installation

should be done by a qualified installer.

Before you begin the installation process, it is recom-

mended that you read this entire installation guide. There

are key details that you should take special care to

observe during the installation. By reading these instruc-

tions carefully, you will make the installation process

easier, problem-free and most importantly, safe.

Any questions or problems regarding the installation

should be directed to your authorized Sub-Zero dealer or

Sub-Zero customer care at 800-222-7820. You may also

check the contact & support sectionofour website,

subzero.com.

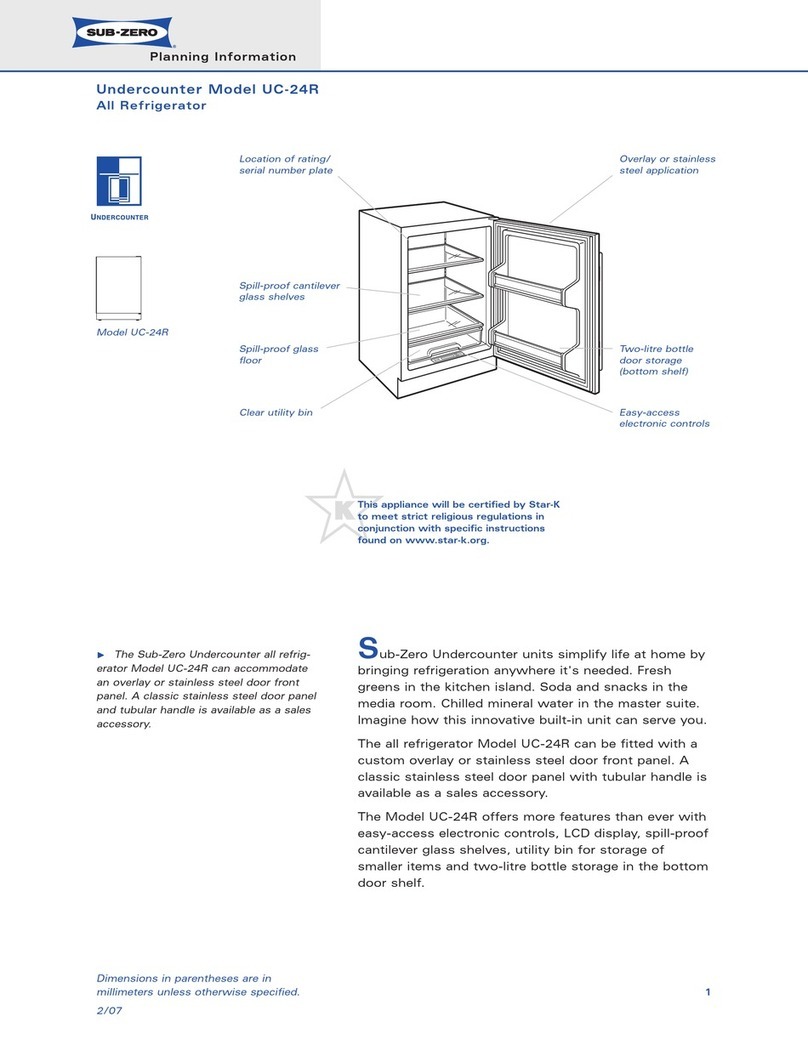

Important product information, including the model and

serial number of your unit are listed on the product rating

plate. For column models, the rating plate is located inside

the top drawer near the drawer guide opposite the hinge.

For tall and drawer models, the rating plate is located

inside the cabinet, to the left of the upper drawer. Refer to

the illustrations below.

Integrated Refrigeration 3

subzero.com/specs

Before You Start

Make sure the opening dimensions, door and drawer

clearances, electrical service and plumbing are correct for

the model you are about to install. Refer to specifications

on the following pages.

IMPORTA T OTE: The inside edges of the rough

opening, as well as the sides and a portion of the

backside of the decorative panels will need to be finished,

as they will be exposed when the doors are open.

TOOLS A D MATERIALS REQUIRED

•Appliance dolly able to support 500 lbs (227 kg) and

adequate manpower to handle the weight of the unit.

•Phillips and slotted screwdrivers.

•Allen, standard and crescent wrenches.

•Various sized pliers.

•5/16" hex bolt nut driver.

•Cordless drill and assorted drill bits.

•Level—2' (.6 m) and 4' (1.2 m) recommended.

•4' (1.2 m) of 1/4" copper, braided stainless steel or

PEX tubing and saddle valve for water line (do not use

self-piercing valves).

•Tubing cutter.

•Masonite, plywood, pressed fiberboard, cardboard or

other suitable material to protect finished flooring.

•Appropriate materials to cover and protect the home

and furnishings during installation.

Tall and drawer models.Column models.

RATING PLATE

RATING PLATE