8. If X - Y is less than 21”, then an opening 9 5/8” x 9 3/8” must be cut through

the inner wall only. DO NOT CUT THROUGH COACH SKIN. (See Figure

2.) Next, locate the center line of the exhaust and intake tube. Cut two 2 1/4”

diameter holes through the outer skin as shown in Figure 4.

NOTE: Whenever the furnace cabinet is installed through the outside wall, the

return air louvers on the furnace cabinet must not be blocked. The maximum

projection of the furnace cabinet into the wall is 2 1/2”. (See Figure 2.)

NOTE: Furnace cabinet approved for 0” clearance to combustible materials rear

2 1/2” of furnace cabinet.

9. If X - Y is 21” or greater, two methods may be used to install the furnace.

a. Cut a 4” x 7 1/2” opening through combustible wall as shown in Figure 3.

DO NOT CUT THROUGH TRAILER SKIN. Next, locate the center line of

the exhaust and intake tube. Cut two 2 1/4” diameter holes through trailer

skin. (See Figure 4.)

b. If you do not wish to cut the 4” x 7 1/2” opening, locate the center line of

the exhaust and intake tube as shown in Figure 4. Next, cut two 2 3/4”

diameter holes through trailer skin and also the combustible wall of the

trailer as illustrated in Figure 6. Care must be taken when locating the

center line of the exhaust and intake tube as well as when cutting the holes

in order to assure a 3/8” clearance around the exhaust and intake tube to

combustible materials.

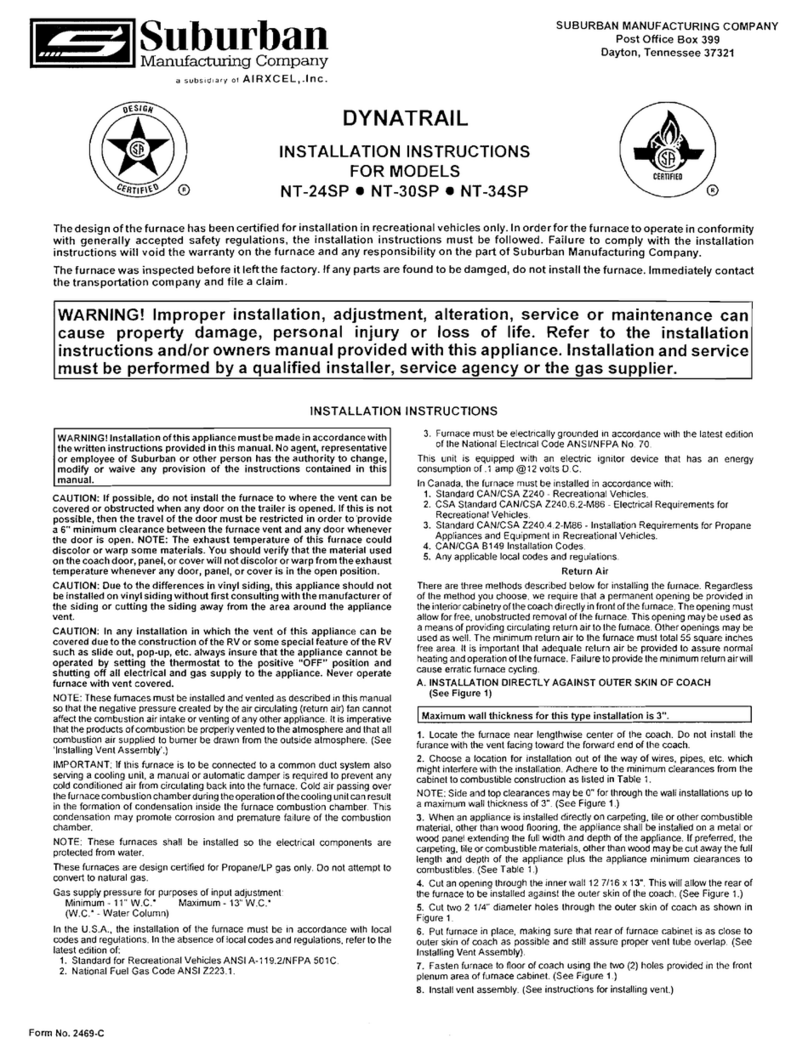

10. Refer to the chart in Figure 1 and select the range for which the ‘X’ dimension

falls. The intake tube length directly to the left of the selected range is

the length required. NOTE: The 7 3/4” length exhaust tube assembly will

accommodate all approved installation depths - only the intake tube must be

ordered when needed. Under no circumstances should the standard 5” intake

tube be cut or altered to adapt to the 21” - 23 1/4” range.

11. Secure furnace to the oor using the two holes provided in furnace cabinet.

(See Figure 2 or Figure 3.)

12. NOTE: OPTIONAL DISCHARGE DUCT ADAPTER -The cabinet has a 4”

diameter knockout on the left side of cabinet. (See Figure 6A.) A 4” diameter

connector can be attached to this location to provide a warm air discharge

duct. (Not to exceed 10” in length.)

CONNECTING GAS SUPPLY

A 3/8” are connection is provided on the right side of the furnace for the gas supply

connection to the furnace.

Connect the gas supply to the furnace at the manifold, following the suggestions

outlined below. It will be necessary to hold the are tting on the furnace manifold

when connecting or loosening gas lines.

NOTE: Be sure all male joints have been treated with a sealing compound

resistant to the action of liqueed petroleum (LP) gas.

In order to maintain a check on gas supply pressure to the furnace. Suburban

advises the installer to provide a 1/8” NPT plug tap for test gauge connection

immediately upstream of the gas supply connection to the furnace.

NOTE: The appliance must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressure in excess of 1/2 PSIG.

The appliance must be isolated from the gas supply piping during any pressure

testing of the gas supply piping system at test pressure equal to or less than 1/2 PSIG.

WARNING! All joints must be checked for leaks. Do not use open ame to check for

leaks! Use a soap and water solution.

CONNECTING ELECTRICAL SUPPLY

CAUTION: These furnaces are designed for a negative ground 12 volt

D.C. system only. Do not attempt to alter the furnace for a positive ground

system or connect the furnace directly to 115 volts A.C. Damage to furnace

component parts will occur. Connect only to a protected circuit fused for

not more than 7.5 amps.

Be sure all wiring to the furnace is of heavy enough gauge to keep the voltage

drop through it to a minimum and to provide enough power for start-up surge. No.

12 gauge wire is recommended.

If any of the original wire that is supplied with the appliance must be replaced, it

must be replaced with Type 105° C or its equivalent.

Connect the power supply to the red and yellow wires on the right side of the

furnace. The wires are color coded, red for positive (+) and yellow for negative

(-). This polarity must be observed so the furnace motor will run with the proper

direction of rotation to insure correct air delivery. (See wiring diagram.)

If the furnace power supply is to be from a convertor, we recommend that the

convertor system used to power the furnace be wired in parallel with the battery.

This will serve two purposes:

1. Provide a constant voltage supply to the furnace.

2. Filter any A.C. spikes or volt surges.

NOTE: Furnace models NT-16SEQ AND NT-20SEQ are equipped with an electric

ignitor device that has an energy consumption of.1 amps at 12 volts D.C.

CONNECTING THERMOSTAT

The thermostat used with this unit must have NO voltage output to return leg when

there is not a call for heat or in the “OFF” setting.

Locate the room thermostat approximately 4-1/2 feet above the oor on an inside

bulkhead where it is not affected by heat from any source except room air. Connect

thermostat wiring to the blue wire and blue-white striped wire (blue-white striped

wire is power to the thermostat) on right side of furnace. (See wiring diagram.) If

your furnace is equipped with a thermostat that has an adjustable anticipator, the

anticipator should be set at .7 amps. If you desire longer heating cycles, adjust

the anticipator to a higher setting. If you desire shorter heating cycles, adjust the

anticipator to a lower setting. Adjustments to the anticipator setting should be

made in .5 amp increments.

INSTALLING VENT ASSEMBLY

The vent outlet must be installed so it is in the same atmospheric pressure zone

as the combustion air intake. The exhaust and intake tubes must be installed

from the outside, pass through the RV skin and slide onto the furnace exhaust

and intake.

WARNING! Do not alter the vent assembly supplied with this furnace. Any modications

will result in improper installation which could cause unsafe furnace operation. Never

operate furnace with vent covered.

CAUTION! Combustion air must not be drawn from the living area. All air for

combustion must be drawn from the outside atmosphere. All exhaust gases

must be vented to the outside atmosphere - never inside the RV. Therefore,

it is essential to insure that the vent cap and tube assemblies are properly

installed.

1. Apply caulking to RV skin behind vent cap as shown in Figure 6. Apply

caulking generously around perimeter of vent cap and across center as

shown.

2. Insert intake tube through RV skin and slide it onto the furnace intake (See

Figure 1.) Minimum tube overlap of 1/2” is required.

3. Insert vent cap exhaust tube through RV skin and slide it onto the furnace

exhaust (See Figure 1.) Minimum tube overlap of 1 1/4” is required.

4. Attach vent cap assembly to outer skin of RV with the six (6) screws provided.

Do not install vent assembly upside down. The word “Suburban” must be right

side up.

Due to high temperatures, the unit should be located out of trafc and

away from furniture and draperies.

Children and adults should be alerted to the hazards of high surface

temperatures and should stay away to avoid burns or clothing ignition.

Young children should be carefully supervised when they are in the same

room as the unit.

Clothing or other ammable material should not be placed on or near

the unit.

Any safety screen or guard removed for servicing the unit must be

replaced prior to operating the unit.

The area around the unit must be kept clear from combustible materials,

gasoline and other ammable vapors and liquids.

Installation and repairs should be done by a qualied service person. The

unit should be inspected before use and at least annually by a qualied

service person. More frequent cleaning may be required due to excessive

lint from carpeting, bedding material, etc. It is imperative that control

compartments, burners, and circulating air passageways of the unit be

kept clean.

PARTS AND SERVICE

Contact a conveniently located recommended Suburban Service Center.

Describe to them the nature of your problem, make an appointment, if necessary,

and provide for delivery of your RV with the appliance installed.

To obtain information on locating a local service agency, contact:

AIRXCEL, Inc., - Suburban Division

Customer Service Department

676 Broadway Street

Dayton, TN 37321

(423) 775-2131 Ext. 7101

www.Airxcel.com

VENT TUBE (INTAKE) SEE CHART

MOUNTING SURFACE

VENT TUBE (EXHAUST) 8" X 2" O.D.

2" O.D. X 2 3/4" SPECIAL

2" O.D. X 5" *STANDARD

2' O.D. X 7 1/4" SPECIAL

INTAKE TUBE LENGTH ONLY

STANDARD TUBE FURNISHED WITH FURNACE.

THE SPECIAL TUBES, IF NEEDED, MUST

PART NO.

NEVER INSTALL VENT TUBES

ON INTAKE & 1 1/4" ON EXHAUST

WITH LESS THAN 1/2" OVERLAP

X050708

X050711

X050712

1 1/4" MIN. OVERLAP

"X"

"X" DIMENSION

25 1/2" TO 27 3/4"

21" TO 23 1/4"

23 1/4" TO 25 1/2"

TRAILOR SKIN

2 1/4"

VENT CAP

1/2" MIN. OVERLAP

DIA.

2 1/4"

Y"

7 1/2" DIA.

21" OF INTAKE TUBE

ON EXHAUST

Figure 1

2