Succeeder SF-8100 User manual

1

Beijing SUCCEEDER Technology Development Co., Ltd.

SF-8100 Automated Coagulation Analyzer

2

1. Table of Contents

1. Table of Contents................................................................................................................................2

2. Warnings and Cautions ...................................................................................................................5

2.1. General Warnings...........................................................................................................................5

2.2. Safety of Login ..............................................................................................................................5

2.3. Warning before use ........................................................................................................................5

2.4. Quality Commitment .....................................................................................................................6

3. Circuit diagram and description.....................................................................................................7

3.1. Power module ................................................................................................................................7

3.2. Movement module .........................................................................................................................8

3.3. Sensor module................................................................................................................................8

3.4. Liquid flow module........................................................................................................................8

4. Technical specification ...................................................................................................................10

5. Description of device......................................................................................................................11

5.1. Intended Use ................................................................................................................................11

5.2. Application...................................................................................................................................11

5.3. Principle of clotting method.........................................................................................................11

5.4. Chromogenic substrate method....................................................................................................12

5.5. Immunoturbidimetric Method......................................................................................................12

5.6. Procedure Description..................................................................................................................13

6. Installation instruction...................................................................................................................14

6.1. Appearance; .................................................................................................................................14

6.2. Parts Description:.........................................................................................................................16

6.3. Cuvette supply system; ................................................................................................................19

6.4. Carry-Handles;.............................................................................................................................20

6.5. Work platform requirement;.........................................................................................................20

6.6. Unpack machine...........................................................................................................................21

6.7. Parts Release................................................................................................................................23

6.8. Connection...................................................................................................................................25

6.9. Cuvette rolls Installation..............................................................................................................26

6.10. Connect to computer. ...................................................................................................................28

6.11. Software installation. ...................................................................................................................29

6.12. Software introduction...................................................................................................................33

6.13. Routine test ..................................................................................................................................34

7. Maintenance ...................................................................................................................................36

7.1. Environment: ...............................................................................................................................36

7.2. Placement:....................................................................................................................................36

7.3. Communication analyzer .............................................................................................................36

3

7.4. Daily maintenance .......................................................................................................................38

8. Storage ............................................................................................................................................39

9. Troubleshooting..............................................................................................................................40

10. Symbols...........................................................................................................................................44

11. Circuit description & map.............................................................................................................45

12. Special tools ....................................................................................................................................46

13. Spare part list .................................................................................................................................47

14. Index................................................................................................................................................48

4

Thank you for purchasing our product

Read this manual carefully before use.

Model: SF-8100

Name: Automated Coagulation Analyzer

Manufacturer: Beijing Succeeder Technology Development Co., Ltd

Service hotline: Please contact with local authorized representative.

Fax: +86 -10-89701711

Address:Tower 1A, No. 27 Chuangxin Road, Changping District, Beijing 102200, China

Postcode: 102200

http://www.succeeder.com.cn

Service e-mail: aftersales@succeeder.com.cn

INFORMATION ABOUTAUTHORISED REPRESENTATIVE

Name:

Tel:

Fax:

Address:

Please send us information below for better service.

User Name:

Laboratory Name:

Instrument SN No:

Operator:

5

2. Warnings and Cautions

2.1. General Warnings

Read before first-use or installation. Failure to follow the recommended instructions will

adversely affect the safety and effectiveness of the SF-8100 analyzer system.

Succeeder shall not be held responsible if the procedures described in this manual are not strictly

observed, or if procedures not described in this document are used. Read the SF-8100 Operator’s

Manual carefully and respects all the instructions given therein.

With regard to the handling of test reagents, calibrator plasmas, control plasmas and patients’

plasmas, read carefully the package inserts provided in the relevant reagent kits and respect all the

instructions.

2.2. Safety of Login

When first login SF-8100 software, user name and password as below:

User Name: admin

Password: “no password”

Password is suggested to be modified when first login.

2.3. Warning before use

Protective earth terminal is required. The earth terminal of instrument has a sign of

“ “which should be connected to earth. Leakage protector is also required when there is

an in humid environment.

The instrument label contains device Name, model, company name, SN number, voltage, HZ,

KW, etc.

Pay attention to the sign” ”, read its relevant details in operation manual before use.

Once machine was installed, don’t move it without fixing parts.

Closed upper cover for safety before testing. If running for 24 hours without switching off,

click “Rinse” before test since 30 minutes from last test.

Do not disassemble repair for safety unless it is mentioned in operation manual.

Avoid to potential infection from sample, please use gauntlet or safety measures during

operating. Please deal with the waste follow local medical waste policy.

Our product was designed to work indoor.

No EMI, strenuous vibration, or corrosive gas nearby.

Indoor temperature within 15℃~30℃, relative humidity below 70%, ATMOS 86.0 kPa~

106.0kPa;

6

For unpacked machine: Indoor temperature -20℃~55℃, relative humidity below 93%, no

corrosive gas and drafty indoor.

Not apply in damp environment.

Power supply must be grounded firmly. A leakage protector is needed in damp environment.

Our product was designed with power stabilizer. UPS was recommended when the power supply

in user field was not stable that the voltage of wave

2.4. Quality Commitment

Products undergo strict quality testing, full compliance with the product register standards;

Our Products passed safety and performance testing of medical device testing institutions,

conform to national standards and industrial standards and the implementation of the EU

98/79 / EC Directive;

Our company passed the TUV, ISO13485 and ISO9001 certification;

Our product has one year warranty, and 7 years maintenance according to CE.

7

3. Circuit diagram and description

The instrument is designed in a modular format consisting of a power module, movement module

and a sensor module. The electrical module contains the power supply and other boards which

contains all components,

3.1. Power module

The power module can be described in three sections: the power supply, the voltage regulator,

and the power board.

Power

system

Switch power

Power

pinboard

Communication

board Mainboard Filter board

Pump board

Motor pinboard

Motor

board

Probes

board

Hook motor

board

Reagent probe

Heating board

Optics test

board

Magnetic bead

test board

Motion control

system

Test system

Temperature&status

system

Electromagnet

control board

LED board

Electromagnet

Driving board

Temperature

Control board

Heat board

8

3.2. Movement module

The movement module is a unit that contains mechanism of manipulator, arm with XYZ

direction, probes and other necessary parts.

Communication system

cuvette Temperature and

status

Sample

loading Test Clean

release

detach

move

Temp control

heat

cool

Status detection

Sample rack

Open alarm

XYZ move

loading probe

Loading pump

Magnetic bead

Optics

pipeline

Inflow/outflow

pump

3.3. Sensor module

The sensor module can be divided into three parts including test channel, temperature

board and main board

3.3.1. Test channel use mechanical method which could drive the bead inside cuvette during

test cycle;

3.3.2. Temperature board which could provide 37℃to incubation area, test area and also

reagent area to incubate samples and reagents;

3.3.3. Main board could detect and measure the bead inside cuvette, and then calculate the

right result by the bead movement.

3.4. Liquid flow module

The sample flow rate is monitored by measuring the micropipette which calibrated flow

restrictor.

Liquid flow module consists of inflow pump, inflow valve, injectors, electronic valves,

probes, pipelines, outflow pump and some other parts. It ensures correct sample

amount of the whole system.

9

10

4. Technical specification

Type (Overvoltage category): II

Level of contamination: Level 2

Power: voltage: 100V-240V

Frequency:(50-60)Hz

Work environment: temperature: 15℃~30℃

Humidity ≤70 %

Atmospheric pressure 86.0kPa~106.0kPa

No strong magnetic field interference, no intensive shake、no caustic gas near test system which

should avoid direct sunshine and away from heat.

Test principle:

Test method: Clotting method, optical method (chromogenic substrate method and

immunoturbidimetric method).

Judgment method: Eddy current sensor, optical colorimetric, turbidimetric.

SF-8100: Clotting method、optical method.

Test sample: Platelet-poor plasma using sodium citrate as anticoagulant (PPP).

Accuracy and reproducibility

Item

CV

Normal sample

Abnormal sample

PT

≤3&%

≤8%

APTT

≤4%

≤8%

FIB

≤8%

≤15%

TT

≤5%

≤10%

D-Dimer

≤8%

≤6%

11

5. Description of device

5.1. Intended Use

For in vitro Diagnostic Use Only.

SF-8100 is an automated laboratory instrument designed to perform in vitro tests which aid in the

diagnosis of coagulation abnormalities as well as to assist in monitoring anticoagulant therapy.

The instrument is capable of performing clotting assays on plasma samples.

5.2. Application

SF8100 is to measure a patient's ability to form and dissolve blood clots. To perform various

test items SF8100 use mechanical assay.

5.3. Principle of clotting method

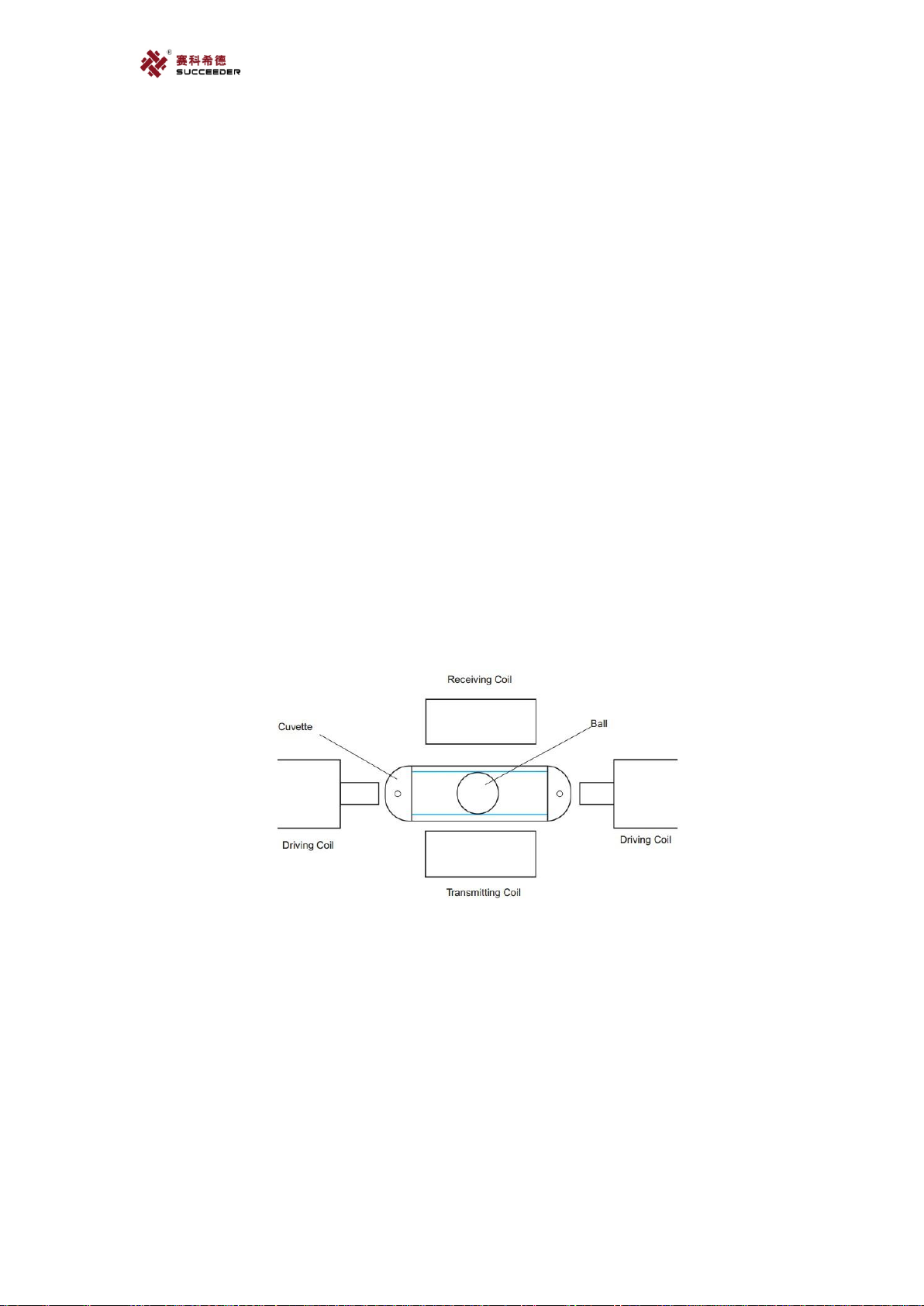

The detection system for clotting-time assays on the SF-8100 instrument is based on the

increase of viscosity of the plasma being tested. This increase of viscosity is measured through the

motion of a stainless steel ball that is made to affect pendular swings on the two graphd rail tracks

provided in the bottom of the cuvette containing the test plasma.

Constant pendular swings of the ball are created by an electromagnetic field that is applied

alternately on opposite sides of the cuvette by two independent coils. The energy of the

electromagnetic field can be varied depending on the test being performed (weak clot for

Fibrinogen, normal clot for all the others).

Physical Principle of Measurement System

At constant plasma viscosity, ball motion remains constant.

However, as soon as the plasma starts to clot (as a result of the coagulation process being

initiated by the addition of the clot starting reagent), the viscosity of the plasma starts to increase,

and this change in plasma viscosity affects ball movement, slowing it down.As the viscosity

increases, the oscillation amplitude of the ball swing decreases. An algorithm uses these variations

in oscillation amplitude to determine the clotting time.

12

Ball Motion Schema

5.4. Chromogenic substrate method

Enzymes are proteins that catalyze most of the chemical reactions that take place in the

body. They make it possible for chemical reactions to occur at neutral pH and body

temperature. The chemical compound upon which the enzyme exerts its catalytic activity

is called a substrate. Proteolytic enzymes act on their natural substrates, proteins and

peptides by hydrolyzing one or more peptide bond(s).This process is usually highly

specific in the sense that only peptide bonds adjacent to certain amino acids are cleaved.

Chromogenic substrates are peptides that react with proteolytic enzymes under the

formation of color. They are made synthetically and are designed to possess a selectivity

similar to that of the natural substrate for the enzyme. Attached to the peptide part of the

chromogenic substrate is a chemical group which when released after the enzyme

cleavage gives rise to color. The color change can be followed spectrophotometrically and

is proportional to the proteolytic activity. The chromogenic substrate technology was

developed in the early 1970s, and has since then become a tool of substantial importance

in basic research. The majority of chromogenic substrate applications are found in various

clinical fields. In particular they have been used to generate fundamental knowledge of the

mechanisms regulating blood coagulation and fibrinolysis.

5.5. Immunoturbidimetric Method

Immunoturbidimetric are chemical tests used to detect or quantify a specific substance, the

analyte, in a blood or body fluid sample, using an immunological reaction. Immunoassays

are highly sensitive and specific.

Their high specificity results from the use of antibodies and purified antigens as reagents.

An antibody is a protein (immunoglobulin) produced by B-lymphocytes (immune cells) in

response to stimulation by an antigen. Immunoassays measure the formation of

antibody-antigen complexes and detect them via an indicator reaction. High sensitivity is

achieved by using an indicator system (e.g., enzyme label) that results in amplification of

the measured product.

Clotting

13

5.6. Procedure Description

The plasma is pipetted by sampling probe then distributed in a cuvette of incubation site.

If the first reagent is needed, the sampling probe will pipette the first reagent to the cuvette

of incubation site. When reaching incubation time, cuvette-hooking system startup,

hooking the cuvette of incubation site to test site. At the same time, reagent probe pipettes

reagent to the cuvette of test site, then test starts. When test finished, cuvette-hooking

system will hook the cuvette from test site and throws it into the waste bin.

14

6. Installation instruction

6.1. Appearance;

6.1.1. External structure.

External structure;

1. Left cover

2. Switch & ports

3. Upper cover

4. Swiping area

5. Sample racks

6. Right cover

7. Waste box

6.1.2. Connectors & Rinse button

3. Upper cover

4. Swiping area

5. Sample racks

1. Left cover

2. Switch & ports

6. Right cover

8. Connectors

7. Waste box

9. Rinse button

15

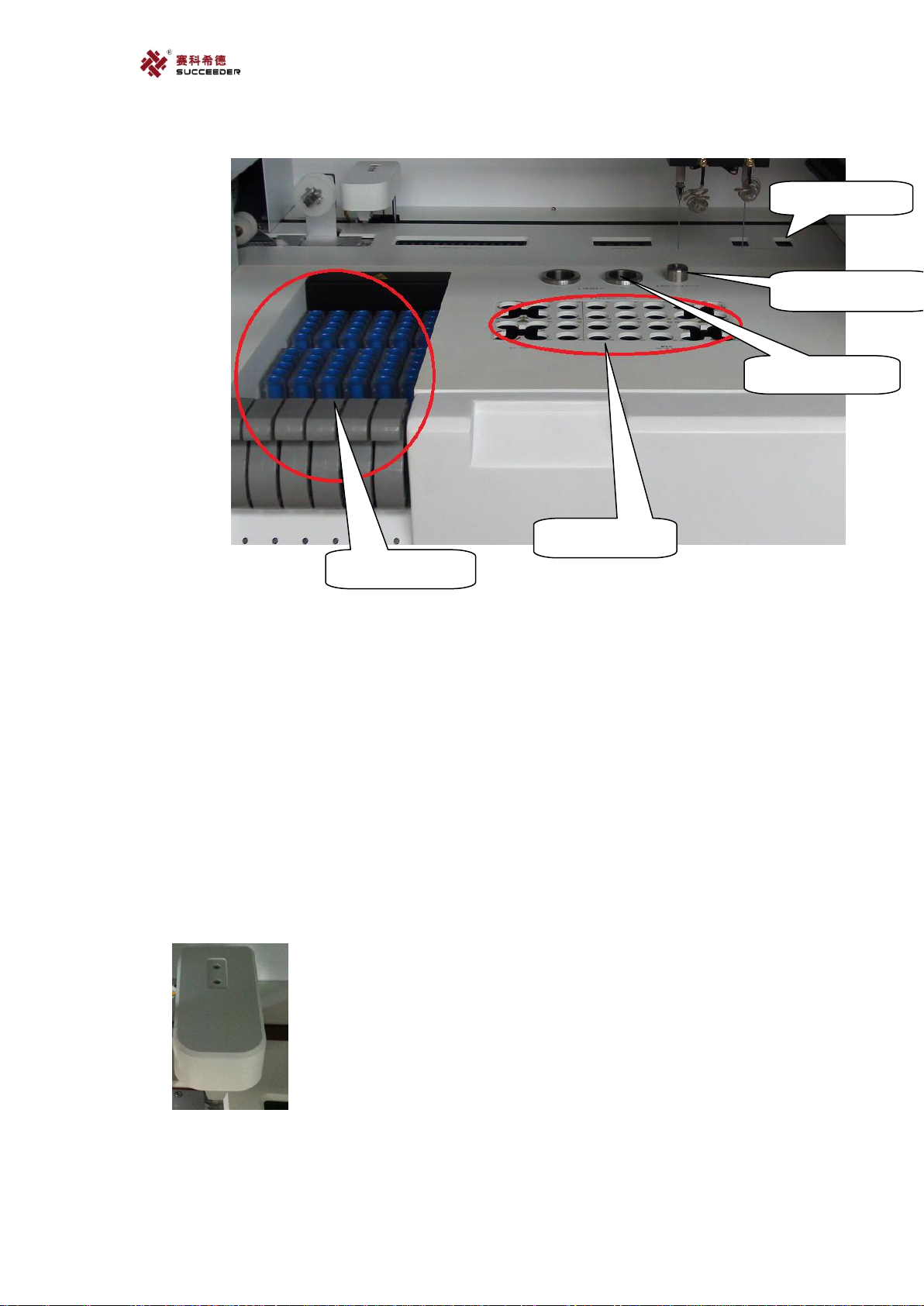

6.1.3. Working Space;

Working space

1. Manipulator

2. Sample incubation area

3. Test area

4. Sample probe

5. Reagent

probe

Power connector

Power switch

Network port

USB port

Sensor connector of

cleaning water box

Tube connector of

cleaning water

Sensor connector of

waste liquid box

Tube connector of

waste liquid

16

1. Manipulator.

2. Sample incubation area.

3. Test area.

4. Sample probe.

5. Reagent probe.

6. Cuvette outfall.

7. Cleaning position.

8. SFT position x2.

9. Reagent area.

10. Sample area.

11. Sample area

6.2. Parts Description:

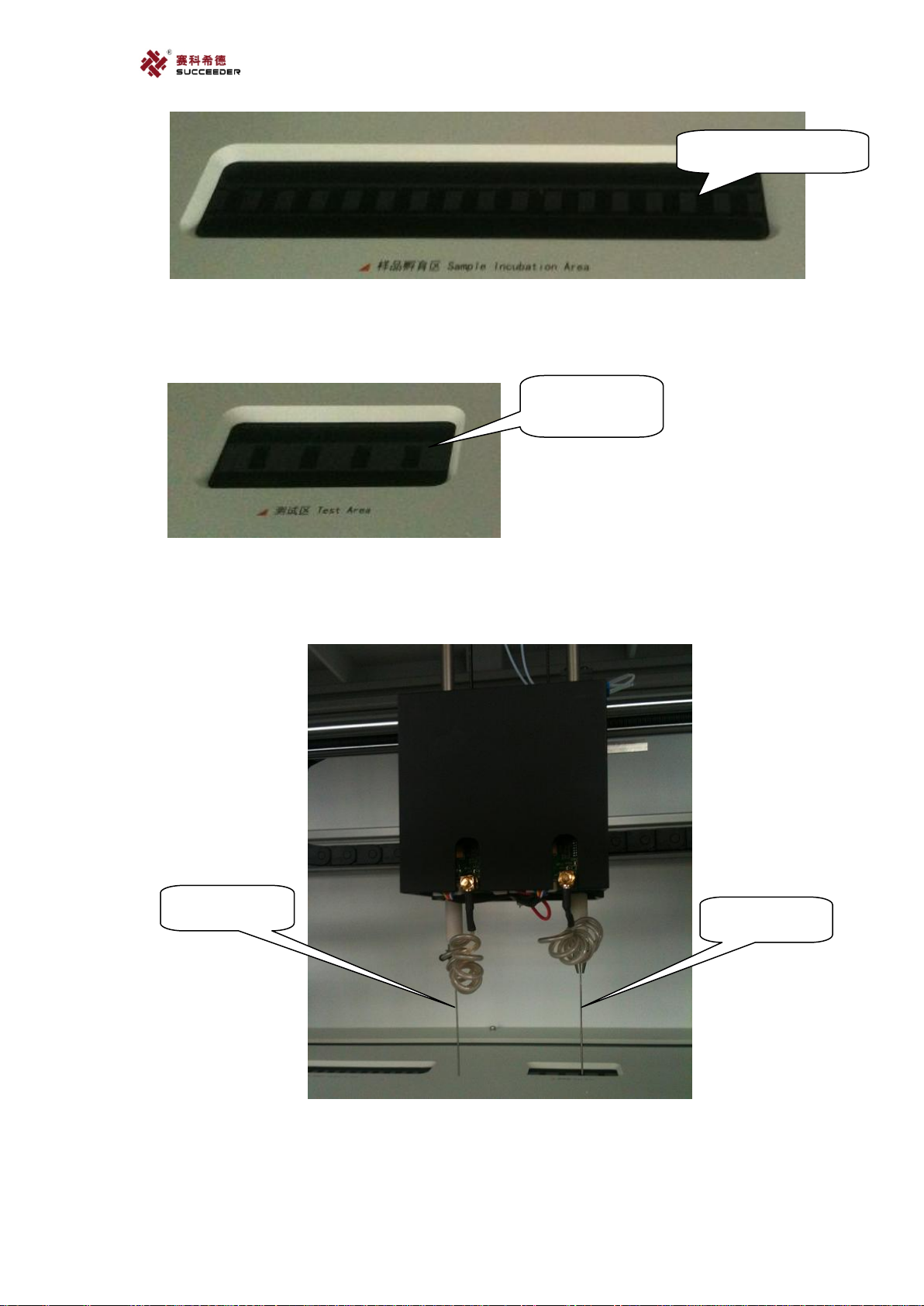

a. Manipulator.

The part is designed for catch the cuvette to specified position of incubation area.

b. Sample incubation area.

The position is designed for warm up the sample forward to 37℃, it contained with 16

6. Cuvette

outfall

8. SFT position x2

7. Cleaning position

9. Reagent area

10. Sample area

17

positions.

c. Test area.

It is designed for testing with methods of magnetic and optics. It contained with 4 positions

that can be test separately.

d. Sample probe &Reagent probe.

Two probes are designed for suck sample and reagent. The left one is sample probe, the right

one is reagent probe.

e. Cuvette outfall

It is designed for abandon the used cuvette into waste box. It contained with two positions.

16. Incubation

positions.

4 test positions.

Sample probe

Reagent probe

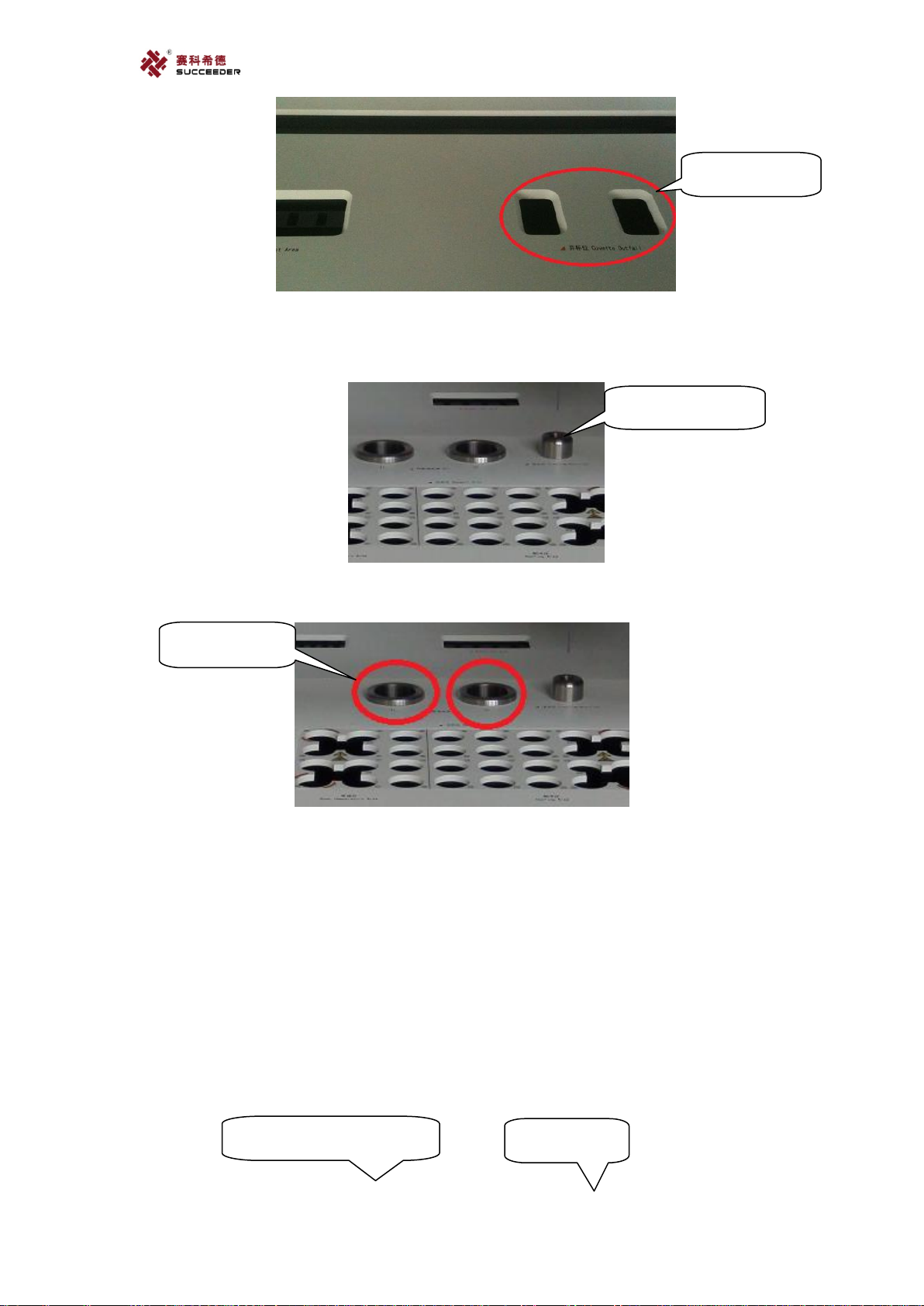

18

f. Cleaning position.

It is designed for clean both probes with cleaning liquid.

g. SFT position x2.

The two SFT positions are designed for clean probes with special cleaning fluid.

h. Reagent area.

The area is designed for placing reagent. It consists of 36 positions that separated by room

temperature area and cooling area, left part for keep reagent in room. temperature, right part

for keep reagent with 16℃.

Cleaning position

SFT position x2

Room temperature area

Cooling area

Cuvette outfall

19

i. Sample area.

It consists of six racks which contained 60 sample positions.

6.3. Cuvette supply system;

6.3.1. Structure of Cuvette supply system;

Cuvette supply system

1. Roll Locker

2. Cuvette roll

Sample area

20

1. Roll locker

2. Cuvette roll

3. Cuvettes

4. Upper roller

5. Lower roller

6. Locker

7. Tighten roller

6.4. Carry-Handles;

Four carry-handles are located at four lower corners that designed for carry machine easily.

6.5. Work platform requirement;

Minimum Size: 1020x 698 cm

Min load bearing: 90kg

Horizontal requirement: Yes

4. Upper roller

Lower roller

5. Lower roller

7. Tighten roller

6. Locker

3. Cuvettes

Carry-handles

Table of contents

Other Succeeder Measuring Instrument manuals