Succeeder SF-8200 User manual

SF-8200 Operation Manual

1/ 76

Thank you for purchasing our product!

Read this manual carefully before using this analyzer!

Specification: SF-8200 Product: Fully Automated Coagulation Analyzer

Beijing Succeeder Technology Inc.

Tower 1A, No. 27 Chuangxin Road, Tec h Park, Changping District, Beijing 102200 China

Te l : +86-10-53855569

Fax: +86-10-53855570

www.succeeder.com.cn

service@succeeder.com.cn

INFORMATION ABOUT AUTHORISED REPRESENTATIVE

NAME: Wellkang Ltd t/a Wellkang Tech Consulting

Te l : +44 (20)30869438, 32876300

Fax: +44(20)76811874

Address: Suite B, 29 Harley Street LONDON W1G 9QR, England, United Kingdom

Please record the following information

User Name:

Laboratory Name:

Analyzer No.: Operator:

SF-8200 Operation Manual

2/ 76

Contents

QUALITY COMMITMENT .........................................................................................................................5

PRECAUTIONS ........................................................................................................................................6

1 GENERAL PRECAUTIONS ............................................................................................................6

2 NOTES ON THE USE OF BIOLOGICAL PRODUCTS ...................................................................6

3 NOTES ON THE USE OF THE INSTRUMENT ..............................................................................6

4 NOTES FOR PREPARING THE TEST ...........................................................................................7

4.1 SAMPLE PREPARATION .....................................................................................................7

4.2 PREPARATION OF REAGENTS ..........................................................................................8

4.3 PROJECT SETTINGS AND INSTRUMENT STATUS...........................................................8

I SF-8200 SIMPLE INTRODUCTION........................................................................................................9

1 OVERVIEW.....................................................................................................................................9

2 INSTALLATION...............................................................................................................................9

2.1 INSTALLATION STATEMENT...............................................................................................9

2.2 INSTALLATION ENVIRONMENT .........................................................................................9

2.3 WORKING ENVIRONMENT...............................................................................................10

2.4 PERIPHERALS...................................................................................................................10

3 INSTRUMENT SPECIFICATIONS ............................................................................................. 11

3.1 INSTRUMENT COMPOSITION.......................................................................................... 11

3.2 Specifications...................................................................................................................... 14

4. ANALYSIS PRINCIPLE................................................................................................................16

4.1 SOLIDIFICATION TEST SYSTEM DESCRIPTION ............................................................ 16

4.2 OPTICAL METHOD TEST SYSTEM DESCRIPTION ......................................................... 16

4.3 TEST PROCESS INTRODUCTION.................................................................................... 17

II ROUTINE USE .................................................................................................................................... 18

1 START THE INSTRUMENT BEFORE CHECKING ......................................................................18

1.1 GARBAGE BASKET INSPECTION ....................................................................................18

1.2 DRAINAGE INSPECTION ..................................................................................................19

2 START THE INSTRUMENT..........................................................................................................21

2.1 TURN ON ...........................................................................................................................21

2.2 LOGIN SAFETY PRECAUTIONS.......................................................................................21

2.3 SOFTWARE INTERFACE DESCRIPTION .........................................................................21

2.4 FUNCTION PANEL.............................................................................................................22

3 REAGENT PREPARATION ..........................................................................................................23

3.1 PREPARE REAGENTS ......................................................................................................23

3.2 REAGENT LOADING / UNLOADING ................................................................................. 24

4 CHECK THE CALIBRATION CURVE ...........................................................................................25

5 QUALITY CONTROL TEST ..........................................................................................................26

6 SAMPLE PREPARATION .............................................................................................................28

6.1 PREPARE THE PLASMA ...................................................................................................28

6.2 PASTE THE BAR CODE .................................................................................................... 28

6.3 SAMPLE LOADING / UNLOADING.................................................................................... 29

III SAMPLE MANAGEMENT...................................................................................................................31

SF-8200 Operation Manual

3/ 76

1. SAMPLE LOADING .....................................................................................................................31

1.1 SAMPLE INTERFACE ........................................................................................................31

1.2 SAMPLE LOADING ............................................................................................................32

1.3 EMERGENCY SAMPLES...................................................................................................34

2 TEST ANALYSIS........................................................................................................................... 35

2.1 "TEST" INTERFACE ........................................................................................................... 35

2.2 TEST TASKS ......................................................................................................................35

2.3 CHECK THE TEST STATUS ..............................................................................................36

3 TEST RESULTS ........................................................................................................................... 38

3.1 SAMPLE SEARCH .............................................................................................................38

3.2 VIEW SAMPLE RESULTS..................................................................................................39

3.3 SAMPLE RESULT REVIEW ...............................................................................................40

3.4 DELETE THE SAMPLE ......................................................................................................40

3.5 PRINT SAMPLE RESULTS ................................................................................................41

ⅣREAGENT MANAGEMENT............................................................................................................... 43

1 BATCH MANAGEMENT ............................................................................................................... 43

2 ENTER REAGENT INFORMATION MANUALLY..........................................................................43

3 SUPPLIES RECHARGE ...............................................................................................................44

4 QUALITY CONTROL PARAMETERS ENTRY.............................................................................. 45

5 REAGENT LOADING ................................................................................................................... 45

5.1 AUTOMATICALLY SAVE AND LOAD REAGENT LAYOUTS..............................................45

5.2 REAGENT LOADING/UNLOAING......................................................................................46

ⅤQUALITY CONTROL.........................................................................................................................47

1 QC SETTING................................................................................................................................47

2 QC TEST ...................................................................................................................................... 48

3 INQUIRE THE QUALITY CONTROL RECORD............................................................................ 48

ⅥCALIBRATION ................................................................................................................................... 50

1 CHECK THE CALIBRATION CURVE ...........................................................................................50

2 CREATE A CALIBRATION CURVE...............................................................................................50

2.1 SET THE CURVE PARAMETERS......................................................................................50

2.2 LOAD CALIBRATORS AND REAGENTS ........................................................................... 51

2.3 CREATE A CALIBRATION CURVE .................................................................................... 52

3 MODIFY THE CURVE ..................................................................................................................54

4 DELETE THE CURVE ..................................................................................................................54

ⅦINSTRUMENT SETTING...................................................................................................................55

1 GENERAL SETTING .................................................................................................................... 55

1.1 REPORT SETTING ............................................................................................................55

1.2 USER SETTING .................................................................................................................55

1.3 LANGUAGE SETTING ....................................................................................................... 56

1.4 LIS SETTING...................................................................................................................... 57

1.5 REPORT RANGE SETTING............................................................................................... 57

1.6 DATA BACKUP ...................................................................................................................57

2 TEST ITEM SETTING................................................................................................................... 58

2.1 TEST INFORMATION ......................................................................................................... 58

SF-8200 Operation Manual

4/ 76

2.2 TEST ITEM PROCEDURE SETTING................................................................................. 59

2.3 TEST PARAMETERS AND DILUTION FUNCTION SETTING ...........................................61

2.4 RESULT UNIT SETTING ....................................................................................................63

2.5 ADD OTHER ITEMS........................................................................................................... 64

3 DICTIONARY SETTINGS ............................................................................................................. 65

4 EQUIPMENT ADVANCED FEATURES OPTIONS .......................................................................66

4.1 CHANNEL SETTING ..........................................................................................................66

4.2 REAGENT AREA POSITION CHECKING ..........................................................................66

4.3 SETTINGS FRO DIPOSE THE CUVETTE WHICH LACK REAGENT ............................... 66

4.4 SETTINGS FOR CALCULATE THE MEAN VALUE AUTOMATICALLY..............................66

5 SYSTEM INFORMATION ............................................................................................................. 67

5.1 INSTRUMENT INFORMATION...........................................................................................67

6 LOG ..............................................................................................................................................68

ⅧMAINTENANCE ................................................................................................................................69

1 MAINTENANCE SCHEDULE ....................................................................................................... 69

2 DAILY MAINTENANCE.................................................................................................................69

2.1 MAINTAIN INTERFACE...................................................................................................... 69

2.2 DAILY MAINTENANCE....................................................................................................... 70

3 MONTHLY MAINTENANCE.......................................................................................................... 70

4 HALF YEAR MAINTENANCE ....................................................................................................... 73

5 SPARE PARTS RECHARGE ........................................................................................................ 73

ⅨFAQ ................................................................................................................................................... 75

1 FAQ SOLVING.............................................................................................................................. 75

SF-8200 Operation Manual

5/ 76

QUALITY COMMITMENT

The company's manufactured products undergo a rigorous quality inspection, would be in full com-

pliance with the technical requirements of this product

The analyzers pass the safety testing and performance testing of medical device testing agencies,

they would be in line with national standards and industry standards

The product is manufactured under the quality system conforming to ISO13485 and ISO9001. The

quality system of our company is certified by TUV

The device complies with the emission and immunity requirements of GB / T18268.1-2010 and GB /

T18268.26-2010

This equipment is designed and tested according to Class A of GB4824. This equipment may cause

radio interference in home environment and need protective measures

It is recommended to evaluate the electromagnetic environment before using this equipment

Do not use the device near strong radiation sources (such as unshielded RF sources), otherwise it

may interfere with the normal operation of the device

The company product’ design life is 5 years, one year warranty and lifetime maintenance.

SF-8200 Operation Manual

6/ 76

PRECAUTIONS

1 GENERAL PRECAUTIONS

Before installing and using the instrument for the first time, please read the instructions in the

manual carefully and strictly observe the operating procedures and precautions. The instrument must be

operated in accordance with the methods specified in this manual. Failure to use the device in accord-

ance with the methods specified in this manual may damage the protection provided by the device.

Before reading the manual, make sure you understand the following logo. Please refer to "Chapter 1 3.1

Instrument Composition."

Attention

Be careful of burns

Laser radiation

Biohazard

Protect the ground

Any failure to observe the above marks and operate the instrument incorrectly may result in injury to

the operator, adverse effects on output, and potential hazards of property damage.

This product is a clinical testing instrument, Based on the analysis results, the doctor is required to

consider the clinical test results and other test results at the same time.

2 NOTES ON THE USE OF BIOLOGICAL PRODUCTS

For all biological products (reagents, calibrators, quality control plasma and patient plasma, etc.),

please read the precautions regarding potential contamination carefully.

1) Do not eat or smoke in areas where biological products are used;

2) Do not use expired reagents;

3) Reagents are chemicals used for in vitro diagnosis and can not be used as medicines.

4) When using biological products, please wear disposable rubber gloves, if the biological products come

into contact with your skin wounds or mucous membranes, rinse immediately with water and see a doc-

tor;

5) Dispose of all used biological waste products according to local laws or regulations (eg. heat steriliza-

tion, discard, waste water treatment with sodium hypochlorite, etc.).

3 NOTES ON THE USE OF THE INSTRUMENT

1) The instrument has protective measures in the transport package. It must be installed by a profes-

sional engineer trained by our company or authorized engineer of our company.

2) All the warning signs, the operator must check the instructions in the relevant content, identifying po-

tential hazards;

SF-8200 Operation Manual

7/ 76

3) The network power must have a protective earth terminal. Internal protective grounding terminal

marked with symbols, must be reliably grounded through the power outlet.

4) The network power input socket is a disconnect device for the power supply of the instrument and the

network. Do not install this device in a hard-to-disconnect position.

5) In the possible damp places, should be installed leakage protector.

6) For safety, do not open the front cover of the instrument or insert your fingers into the instrument dur-

ing testing, which may result in personal injury. If the front cover is opened during the test, the instrument

will sound the alarm and stop working at the same time. When closing the front cover, hold the front cover

with your hands and slowly lower it. During the test, the operation table inside the instrument prohibits

placing extra items.

7) Unless instructed in this manual, do not attempt to open it yourself. It may cause high voltage or other

hazards to you. Maintenance of these parts should be done by qualified personnel.

8) When inspecting or maintaining, please use protective rubber gloves or other protective measures,

and use specific tools or parts. After finishing the work, please wash your hands with disinfectant.

9) The company's instruments are equipped with a power regulator, generally do not need an external

voltage regulator. Only when the external power supply voltage fluctuations exceed 100-240V, you can

use the UPS regulator, you cannot use the ordinary regulator.

4 NOTES FOR PREPARING THE TEST

4.1 SAMPLE PREPARATION

1) Selection and dosage of anticoagulants

Anticoagulant 105-109mmol / L, 3.13% -3.2% (usually described as 3.2%) of sodium citrate

(Na3C6H5O7 • 2H2O), other anticoagulants such as heparin, EDTA, oxalate, etc. are not allowed to use.

The final concentration when anticoagulant is mixed with blood is usually 10.9-12.9 mmol / L. Anticoag-

ulant and blood volume ratio of 1: 9.

If the patient's hematocrit (HCT) greater than 55% or less than 20%, usually need to adjust the

amount of anticoagulant.

The amount of anticoagulant can be adjusted according to the following formula:

X = required anticoagulant amount × [(100 - HCT) / (595 - HCT)]

Of which: x - ml, the amount of anticoagulant required

HCT -%, hematocrit

Such as: need 5ml anticoagulant, the patient's HCT = 20%, the required anticoagulant x = 0.7ml

2) Sample collection

Equipment in contact with blood, such as test tubes, pipettes, and syringes must be plastic.

Acquisition should be fasting state in the morning, take the elbow venous blood, the sample size can not

be less than 2 ml. Blood should be sharp, avoid repeated puncture, to avoid hemolysis, platelet aggre-

gation, pumping tissue fluid or bubbles mixed phenomenon, such as hemolysis should be re-drawn

blood.

Bleeding blood and anticoagulants, the method should be gentle, not violent shaking. The antico-

agulant mixture was centrifuged at a temperature of 25-32 ° C, the relative centrifugal force of plasma

separation was 1500 × g, and the centrifugation time was controlled at about 15 minutes until the cen-

trifuge was stopped naturally (for example, hemolysis should be reabsorbed ), Test tube supernatant

SF-8200 Operation Manual

8/ 76

liquid is platelet poor plasma (PPP).

3) Sample placement

Coagulation Test The PT test sample should be tested within 24 hours at (18-24) °C; the APTT test

sample should be tested within 4 hours; other tests (eg FIB, PC, Factor V, Foctor VIII, D-Dimer, FDP, etc. )

Should be tested within 4 hours.

If the clotting test cannot be performed immediately, the sample can be stored at 4 °C for 2 hours. If

the PT test sample cannot be tested within 24 hours or the APTT and other tests cannot be tested within

4 hours, the plasma sample can be stored frozen below-20 °C for two weeks and below -70 °C for 6

months. Frozen samples should be rapidly thawed at 37 °C and tested immediately. Frozen samples may

affect the APTT test.

4.2 PREPARATION OF REAGENTS

1) Use of reagents

Users in the reagent before use, be sure to read the instructions inside the kit, and strictly in ac-

cordance with the provisions of the manual to use and save.

Test reagent configuration and dosage can refer to the user to use the reagent packaging and in-

structions, reagents should choose a legal solidification method, the optical method of reagent determi-

nation of the box, the use of different batches and manufacturers of reagents need to do calibration,

coagulation test for calibration Calibrators must be used, different batches, different components cannot

be mixed.

2) PT reagent selection

Select a reagent labeled ISI (International Sensitive Index) for quality control. The lower the ISI

value of the reagent, the more sensitive it is to each coagulation factor measured.

4.3 PROJECT SETTINGS AND INSTRUMENT STATUS

1) Project Settings

Experimental settings must be provided by the manufacturer of reagents set, such as temperature

incubation time, test time, and sample, reagent, buffer, the amount of cleaning fluid.

2) Needle and pipeline maintenance

The purpose of the needle maintenance is to clean the outer surface of the needle to avoid

cross-contamination affect the test results. The purpose of pipeline perfusion maintenance is to make the

pipe filling part of the filling system full of cleaning liquid to reduce the wall bubble, to avoid the amount of

sample is not allowed to affect the test results.

Every morning before the start of the test need to carry out the needle and the pipeline maintenance,

in the course of one day of use, half an hour to suspend the use of the instrument, please use pipeline

maintenance before use.

SF-8200 Operation Manual

9/ 76

I SF-8200 SIMPLE INTRODUCTION

1 OVERVIEW

SF-8200 fully automated coagulation analyzer for coagulation and anticoagulation of human

plasma, fibrinolysis and anti-fibrinolytic function of the test, to quickly and accurately analyze a large

number of samples.

This instrument is for in vitro diagnosis only.

Figure 1.1 SF-8200 Fully automated coagulation analyzer

2 INSTALLATION

2.1 INSTALLATION STATEMENT

The SF-8200 Automated Blood Coagulation Tester has been thoroughly inspected at the factory

and carefully packed to prevent damage due to vibration during shipping.

After delivery, please double-check the packaging to confirm that the instrument is free from any ex-

ternal damage.

SF-8200 automated coagulation analyzer can only be Beijing Succeeder Technology Inc. profes-

sional engineers or by the Company authorized engineers to install at the same time the initial set.

After the instrument is installed and running, it should not be moved normally. If you really need to move,

you should empty the pipes and trash basket waste, and fixed XYZ sampling arm mechanism, robot

movement mechanism and trash basket. There is a groove on each side of the bottom of the instrument.

When transporting, put your hand here and raise it horizontally.

2.2 INSTALLATION ENVIRONMENT

1) Choose a stable level surface to avoid functional errors when installing.

2) Make sure the installation space is large enough for operation and maintenance. Place the computer

on the left side, wash tub and waste tub on the right side, and make sure that the bin on the right side is

completely removable.

3) The network power must have a protective earth terminal. Internal protective grounding terminal

marked with symbols, must be reliably grounded through the power outlet.

SF-8200 Operation Manual

10 / 76

4) The network power input socket is a disconnect device for the power supply of the instrument and the

network. Do not install this device in a hard-to-disconnect position.

5) The analyzer contains non-corrosive gases, non-toxic gases, no special ventilation requirements.

Figure 1.2 Instrument Installation Environment

2.3 WORKING ENVIRONMENT

1) Installation category: II (overvoltage category)

2) Class of pollution: II

3) Voltage: AC100-240V(50Hz)

4) Temperature: 15℃~30℃(23℃best)

5) Relative humidity: Not exceed 75%(30% - 75% best)

6) Barometric pressure: 86.0kPa~106.0kPa

7) Operation system: Win98/ME/WINNT4/WIN2000/WINXP/WIN7/WIN10

8) Avoid direct heat and light exposure

WARNING: Make sure the instrument is grounded. Improper grounding may cause electric

shock.

2.4 PERIPHERALS

1) The computer system is not less than the following configuration:

CPU: frequency 1GHZ above, 32-bit or 64-bit processor;

Display: VGA color display, supports 1024 × 768 resolution and above;

Hard disk: at least 16 GB of free space (based on 32 bits) or 20 GB of free space (based on

64 bits)

Memory: The minimum requirement is at least 1G, more than 2G recommended;

Graphics Card: DirectX 9 graphics device with WDDM 1.0 or later driver;

Operating System: Correct preinstalled Win98 / ME / WINNT4 / WIN2000 / WINXP / WIN7 /

WIN10 operating system;

Printer: support for the operating system and motherboard

2) External socket

①USB (IC card)

②RJ45

③Power cord

SF-8200 Operation Manual

11 / 76

④Alarm for waste solution

⑤Alarm for cleaning solution

⑥Inflow socket

⑦Outflow socket

3 INSTRUMENT SPECIFICATIONS

3.1 INSTRUMENT COMPOSITION

3.1.1. Instrument appearance

Left side view of the instrument

1) Communication interface

USB interface: IC card reader connection port, connected with the PC;

RJ45 network port: instrument communication port, connected with the PC;

2) left maintenance window

Used to check the positioning of manipulator grasping maintenance window, the need to open the tool;

3) Fuse box window

To facilitate the replacement of the instrument's internal circuit board fuse set maintenance window, the

need to open the tool;

4) Power switch and interface

Use the power cord provided by the manufacturer to power the instrument;

|: Turn on the power;

○: Turn off the power;

WARNING: TO PREVENT ELECTRICAL SHOCK, CONNECT THE POWER CORD

WITH POWER OFF.

5) Left front door

Can be opened, used to replace the test cuvette and plate, the specific operation refer to "Chapter II 1.3

Test Cuvette Check";

6) IC card swipe area

For consumables recharge and reagent information entry, the specific operation refer to "Chapter VII 1.2

consumables recharge";

7) front cover

The front cover of the instrument has the function of opening and closing the cover to stop the

machine and the instrument can work normally only when the front cover is closed. At the same time,

closing the bezel minimizes ambient light interference to ensure a good optical test environment.

SF-8200 Operation Manual

12 / 76

56 87

WARNING: Do not open the front cover during

instrument testing as this may cause the

instrument to stop operating or produce incorrect test results.

8) reagent barcode scanning window

For reagent automatic scanning code loading, the specific operation refer to "Chapter II 3.2 rea-

gent loading / unloading";

Attention! Bar code scanner is on, the brightness is higher, do not look directly at the light

beam.

9) In/outflow port

Waste liquid connection interface: with liquid waste alarm indicator light, full liquid switch to con-

nect the faucet and alarm connector;

Cleaning liquid connection interface: lack of liquid cleaning liquid alarm indicator, the lack of liquid switch

to connect the tap and alarm connector;

10) Garbage basket

Test cuvettes after use will be discarded in trash baskets, please use trash bags, and clear the

trash baskets in time.

WARNING: Rubbish baskets contain potentially biodegradable materials. Wear rubber

gloves for disposal and disposal in accordance with local regulations.

SF-8200 Operation Manual

13 / 76

3.1.2. Internal components of the instrument

1) manipulator

Used to test the handling of the cuvette, with rotation, can avoid the needles, improve operating

efficiency.

2) Reagent arm

Independent loading arm, used to start the reagent loading, running the reagent zone for the rea-

gent zone start reagent zone and the test position;

Reagent needle has a heating function, draw reagent, the reagent warmed up quickly to meet the

test requirements;

WARNING: Beware of possible heat burns on the surface of the

reagent needle. Use

caution.

3) Sample arm

Independent loading arm, for sample and intermediate reagent loading, the operating area for the

reagent reagent in the middle of the reagent zone and temperature;

4) temperature position

20 holes temperature, temperature control and design of insulation to ensure good wet and cold

areas, the effect of temperature.

Warning: Beware of possible high temperature on the surface of the incubation temper-

ature.

5) sample bit

Six pull-out tube rack, each tube rack has 10 sample holes, a total of 60 sample positions.

Built-in sample barcode scanner, you can automatically determine the sample rack into and out, only

SF-8200 Operation Manual

14 / 76

push the bar code scanning, and prompted to load the sample information in the software.

Warning: The sample has potential biochemical hazards, please wear rubber gloves

operation.

Warning: laser radiation, do not look directly at the light beam.

6) Reagent positions

Intermediate reagent area: 24 holes, can place 1 bottle of 25ml specifications reagent, 3 bottles of

15ml specifications reagent, 10 bottles of 5ml specifications reagent, 10 bottles of 2ml specifications

reagent, which contains two reagent stirring position, located in the middle reagent position

Start the reagent area: 18 holes, can place 3 bottles of 25ml specifications reagents, 15 bottles of

5ml specifications reagent, which contains three reagents stirring position, left in the start reagent posi-

tion three holes.

2 sets of independent cleaning tank, respectively, cleaning the sample needle and reagent needle.

With condensate collection and discharge function, to improve the reagent position in high temperature

and humidity environment stability.

7) test positions

Solidification test positions: 4

Optical method test positions: 4

Test zone heating function, for the sample during the test to maintain a constant temperature.

Warning: Beware of possible high temperatures on the surface of the test site. Use cau-

tion.

3.2 Specifications

1) temperature control

When the room temperature is 15℃~ 30℃, the temperature control in the following range:

Temperature and test position temperature control bit 37.0℃± 1.0℃;

Reagent temperature control does not exceed 16℃;

The preset temperature is reached within 30 minutes after the power is turned on.

2) test items and reporting units

Using the clotting method, chromogenic substrate method, immunoturbidimetric method for the

following coagulation tests and scalable items

Items

Clotting method

(Mechanical method)

Optical method

Reportable unit

chromogenic sub-

strate method

immunoturbidimetric

method

PT ※s, INR, %, R

APTT ※s

SF-8200 Operation Manual

15 / 76

TT ※s

APC-R ※s

FIB ※s, g/l, mg/dl

PC

※s, %

※%, OD/min

PS

※s, %

※%, OD/min

PLG ※%, OD/min

PAI ※%, OD/min

D-Dimer ※DOD, μg/ml

FDP ※DOD, μg/ml

FM ※DOD, μg/ml

vWF ※※%, DOD, s

TAFI ※%, DOD

Free-Ps ※%, DOD

AP ※%, OD/min

E Factor ※※s, %

I Factor ※※s, %

HNF/UFH

※IU/ml, s

※IU/ml, OD/min

LMWH ※※IU/ml, OD/min

AT-Ⅲ

※s, %

※%, OD/min

3) sample volume range

5 μl - 250 μl

4) carrying pollution rate

FIB high concentrations of low concentrations of carrier pollution should be ≤ 10%

FIB or TT on PT or APTT carrier contamination rate ≤ 2%

PT or APTT on AT-Ⅲcarrier pollution rate ≤ 2%

The carrying rate of D-Dimer by PT or APTT is less than 2%

5) Repeatability

Item(Unit)

CV

Normal Sample Abnormal Sample

Clotting method(Mechanical method)

PT(s)≤3.0% ≤5.0%

APTT(s)≤3.0% ≤5.0%

FIB(g/L)≤5.0% ≤10.0%

TT(s)≤3.0% ≤5.0%

SF-8200 Operation Manual

16 / 76

Optical

method

chromogenic sub-

strate method

AT-Ⅲ(%)≤5.0% ≤10.0%

immunoturbidimetric

method

D-Dimer(μg/ml)≤10.0% ≤5.0%

Note:

1, the conventional four abnormal samples refers to not less than twice the median value of the normal reference range

of the instrument;

2, AT-Ⅲnormal sample concentration of 80% -120%, abnormal sample concentration of 30% -79% and 120% -140%;

3, D-Dimer normal sample content (0.15-0.5) μg / ml, abnormal sample concentration (0.5-8) μg / ml

6) Accuracy

The relative bias measured by the FIB does not exceed ± 10.0%.

AT-Ⅲmeasurement results should be consistent with the quality control of the target range.

D-Dimer measurement results should be consistent with the control target range.

7) Linearity

The linearity range of FIB was determined to be 0.7-7 g / L, r ≥ 0.975.

The linearity range of AT-III was determined: 9% -140%, r> 0.98.

The linearity range of D-Dimer was determined to be 0.15-8 ug / ml, r> 0.98.

4. ANALYSIS PRINCIPLE

4.1 SOLIDIFICATION TEST SYSTEM DESCRIPTION

The test is based on the increasing viscosity of the plasma being tested, and an increase in the

viscosity of the plasma is detected by the curved movement of the test bead at the base of the cuvette.

Independent coils on both sides of the cuvette generate opposite electromagnetic fields that drive the

test bead. The viscosity does not change when the plasma does not coagulate, and the test beads will

swing with a constant amplitude; When the plasma is coagulated, fibrous protein occurs, plasma vis-

cosity will be increased, and the amplitude of test bead will be attenuated. The change of amplitude is

calculated by mathematical algorithm and then get the clotting time.

4.2 OPTICAL METHOD TEST SYSTEM DESCRIPTION

There are two methods of optical method: chromogenic substrate method, immune turbidimetry.

Chromogenic substrate method: artificial synthesis of a cleavage site compounds and chromogenic

substances linked to form a specific substrate for the enzyme, due to the presence or reaction of the

sample was generated during the activity of the enzyme, the substrate was Hydrolysis and release of

chromogenic substances, the reaction system of color change, colorimetric method to detect the extent

of its color change, and the enzyme activity or analyte into a certain relationship.

Immunoturbidimetric method: the use of antigen and antibody specificity between the characteris-

SF-8200 Operation Manual

17 / 76

tics of the test substance and labeled with its specific antibody particles, making the reaction system of

turbidity change, by measuring the change in light intensity to be Method of measuring objects.

Optical method detection principle: After a monochromatic light through the reaction vessel, part of

the incident light is absorbed or refracted by the reaction medium, the transmitted light is detected by the

detection system, and through the formula converted into absorbance (optical density, O. D.).

4.3 TEST PROCESS INTRODUCTION

Test process diagram:

测试位37℃恒温育温位37℃育温

血浆 启动试剂

样本针

测试杯

中间试剂

试剂针

测试杯

机械手运送 即时测试

结果计算

清洗 清洗

The sample needle aspirates a quantitative amount of plasma and adds to the test cuvette at the

incubation temperature. According to the project requirements, if you need to add intermediate reagent,

the sample needle to absorb the corresponding reagent added to the test cuvette co-incubation tem-

perature. The sample needle will be properly cleaned after each pipetting step. When the incubation

time is reached, the robotic arm moves the test cuvette from the incubation temperature to the test

position. At this point, the reagent needle aspirates the starter reagent into the test cuvette of the test

position and begins the test at the same time. Similarly, reagent needles are cleaned after each pipet-

ting step. When the test is completed, the robotic arm system drops the test cuvette into the trash bas-

ket.

5. Storage conditions

The packaged tester should generally be stored in an ambient temperature of -20 ℃~ 55 ℃, rela-

tive humidity less than 85%, non-corrosive gases and well-ventilated room.

Contraindications

Not yet found

plasma

test

cleanclean

Intermediate

Reagent

Activation

Reagent

plasma

37

℃

incubation

cuvette

37

℃

incubation

cuvette results

Sample needle

reagent needle

transfer

SF-8200 Operation Manual

18 / 76

II ROUTINE USE

1 START THE INSTRUMENT BEFORE CHECKING

1.1 GARBAGE BASKET INSPECTION

垃圾袋

垃圾筐

Pull out the instrument trash basket, remove the distance of about 260mm, remove the trash bag,

dispose of bio-waste according to local regulations;

The new garbage bag into the rubbish box, the garbage basket pushed back to the instrument;

Note! Please reserve enough space on the right side of the instrument to facilitate the re-

moval of rubbish baskets.

Instrument has a "garbage basket in place detection" function, if not placed in place, the instrument may

not work and alarm

WARNING: Rubbish baskets contain potentially biodegradable materials. Wear rubber

gloves for disposal and disposal in accordance with local regulations.

Plastic bag

Waste basket

SF-8200 Operation Manual

19 / 76

1.2 DRAINAGE INSPECTION

废液满液报警接口

及排水水嘴接头

清洗液缺液报警接口

及进水水嘴接头

Alarm interface with quick connector, insert, you need to limit the connector and the interface of the

instrument alignment;

When the water inlet and exhaust nozzles are equipped with quick-closing faucets, press the reed

of the water faucets, the water faucets will pop up automatically when the faucet is clicked; if it cannot be

inserted, please check the spring Whether the film is pressed in place.

Note! Drainage faucet if not in place, will cause drainage blockage, cannot be discharged in

time, leading to overflow within the instrument.

Check the cleaning liquid tank. If the liquid level of the cleaning liquid is low, replace the liquid

cleaning liquid. The liquid cleaning liquid cannot be replaced by other liquid, and dispose of the waste

liquid tank at the same time.

WARNING: Waste drums contain

potentially biodegradable materials. Wear rubber gloves

and dispose of in accordance with local regulations.

L

iquid-overflow switch

Liquid deficient switch

Waste liquid barrel

Cleaning liquid barrel

Liquid-

overflow alarm and

outflow pipe adapter

Liquid-

outflow alarm and

inflow pipe adapter

Table of contents

Other Succeeder Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Martek Instruments

Martek Instruments Mark 25 instruction manual

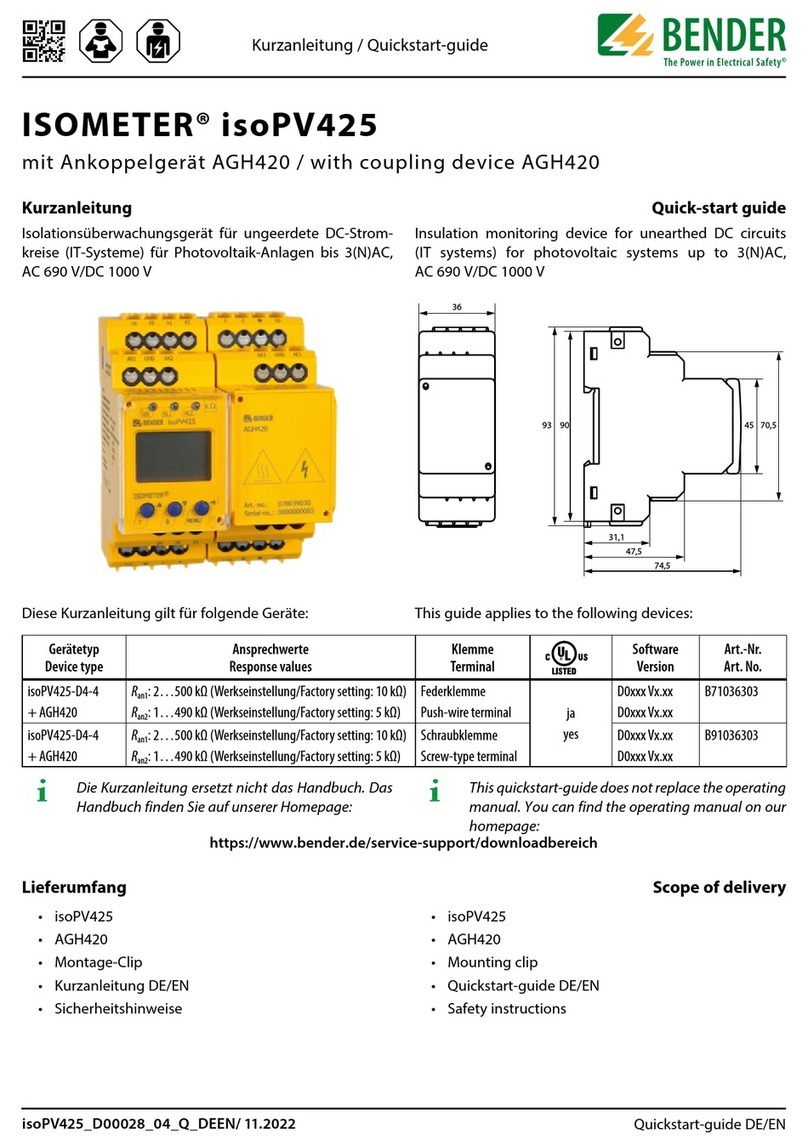

Bender

Bender ISOMETER isoPV425 with AGH420 Quick Star Guide

Thermo

Thermo DCT7088 user manual

EINHELL

EINHELL 21010 Original operating instructions

Owon

Owon HSA1000 Series user manual

Teledyne Lecroy

Teledyne Lecroy MDA810 Getting started guide

Kingfisher

Kingfisher KI6106 Series user manual

AST

AST A250 PL/TL BT user manual

T&D

T&D RTR-574-S manual

Elenco Electronics

Elenco Electronics TT-400K Assembly and instruction manual

PCB Piezotronics

PCB Piezotronics 351B14 Installation and operating manual

Mirion Technologies

Mirion Technologies LDM 320 user manual