4.

ZERO

SETTING

(CALIBRATION)

.... 1. Remove

the

cap

of

the nozzle.

....

2.

Dip

the tip

of

the nozzle in water,

and

then squeeze

and

release the

tube pump. The

water

is sucked

into

the sample chamber in this

process.

.... 3. Confirm

that

the sample chamber has been filled with water. If

bubbles are still in the sample chamber, operate the tube pump again

to

suck water to fill the sample chamber.

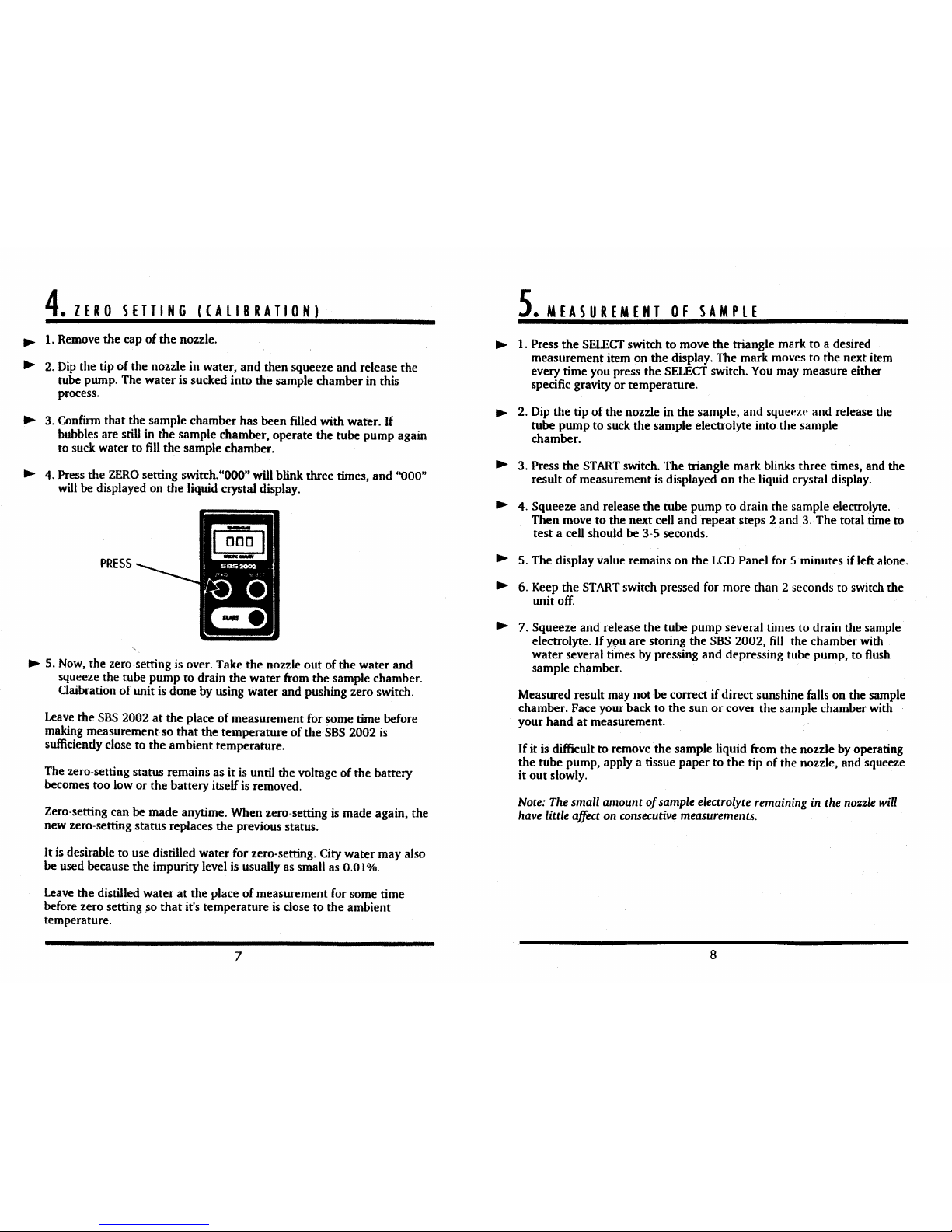

.... 4. Press

the

ZERO

setting switch."000" will blink three times,

and

''000''

will be displayed on the liquid crystal display.

PRESS

.... 5.

Now,

the zero-setting is over. Take the nozzle

out

of

the

water

and

squeeze the tube pump

to

drain the

water

from the sample chamber.

Claibration

of

unit is

done

by using water and pushing zero switch.

Leave the

SBS

2002

at

the place

of

measurement for some time before

making measurement

so

that

the temperature

oftheSBS

2002 is

sufficiently close

to

the ambient temperature.

The zero-setting status remains

as

it

is until the voltage

of

the battery

becomes too low

or

the battery itself is removed.

Zero-setting can

be

made anytime. When zero-setting

is

made again, the

new zero-setting status replaces

the

previous status.

It is desirable to use distilled water for zero-setting. City water may also

be used because the impurity level is usually as small as 0.01%.

Leave the distilled water

at

the place

of

measurement for some time

before zero setting

SO

that

it's temperature

is

close to

the

ambient

temperature.

7

5.

MEASUREMENT

OF

SAMPLE

.... 1. Press

the

SELECT

switch

to

move the triangle mark to a desired

measurement item

on

the

display. The mark moves to the next item

every time you press the

SELECT

switch. You may measure either

specific gravity

or

temperature.

.... 2.

Dip

the

tip

of

the nozzle in the sample, and squeezp and release the

tube pump to suck the sample electrolyte into the sample

chamber.

.... 3. Press

the

START

switch. The triangle mark blinks

three

times, and the

result

of

measurement is displayed

on

the liquid crystal display.

.... 4. Squeeze

and

release the tube pump

to

drain the sample electrolyte.

Then move

to

the next cell and

repeat

steps 2 and 3. The total time to

test a cell should be 3-5 seconds.

.... 5. The display value remains

on

the

LCD

Panel for 5 minutes if left alone.

.... 6. Keep the

START

switch pressed for more than 2 seconds to switch the

unit off.

.... 7. Squeeze

and

release the tube pump several times to drain the sample

electrolyte.

If

YQU

are storing the

SBS

2002,

fill

the chamber with

water

several times

by

pressing

and

depressing tube pump, to flush

sample chamber.

Measured result may

not

be correct ifdirect sunshine falls on the sample

chamber. Face your back to

the

sun

or

cover the sample chamber with

your hand

at

measurement.

If

it is difficult

to

remove the sample liquid from the nozzle by operating

the tube pump, apply a tissue paper to

the

tip of the nozzle, and squeeze

it

out slowly.

Note: The small amount

of

sample electrolyte remaining in the nozzle will

have little affect on consecutive measurements.

8