TROUBLESHOOTING

8

Display blank

*CheckOn/Offswitchisilluminated.

*Checkexternal250mAfusehasnotfused.

*Checkelectricsupply:210-230V50Hz

*IfproblempersistscontactTECHNICALSERVICE.

Hydrolysis does not reach maximum intensity

*Checksodiumbromideorcommonsaltconcentrationinwater.

*Checkcellstatus(maybeincrustedorcalcified).

*Cleanelectrodefollowinginstructionsinsection6.

*Cleanflowdetectorsituatedinthecellcasing.

*Check titanium cell is not worn (remember that the cell is guaranteed for 5000-6000

hours(approx.2-3yearsofSummerusage)-seetroubleshootingformoreinformation).

Free chlorine levels don't reach 0,2ppm. First thing in the morning

*INCREASEFILTRATIONINTERVAL.

*INCREASEhydrolysislevel.

*Checklevelsofsodiumbromideorcommonsaltinthepool(1gr.NaCl/L).

*Checklevelofisocyanuricacidinpool(30-50ppm.)ONLYifusingCOMMONSALT.

*CheckreactiveagentsintestkitarenotTOOOLD.

*Hasthetemperatureoramountofusersrisen(see3.1/3.2seechapter“Watermaintenance”).

*pHisabove7,8andmustbeadjusted.

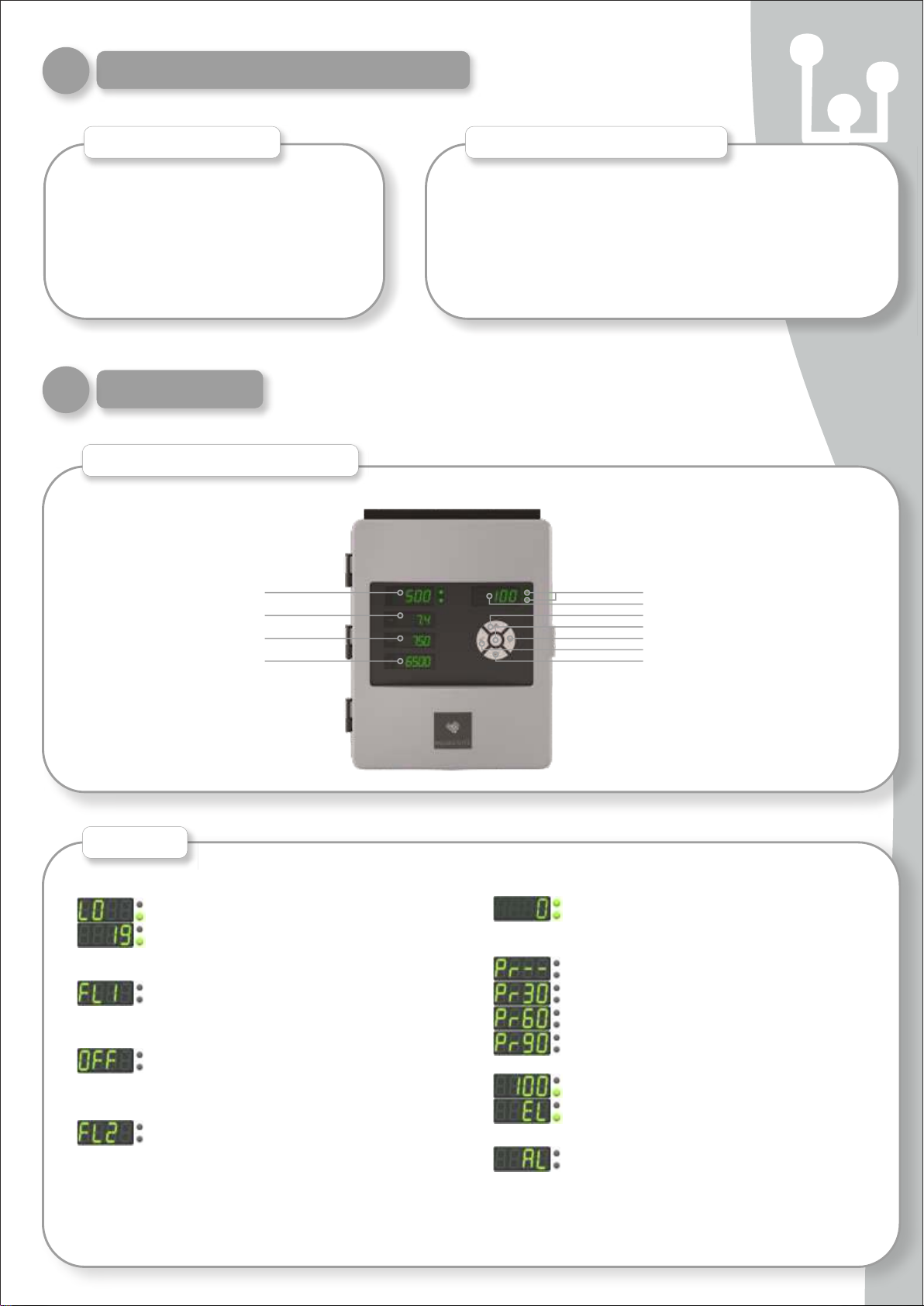

Hydrolysis display shows LO

*Waterlacksconductivity(seesection3“waterpreparation”).

*Checkforincrustationsoncell.

*Seetroubleshooting“Hydrolysisdoesnotreachmaximumintensity”.

White flakes in pool

*Thishappensinexcessivelyhardunbalancedwaters.

*Balancethewaterandcheckthecell,proceedingtocleanitifnecessary.

Hydrolysis display shows FL

*Checkflowdetectorcable.

*Cleanincrustationsofflowdetectorattopofcellcasing.

*Checksystemisfreeofair(Probemustbealwayssubmerged).

RUST on metallic components in pool

*Metallic elements lack standardized earth connection. Contact an electrician to

solve.

*Rustedcomponentsarenotstainlesssteel:

minimum304-recommended316.

EARTHING

All metallic components in the pool, such as lamps, ladders, heat exchangers, drains or similar elements within 3.00m. from pool (10feet) must be connected to an earth below

37Ohms.

WERECOMMENDHEATEXCHANGERSBEMADEOFTITANIUM.

CLEANINGFILTER

EnsureAQUASCENICisNOTRUNNINGduringbackwash.

VERYIMPORTANT

REMEMBERthatthesystemneedssometimetoadapttoyourpoolandyouwillhavetoincreasechemicallevelsforthefirst5days.

WARNING

Keepchemicallevelsinpoolasinstructedinthismanual

SECURITY

Toavoidaccidentsthisproductshouldnotbehandledbychildrenunlesssupervisedbyanadult.

Childrenshouldbesupervisedatalltimeswheninornearaspa,poolorJacuzzi.

HANDLINGANDDOSINGDANGEROUSCHEMICALS

Chemicalsshouldbehandledwithextremeprecaution. WhenpreparingACID,ALWAYSADDTHEACIDTOWATER,neveraddwatertoacid!!!VERYdangerousgassesmaybe

produced.

EXCESS OXIDATION in water

*LowerHydrolysiscelllevel.

*If your system includesAUTOMATIC REDOX CONTROL check REDOX

SETPOINT.

*CheckREDOXprobeandcalibrateifnecessary.

Titanium cell incrusted in less than 1 month

*VeryhardwaterswithahighpH andtotal alkalinity(Balance wateradjusting

pHandtotalalkalinity).

*Checktoensurethesystemautomaticallychangespolarity(LED'salternate

every300min.approx.).

*CONSULT with our technical service to consider ACCELERATING THE

polaritychange(Auto-cleaning)WARNING:acceleratingthepolaritychange

decreasesthecelllifeproportionally.

Polarity 1 reaches max. intensity but polarity 2 (Auto clean) does not

*Whenpolarity2doesnotreach50%werecommendsubstitutingcellforanewoneifduringthesummerormaximumusageperiod.

Ifthisshouldhappeninwinterchangebeforethenextseason(summer).