2

Please note:

(1) Press【AUTO RESET】for three seconds, display value is the time auto reset begins, i.e. “4” means auto reset starts

in 2 seconds (4/2=2) after the test; “6” means 3 seconds (6/2=3). To complete setting, press【ENTER】.

(2) Press ▲(increase) and ▼(decrease) to adjust to preferred value (note that is the value/2 is the actual seconds),

then press【ENTER】to complete the setting.

4. Press【UNIT】to select preferred one.

5. Press【SET】to set up maximum and minimum test result, press ▲(increase) and ▼ (decrease) to adjust value.

For example: when the LOWER light is on, enter 300 lbf.ft; when the UPPER light is on, enter 350 lbf.ft.

The LOW light will illuminate when test value is below 300 lbf.ft.

The HIGH light will illuminate when test value is above 350 lbf.ft.

The PASS light will illuminate when test value is between 300 lbf.ft and 350 lbf.ft.

※Green light outside black case will light up when test result passes.

6. To display B.P.M. value while testing, press【SET】and select B.P.M. function.

7. Press【SET】and select SET1 to set up testing duration (3~5 seconds recommended), press ▲(increase) and

▼(decrease) to adjust value.

8. Adjust test frequency【MODE FREQ】: Do not adjust unless necessary.

(1) Press【RUN MODE】and select preferred function: SHUT OFF / IMPULSE / IMPACT / TORQUE WRENCH.

(2) Press【MODE FREQ】and adjust frequency using ▲ and ▼. Press【ENTER】to complete.

Note: No need to adjust frequency value of【CCW】(anti-clockwise testing) and【TORQUE WRENCH】.

(3) Press【MODE FREQ】and adjust frequency using ▲ and ▼. Press【ENTER】to complete.

Note: No need to adjust frequency value of【CCW】(anti-clockwise testing) and【TORQUE WRENCH】.

9. 【CCW】lights up indicates anti-clockwise testing:

Press【CCW】until the screen displays signal(-)to do anti-clock testing.

Press【CCW】again,(-)signal will disappear.

※Red button on the black case is available for switching on/off CCW function.

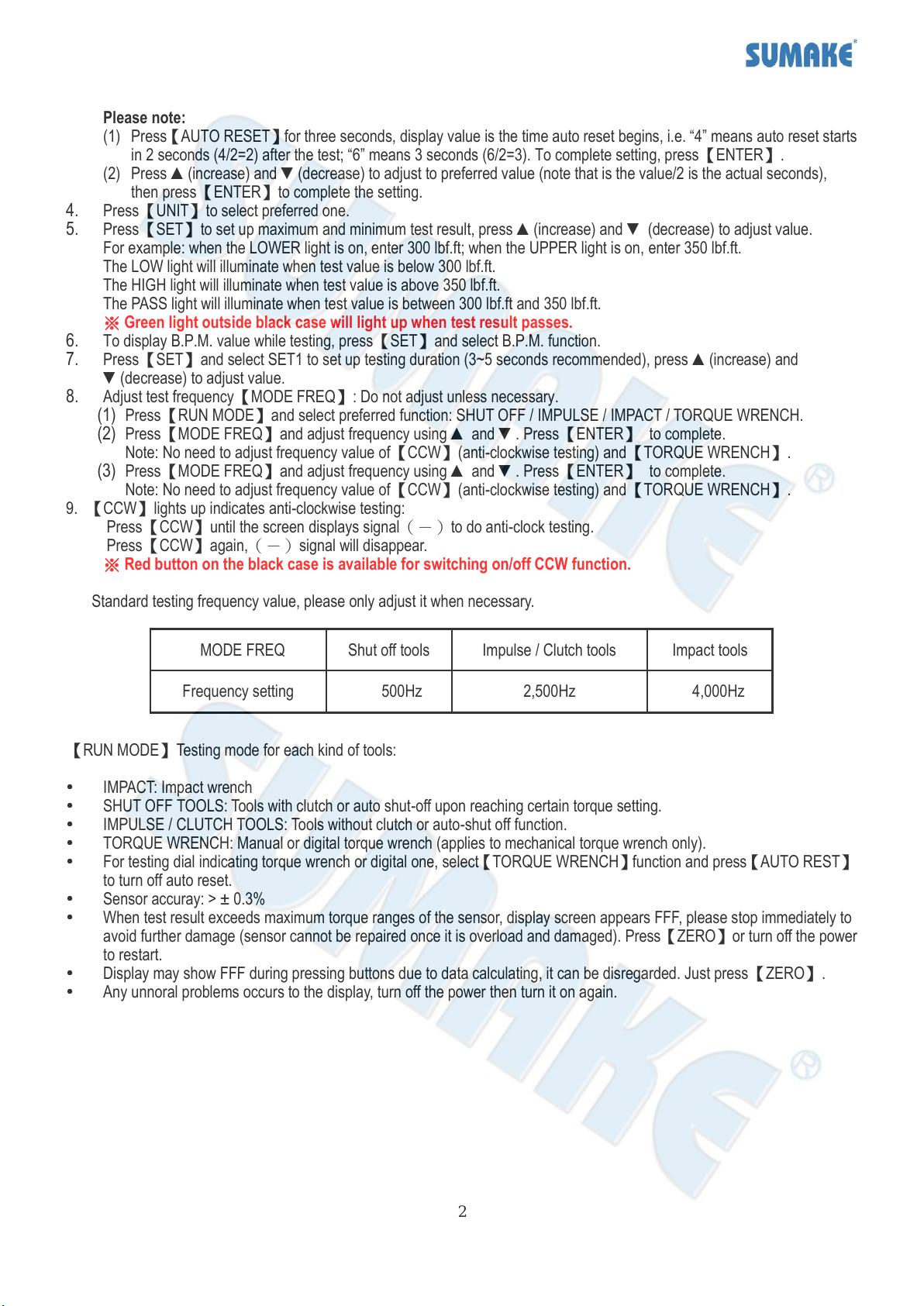

Standard testing frequency value, please only adjust it when necessary.

【RUN MODE】Testing mode for each kind of tools:

IMPACT: Impact wrench

SHUT OFF TOOLS: Tools with clutch or auto shut-off upon reaching certain torque setting.

IMPULSE / CLUTCH TOOLS: Tools without clutch or auto-shut off function.

TORQUE WRENCH: Manual or digital torque wrench (applies to mechanical torque wrench only).

For testing dial indicating torque wrench or digital one, select【TORQUE WRENCH】function and press【AUTO REST】

to turn off auto reset.

Sensor accuray: > ± 0.3%

When test result exceeds maximum torque ranges of the sensor, display screen appears FFF, please stop immediately to

avoid further damage (sensor cannot be repaired once it is overload and damaged). Press【ZERO】or turn off the power

to restart.

Display may show FFF during pressing buttons due to data calculating, it can be disregarded. Just press【ZERO】.

Any unnoral problems occurs to the display, turn off the power then turn it on again.