Polaris Easy Cast User manual

Casting Machine

Instruction Manual

Easy cast

How to use the manual 6

Terminology and signs 7

Company’s liabilities 10

Guarantee 10

Main parts 12

Panel description 13

Technical features and start-up basics 14

Technical information 14

Unboxing 18

Transportation 18

Environmental conditions 18

Installation 19

Experimental start-up of Device (without alloy) 22

Selecting the Proper Crucible 24

Alloy melting and injection 24

Argon gas 28

General safety 30

Safety measures of device 31

Clean-up 34

Periodical maintenance 34

Maintenance technical instructions 35

Contents

1

Casting Machine

Easy cast

Dear Customer

We thank you for your selectivity and trust in purchasing domestically pro-

duced products, and we are pleased that after continuous efforts, we have

been able to manufacture EasyCast Induction Casting Machine and put it at

your disposal.

This product has been designed by our technical and engineering team of ex-

perienced and committed people in the elds of mechanical, electronics and

computer engineering, and by utilizing updated technology and building upon

25 years of experience in manufacturing dental equipment, this product has

reached production of export index quality.

In designing the product, three principles of accuracy, reliability and safety per-

formance and also user friendly have been considered, so in order to correctly

and completely utilize product features, we ask you to read the instruction

manual carefully and if you have any questions or you need more information,

contact the after-sales unit.

The instruction manual is a comprehensive reference for the efcient and safe

use of the product. Following the instructions of this manual has a great role in

reducing consumable costs, avoiding risks and ultimately increasing product

life. The instruction manual should always be kept near the product and the

user should periodically read it.

Please impart us with your constructive guidance, so that we can benet from

your comments, recommendations, and gain knowledge about your needs.

We hope that you will nd using Easy Cast to be an enjoyable and successful

experience,

Polaris Engineering and Manufacturing

Casting Machine

Easy cast

Introduction

Easy Cast

6

This manual presents the instructions about use, installation, and maintenance of Laboratory

and preclinical bench made by Polaris Co. It should be noted that:

• The product should be used according to the instructions of this manual. Thus, all parts of

it should be read carefully before starting and instaling the tool. Special attention should be

paid to the highlighted parts. (refer to section 2-1).

• Observing the instructions of the manual assures the health and safe operation of the tool.

• Manual is an integral part of the product. Thus, it should always come with the product and

should be used optimally as a reference for use during the operation of the product. It should

be available even during the sale of the product, or even when it is not used.

• In case of losing or damaging the manual, get a replacement one from the after-sales service

department of Polaris Co.

The following are explained in detail in this manual:

• Primary installation and start-up of the product by authorized experts

• Operation details of the product and its parts

• Maintenance program

• Primary safety and preventive details

Specications

Method of Using manual

7

Casting Machine

Easy cast

Vocabularies and Signs

Knowledge of signs meanings is of great importance. A list of signs has been introduced in

the following for initial recognition and reference to them if necessary.

Danger!

Indicates compulsory warnings.

Warning!

Indicates functional recommendations.

Forbidden!

Indicates forbidden activities.

Caution!

Refers to user instructions of the tool.

General Information

Easy Cast

10

Scope of the company's obligations

Specications

Company liabilities

Polaris Co. is not liable for any problem involving the following: Failure to follow the

instructions of this manual (incorrect use of the product), repair by an unauthorized person

and part replacement without coordination with the after-sales service department, failure due

to power uctuations.

Guarantee

Guarantee of this product includes repairs, supply, and replacement. If used appropriately, the

guarantee of Polaris Co covers all main parts of the device for 18 month.

Following cases and parts are not covered by guarantee:

• power uctuations

• incorrect transportation of device(not evacuating the water chamber

while transporting

• inappropriate and frequent use of device despite having obvious aws

or over using the device

• not observing the maintenance instructions

• installation or making changes by unauthorized persons

• any repair or replacement by unauthorized persons.

Commutation fees of company representatives to install or repair during

guarantee period will be received from buyer at site.

Generally parts of the hand piece and pedal are not guaranteed except when

a problem in the mentioned parts occurs during delivery to the users.

Before completing the installation and ensuring the accuracy of the protective

components, the device is not ready to use.

Authorized representatives of Polaris Co.

These persons are endorsed by the company to work on the device under any operational

circumstances. They are also authorized to do any electrical and mechanical adjustment/

repair, maintenance program and authorized parts replacement.

11

Casting Machine

Easy cast

Introduction of device

Easy Cast

12

The Buyer shall receive a detailed Operations Manual for casting safely all

precious and non-precious alloys (except Titanium).

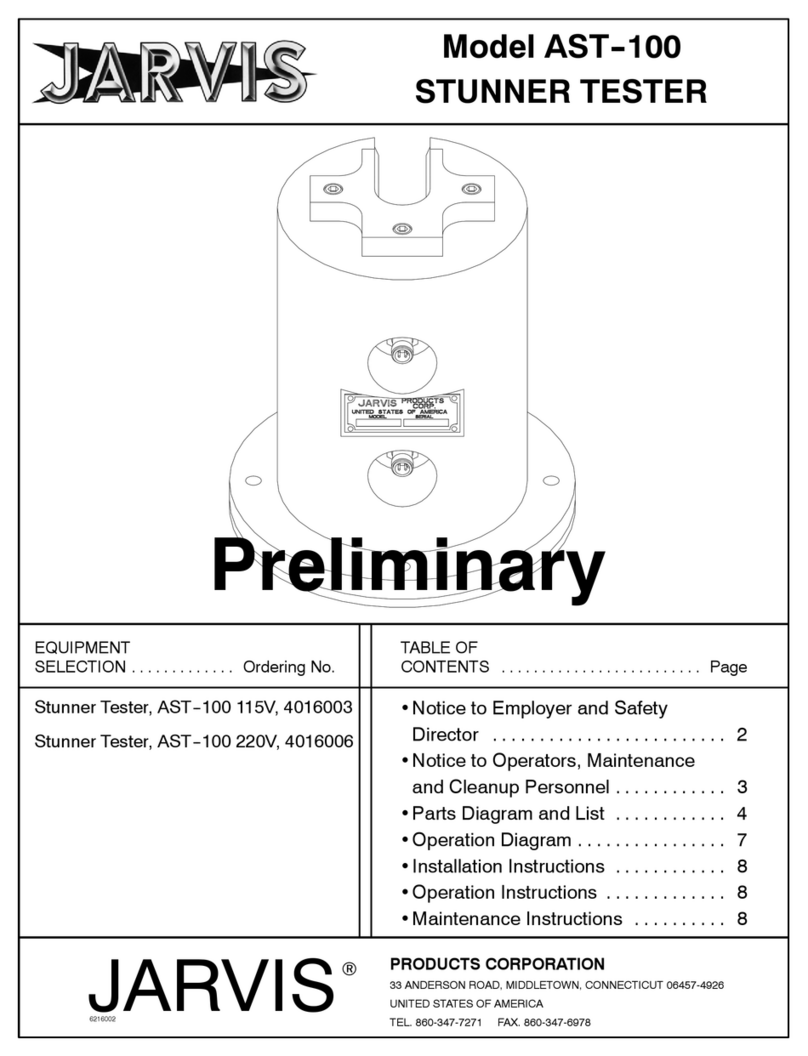

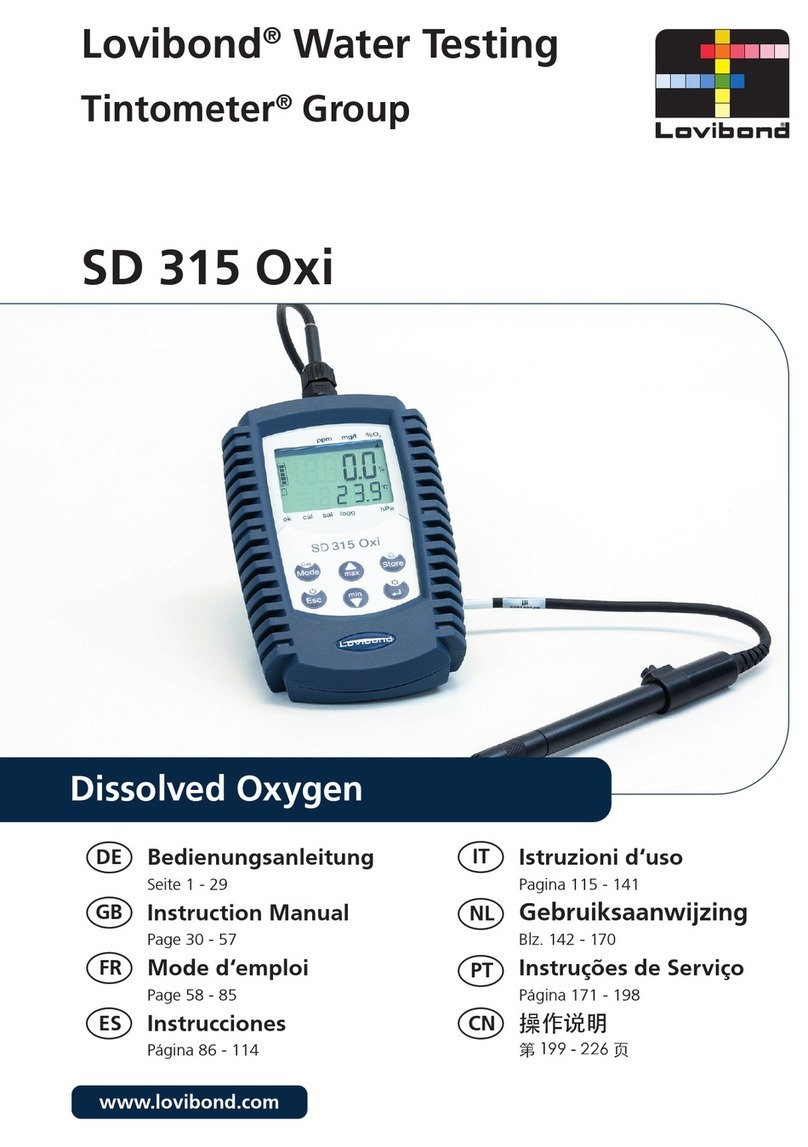

Main parts

The main components of the product are:

1. Glass viewnder

2. Argon gas out let valve

3. Cylinder base position

4. Water tank

Fig. 1: Main components of the EasyCast Induction Casting System

Product introduction

12

Specications

1

2

43

13

Casting Machine

Easy cast

7

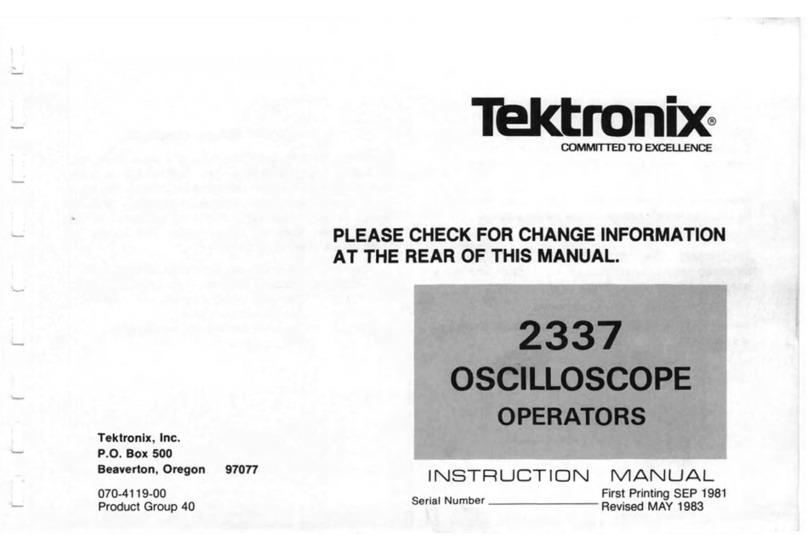

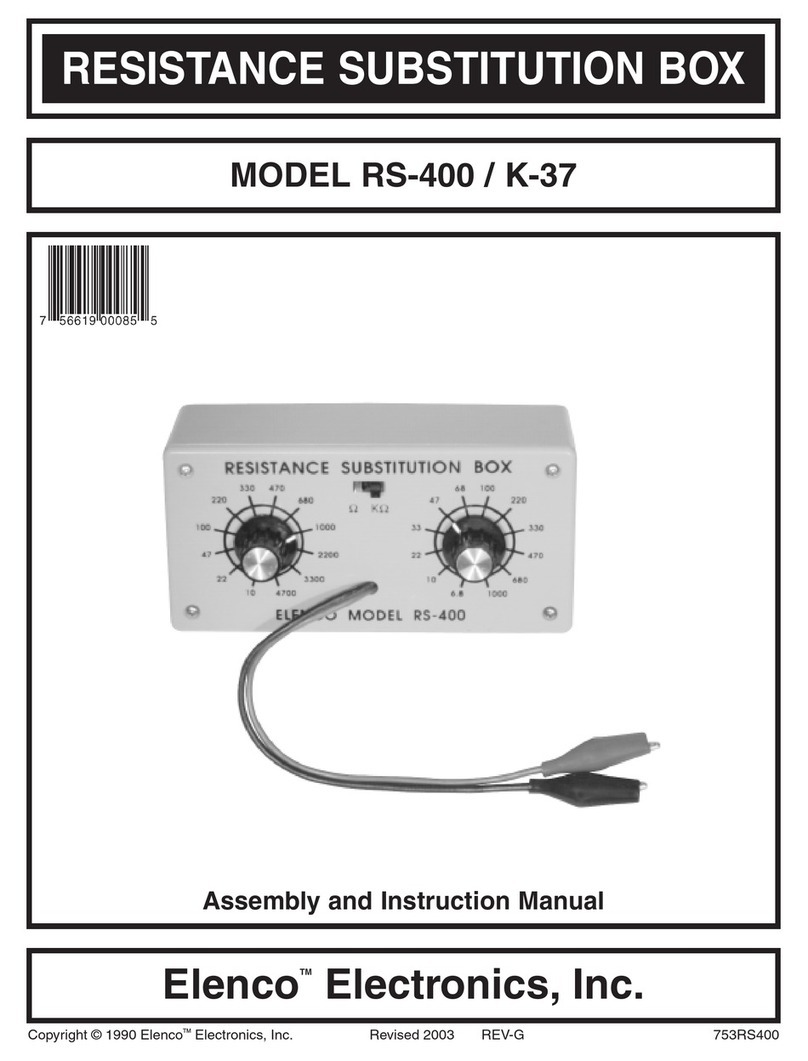

Fig. 2: The Easy Cast panel

The panel consists of the following parts:

1. on/off switch

2. Fast/Slow switch for the speed control arm

3. Indicator light with alarm for correct positioning of the centrifuge arm

4. Button for lifting the heating coil(self)

5. voltage dimmer (for adjusting the alloy melting speed)

6. Switch for start of melting the alloy (fusion)

7. The indicator light for the start of melting operations

8. Injection switch indicating the start of alloy injection operations (operates

only when the top cover is placed in the closed position)

9. The indicator light for the start of ally injection

10. Stop switch

Panel description

2

5

3

9

10

8

6

4

1

14

Technical features

Technical features and operation rules of device

Polaris Co. products are manufactured based on the latest technologies

and are of the highest qualities. The most recent design and manufacturing

methodologies are employed to increase the lifetime and quality of products.

This product described in the present manual is an electronic centrifuge for

melting metals at high temperatures. The employed technology is providing the

required electrical current via electromagnetic induction.

The alloy to be melted is placed within a crucible and then transferred to the

centrifuge for melting. Due to the centripetal force, the crucible slides towards

the center of the cylinder (The Easy Cast torque arm has full balance with the

cylinder tray and the related cylinders are balanced).

For increased safety, the top lid (cover) is automatically locked during the

operation of the centrifuge and unlocks only at the completion of the centrifuge

operation.

Technical Information

Technical specications of the EasyCast Induction Casting Machine are given

in Table 1.

Table 1: Technical specications of the product

Voltage Supply 220 V, 50/60 Hz

Rated Generator Frequency 135 kHz

Power 2500 W

Current 12 A

Max. Temperature 1500 deg Centigrade

The rotational speed of the arm 500 rpm

Crucible Capacity 50 gr (gold or equivalent)

15

Casting Machine

Easy cast

Cooling Systems

-For cooling the electricity generator, a 120 cm x 120 cm cooling coil has

been integrated on the system.

-A closed water circulation system (tank capacity= 18 lit) is added for

cooling the induction coil.

Accessories:

Table 2: Accessories of the product

Argon Gas Injection Rate 15 lit/min

Width 690 mm

Depth 585 mm

Height 970 mm

Net Weight 110 kg

Water Tank Capacity 18 lit

Component/Part Number

Crucible for melting alloys 4

Complete set of casting cylinders with vax-

up cylinder

4 sizes

Forklet under the cylinder 1

Fuse 20 2

Fuse 10 1

Glass blender 1

17

Casting Machine

Easy cast

Transportation and installation

Easy Cast

18

In order to avoid accidents, it is really important to follow the following instructions

during the installation and xing of equipment. All steps are explained in detail:

Unboxing

Having received the device, make sure that the main box is sealed and intact.

Otherwise, inform the after-sales service department of Polaris, or its authorized

representatives.

How to move the device

The device should be moved as follows:

1.Unplug the system from the power supply

2.Empty the water tank

3.Keep the product in an upright position throughout the displacement. For

safety and prevention of accidents resulting from non-observance of technical

recommendations, see Section 4.2.

Environmental circumstances

It is important to choose an appropriate environment during installation

and operation for personal safety, correct operation and long lifetime. This

environment not only should be big enough but also should be on enough, have

proper ventilation and should be kept away from dust and direct sunlight. It

should be noted that the device must be placed in a way, so that the connections

may be managed easily.

Workplace temperature: 0-40OC

Maximum humidity: 75%

Failure to follow the aforementioned instructions results in device

being damaged, and Polaris Co, won’t be held liable.

The device should not be used in a place where there is danger of

explosion or ring

Transportation and installation

Table of contents