Air Nutrunner Air Start Shut-off Operator’s Manual

3

M5 port-Automated Signal Chart:

1. P1 appears when M5 Signal Port detects the pressure as the air tool switches on.

2. P0appears when M5 Signal Port turns off the pressure back to 0, when the torque has reached the target.

3. Central Processing Unit will determine on or off due to pressure by the sign of P1 or P0.

4. Ts1 < tolerance zone = float mode.

Ts2 within tolerance zone = lock torque.

Ts3 > tolerance zone = loose thread.

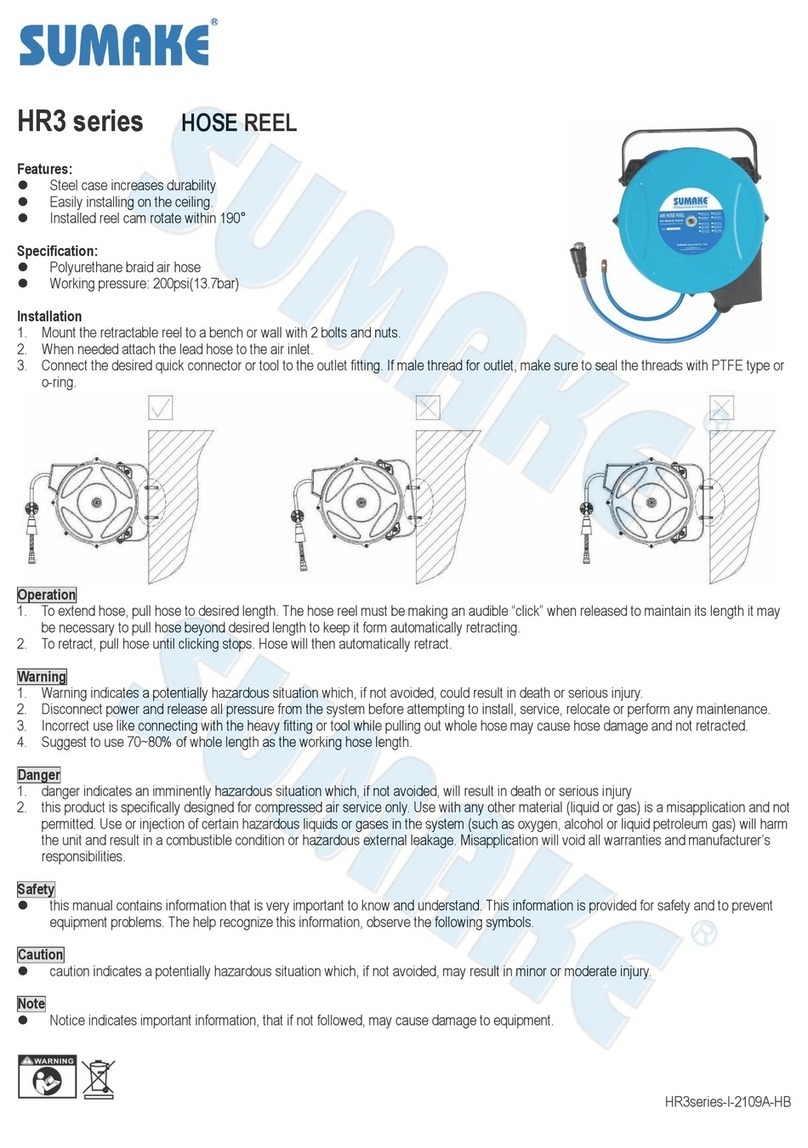

Air supply conditions & Do's and Don'ts:

1. There are some adverse effects for pneumatic tools when the air compressor contains too much water and

dust. Therefore, it is necessary that the pneumatic tubes equipped with water filter and automatic supply

lubricating oil to filter extra substances, and to drain water out of the drain tank.

2. Before the air screwdriver is installed, please connect inlet pipe and pipe coupling onto inlet nuts.

3. To prevent gathering too much water and dust on the pneumatic circuit and pipe coupling, please keep the

pipes clean or the inner diameter could possibly shrink in a long term use.

4. When the air screwdriver and the pneumatic tubes are detached, you must not drop the pneumatic tube

connector on the floor. This will gather dust and other extra substances into the pneumatic circuit and damage

the equipment.

5. In general, it is suggested that the pressure for main pneumatic circuit be 7.0kg/cm2or 8.0kg/cm2(100/140psi),

and to install pressure regulator before the air screwdriver is connected to the sub pneumatic circuit. The

pressure needs to be stabilized at 5.5kg/cm2or 6.0kg/cm2(80-90psi). If you choose the inner diameter for sub

pneumatic circuit as suggested in our chart, it will work for most of the screws. Please do not use the pressure

over the regulated one, otherwise it will shorten the life of the air screwdriver.

6. The installation of pressure regulator could stabilize the pressure of the pneumatic circuit, and to make sure

the accuracy of the air screwdriver twisting force(repeatability precision).

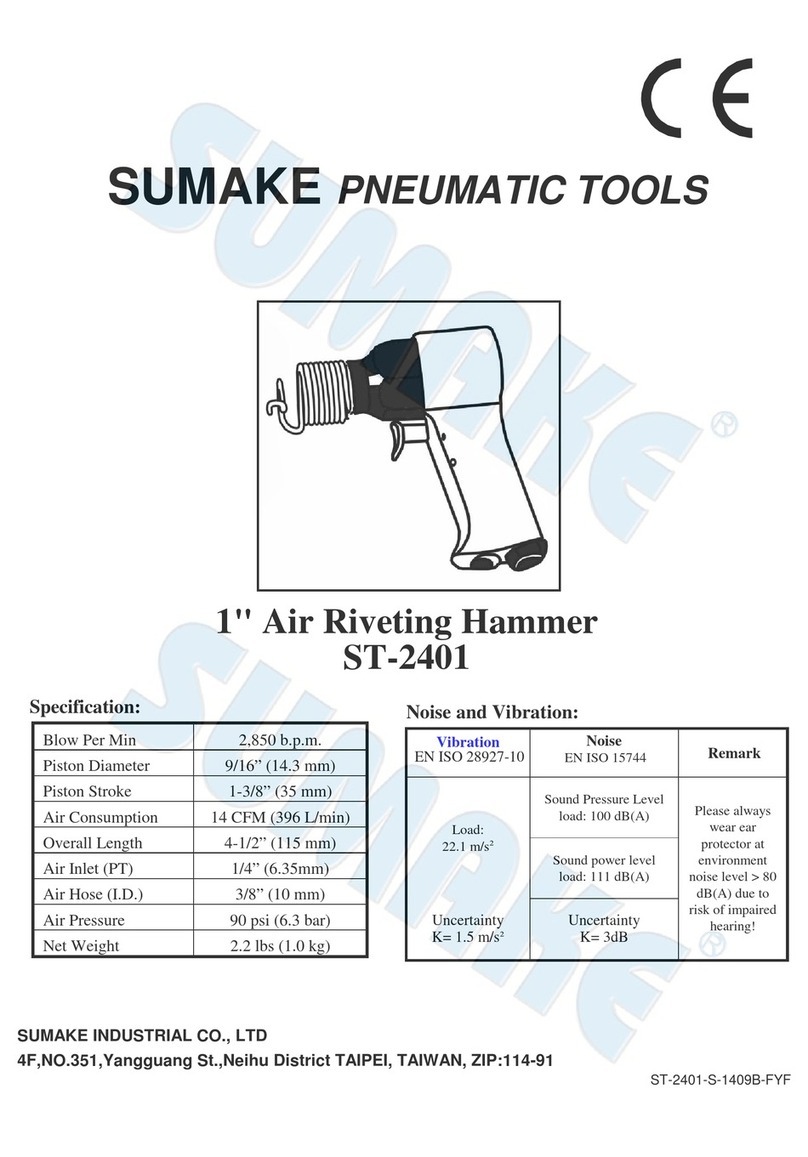

Maintenance note:

1. If the air screwdriver is not going to be used for a long time, please add lubricating oil for a better

preservation. Otherwise, the air screwdriver will be damaged and get rusty.

2. To use the FRL automatic lubricating tool could extend the life of the equipment.