2

Warranty InforMatIon

General warrants its instruments and accessories, and

digital tools products against defects in material or

workmanship for one year from the date of purchase

unless otherwise stated on the packaging, user’s manual,

and/or marketing materials. General also warrants its

nondigital tools products against defects in material or

workmanship on a limited lifetime term. General will

replace or repair the defective unit, at its option, subject to

verification of the defect.

This warranty does not apply to defects resulting from

abuse, neglect, accident, unauthorized repair, alteration, or

unreasonable use of the product. It also does not cover

products purchased from unauthorized distributors. A proof

of purchase must accompany each warranty claim.

Any implied warranties arising from the sale of a General

product, including but not limited to implied warranties of

merchantability and fitness for a particular purpose, are

limited to the above. General shall not be liable for loss of

use of the product or other incidental or consequential

damages, expenses, or economic loss, or for any claim of

such damage, expenses, or economic loss. State laws vary.

The above limitations or exclusions may not apply to you.

For more details or to file a warranty claim, contact General

Tools & Instruments Technical Support at

return for rePaIr PoLIcy

Every effort has been made to provide you with a reliable

product of superior quality. However, in the event your

instrument requires repair, please contact our Customer

Service to obtain an RGA (Return Goods Authorization)

number before forwarding the unit via prepaid freight to the

attention of our Service Center at this address:

General Tools & Instruments

75 Seaview Drive Secaucus, J 07094 212-431-6100

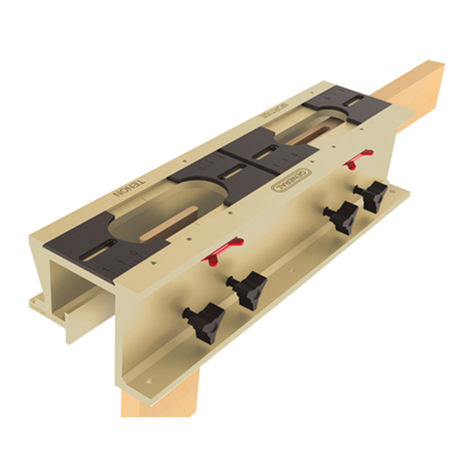

3. Center the work piece to be drilled

through in the jig and clamp it tightly

using the black plastic thumbnut

(Callout 9).

4. After making sure that your drill and

bit are up to speed, drill the pocket

hole(s) until the stop collar hits the

metal ring on the top of the jig. For

cleaner cut holes and easier drilling,

do not attempt to drill the entire

depth with one stroke. Instead, use

short strokes until the drill has

reached its final depth. When you’re

finished, unclamp the drilled-through

work piece and remove it from the jig.

5. Clamp the drilled-through work piece and its mate

together in the desired joint configuration (angled, edge-

to-edge, or 90º).

To complete the joints, use the included square drive bit

(Callout 5) to drive screws through the drilled-through

work piece into its mate, adding glue if desired.

6. The vertical piece of the #854 jig can

be separated from the base to create

pocket holes on horizontal work

pieces, or in hard-to-reach areas,

such as corners.

To detach the base of the jig from its

vertical piece, use the included hex

wrench to loosen and remove the

two hex head screws (Callout 11)

that connect the two sections. Two

spare hex head screws are included,

should one or both screws go

missing while the sections are

separated.

7. To use the vertical piece (including

the drilling platform) separately,

follow the same instructions as

above. Use a separate clamp (not

included) to secure the work piece

and vertical piece before drilling.