1. Main Applications

․de-slagging, de-sputtering of welds

․shot-peening after welding

․cleaning metal surfaces of rust and

scale

․stripping paint

․cleaning castings

․removing cores

․cleaning brick and stone-work

․cleaning ship plates, barges, buoys

2. Cautions for use

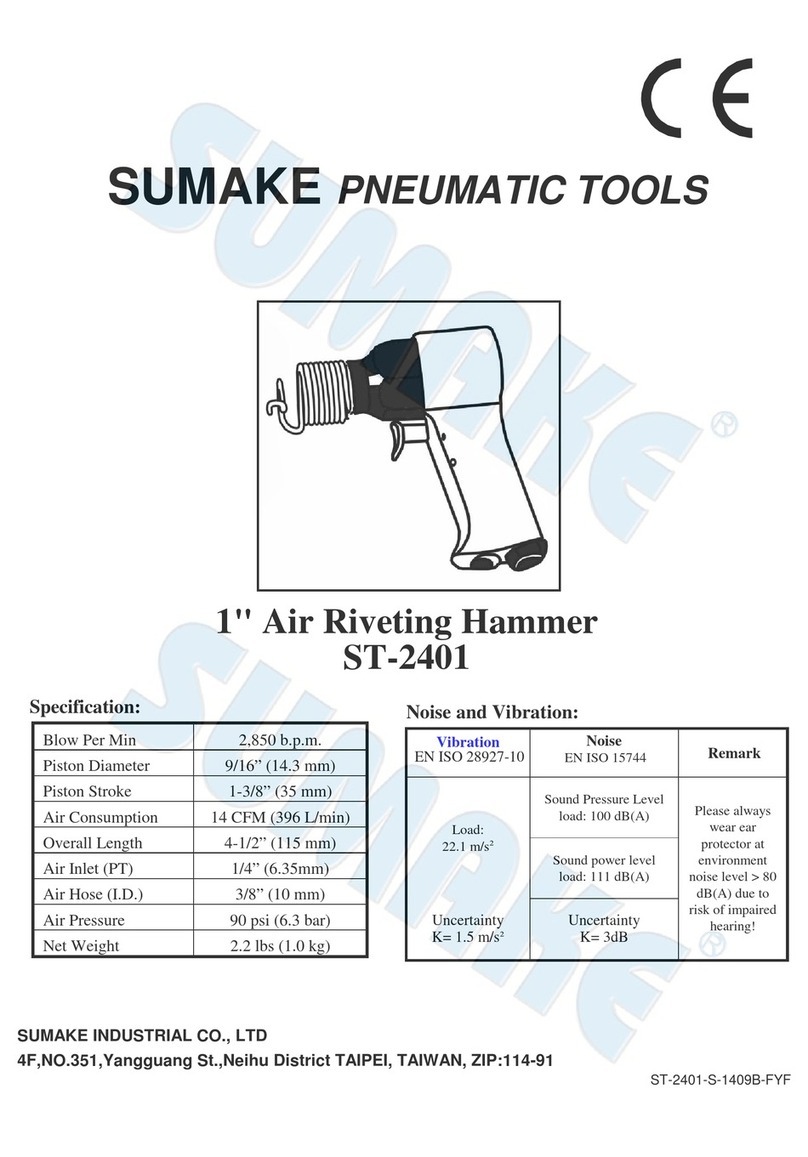

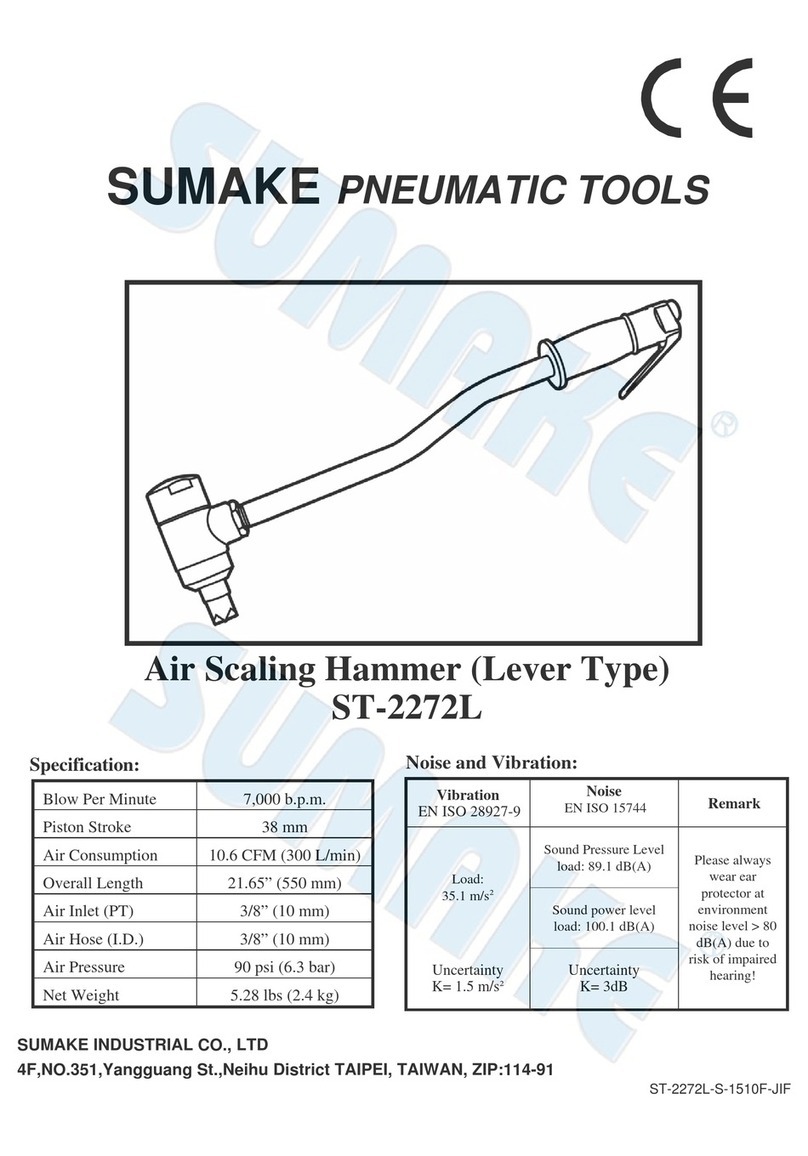

2-1 Air pressure

Maximum performance is displayed at

a gauge pressure of 6 kg/cm². Range-

-wise, this is an air pressure from 5 to 7

kg/cm² (70 to 100 psi)

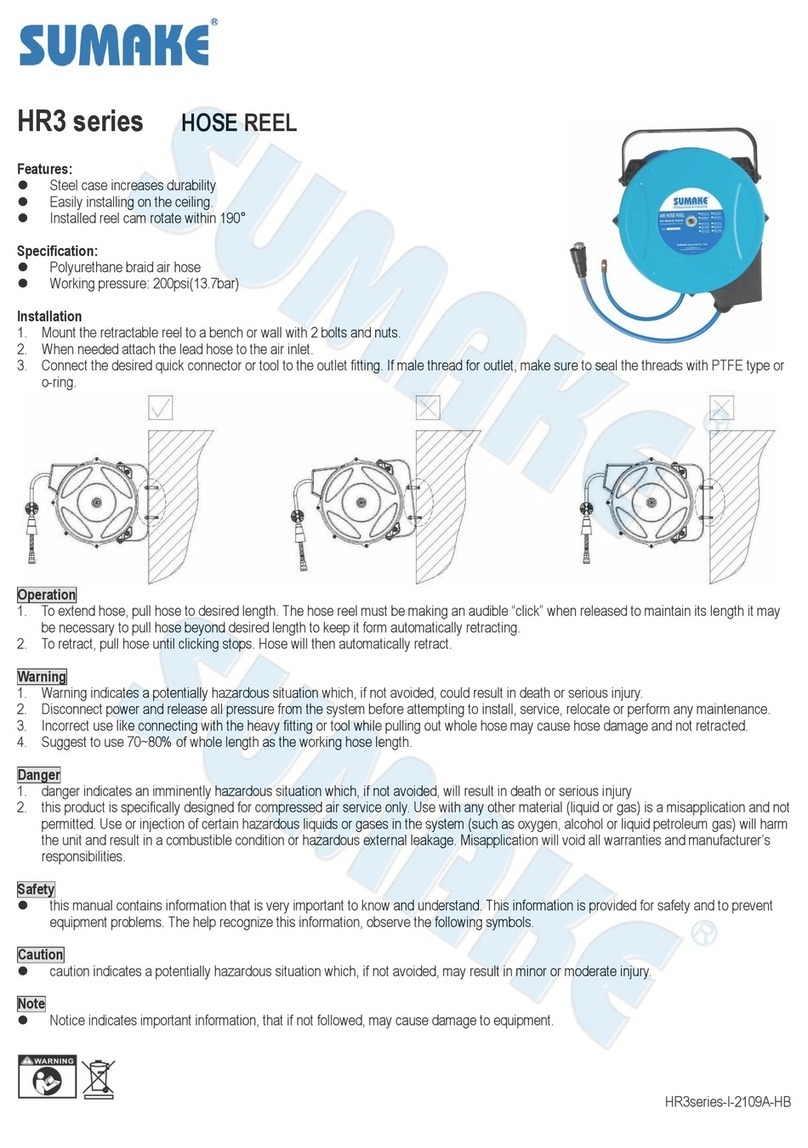

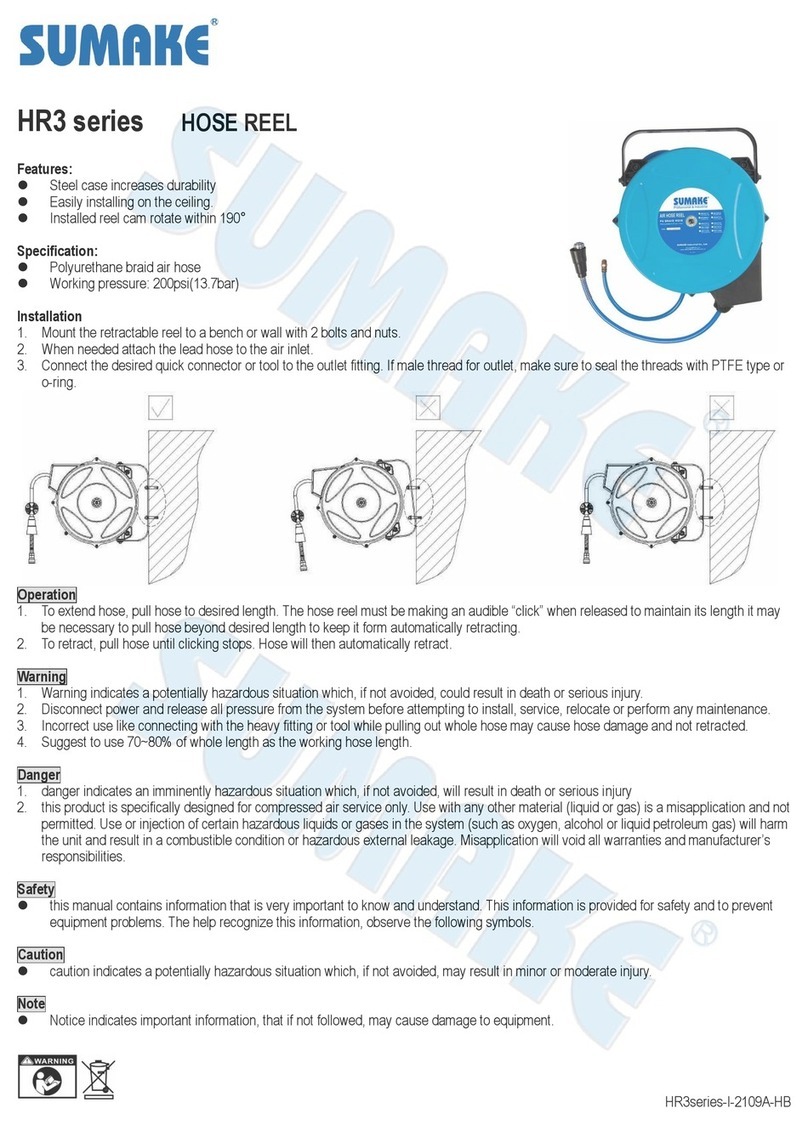

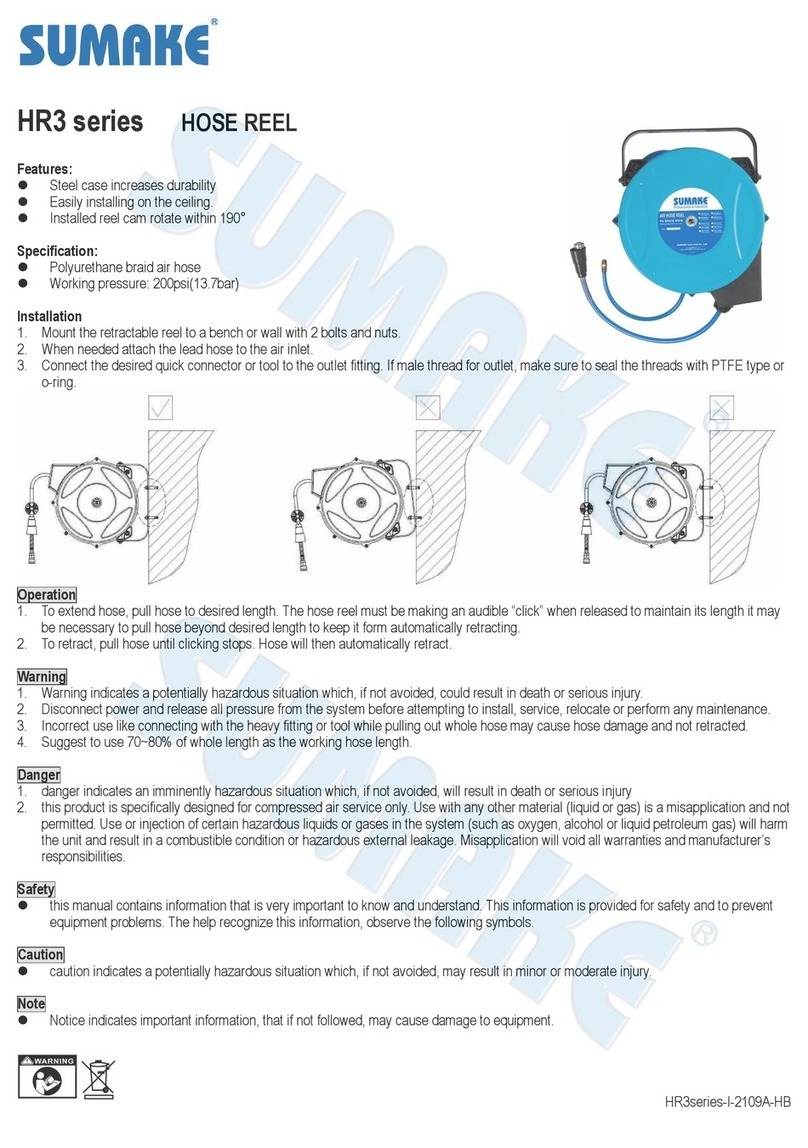

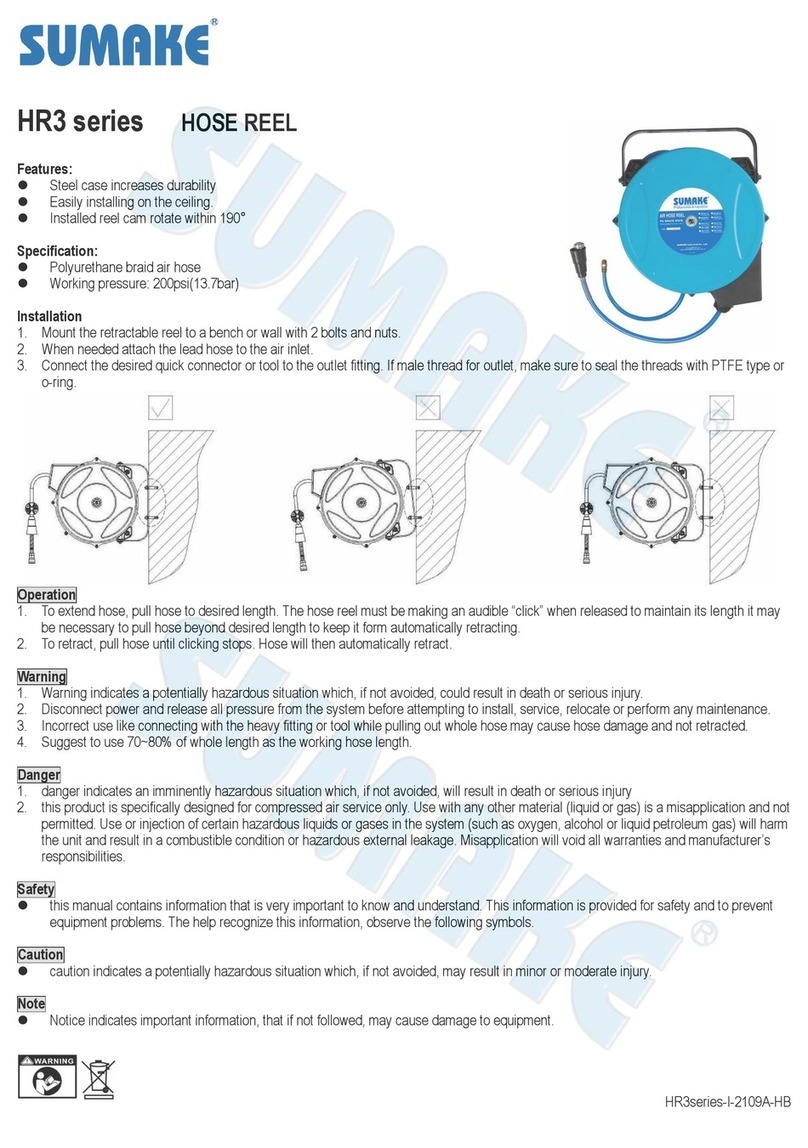

2-2 Air line

Use a 3/8” air hose between the

compressor and the tool. Compressed air

is cooled and its water content separated,

as soon as the air leaves the compressor.

A portion of the water content, however, is

condensed in the piping, and can enter the

tool mechanism, and may cause trouble.

Always install an air filter and an oiler be-

tween the compressor and the tool. The

compressor used should have 1 or higher

horsepowers in the case of using each one

unit.

2-3 Air hose

Blow compressed air through the supply

hose before connecting the tool.

2-4 Lubrication

Before connecting the hose apply 4 or 5

drops of #60 spindle oil at the air inlet. (No

lubrication is required when oiler is used)

Use of a thicker oil can lead to reduced

performance or malfunction. If a thicker oil

is used by accident, wash it away

immediately. Also, every 3 or 4 hours of

operation oiling is necessary.

2-5 Idle running

Idle operation will shorten the life of the

tool and needles and should be avoided.

3. Cautions for operation

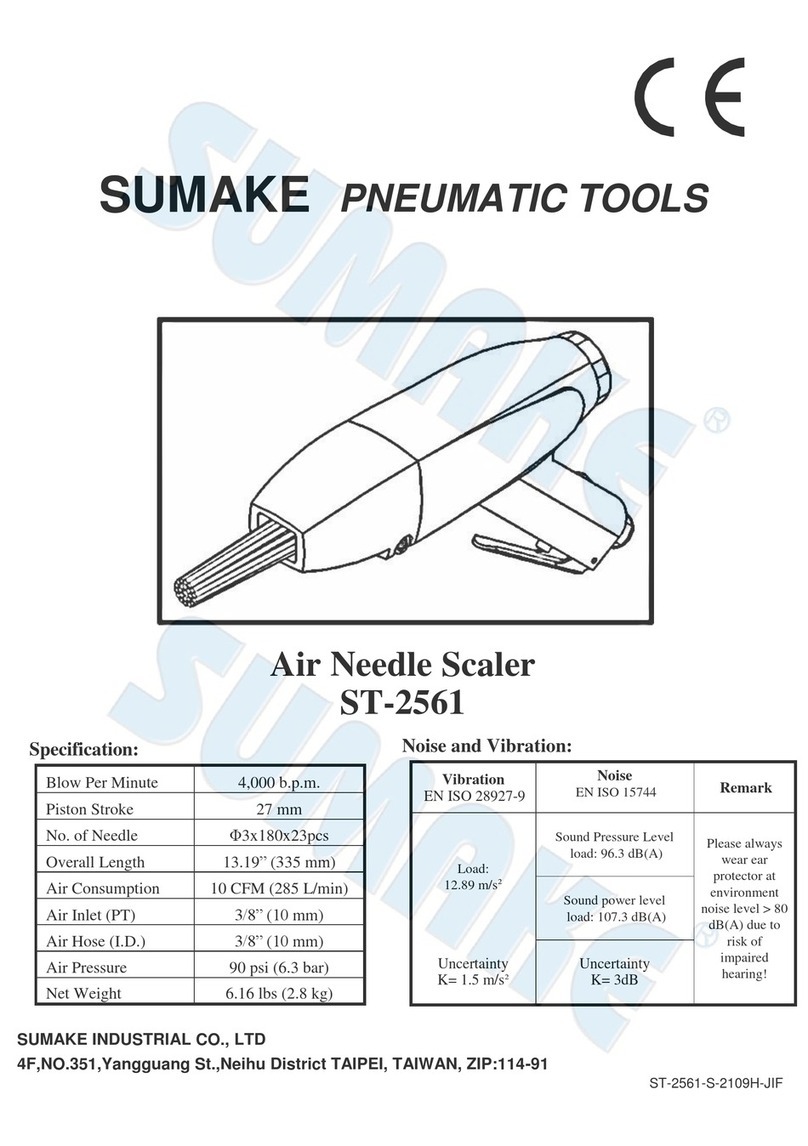

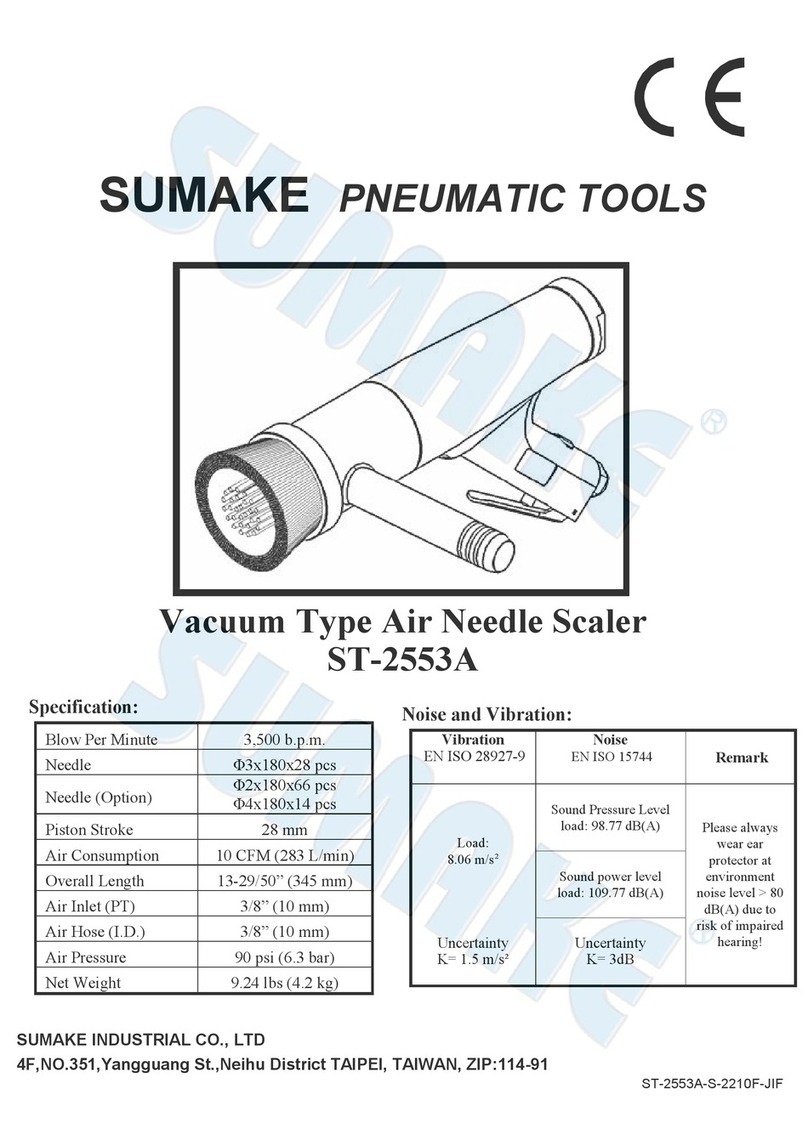

The quick-reciprocating needles of Jet

Chisel adjust automatically to a surface

contour during cleaning. Slight pressure of

the needles against the work surface is

sufficient for maximum performance. An

upright tool position is best. The tool will

efficiently clean uneven surfaces, get into

grooves, corners, and gaps, clean outside

and inside surfaces, and clean spaces

inaccessible and too confined for other

types of tools.

We can supply Φ3 needles for

ST-NS11A-R, ST-NS11A-H

Change needles according to your

work. Change the kind of needle guide

according to your work.

The broken heads of needles must be

removed from the cylinder, otherwise

continuous operation with them causes

malfunction and shortened the life of

needle supporter.

4. Changing Needles

(1) Unfasten the hexagon socket head bolt

of the needle guide with the hexagon

wrench key and pull out the needle guide.

(2)Remove the safety band from the grip

groove.

(3)Loosen the stop ring and remove. Take

out the needle supporter by pulling out the

needles.

(4)Extract the needles. The needles must

be changed whenever damaged during

operation.

(5)After changing needles, assemble in the

reverse manner of disassembly.

5. Storage

Avoid storing the tool. in a location subject

to high humidity. If the tool is left as it is

used, residual moisture on the inside can

cause rusting. Before storing, and after

operation oil the tool at the air inlet with

spindle oil and run it for a short time.

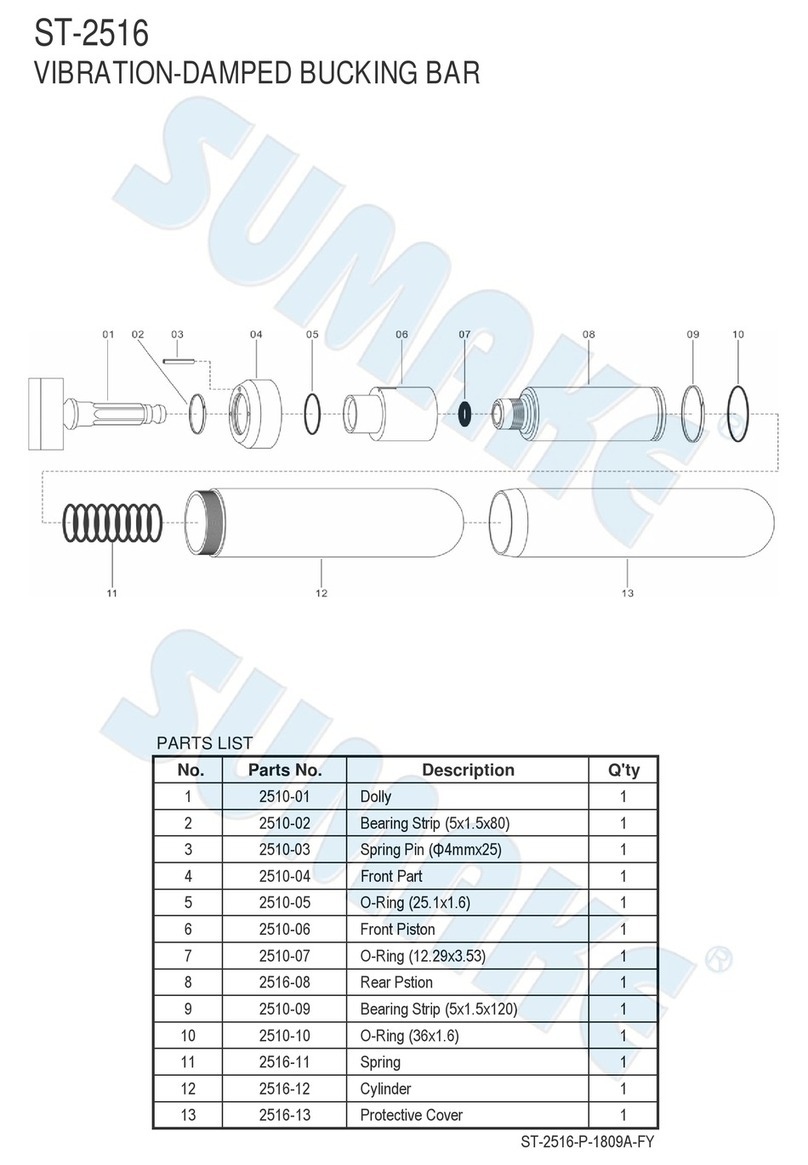

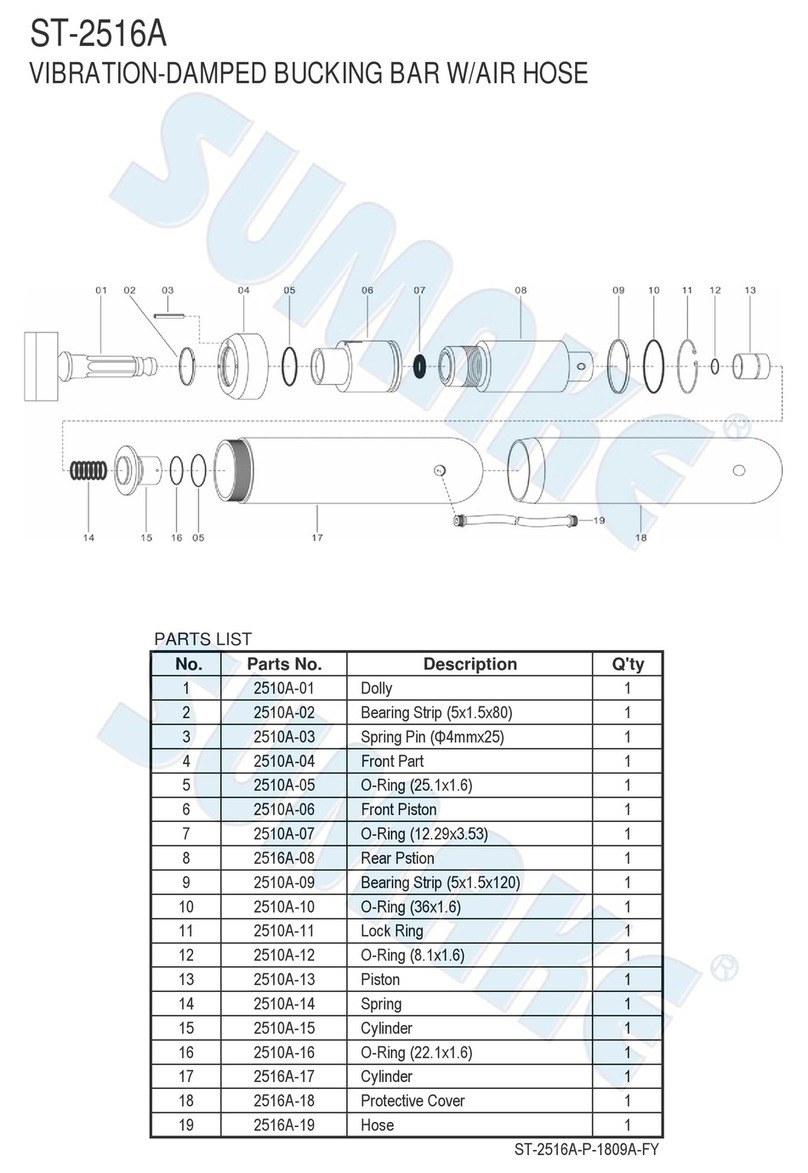

6. Ordering Service Parts

★For further operational and handling

information or for replacement of parts and

components, contact the sale agent from

whom you purchased the tool or the ser-

vice division of our company.

★In ordering parts and components, give

parts number(s), name and part quantities.

ST-NS11A-I-1811A-JI